In an era where planned obsolescence seems to be the norm, there’s something remarkable about engines that can withstand the test of time and mileage.

These mechanical marvels don’t just survive; they thrive well beyond what most consider a full automotive lifespan.

While the average modern vehicle might last 150,000-200,000 miles before major issues arise, certain engines have earned legendary status for routinely crossing the 300,000-mile threshold with minimal fuss.

These powerplants represent the pinnacle of engineering reliability, often continuing to run smoothly long after the vehicle’s body, electronics, and other components have deteriorated.

What separates these exceptional engines from their less durable counterparts? It typically comes down to overbuilt designs, conservative tuning, simple yet effective engineering solutions, and materials chosen for longevity rather than cost-cutting.

These engines weren’t designed to be disposable; they were built to endure. For budget-conscious consumers, enthusiasts seeking dependable project vehicles, or anyone who values longevity over the latest features, understanding which engines offer true bulletproof reliability can be invaluable knowledge.

Let’s explore ten extraordinary engines that have consistently demonstrated their ability to surpass 300,000 miles while maintaining their integrity and performance.

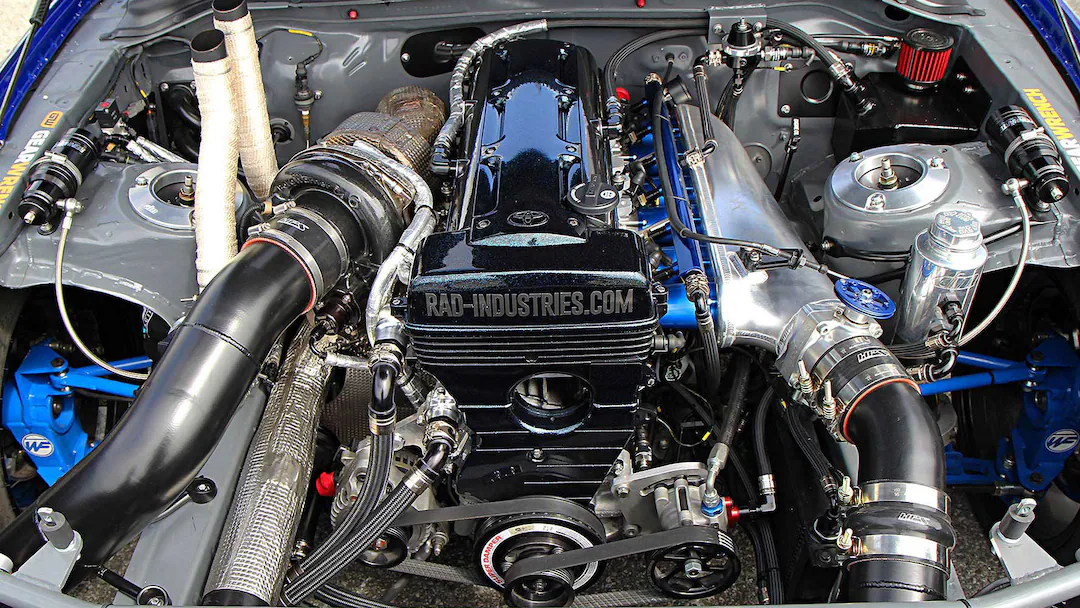

1. Toyota 2JZ-GE/GTE Inline-Six

The Toyota 2JZ engine family, particularly the naturally aspirated GE and turbocharged GTE variants, has achieved near-mythical status in automotive circles for combining exceptional performance with unparalleled durability.

Introduced in the early 1990s and most famously powering the Toyota Supra, these 3.0-liter inline-six engines were massively overengineered during Japan’s economic bubble, resulting in blocks that could handle far more power than they were initially rated for.

What makes the 2JZ truly exceptional is its iron block construction with seven main bearings supporting a forged steel crankshaft.

This robust foundation provides incredible structural integrity even under extreme stress.

The closed deck design offers a superior cylinder seal and minimizes warping under pressure, while the timing belt (rather than a chain) is surprisingly reliable when maintained according to schedule.

The stock head studs, connecting rods, and bearings were built to withstand forces far beyond factory specifications.

The naturally aspirated 2JZ-GE, found in vehicles like the Lexus GS300, IS300, and SC300, routinely surpasses 300,000 miles with basic maintenance, often running without major issues well into the 400,000-mile range.

