Hyundai vehicles are known for their reliability, affordability, and advanced features. However, neglecting regular maintenance and care can lead to a range of common problems that Hyundai owners may face.

These issues can affect the vehicle’s performance, safety, and longevity, leading to increased repair costs and reduced driving enjoyment. Understanding and addressing these problems promptly is essential for maintaining the health and reliability of a Hyundai.

In this article, we will explore ten common problems that Hyundai owners face due to neglect. By recognizing these issues and taking proactive steps to address them, Hyundai owners can ensure their vehicles remain in peak condition and provide a safe and enjoyable driving experience. Let’s look into each of these common problems and learn how to avoid them for a more reliable and worry-free ownership experience.

1. Engine Oil Sludge Build-up

Engine oil sludge is a thick, gel-like substance that can form when engine oil breaks down and mixes with contaminants such as dirt, debris, and combustion byproducts. This build-up can have severe consequences for a Hyundai engine, leading to clogged oil passages, restricted oil flow, and increased friction and wear on engine components.

Sludge formation typically occurs when regular oil changes are neglected, and the oil is not replaced at the manufacturer’s recommended intervals. Over time, the oil’s ability to lubricate and protect the engine diminishes, leading to the accumulation of sludge. This can cause several issues, including reduced engine performance, increased fuel consumption, and potential engine failure.

One of the primary functions of engine oil is to create a lubricating film between moving parts, reducing friction and preventing metal-to-metal contact. When sludge forms, it can obstruct this lubrication, causing excessive wear and tear on components such as the pistons, crankshaft, and camshaft. This can result in decreased engine efficiency, rough idling, and difficulty starting the vehicle.

Additionally, engine oil helps dissipate heat generated during combustion. Sludge build-up can hinder this heat dissipation, leading to overheating and potential damage to critical engine components. Overheating can cause the engine to seize, resulting in costly repairs or even complete engine replacement.

To prevent engine oil sludge build-up, Hyundai owners should adhere to the manufacturer’s recommended oil change intervals. This typically involves changing the oil every 5,000 to 7,500 miles or every six months, whichever comes first. Using high-quality engine oil that meets the specifications outlined in the owner’s manual is also crucial for maintaining proper lubrication and protection.

In addition to regular oil changes, it is essential to use the correct oil filter. A high-quality oil filter helps remove contaminants from the oil, preventing sludge formation and ensuring clean oil circulates through the engine. Regularly inspecting and replacing the oil filter according to the manufacturer’s recommendations is a key part of engine maintenance.

Engine oil sludge build-up is a preventable issue that can have serious consequences for a Hyundai engine. By following the manufacturer’s recommended maintenance schedule, using high-quality oil and oil filters, and performing regular inspections, Hyundai owners can ensure their engines remain free of sludge and operate smoothly and efficiently. Taking proactive measures to prevent sludge formation helps extend the engine’s lifespan and maintain the vehicle’s performance and reliability.

2. Transmission Fluid Degradation

Transmission fluid is essential for the smooth operation of the transmission system in a Hyundai vehicle. It serves multiple functions, including lubricating transmission components, cooling the transmission, and facilitating gear shifts. Over time, however, transmission fluid can degrade and become contaminated with metal particles, dirt, and other debris. This degradation can lead to poor shifting performance, increased friction and wear, and potential transmission failure.

One of the primary reasons for transmission fluid degradation is neglecting regular fluid changes. As transmission fluid ages, its ability to lubricate and protect transmission components diminishes. This can result in increased friction between moving parts, leading to wear and tear on components such as gears, clutches, and bearings. Degraded fluid can also cause overheating, which can further damage the transmission and reduce its efficiency.

Poor shifting performance is a common symptom of transmission fluid degradation. Drivers may experience delayed or rough shifts, slipping gears, or a noticeable decline in acceleration. These issues can affect the driving experience and, if left unaddressed, can lead to more severe transmission problems.

