General Motors’ commitment to achieve carbon neutrality by 2040 represents one of the most ambitious environmental initiatives in automotive history.

Announced in January 2021, this comprehensive strategy extends far beyond simply transitioning to electric vehicles, encompassing every aspect of GM’s global operations, from manufacturing and supply chain to product lifecycle and end of life recycling.

The commitment marks a fundamental shift for one of the world’s largest automakers, which has historically been associated with large SUVs and pickup trucks.

The magnitude of this transformation cannot be understated GM plans to invest more than $35 billion in electric and autonomous vehicles through 2025, while simultaneously working to reduce emissions across its entire value chain.

The company’s strategy is multi-faceted, combining technological innovation, operational improvements, and strategic partnerships to achieve its environmental goals. This includes plans to power all US facilities with 100% renewable energy by 2025, develop new battery technologies, and establish circular economy principles throughout its business.

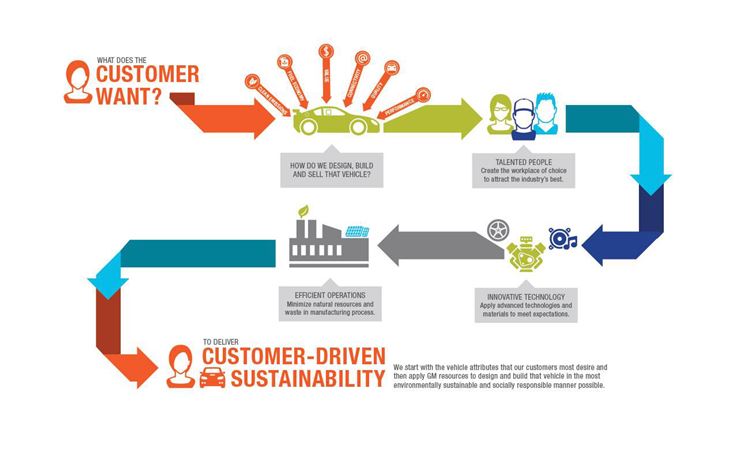

What makes GM’s approach particularly noteworthy is its holistic nature. Rather than focusing solely on vehicle electrification, the company has recognized that achieving true carbon neutrality requires addressing emissions at every stage of the automotive lifecycle.

This includes tackling scope 1, 2, and 3 emissions from direct operations to indirect emissions from suppliers and product use. As we examine the various components of GM’s strategy, we’ll explore how these initiatives work together to create a comprehensive roadmap toward carbon neutrality.

Vehicle Electrification Strategy

At the core of General Motors’ (GM) carbon neutrality commitment is an aggressive vehicle electrification strategy aimed at eliminating tailpipe emissions from its light-duty vehicle lineup by 2035.

Central to this vision is the Ultium platform, a flexible and modular architecture designed for various vehicles, from compact crossovers to full-size pickup trucks.

The Ultium platform’s modularity allows for battery configurations between 50 to 200 kWh, providing driving ranges up to 400 miles per charge. This approach aims to reduce manufacturing complexity and costs, making electric vehicles (EVs) more accessible.

By 2025, GM plans to introduce 30 new global EVs, with a significant portion available in North America.

This includes models across different price points and segments, from the Chevrolet Equinox EV to the Cadillac CELESTIQ, to accelerate EV adoption and cater to diverse consumer preferences. The transition to electric vehicles includes converting existing plants for EV production and investing in advanced manufacturing processes to increase efficiency and reduce environmental impact.

Battery Production and Sustainability

Part of GM’s electrification strategy includes battery production and sustainability. GM, through Ultium Cells LLC, a joint venture with LG Energy Solution, is building multiple battery cell manufacturing plants in the US.

These facilities focus on sustainability by incorporating renewable energy and advanced recycling technologies. The Ultium batteries emphasize high performance and cost-effectiveness, aiming to maximize energy density and reduce costs to make EVs more affordable.

Charging Infrastructure and Consumer Acceptance

To support EV adoption, GM is investing in a robust network of charging stations in collaboration with governments, utilities, and other automakers.

This aims to alleviate range anxiety and provide convenient charging options for consumers. Additionally, GM is promoting EV acceptance through educational initiatives and incentives such as tax credits and rebates, encouraging more consumers to switch to electric mobility.

Sustainable Manufacturing

GM’s commitment to sustainable manufacturing involves powering all US facilities with 100% renewable energy by 2025 and global facilities by 2035.

The company’s sustainability initiatives include energy efficiency, water conservation, waste reduction, and materials management. Advanced energy management systems optimize power consumption, while closed-loop recycling systems and zero waste to landfill strategies reduce water use and waste generation.

GM aims to use at least 50% sustainable materials in its vehicles by 2030, embracing circular economy principles to minimize waste and environmental impact.

Supply Chain Sustainability

GM collaborates with suppliers through the Supplier Sustainability Initiative, which requires setting science-based emissions reduction targets.

This collaboration extends to renewable energy projects, aiming for 100% of strategic suppliers to use 100% renewable energy by 2035. Joint efforts with suppliers also focus on recycling infrastructure and sustainable materials, driving innovation and reducing emissions across the supply chain.

GM is optimizing transportation logistics to minimize environmental impact by using electric and alternative fuel vehicles, as well as exploring rail and water transportation options.

Progress Monitoring and Reporting

GM has established systems for monitoring and reporting progress toward carbon neutrality, ensuring transparency and accountability.

The company uses science-based targets aligned with the Paris Agreement and reports through frameworks like the Carbon Disclosure Project (CDP) and the Task Force on Climate related Financial Disclosures (TCFD).

This comprehensive approach combines innovative technology, significant investments in manufacturing and infrastructure, and collaboration with suppliers to lead the automotive industry toward a sustainable future.