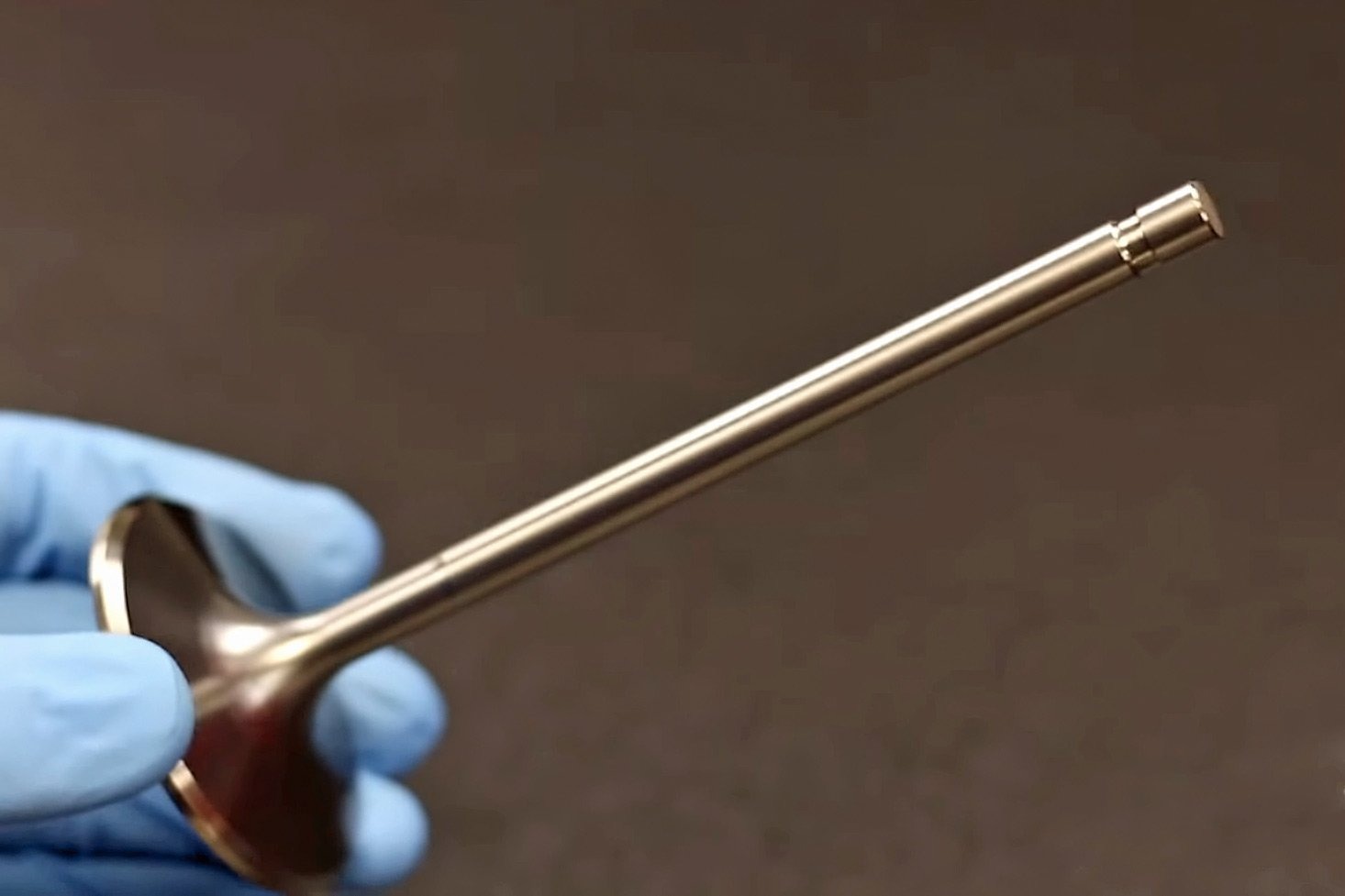

When it comes to engine performance, the type of valve a car uses can play a major role. Some vehicles are equipped with titanium valves, while others make use of bent steel valves.

Though both types have their place in engine design, their behavior under pressure, weight characteristics, and long-term durability give them very different strengths and weaknesses.

Understanding how each of them works helps you know what kind of performance to expect from the vehicle, especially when it is pushed to high limits or used for heavy-duty driving.

Titanium valves are often used in high-performance cars because of their light weight and resistance to heat. They are strong enough to hold up under extreme conditions, which makes them a common choice in racing and sports cars.

Because they weigh less than steel, they allow engines to rev faster, helping with quick acceleration and higher engine speeds. However, they are more expensive to produce and harder to replace when damaged.

Bent steel valves are found more often in regular or budget-friendly cars. These valves are heavier than titanium but are also cheaper and easier to manufacture.