To prevent transmission fluid degradation, Hyundai owners should follow the manufacturer’s recommended maintenance schedule for fluid changes. This typically involves changing the transmission fluid every 30,000 to 60,000 miles, depending on the specific model and driving conditions. Using the correct type of transmission fluid specified in the owner’s manual is also crucial for ensuring compatibility and optimal performance.

In addition to regular fluid changes, it is essential to check the transmission fluid level periodically. Low fluid levels can cause the transmission to overheat and lead to shifting issues. If the fluid level is low, it may indicate a leak in the transmission system, which should be addressed promptly to prevent further damage.

Regular inspections of the transmission system can help identify potential issues before they become major problems. This includes checking for fluid leaks, inspecting the condition of the transmission pan and filter, and monitoring the performance of the transmission. Addressing any signs of wear or damage promptly can prevent extensive damage and costly repairs.

Transmission fluid degradation is a common problem that can have serious consequences for a Hyundai vehicle. By following the manufacturer’s recommended maintenance schedule, using the correct transmission fluid, and performing regular inspections, Hyundai owners can ensure their transmissions operate smoothly and efficiently. Taking proactive measures to prevent fluid degradation helps extend the transmission’s lifespan and maintain the vehicle’s performance and reliability.

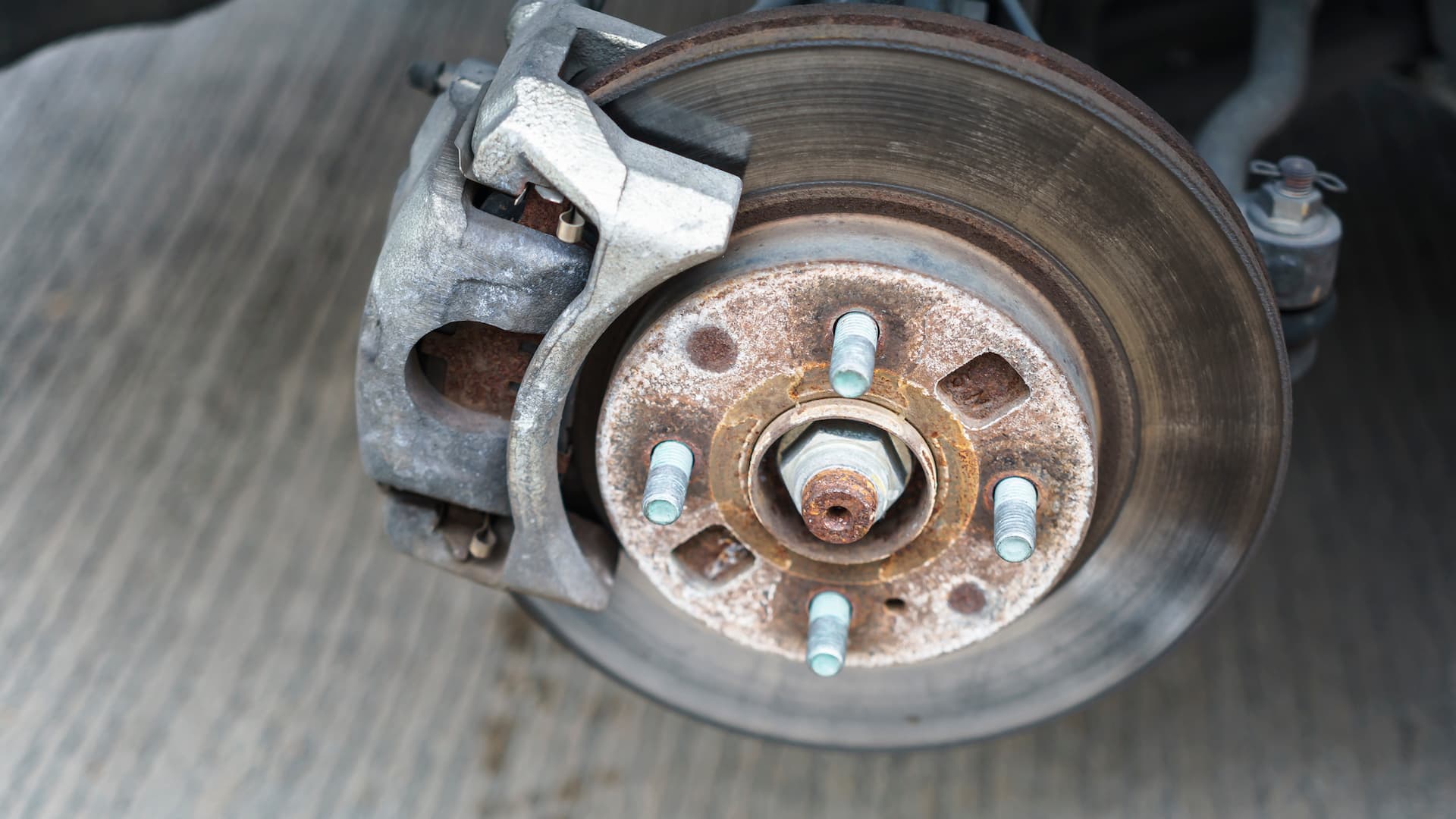

3. Brake System Deterioration

The brake system is one of the most critical safety features of any vehicle, including Hyundai cars. Neglecting brake system maintenance can lead to reduced braking performance, increased stopping distances, and potential brake failure. Common issues that contribute to brake system deterioration include worn brake pads, warped rotors, and contaminated brake fluid.

Brake pads play a vital role in the braking process by creating friction against the rotors to slow down and stop the vehicle. Over time, brake pads can wear down, reducing their effectiveness and increasing stopping distances. Worn brake pads can also cause damage to the rotors, leading to additional repair costs. Regularly inspecting and replacing brake pads when they reach the minimum thickness specified in the owner’s manual is essential for maintaining optimal braking performance.