The turbocharged 2JZ-GTE, despite enduring more heat and pressure, demonstrates similar longevity when properly maintained and not excessively modified.

Most impressive is the engine’s tolerance for neglect. Stories abound of 2JZ engines surviving extended oil change intervals and various forms of abuse that would destroy lesser powerplants.

The engine’s cooling system was also generously designed, with excellent heat management that helps prevent the head gasket issues that plague many high-performance engines.

Toyota’s fastidious quality control and conservative factory tuning meant these engines weren’t pushed to their mechanical limits from the factory, leaving substantial headroom for reliable operation over extended periods.

Even in modified form, the 2JZ platform continues to demonstrate exceptional reliability when upgraded with quality components, with many examples delivering decades of service despite producing double or triple their original horsepower ratings.

2. Mercedes-Benz OM617 Diesel Inline-Five

The Mercedes-Benz OM617 diesel engine is perhaps the most indestructible passenger car engine ever mass-produced.

This 3.0-liter five-cylinder diesel, manufactured from 1974 to 1991, powered the W123, W126, and G-Class models through some of the most punishing conditions on earth while establishing Mercedes’ reputation for bulletproof reliability.

The brilliance of the OM617’s design lies in its simplicity and robust construction.

Built with an iron block featuring seven main bearings for the forged steel crankshaft, the engine was essentially overbuilt from the start.

Its indirect injection system, while less efficient than modern direct injection, proved remarkably reliable and tolerant of varying fuel quality a crucial advantage in developing countries where these vehicles often served as taxis and utility vehicles for decades.

Unlike many modern high-pressure diesel systems, the OM617’s relatively low-pressure injection pump and mechanical design meant fewer complex components to fail.

The pre-combustion chamber design allowed the engine to run smoother and quieter than many contemporary diesels while maintaining excellent longevity.

With proper maintenance, these engines routinely surpass 500,000 miles, with many documented cases exceeding 1,000,000 miles on their original internals.

The OM617 turbo variant, introduced in the early 1980s, added forced induction without compromising reliability.

Even with the additional heat and stress of turbocharging, these engines maintained their legendary durability.

Their robust timing chain design eliminated the need for timing belt replacements, further enhancing long-term reliability.

Maintenance on the OM617 is straightforward, with accessible components and generous service intervals for its era.

The engine responds well to regular oil changes with high-quality diesel specific oil, and its mechanical fuel injection system remains adjustable and serviceable decades after manufacture a stark contrast to modern computerized systems that may become unsupportable as technology advances.

Perhaps most impressive is the OM617’s adaptability to alternative fuels.

Many examples run on biodiesel or waste vegetable oil with minimal modifications, demonstrating remarkable flexibility that extends their useful life well into the modern era despite increasingly stringent emissions standards.

These engines didn’t just survive; they established a standard for diesel durability that manufacturers still strive to match decades later.

3. Honda B-Series VTEC Engines

Honda’s B-series VTEC engines, produced from 1989 to 2001, represent a remarkable engineering achievement: highly efficient, high-revving performance engines that simultaneously offer exceptional reliability and longevity.

These 1.6-1.8 liter four-cylinder engines, most notably found in the Civic, Integra, and Del Sol models, revolutionized the compact performance segment by delivering motorcycle-like specific output (horsepower per liter) while maintaining Honda’s reputation for durability.

The B-series longevity stems from several key design elements. Unlike many competitors who chased torque through displacement, Honda engineered a lightweight, high-compression engine with an exceptional valvetrain.

The now-famous VTEC (Variable Valve Timing and Lift Electronic Control) system provided two distinct cam profiles one for efficiency, and another for performance allowing the engine to operate conservatively during normal driving conditions, reducing wear and stress on internal components.

Honda’s fanatical attention to material quality and precision manufacturing resulted in engines with extraordinarily tight tolerances that maintained their efficiency and performance characteristics over hundreds of thousands of miles.

The forged crankshaft, oil-cooled pistons, and robust connecting rods in performance variants like the B16 and B18C were significantly overbuilt for their power levels, providing substantial mechanical headroom.

What truly distinguishes the B-series is its tolerance for high-RPM operation. While many engines develop problems when consistently operated near redline, Honda’s B-series thrives on it, with many examples accumulating over 300,000 miles despite enthusiastic driving.