While they might not handle high heat or pressure as well as titanium valves, they do a fine job in engines that do not need to operate at extreme speeds or under racing conditions. Bent steel valves can also be reshaped or repaired in some cases, which gives them another advantage in terms of cost and service life.

We are going to compare five cars that come with titanium valves and five that are fitted with bent steel valves. We will look into how each type affects performance, maintenance, reliability, and the driving experience of each car. This should give you a deeper understanding of which type fits your driving needs better.

5 Cars with Titanium Valves

1. Ferrari 458 Italia

The Ferrari 458 Italia was engineered with high-speed driving in mind. It comes with a naturally aspirated 4.5-liter V8 engine, and one of its major performance upgrades includes titanium intake valves.

This lightweight metal helps the car respond faster when the driver pushes the throttle. Because the titanium valves weigh much less than steel, the engine does not need to work as hard to move them. This leads to quicker revs, more immediate power delivery, and better engine efficiency at high RPMs.

What sets this Ferrari apart is how stable the engine remains even when pushed hard. Titanium can resist the kind of heat that comes from high-rev driving, especially above 9,000 RPM.

When the engine is spinning at such speed, traditional steel valves would begin to flex or wear out faster, but titanium keeps its shape and strength much longer. This is part of why the 458 is often described as smooth, responsive, and consistent during aggressive performance driving.

Another advantage of the titanium valves in the 458 Italia is durability under stress. Titanium does not corrode easily, and it holds up well even in high-friction parts of the engine.

While the material itself is more costly to produce and machine, the benefits it brings in terms of reliability and throttle response make it ideal for drivers who enjoy sporty cars with quick reflexes. The engine in the 458 Italia becomes more dependable under track conditions because of this thoughtful choice in materials.

2. Yamaha R1-Derived Engine in Lexus LFA

The Lexus LFA stands out because of the engine it carries. Inspired by Yamaha’s experience with motorcycle engines, the 4.8-liter V10 used in the LFA was designed to rev higher and faster than most engines in its class.

One reason it can do this is the use of titanium valves. In this setup, the valves allow the engine to respond instantly when the accelerator is pressed, giving the driver a more engaging and direct driving feel.

The titanium valves inside the LFA’s engine are not only about speed. They also bring down the entire weight of the engine’s moving parts, which improves the balance of the car.

With less weight moving up and down inside the engine, vibrations are reduced, and the engine becomes more stable, even at higher revolutions. This also means less wear and tear, as titanium tends to keep its form better than most metals used in engine construction.

In terms of sound, the LFA has one of the most recognized engine notes of any sports car, and the titanium valves play a part in that. Because the engine revs so quickly, the sound builds up sharply and cleanly. The valves help maintain airflow at high speed, which adds to the car’s high-pitched exhaust tone.

Drivers who love precise control and fast response will appreciate how much the titanium valves add to the car’s driving character. It is one more example of how material choice affects both performance and experience behind the wheel.

Also Read: 5 Cars with Stall-Proof Fuel Systems vs 5 that Stall in Traffic

3. Porsche 911 GT3 (992)

The Porsche 911 GT3 from the 992 generation delivers performance that stays consistent during long drives on both roads and tracks. A part of its engine setup includes titanium valves that help the 4.0-liter flat-six engine breathe more efficiently.

This upgrade matters most when the car is revving at its redline, where air and fuel need to move freely and fast. The titanium valves make it easier for the engine to stay stable at high RPMs, reducing stress on the camshaft and valve springs.

One thing Porsche engineers focus on is how quickly the engine can respond when the driver asks for more power. Titanium valves move faster and return to position more easily, which makes throttle response crisp and predictable. This translates into faster gear changes, better acceleration out of corners, and stronger power delivery through each gear range.

This GT3 is built for more than straight-line speed. It is also designed to handle curves with precision, and that demands an engine that can stay consistent under load. Titanium valves support this kind of driving because they are more resistant to wear caused by heat and friction.

For drivers who often take their cars to track days or high-speed roads, this offers peace of mind that the engine won’t lose performance after repeated hard driving. So while the titanium valves do add to the car’s cost, the gains in responsiveness, engine life, and performance during track sessions make them a worthy inclusion. They help turn the GT3 into a machine built for both excitement and reliability.

4. Nissan GT-R R35

The Nissan GT-R R35 blends technology and engineering in a way that delivers sharp power and track-level performance. One of the hidden strengths behind its engine performance comes from the use of titanium intake valves.

This feature helps reduce the weight of the valvetrain, which plays a direct role in making the 3.8-liter twin-turbo V6 engine more responsive and durable at high engine speeds.

With titanium valves, the GT-R gains a quicker throttle reaction because the engine can rev faster without needing as much force to open and close the valves. This makes a big difference when a driver pushes hard through corners or wants rapid acceleration during overtaking.