Warped rotors are another common issue that can affect the brake system. Rotors can become warped due to excessive heat generated during braking, uneven wear, or improper installation. Warped rotors can cause vibrations or pulsations when braking, reducing the vehicle’s stopping power and making it difficult to control. Regularly inspecting the rotors for signs of warping and replacing or resurfacing them as needed helps maintain smooth and efficient braking.

Contaminated brake fluid can also contribute to brake system deterioration. Brake fluid is hygroscopic, meaning it absorbs moisture from the air over time. This moisture can lower the fluid’s boiling point, reducing its effectiveness and leading to brake fade during prolonged or heavy braking. Contaminated brake fluid can also cause corrosion within the braking system, leading to leaks and reduced performance. Regularly flushing and replacing the brake fluid according to the manufacturer’s recommendations is crucial for maintaining optimal braking performance and preventing corrosion.

Regular brake system inspections are essential for identifying and addressing potential issues before they become major problems. This includes checking the brake pads, rotors, calipers, and brake fluid levels, as well as inspecting the brake lines for signs of wear or leaks. Addressing any signs of wear or damage promptly ensures that the braking system remains in optimal condition and provides safe and reliable stopping power.

Neglecting brake system maintenance is a serious issue that can compromise the safety and performance of a Hyundai vehicle. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and replacing worn components, and maintaining the brake fluid, Hyundai owners can ensure their brake systems operate efficiently and safely. Taking proactive measures to prevent brake system deterioration helps maintain the vehicle’s reliability and safety.

4. Fuel System Contamination

The fuel system in a Hyundai vehicle is responsible for delivering clean, pressurized fuel to the engine for combustion. Over time, contaminants such as dirt, rust, and debris can accumulate in the fuel tank and fuel lines, leading to fuel system contamination. This can cause several issues, including reduced fuel efficiency, poor engine performance, and increased emissions.

