Identifying early signs of gearbox issues can help you prevent further damage and costly repairs. Unusual noises, such as grinding, whining, or clunking sounds, are often signs of internal gearbox issues.

These sounds may be caused by worn bearings, gears, or other components. Difficulty in shifting gears is another symptom of gearbox problems.

If you experience resistance, grinding, or difficulty shifting gears smoothly, it could indicate internal damage or wear.

Leaking transmission fluid around the gearbox is also a critical warning sign. Transmission fluid plays an essential role in lubrication and cooling, and any leakage can cause significant damage if left unaddressed.

Common Warning Indicators

Modern vehicles are equipped with various warning systems that notify you of potential gearbox issues. One of the most common indicators is the check engine light.

While it doesn’t specifically point to the gearbox, its illumination signals that something in the system requires attention, which could include transmission problems.

Another sign is transmission slipping, where the gearbox unexpectedly shifts gears. This could be caused by worn clutch plates or low transmission fluid.

A delayed gear engagement is also a warning. If you notice a delay when shifting from park to drive or reverse, it may indicate a deeper gearbox issue.

Initial Diagnostic Steps

If you suspect gearbox problems, start by performing basic diagnostic steps to determine the cause. Begin with a visual inspection to check for any obvious signs of damage, such as leaks or worn-out components.

After that, check the transmission fluid level. Low fluid can cause various issues, including overheating and inefficient gear shifting. If the fluid level is low, it’s essential to identify and repair the leak.

Listening for unusual sounds while the vehicle is running can also help identify the issue. The nature of the sound can provide clues, whether it’s related to gears, bearings, or other internal components.