The engines feature exceptional oil control systems, including integrated oil squirters that cool the underside of pistons during high-load operation technology typically reserved for much more expensive performance engines.

Maintenance simplicity further contributes to the B-series longevity. Timing belt service, while necessary every 90,000 miles, is straightforward and inexpensive compared to many competitors.

The engines respond exceptionally well to regular oil changes, and their non-interference design means that even in the rare event of timing belt failure, catastrophic valve to piston contact is avoided.

The B-series’ legendary reliability is particularly impressive considering many were subjected to modifications and performance enhancements.

Even modified examples often maintain excellent reliability when properly tuned, a testament to the substantial engineering margin built into the original design.

Despite being designed over three decades ago, these engines continue to power hundreds of thousands of vehicles worldwide, with many original examples still delivering the same exhilarating performance and exceptional fuel economy they offered when new.

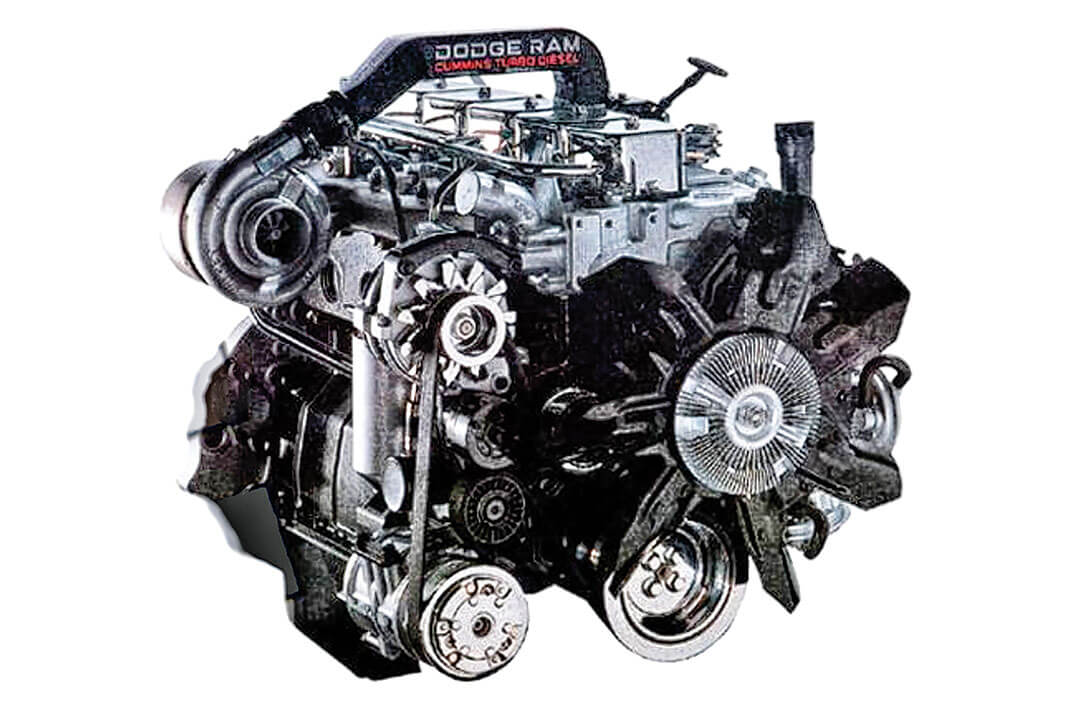

4. Cummins 5.9L ISB Inline-Six Diesel

The Cummins 5.9L ISB inline-six diesel engine represents the gold standard of reliability in the consumer truck market, having powered Dodge Ram trucks from 1989 through 2007 before evolving into the 6.7L version that continues today.

This legendary powerplant has fundamentally altered consumer perceptions of what longevity means in a heavy-duty pickup truck, with many examples eclipsing the 500,000-mile mark with their original internals intact.

The foundation of the 5.9L Cummins’ extraordinary durability begins with its architecture a straight-six configuration that inherently balances reciprocating forces, reducing vibration and stress on the rotating assembly.

The cast iron block and head provide exceptional strength and thermal stability, while the massive forged steel crankshaft rides on seven main bearings, delivering unparalleled support even under extreme loads.