One of the primary components susceptible to contamination is the fuel injectors. Fuel injectors are responsible for spraying a precise amount of fuel into the combustion chamber. When they become clogged with deposits, they can no longer deliver the correct amount of fuel, leading to a lean or rich fuel mixture. This can result in rough idling, reduced power, and hesitation during acceleration. In severe cases, clogged injectors can cause engine misfires and damage to the catalytic converter.

The fuel filter is another critical component that can become clogged with contaminants. The fuel filter’s job is to remove impurities from the fuel before it reaches the engine. A clogged fuel filter can restrict fuel flow, causing the engine to run poorly or stall. Regularly replacing the fuel filter according to the manufacturer’s recommendations is essential for maintaining optimal fuel flow and preventing contamination.

To prevent fuel system contamination, Hyundai owners should use high-quality fuel from reputable sources and avoid filling up the tank from stations with questionable fuel quality. Additionally, using fuel system cleaners and additives can help remove deposits and keep the injectors and fuel lines clean. These products are designed to break down and dissolve contaminants, ensuring that the fuel system remains free of blockages.

Regular maintenance of the fuel system also includes checking for leaks and inspecting the fuel lines for signs of wear or damage. Fuel leaks can pose a serious safety hazard and should be addressed promptly by a qualified technician. Ensuring that the fuel system components are in good condition helps prevent contamination and maintains the vehicle’s performance and efficiency.

Fuel system contamination is a common problem that can have significant consequences for a Hyundai vehicle. By using high-quality fuel, regularly replacing the fuel filter, and using fuel system cleaners, Hyundai owners can prevent contamination and ensure their fuel systems operate smoothly and efficiently. Taking proactive measures to maintain the fuel system helps improve fuel efficiency, reduce emissions, and extend the engine’s lifespan.

5. Cooling System Failure

The cooling system in a Hyundai vehicle is essential for regulating the engine’s temperature and preventing overheating. Components such as the radiator, water pump, thermostat, and hoses work together to circulate coolant and dissipate heat. Cooling system failure can lead to overheating and severe engine damage, making regular maintenance and inspections crucial for ensuring the system operates efficiently.

One of the primary causes of cooling system failure is coolant degradation. Coolant, also known as antifreeze, loses its effectiveness over time and can become contaminated with rust, scale, and other debris. Degraded coolant can no longer effectively absorb and dissipate heat, leading to overheating and potential engine damage. Regularly flushing and replacing the coolant according to the manufacturer’s recommendations helps maintain its effectiveness and prevent cooling system failure.

Another common cause of cooling system failure is leaks. Coolant leaks can occur due to worn or damaged hoses, a faulty radiator cap, or a failing water pump. Leaks can lead to low coolant levels, reducing the system’s ability to regulate the engine’s temperature. Regular inspections of the cooling system components, including hoses, clamps, and radiators, help identify and address leaks before they cause significant issues.

The radiator is a key component of the cooling system, responsible for dissipating heat from the coolant. Over time, the radiator can become clogged with debris or develop internal blockages, reducing its efficiency. Regularly inspecting and cleaning the radiator, as well as checking for external damage helps ensure optimal heat dissipation and prevents overheating.

The water pump is another crucial component that circulates coolant through the engine and radiator. A failing water pump can lead to inadequate coolant circulation and overheating. Signs of a failing water pump include coolant leaks, a whining noise from the engine, and overheating. Regularly inspecting the water pump and replacing it according to the manufacturer’s recommendations helps maintain proper coolant circulation.

The thermostat regulates the flow of coolant between the engine and the radiator, ensuring that the engine operates at the optimal temperature. A faulty thermostat can become stuck in the open or closed position, leading to either overcooling or overheating. Regularly testing and replacing the thermostat as needed helps maintain the correct engine temperature and prevent cooling system failure.