The lightness of titanium also reduces strain on valve springs, improving engine response without affecting long-term reliability. Apart from speed, heat resistance is another reason titanium valves were selected for the GT-R’s engine. During hard driving or track runs, the engine gets extremely hot.

Titanium does not expand or deform easily under those conditions, so the engine remains stable even when pushed close to its limits. This lets the car perform without needing frequent maintenance or suffering from power loss due to heat damage.

The GT-R’s racing DNA can be felt every time the engine revs smoothly and power builds without delay. The titanium valves work quietly behind the scenes to ensure this smooth performance.

For a car that is often compared to exotic supercars, these valves support its status by giving it both speed and strength in a lightweight package that lasts.

5. Chevrolet Corvette Z06 (C6)

The C6-generation Chevrolet Corvette Z06 was built for drivers who want race car performance in a street-legal vehicle. One of the features that made this possible is the use of titanium intake valves in its LS7 7.0-liter V8 engine. These valves help keep engine weight down while improving how the engine handles airflow and heat under heavy loads.

Titanium’s lightweight means the valve train can move faster without stressing the camshaft or springs. This is especially useful in an engine like the LS7, which revs higher than most V8s. When you combine that with the engine’s high displacement, it gives the Z06 strong acceleration with less delay between throttle input and engine response.

The LS7 engine also benefits from titanium valves when it comes to engine longevity. Heat is one of the biggest challenges in high-performance engines, and these valves are built to hold up in high-temperature environments. Their resistance to wear and corrosion helps the Z06 deliver dependable performance even after many hard runs on track or road.

Chevrolet’s decision to include titanium valves was part of its goal to give the Z06 a performance edge without compromising reliability. This makes the car suitable not just for spirited driving, but also for long-term ownership with fewer engine problems.

The balance between lightweight design, power delivery, and strong materials helps the Z06 stand out as one of the most well-rounded sports cars from its era.

Cars with Bent Steel Valves

1. Toyota Corolla (1.8L 4-Cylinder)

The Toyota Corolla is known for its long service life and dependable performance, and a part of that is the engine design. Its 1.8-liter four-cylinder engine uses bent steel valves, which help manage airflow and exhaust release during combustion. These valves are strong, easy to produce, and widely available in many budget-friendly cars like the Corolla.

Bent steel valves might not be as lightweight as titanium ones, but they perform well under regular driving conditions. Since the Corolla engine is not made for racing or high-revving situations, the added weight of steel valves does not affect performance in any noticeable way. Instead, they give the car a solid and stable engine that requires less maintenance as time goes on.

Another thing that works in favor of bent steel valves is their repair potential. If one becomes damaged or warped, it can often be reshaped or replaced without needing to replace the entire head assembly. This brings down long-term service costs and makes the Corolla a more affordable car to maintain.

While the car might not offer the speed or fast throttle response of a sports model, its smooth operation and quiet engine performance make it a great fit for daily use. The steel valves support consistent engine behavior without overheating or causing excessive friction.

For drivers who just want a reliable, fuel-efficient car that runs without issues for years, the Corolla, with its bent steel valves, proves to be a sensible choice.

2. Honda Civic (1.5L Turbocharged)

The 1.5-liter turbocharged engine found in several recent Honda Civic models is equipped with bent steel valves. These valves help the engine operate at moderate speeds with a strong focus on fuel efficiency and long-term reliability. Honda designed this engine to give a mix of performance and comfort, and steel valves fit well into that idea.

Though they add some weight to the valve train, the steel valves in this engine are built to handle daily driving tasks with ease. They can withstand heat produced under moderate boost levels without losing their shape. This helps the Civic maintain smooth running over long distances, even if the car is used regularly in traffic or for commuting.

One area where the steel valves stand out is cost and maintenance. Replacing or fixing them is simple and affordable. Mechanics can find parts quickly, and the process of reshaping or grinding a bent steel valve is much easier than trying to fix or machine a titanium one. For many Civic owners, this keeps service bills low and engine reliability high.

Even though this car is turbocharged, the choice to use steel valves shows Honda’s focus on balanced power instead of outright speed. The engine still feels responsive, but it favors smoothness and fuel-saving features over aggressive performance. This makes the Civic a good option for people who want a bit of punch without the higher expenses that come with racing-level components.

3. Hyundai Elantra (2.0L MPI Engine)

The Hyundai Elantra with its 2.0-liter MPI engine follows a design that places importance on cost control and engine reliability. One of the ways the engineers achieved this is by fitting the car with bent steel valves. These valves are simple, durable, and easy to produce, making them a common choice for everyday vehicles that don’t need to reach extremely high speeds or power levels.