The connecting rods and wrist pins are similarly overbuilt, allowing the engine to handle stresses far beyond factory specifications.

The 12-valve versions (1989-1998) are particularly renowned for their simplicity. With fully mechanical direct injection using the bulletproof Bosch P7100 injection pump and mechanical lifters rather than hydraulic ones, these earlier versions had minimal electronics to fail.

This mechanical simplicity makes them not only exceptionally reliable but also remarkably serviceable decades after manufacture, with parts availability remaining strong due to the engine’s popularity.

Even as electronic controls were introduced in the 24-valve models (1998-2007), the core mechanical integrity remained, with improvements in power and emissions control adding complexity without compromising fundamental reliability.

The gear-driven timing system eliminated timing belt or chain issues that plague many engines, while the robust cooling system effectively managed heat even under extreme towing conditions.

What truly separated Cummins from competitive diesel offerings was its commercial heritage.

Unlike engines designed primarily for passenger vehicles, the 5.9L ISB was essentially a detuned commercial truck engine, operating well below its design limits in pickup truck applications.

This substantial engineering margin allowed the engine to handle the rigors of towing and hauling while maintaining exceptional longevity.

The Cummins’ reputation for reliability is particularly impressive considering many examples spent their lives under extreme working conditions towing heavy trailers, operating in extreme temperatures, and running under sustained high loads.

Even with these challenges, proper maintenance typically results in hundreds of thousands of trouble-free miles, with complete rebuilds often only necessary after half a million miles or more of service.

For many owners, the truck body deteriorates long before the Cummins engine shows signs of giving up.

Also Read: 10 Vintage Cars That Still Have a Loyal Fanbase

5. Toyota 22R/22RE Inline-Four

The Toyota 22R and its fuel-injected counterpart, the 22RE, stand as monuments to purposeful engineering simplicity, having powered Toyota trucks, 4Runners, and Celicas from 1981 through 1995.

This 2.4-liter inline-four engine family earned its bulletproof reputation through an almost obsessive focus on reliability rather than impressive specifications, becoming the backbone of Toyota’s global reputation for indestructible vehicles.

What makes the 22R/22RE extraordinary isn’t technological innovation but rather Toyota’s commitment to refined, proven engineering principles.

The iron block features a simple overhead cam design with a robust timing chain that, unlike many competitors’ engines, includes a dual-row chain setup on earlier models and was upgraded to an even more durable design in 1985.

This timing system often exceeds 300,000 miles before requiring replacement a stark contrast to the 60,000-100,000 mile intervals common with timing belts.

The engine’s round exhaust ports prioritized thermal stability and consistent cooling over maximum flow, preventing the hot spots that lead to head gasket failures in many four-cylinder engines.

The cylinder head itself was designed with generous material thickness, providing excellent clamping force when properly torqued and reducing the likelihood of warping.

Toyota’s precision manufacturing ensured exceptional consistency between engines, with tight tolerances that maintained oil pressure and minimized internal wear even after hundreds of thousands of miles.

Perhaps most impressive is the 22R/22RE’s tolerance for neglect. These engines routinely survive extended oil change intervals, overheating events, and even periods of operation with compromised cooling systems that would destroy most modern engines.

In developing countries, these engines often powered vehicles well beyond 500,000 miles with only rudimentary maintenance, cementing Toyota’s global reputation for building vehicles suitable for the most demanding environments.

The fuel-injected 22RE variant added electronic fuel injection without compromising reliability, featuring a simple and robust injection system that maintained functionality for decades.

While power output was modest by modern standards (approximately 105-116 horsepower depending on the year), the engine produced adequate torque for its applications while operating well within its mechanical limits, leaving substantial headroom for longevity.

The 22R/22RE’s service-friendly design further contributed to its legendary status.

With accessible components, straightforward adjustment procedures, and excellent parts availability even decades after manufacture, these engines remained economically viable to maintain far longer than most competitors.

This combination of inherent durability and repairability has kept thousands of Toyota trucks and 4Runners on the road long after their contemporaries have been scrapped, with many enthusiasts specifically seeking out these engines for vehicles intended to provide decades of reliable service.

6. Lexus/Toyota 1UZ-FE V8

The 1UZ-FE V8 engine, introduced by Toyota in 1989 for its flagship Lexus LS400 and subsequently used in various Toyota and Lexus luxury vehicles until 2002, represents perhaps the most overengineered production engine ever to reach the mass market.