Cooling system failure is a serious issue that can lead to significant engine damage and costly repairs. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and replacing components, and addressing any signs of wear or damage promptly, Hyundai owners can ensure their cooling systems operate efficiently and effectively. Taking proactive measures to maintain the cooling system helps prevent overheating, extend the engine’s lifespan, and maintain the vehicle’s performance and reliability.

6. Suspension Component Wear

The suspension system in a Hyundai vehicle is responsible for providing a smooth and comfortable ride, as well as ensuring safe handling and control. Over time, suspension components such as shocks, struts, and bushings can wear out, leading to a rough ride, poor handling, and increased tire wear. Ignoring suspension system maintenance can result in reduced performance and potential safety hazards.

Shocks and struts are key components of the suspension system that help absorb road impacts and maintain vehicle stability. Worn shocks and struts can lead to a bouncy or uncomfortable ride, decreased handling performance, and increased braking distances. Common signs of worn shocks and struts include excessive bouncing, nose-diving during braking, and uneven tire wear. Regularly inspecting and replacing shocks and struts according to the manufacturer’s recommendations helps maintain ride quality and handling performance.

Bushings are small rubber or polyurethane components that provide cushioning and reduce vibrations between metal parts of the suspension system. Over time, bushings can deteriorate, crack, or become worn, leading to increased noise, vibrations, and a rough ride. Regularly inspecting and replacing worn bushings helps maintain a smooth and comfortable driving experience.

Alignment and wheel balance are also important aspects of suspension maintenance. Misaligned wheels can cause uneven tire wear, reduced fuel efficiency, and poor handling. Regularly checking and adjusting wheel alignment according to the manufacturer’s recommendations helps ensure proper vehicle stability and tire longevity. Additionally, balancing the tires helps prevent vibrations and extends the lifespan of the suspension components.

The suspension system also includes control arms, ball joints, and sway bars, which contribute to the vehicle’s handling and stability. These components can wear out or become damaged over time, leading to a decrease in suspension performance. Regularly inspecting and maintaining these components, including replacing worn parts, helps ensure optimal handling and control.

Ignoring suspension system maintenance can lead to a range of issues that affect the vehicle’s performance, safety, and comfort. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and replacing worn components, and addressing alignment and balance issues, Hyundai owners can ensure their suspension systems operate efficiently. Taking proactive measures to maintain the suspension system helps provide a smooth and comfortable ride, improve handling performance, and enhance verall vehicle safety.

7. Electrical System Complications

The electrical system in a Hyundai vehicle includes critical components such as the battery, alternator, starter, and various sensors and modules. Neglecting electrical system maintenance can lead to a range of issues, including dead batteries, faulty sensors, and intermittent electrical failures. Addressing these complications promptly is essential for maintaining the vehicle’s reliability and ensuring smooth operation.

The battery is a key component of the electrical system, providing the power needed to start the engine and operate various electrical accessories. Over time, batteries can lose their charge or become corroded, leading to starting issues and electrical failures. Regularly testing the battery’s charge level, cleaning the terminals, and ensuring proper connections help maintain a reliable electrical system. Hyundai owners should replace the battery every three to five years or sooner if signs of reduced performance are noticed.

The alternator is responsible for charging the battery and powering the vehicle’s electrical systems while the engine is running. A failing alternator can lead to dimming headlights, a weak or dead battery, and electrical malfunctions. Common signs of alternator issues include a battery warning light on the dashboard, flickering lights, and unusual noises from the engine. Regularly inspecting and testing the alternator helps ensure it operates effectively and prevents electrical system failures.

Sensors and modules play a crucial role in monitoring and controlling various functions of the vehicle, including the engine, transmission, and safety systems. Faulty sensors can lead to incorrect readings, poor performance, and warning lights on the dashboard. Regularly scanning the vehicle’s onboard diagnostic system for error codes and addressing any sensor issues promptly helps maintain optimal performance and reliability.

