Catalytic converters play a vital role in reducing harmful vehicle emissions, yet many car owners ignore the potential risks until they encounter a serious failure. In the previous edition of Crying Fouled, we discussed how the factory-installed catalytic converter in a ’95 Firebird Firehawk was rendered useless due to contamination from unspent fuel. This resulted in severe airflow blockage and a noticeable drop in performance. While this converter couldn’t be salvaged, it serves as a warning sign for the importance of early detection in avoiding similar failures.

Many catalytic converter failures can be prevented with proper maintenance and timely intervention. Issues such as engine misfires, fuel injector leaks, and overheating can cause significant damage to the converter long before the Check Engine light comes on. By staying proactive with vehicle care and addressing problems early, you can extend the life of your catalytic converter. Below are the primary causes of failure, with a focus on areas where attention and vigilance can help prevent damage to the converter.

The Leading Causes of Catalytic Converter Failure

1. Excessive Exhaust Temperatures

Catalytic converters are engineered to withstand a maximum temperature of 1,400°F. However, factors like exhaust leaks or malfunctioning EGR (Exhaust Gas Recirculation) valves can elevate exhaust temperatures beyond the converter’s safe operating limits. Exhaust leaks introduce unmeasured air into the exhaust system, disrupting the air-fuel ratio and causing higher combustion temperatures. These extreme temperatures can quickly burn out the catalyst material, rendering the converter ineffective.

2. Silicone Contamination

Silicone is commonly used to seal engine parts but can cause severe issues when exposed to the high temperatures of the exhaust system. When silicone burns, it releases gases that coat the O2 sensors, distorting their readings. This causes the engine’s ECU to adjust the air-fuel mixture based on inaccurate data, typically enriching the mixture too much. A rich fuel mixture generates excess heat that can damage the catalytic converter, severely reducing its efficiency and lifespan.

3. Teflon Damage

Teflon, like silicone, can also be harmful when it comes into contact with high heat. When Teflon burns, it releases gases that interfere with the oxygen sensors, compromising the converter’s ability to function correctly. These gases coat the sensors, making it harder for them to provide accurate readings. The ECU, receiving incorrect sensor data, may adjust the fuel mixture too much, raising exhaust temperatures and stressing the catalytic converter.

4. Engine Overheating

When an engine operates at excessive temperatures for prolonged periods, it can severely damage a catalytic converter. Overheating often results from faulty cooling systems or insufficient coolant levels. Excessively high coolant temperatures can induce engine misfires or detonation, which, in turn, can cause the ceramic substrate inside the converter to melt or the matting to fail. This structural damage to the substrate leads to total converter failure, making it impossible to restore.

5. Oil Fouling

Oil fouling occurs when engine oil seeps into the combustion chamber and burns within the engine. This is often a sign of worn-out piston rings, valve seals, or valve guides. As oil burns, it passes through the exhaust system, where it coats the surface of the catalytic converter’s substrate. This creates a layer of contamination that blocks the converter’s ability to efficiently process emissions. Over time, this oil buildup diminishes the converter’s effectiveness, leading to eventual failure.

6. Fuel Injector Leaks and High Fuel Pressure

Fuel injector leaks and high fuel pressure can result in raw, unburned fuel entering the exhaust system. This unspent fuel can ignite inside the catalytic converter, producing soot and carbon deposits. These deposits clog the converter, reducing its efficiency and compromising vehicle performance. This incomplete combustion can not only result in power loss but also reduce fuel economy. Over time, the excess soot and fuel buildup will irreversibly damage the converter.

7. Antifreeze Contamination

Leaks from components like the head gasket, cylinder head, or intake manifold can allow antifreeze to enter the combustion chamber. This antifreeze travels through the exhaust system, where it coats the substrate inside the catalytic converter. The presence of coolant in the exhaust flow reduces the converter’s ability to scrub the emissions and process gases properly. This contamination results in poor emissions control and can even prevent the vehicle from passing emissions tests.

8. Carbon Build-Up

Carbon build-up in the combustion chamber can be problematic, especially when it is not properly managed. Carbon cleaning services can remove this build-up, but when the procedure is delayed until a vehicle is high-mileage, large chunks of carbon can break loose and enter the exhaust system. These larger pieces of carbon can clog the catalytic converter’s substrate, obstructing airflow and hindering its ability to function efficiently. This results in decreased vehicle performance and can shorten the lifespan of the converter.