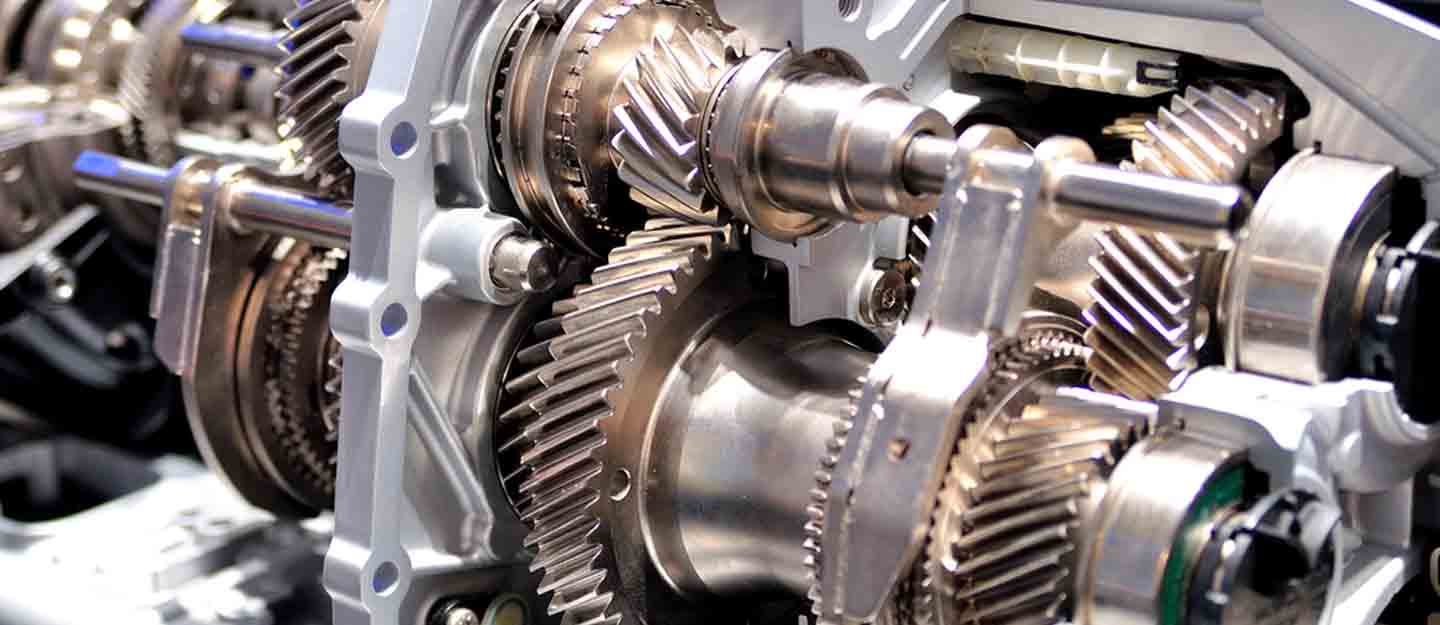

Mechanical Gearbox Problems

Worn Clutch Plates

Worn clutch plates are a common issue in gearboxes, especially in manual transmissions. Detecting and addressing this issue early can prevent further complications.

Symptoms of Clutch Wear

- Slipping Clutch: The engine revs, but the vehicle doesn’t accelerate as expected.

- Burning Smell: Overheating caused by slipping can produce a distinctive odor.

- Difficulty Shifting: Hard-to-shift gears, especially into first or reverse.

Causes of Clutch Deterioration

- Aggressive Driving: Frequent hard shifting or rapid acceleration accelerates clutch wear.

- Overloading: Carrying heavy loads can stress the clutch and contribute to faster wear.

- Poor Maintenance: Failing to regularly inspect and maintain clutch components can lead to issues.

Replacement Process

- Remove the Transmission: To access the clutch assembly, the gearbox must be detached.

- Replace Clutch Disc and Pressure Plate: Install new components to restore proper functionality.

- Reassemble and Test: Reattach the transmission and test drive the vehicle to ensure smooth operation.

Gear Slippage

Gear slippage can significantly impact driving performance and safety. Understanding the causes and solutions is vital for maintaining the gearbox.

Identifying Gear Slippage

- Unexpected Shifts: Gears shift unexpectedly, often slipping into neutral.

- Loss of Power: The vehicle loses power, especially during acceleration.

- High Engine Revs: The engine revs increase without a corresponding gain in speed.

Common Causes

- Low Transmission Fluid: Insufficient fluid can result in poor lubrication and gear slippage.

- Worn Gears: Over time, gears can wear down, reducing their ability to engage properly.

- Faulty Solenoids: Malfunctioning solenoids can disrupt fluid flow and prevent proper gear engagement.

Repair Techniques

- Fluid Top-Up or Replacement: Ensure fluid levels are correct and replace old or contaminated fluid.

- Gear Replacement: If gears show signs of wear, replace them.

- Solenoid Repair: Repair or replace faulty solenoids to restore normal functioning.

Grinding Gears

Grinding gears is a clear sign of internal gearbox issues that should be addressed quickly to avoid further damage.

What Causes Grinding Gears

- Misaligned Gears: Improper alignment can cause gears to grind against each other.

- Worn Synchronizers: Synchronizers, which help match gear speeds, may be worn out and cause grinding.

- Insufficient Lubrication: Without proper lubrication, friction increases, leading to grinding.

Impact on Gearbox

- Increased Wear: Grinding causes rapid wear and tear on gears and other internal components.

- Potential Gear Failure: Continuous grinding can eventually lead to gear failure or breakage.

- Costly Repairs: Delaying repairs can result in more extensive and expensive damage.

How to Address Grinding Issues

- Realign Gears: Properly align gears to eliminate grinding.

- Replace Synchronizers: Install new synchronizers to ensure smooth gear transitions.

- Improve Lubrication: Regularly check fluid levels and ensure proper lubrication to reduce friction.

Hydraulic and Fluid-Related Problems

Leaking Transmission Fluid

Transmission fluid leaks are a common issue that can lead to severe gearbox problems if not repaired quickly. Identifying and addressing fluid leaks is essential to maintaining your gearbox’s health.

Identifying Fluid Leaks

- Puddles Under the Vehicle: Red or brown fluid collecting under the car.

- Low Fluid Levels: Frequent low fluid levels, even after refills.

- Burning Smell: Leaking fluid can overheat and burn, creating a distinct odor.

Causes of Fluid Leaks

- Damaged Seals or Gaskets: Wear and tear can cause seals and gaskets to fail.

- Cracked Transmission Pan: Physical damage to the pan can result in leaks.