Wiring and connections are also important aspects of the electrical system. Damaged or corroded wiring can cause intermittent electrical failures, short circuits, and malfunctions of various components. Regularly inspecting the wiring and connections for signs of wear or damage and addressing any issues promptly helps prevent electrical complications and ensures smooth operation.

The starter motor is responsible for cranking the engine and initiating the combustion process. A failing starter motor can result in difficulty starting the engine or a complete failure to start. Common signs of starter motor issues include a clicking sound when turning the key and slow or no cranking. Regularly inspecting and testing the starter motor helps ensure reliable engine starting and prevents unexpected breakdowns.

Electrical system complications can have significant consequences for a Hyundai vehicle, affecting its performance and reliability. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and testing components, and addressing any issues promptly, Hyundai owners can ensure their electrical systems operate smoothly and efficiently. Taking proactive measures to maintain the electrical system helps prevent unexpected failures and ensures the vehicle remains reliable and safe to drive.

8. Climate Control System Decline

The climate control system in a Hyundai vehicle is responsible for maintaining a comfortable cabin environment by regulating temperature and airflow. Neglecting climate control system maintenance can lead to reduced heating and cooling performance, unpleasant odors, and decreased air quality. Common issues that contribute to climate control system decline include clogged cabin air filters, low refrigerant levels, and faulty blower motors.

The cabin air filter is designed to remove dust, pollen, and other airborne contaminants from the air entering the vehicle’s interior. Over time, the cabin air filter can become clogged, reducing airflow and causing the HVAC system to work harder. This can result in reduced heating and cooling performance, as well as unpleasant odors in the cabin. Regularly replacing the cabin air filter according to the manufacturer’s recommendations helps maintain optimal airflow and air quality.

Refrigerant is a crucial component of the climate control system, responsible for cooling the air before it enters the cabin. Low refrigerant levels can lead to reduced cooling performance and increased wear on the AC compressor. Refrigerant leaks can occur due to damaged hoses, seals, or connections. Regularly checking and maintaining refrigerant levels, as well as inspecting the system for leaks helps ensure efficient cooling performance and prevents compressor damage.

The blower motor is responsible for circulating air through the HVAC system and into the cabin. A failing blower motor can result in weak airflow or no airflow at all, making it difficult to regulate the cabin temperature. Common signs of blower motor issues include unusual noises, weak airflow, and intermittent operation. Regularly inspecting and testing the blower motor helps ensure it operates effectively and provides adequate airflow.

The climate control system also includes various sensors and actuators that regulate temperature and airflow. Faulty sensors can lead to incorrect temperature readings and poor climate control performance. Regularly scanning the vehicle’s onboard diagnostic system for error codes and addressing any sensor issues promptly helps maintain optimal climate control performance.

Neglecting climate control system maintenance can lead to a range of issues that affect the comfort and air quality of the vehicle’s interior. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and replacing components, and addressing any issues promptly, Hyundai owners can ensure their climate control systems operate efficiently. Taking proactive measures to maintain the climate control system helps provide a comfortable driving experience and ensures the vehicle remains inviting and pleasant for occupants.