9. Physical Damage

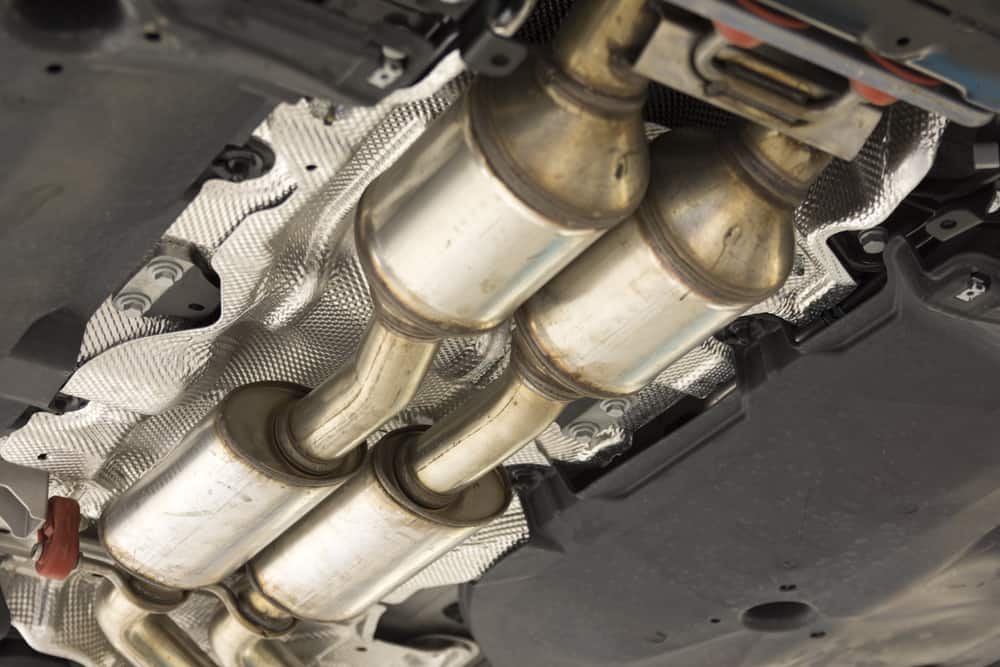

Physical damage to the catalytic converter can occur when road debris, potholes, or speed bumps impact the exhaust system. These hazards can crush the converter’s casing, causing the internal substrate to become dislodged or broken. The resulting damage blocks airflow, severely affecting the exhaust system’s ability to process gases effectively. Low-hanging exhaust systems are particularly vulnerable to these types of physical damages, making regular checks of the exhaust system essential.

The Importance of Proper Installation and Break-In

When installing a new catalytic converter, a proper break-in process is crucial for ensuring its longevity and performance. The matting that holds the ceramic substrate in place must expand correctly during the initial heat-up cycle. If this step is skipped, the substrate may not properly settle within the converter, which could lead to rattling or early failure. Failing to break in the converter properly is a common cause of premature converter failure, even in new parts.

How to Break In Your Converter

To properly break in a new catalytic converter, start the engine and allow it to idle for a few minutes without touching the accelerator. After five minutes of idle time, increase the engine speed to about 2,500 RPM and hold it there for approximately two minutes. This allows the converter to reach its proper operating temperature and ensures the matting expands correctly. Once the break-in period is complete, the vehicle should be road-tested to confirm proper installation and performance.

Prolong Your Converter’s Life

Catalytic converter failures are often the result of preventable issues such as overheating, contamination, or physical damage. By recognizing these signs and addressing underlying problems early, vehicle owners can prolong the life of their converters and prevent expensive repairs. Understanding the causes of failure helps car owners take action before the damage becomes irreversible.

The Importance of Regular Maintenance

Routine engine maintenance, including checking for fuel leaks, ensuring the proper functioning of sensors, and addressing cooling system issues, plays a critical role in preventing catalytic converter failure. Regular inspections and addressing small issues promptly can help keep the catalytic converter functioning optimally, extending its service life.

By understanding the common causes of catalytic converter failure and staying vigilant about engine health and exhaust system care, drivers can keep their vehicles running smoothly. Investing in regular maintenance and staying aware of the early signs of failure allows for safer, more reliable driving, while also preserving the performance and efficiency of the catalytic converter.