- Faulty Transmission Lines: Corrosion or damage to fluid lines can lead to leaks.

Fixing Fluid Leaks

- Seal and Gasket Replacement: Replace damaged seals and gaskets to stop leaks.

- Repair or Replace Pan: Fix or replace a cracked transmission pan.

- Transmission Line Repair: Address any issues with fluid lines, replacing them if necessary.

Contaminated Transmission Fluid

Contaminated transmission fluid can severely affect the performance of an automatic transmission. Regular maintenance and fluid checks are essential.

Symptoms of Contamination

- Dark, Murky Fluid: Healthy transmission fluid is bright red; contamination will cause it to darken.

- Strange Noises: Contaminated fluid may cause whining or grinding sounds.

- Poor Gear Shifting: Sluggish or erratic shifting can be a sign of contaminated fluid.

Effects on Gearbox Performance

- Increased Friction: Contaminants increase friction, which can cause overheating and component wear.

- Reduced Lubrication: Contaminated fluid fails to lubricate the parts effectively.

- Component Damage: Prolonged exposure to contaminated fluid can lead to damage to internal gearbox components.

Fluid Replacement Guidelines

- Regular Fluid Changes: Always adhere to the manufacturer’s recommended intervals for fluid changes.

- Use Quality Fluid: It’s essential to use the type and quality of transmission fluid that the manufacturer recommends.

- Flush the System: Periodically flush the transmission system to remove contaminants and ensure the fluid remains clean.

Low Transmission Fluid Levels

Maintaining the proper level of transmission fluid is critical for the smooth operation of your vehicle’s gearbox. Low fluid levels can lead to a variety of serious issues.

Detecting Low Fluid Levels

- Delayed Gear Engagement: A noticeable delay when shifting from park to drive or reverse.

- Overheating Transmission: Insufficient fluid can lead to the transmission overheating.

- Erratic Shifting: Unstable or unpredictable gear changes are often indicative of low fluid levels.

Causes of Fluid Loss

- Leaks: The most common cause of low fluid levels in a transmission.

- Overheating: Excessive heat can cause the fluid to break down and evaporate.

- Wear and Tear: Over time, seals and gaskets may degrade, allowing fluid to leak.

Refilling and Maintenance Tips

- Regular Checks: Frequently check the fluid levels and top up as necessary.

- Address Leaks Promptly: Fix any leaks immediately to prevent further fluid loss.

- Scheduled Maintenance: Stick to a regular maintenance schedule to keep your transmission in optimal condition.

Electronic and Sensor Issues

Faulty Transmission Sensors

Transmission sensors play a crucial role in ensuring your gearbox operates smoothly. When these sensors fail, they can cause various performance issues in the gearbox.

Types of Transmission Sensors

- Speed Sensors: Measure the speed of both the input and output shafts.

- Position Sensors: Detect the position of the gear selector mechanisms.

- Temperature Sensors: Monitor the temperature of the transmission fluid.

Symptoms of Sensor Failure

- Erratic Shifting: Unpredictable or harsh gear changes.

- Warning Lights: Transmission-related warning lights appearing on the dashboard.

- Poor Performance: A noticeable drop in fuel efficiency and power.

Replacement Procedures

- Diagnostic Testing: Use a diagnostic tool to identify the faulty sensor.

- Sensor Replacement: Remove and replace the malfunctioning sensor with a new one.

- System Reset: After replacement, reset the transmission control system to clear any error codes.

Transmission Control Module Problems

The transmission control module (TCM) is crucial for managing the coordination of the gearbox. Any problems with the TCM can have a serious impact on the performance of the vehicle.

Role of the Control Module

- Gear Shifting: The TCM manages the timing and smoothness of gear shifts.

- Transmission Protection: Monitors the transmission for overheating and overloading.

- Data Communication: Facilitates communication with other electronic control units in the vehicle.

Signs of Module Failure

- Stuck in Gear: The transmission may get stuck in one gear and fail to shift.

- Unresponsive Shifting: Delayed or unresponsive gear changes.

- Error Codes: Diagnostic trouble codes related to the TCM.

Repair and Replacement Options

- Reprogramming: Reflash the TCM’s software to correct any issues.

- Replacement: Install a new TCM if reprogramming does not resolve the problem.