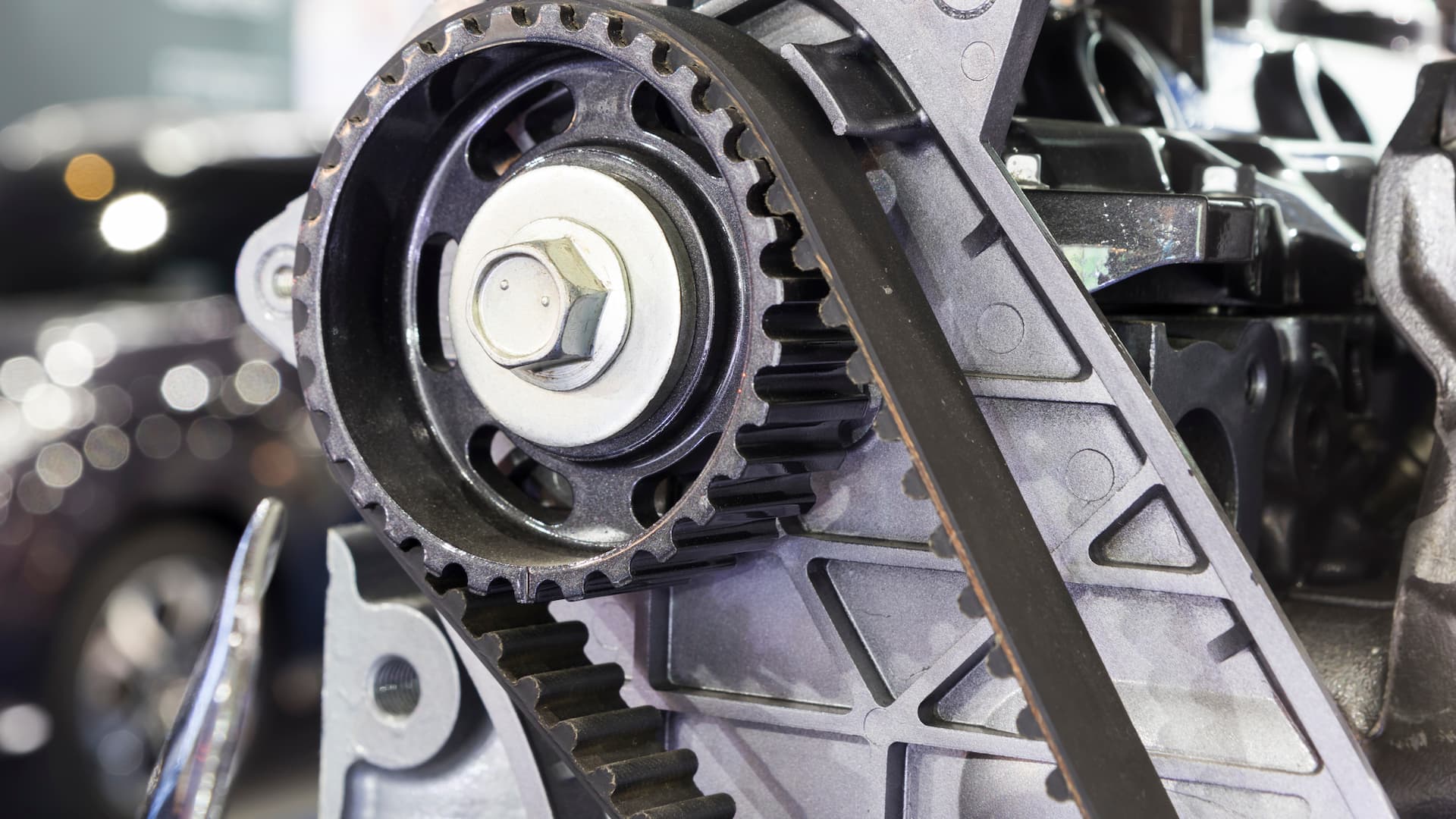

9. Timing Belt and Chain Issues

The timing belt or chain in a Hyundai vehicle is responsible for synchronizing the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at the correct times. Over time, the timing belt or chain can wear out, become loose, or break, leading to severe engine damage. Regularly inspecting and replacing the timing belt or chain according to the manufacturer’s recommendations is crucial for preventing catastrophic engine failure.

The timing belt is a reinforced rubber belt with teeth that mesh with the sprockets on the crankshaft and camshaft. Over time, the rubber can deteriorate, leading to cracks, fraying, or stretching. A worn timing belt can slip or break, causing the engine to lose synchronization and potentially resulting in valve-to-piston collisions. This can lead to bent valves, damaged pistons, and other significant engine damage.