In the Elantra, the steel valves do exactly what they are meant to do: control airflow without drawing too much attention or adding too many extra costs. This helps the car maintain its affordable price tag while still giving dependable performance. The valves are shaped to fit tightly with the valve seats, and they hold up well even after years of regular driving.

Bent steel valves are heavier than titanium options, but since the Elantra does not need high RPMs, that added weight does not affect engine behavior much. The extra mass helps provide a solid seal, which supports consistent combustion and better emissions control. In cars that aim for low fuel consumption and comfort, that kind of valve stability is a big plus.

Service and replacement are also more affordable with steel valves. A technician can clean, lap, or grind them back into shape in many cases, which cuts down on the need for complete replacements. For drivers who want a simple, easy-to-care-for vehicle, the Elantra, with its bent steel valves, fits that need without cutting corners in reliability or performance.

4. Chevrolet Malibu (1.5L Turbo I4)

Chevrolet designed the Malibu’s 1.5-liter turbocharged inline-four engine to give strong performance while keeping production costs under control. This engine makes use of bent steel valves, which allow it to manage airflow and fuel mixture efficiently across a wide range of driving situations.

The design works well for people who spend most of their time in city traffic or on highways, where smoothness matters more than fast acceleration. The choice to use bent steel valves helps keep the Malibu’s engine design simple and strong.

These valves can handle the regular thermal cycles that come with stop-and-go driving. Even under modest turbo boost, the valves maintain their structure and continue to seal properly, which protects the engine from wear and power loss.

Though the valves weigh more than titanium ones, that weight is not a problem for an engine that stays under 6,000 RPM. The added strength of steel gives extra support to the combustion chamber, especially during fuel detonation and pressure buildup. This helps the car deliver consistent torque without making the engine feel rough or noisy.

Another thing that works in the driver’s favor is the way steel valves can be reworked if anything goes wrong. Instead of replacing an entire cylinder head, you can often replace or reshape a few valves.

This makes repair bills much lower and extends the engine’s life. For anyone looking at the Malibu as a practical family car, this detail shows how the brand has kept maintenance and engine performance in check without pushing prices up.

Also Read: 5 Forgotten Family Cars That Last vs 5 Bestseller Family Cars With Issues

5. Ford Focus (2.0L Engine)

Ford’s 2.0-liter engine used in many Focus models was developed to serve as a dependable powerplant for drivers across different types of roads. Inside this engine, bent steel valves manage the air and fuel flow, allowing the car to offer smooth driving performance at normal engine speeds.

These valves are chosen to support cost-effective production, ease of repair, and reliable daily use. While titanium valves are often found in high-end sports cars, steel valves like the ones in the Focus help reduce the chances of unexpected engine trouble.

They are less expensive to produce, and since the Focus is designed to be affordable for the average driver, steel was a natural fit for the valve material. They provide strong sealing at lower engine speeds, which helps support fuel economy and emissions control.

Steel also holds up well under conditions that most daily drivers encounter short trips, long idle times, and occasional highway cruising. The weight of the valves is not a drawback in this case because the engine is tuned for moderate RPMs.

Their reliability adds to the strength of the car’s reputation as a budget-friendly, long-lasting vehicle. Owners of the Focus often benefit from low repair costs. If one of the steel valves bends from heat or wear, it can be reshaped or replaced without much delay.

This keeps engine servicing simple and accessible to drivers who prefer to keep their vehicles for many years without large maintenance bills. The steel valves in the Ford Focus reflect a balanced approach to engine design that meets everyday needs.

Looking through both sets of cars, it becomes clear that the kind of valve used has a strong effect on how the engine behaves and what kind of driving experience the car offers.

Titanium valves, seen in performance models like the Ferrari 458 Italia, Nissan GT-R, Porsche 911 GT3, Corvette Z06, and Lexus LFA, give the engine quicker revs, lighter internal movement, and more control at higher speeds. These cars are built to push boundaries, and the materials inside them reflect that purpose.

Titanium does more than just reduce weight. It also holds its shape better during intense driving, where temperatures and pressures stay high for long periods. That kind of strength supports smooth airflow and sharper response. But this comes at a cost, since titanium parts are more expensive and harder to replace or repair when damage happens.

While cars like the Toyota Corolla, Honda Civic, Chevrolet Malibu, Hyundai Elantra, and Ford Focus show the strengths of bent steel valves. These valves are heavier, but they handle regular use with little trouble.

They can last a long time, are easier to service, and keep production costs low, which makes the cars they support more affordable. In cars made for comfort, steady driving, and low repair bills, bent steel valves continue to do the job well.

The decision between the two types depends on what kind of car you need. If speed, engine response, and high RPM reliability matter most, titanium valves offer those qualities. But if you want a dependable vehicle with lower upkeep, bent steel valves make more sense.