- Professional Service: For more complex issues, seek a professional diagnostic and repair service.

Software and Calibration Issues

Proper calibration and software are essential for the efficient operation of your vehicle’s gearbox. Misalignment or software glitches can cause significant problems.

Importance of Proper Calibration

- Smooth Operation: Proper calibration ensures seamless and efficient gear changes.

- Performance Optimization: Maximizes the fuel efficiency and power output of your vehicle.

- Longevity: Ensures the longevity of transmission components.

Symptoms of Calibration Problems

- Rough Shifting: Abrupt or jerky gear changes.

- Inconsistent Performance: Fluctuating performance and responsiveness.

- Diagnostic Codes: Error codes related to software or calibration issues.

Solutions for Software Issues

- Software Updates: Regularly update the transmission software to ensure it is running the latest version.

- Professional Calibration: Have your transmission calibrated by a professional.

- System Reset: Perform a system reset to clear temporary software glitches.

Preventive Maintenance and Solutions

Regular Gearbox Inspections

Regular inspections are essential for maintaining the health and efficiency of your vehicle’s gearbox. Detecting potential issues early can help you avoid costly repairs.

Importance of Routine Inspections

- Early Problem Detection: Catch problems before they escalate.

- Prolonged Gearbox Life: Routine inspections help extend the life of your gearbox.

- Cost Savings: Identifying and addressing small issues early can prevent costly repairs in the future.

Checklist for Gearbox Maintenance

- Fluid Level and Quality: Ensure that the transmission fluid levels are correct and the fluid is of good quality.

- Visual Inspection: Look for signs of wear, damage, or leaks.

- Test Drive: Listen for unusual noises and pay attention to the smoothness of gear shifting.

Professional vs. DIY Inspections

- DIY Inspections: Basic checks that car owners can perform themselves at home.

- Professional Inspections: Comprehensive evaluations carried out by certified mechanics.

- Recommended Frequency: DIY inspections should be performed monthly, while professional inspections should be done annually.

Fluid Maintenance and Changes

Maintaining proper fluid levels and regular changes is critical for the effective operation of an automatic transmission. Regular fluid changes ensure the gearbox performs optimally and lasts longer.

When to Change Transmission Fluid

- Manufacturer Guidelines: Always follow the manufacturer’s recommended schedule for fluid changes.

- Signs of Fluid Deterioration: Change the fluid if it has become dark or has a burnt smell.

- High Mileage: Vehicles with high mileage may need fluid changes more frequently.

Best Practices for Fluid Maintenance

- Use Recommended Fluid: Always use the type of transmission fluid recommended by the manufacturer.

- Check Fluid Levels: Regularly check and top up the fluid as needed.

- Monitor for Leaks: Inspect the system for leaks and repair them promptly.

Benefits of Regular Fluid Changes

- Enhanced Performance: Fresh fluid improves the smoothness of gear shifting and overall transmission performance.

- Reduced Wear: Clean fluid minimizes friction, which reduces wear on internal components.

- Extended Gearbox Life: Regular fluid changes can prolong the lifespan of your gearbox.

Proper Driving Habits

Adopting good driving habits can have a significant impact on the lifespan and performance of your gearbox. Small adjustments in driving style can prevent many common gearbox problems.

How Driving Style Affects Gearbox

- Smooth Acceleration: Avoid rapid acceleration to reduce strain on the gearbox.

- Gentle Shifting: Shift gears smoothly and avoid forcing the gear lever.

- Avoid Overloading: Never exceed the vehicle’s recommended load capacity.

Tips for Extending Gearbox Life

- Regular Maintenance: Stick to a consistent maintenance schedule.

- Use Parking Brake: Engage the parking brake to reduce strain on the transmission when parked.

- Allow Warm-Up: Let the vehicle warm up before driving, especially in cold weather.

Avoiding Common Driving Mistakes

- Coasting in Neutral: Avoid coasting downhill in neutral, as it can harm the gearbox and reduce control.

- Riding the Clutch: Don’t rest your foot on the clutch pedal when not shifting to prevent unnecessary wear.

- Ignoring Warning Signs: Address any unusual noises, smells, or performance issues immediately.