To prevent these issues, Hyundai owners should adhere to the manufacturer’s recommended timing belt replacement intervals, which typically range from 60,000 to 100,000 miles depending on the specific model and engine type. Regular inspections of the timing belt for signs of wear, such as cracking, fraying, or stretching, are essential for identifying potential issues before they lead to failure.

The timing chain, on the other hand, is a metal chain that also synchronizes the rotation of the crankshaft and camshaft. Timing chains are generally more durable than timing belts and can last longer, but they are not immune to wear.

Over time, timing chains can become stretched, leading to a loss of synchronization and potential engine damage. Common signs of timing chain issues include rattling noises from the engine, poor performance, and a check engine light. Regular inspections and timely replacement of the timing chain according to the manufacturer’s recommendations are crucial for maintaining engine health.

In addition to replacing the timing belt or chain, it is also advisable to inspect and replace other related components, such as the tensioner, idler pulleys, and water pump, during the timing belt or chain replacement. These components work together with the timing belt or chain to ensure proper engine operation, and their failure can also lead to engine damage. Replacing them at the same time as the timing belt or chain can save on labor costs and prevent future issues.

Timing belt and chain issues can have severe consequences for a Hyundai engine, leading to significant damage and costly repairs. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and replacing the timing belt or chain, and addressing any signs of wear or damage promptly, Hyundai owners can ensure their engines remain in optimal condition and operate smoothly. Taking proactive measures to maintain the timing belt or chain helps prevent catastrophic engine failure and extends the engine’s lifespan.

10. Transmission Control Issues

Transmission control issues in a Hyundai vehicle can arise from faulty sensors, solenoids, or the transmission control module (TCM). These components play a crucial role in regulating the transmission’s operation and ensuring smooth gear shifts. Transmission control issues can lead to shifting problems, reduced performance, and potential transmission failure.

Faulty sensors, such as the transmission speed sensor or throttle position sensor, can provide incorrect data to the TCM, leading to erratic shifting and poor performance. Common symptoms of sensor issues include harsh or delayed shifts, slipping gears, and a noticeable decline in acceleration. Regularly scanning the vehicle’s onboard diagnostic system for error codes and addressing any sensor issues promptly helps maintain smooth transmission operation.

Solenoids are electromechanical devices that control the flow of transmission fluid and regulate gear shifts. A failing solenoid can result in shifting problems, such as being stuck in a particular gear or experiencing sudden and unpredictable shifts. Common signs of solenoid issues include transmission warning lights, erratic shifting, and unusual noises from the transmission. Regularly inspecting and testing the solenoids helps ensure they operate effectively and prevent shifting problems.

The TCM is responsible for processing data from various sensors and controlling the transmission’s operation. A failing TCM can cause a range of issues, including erratic shifting, transmission warning lights, and reduced performance. Common signs of TCM issues include difficulty shifting gears, slipping transmission, and poor acceleration. Regularly updating the TCM software and addressing any issues promptly helps maintain reliable transmission performance.

In addition to inspecting and maintaining these components, it is essential to perform regular transmission fluid changes and ensure that the fluid level is within the recommended range. Low or degraded transmission fluid can exacerbate transmission control issues and lead to further complications. Following the manufacturer’s recommended maintenance schedule for fluid changes and inspections helps ensure optimal transmission performance.

Transmission control issues can have significant consequences for a Hyundai vehicle, affecting its performance and reliability. By following the manufacturer’s recommended maintenance schedule, regularly inspecting and testing components, and addressing any issues promptly, Hyundai owners can ensure their transmissions operate smoothly and efficiently. Taking proactive measures to maintain the transmission control system helps prevent shifting problems, extend the transmission’s lifespan, and maintain the vehicle’s performance and reliability.

By avoiding these ten common problems and taking proactive steps to address them, Hyundai owners can ensure their vehicles remain in peak condition, provide a safe and enjoyable driving experience, and maintain their value. Regular maintenance, timely repairs, and proper care are key to preserving the performance and longevity of a Hyundai.