This 4.0-liter quad-cam V8 was Toyota’s statement of engineering prowess, designed to outperform and outlast the German luxury V8s of its era while establishing Lexus as a premium brand.

What makes the 1UZ-FE extraordinary is its no-compromise approach to durability.

The block and heads were constructed from lightweight aluminum alloy, but with significantly more material than necessary, providing exceptional rigidity.

The crankshaft was fully balanced and crafted from forged steel, supported by six main bearings with cross-bolted main caps that ensured extraordinary stability even at high RPMs.

The connecting rods were equally robust, remaining unchanged when the engine was later adapted for supercharging in the Toyota TRD program.

The valvetrain featured dual overhead cams with a belt drive that, while requiring service at 90,000-mile intervals, proved exceptionally reliable when maintained.

Toyota’s choice of timing belt over chain was deliberate the belt operation reduced noise and vibration, crucial for a luxury car engine, while the service interval aligned with other major maintenance milestones.

Most impressively, the 1UZ-FE was a non-interference design, meaning that even in the rare event of timing belt failure, pistons and valves wouldn’t contact, preventing catastrophic engine damage.

Toyota’s engineering thoroughness extended to every aspect of the engine. The sequential fuel injection system was designed with redundancy in mind, capable of maintaining function even with partial failures.

The engine’s cooling system featured precise coolant flow management that prevented hot spots and promoted even thermal expansion.

Early versions even featured provisions for cylinder liners to be replaced a service rarely needed but indicative of the engine’s design for extreme longevity.

In real-world use, the 1UZ-FE routinely exceeds 300,000 miles without internal repairs, with many examples surpassing 400,000 miles on original seals and gaskets.

The engine’s over-engineered nature means it typically operates well below its stress limits in normal driving, contributing to its exceptional longevity.

Even in high-mileage examples, oil consumption remains minimal a testament to the precision of the piston ring design and cylinder bore finishing.

The 1UZ-FE’s reputation has made it a popular choice for engine swaps into everything from sports cars to boats, where its combination of smooth power delivery and exceptional reliability provides the best of both worlds.

For many enthusiasts, this engine represents the peak of Toyota’s engineering-first philosophy before cost-cutting measures became more prevalent in later designs.

7. General Motors LS Series V8

The LS series of V8 engines, introduced by General Motors in 1997, represents one of the most successful engine families ever created, combining exceptional performance potential with remarkable durability.

This pushrod V8 architecture, which powers everything from Corvettes and Camaros to Silverados and Suburbans, has rightfully earned a reputation for achieving high mileage while maintaining performance and reliability.

The LS engine’s exceptional longevity begins with its fundamental architecture. Despite being a modern design, GM chose to retain the traditional overhead valve (pushrod) configuration rather than following competitors to overhead cam designs.

This decision yielded a compact, lightweight package with fewer moving parts and lower reciprocating mass.

The deep-skirt block design, with six-bolt main bearing caps on performance versions, provides exceptional rigidity and crankshaft support, while the cam in block location protects the valvetrain from variable oil pressure conditions that can affect overhead cam systems.

Material innovation plays a crucial role in the LS’s durability. Most variants feature aluminum blocks with cast-iron cylinder liners that provide an optimal combination of lightweight and wear resistance.

The hypereutectic pistons (with high silicon content) maintain tight clearances even as they heat up, reducing noise and improving longevity.

High-flow aluminum heads with minimal shrouding around valves provide excellent thermal management, preventing the hot spots that can lead to detonation and head gasket failures.

The oiling system represents another engineering triumph. GM incorporated a sophisticated windage tray system that maintains consistent oil pressure even during hard cornering and acceleration, while the gerotor-type oil pump provides reliable pressure throughout the engine’s life.

On performance variants, oil squirters cool the underside of pistons during high-load operation, extending ring life and preventing detonation.

Perhaps most impressive is the LS family’s tolerance for modifications and high-performance use. Unlike many engines that become problematic when modified, the LS platform responds exceptionally well to performance enhancements while maintaining reliability.

This headroom has made it the go-to choice for everything from mild street builds to 1,000+ horsepower drag racers, with the basic architecture remaining sound even under extreme conditions.

In stock form, these engines routinely exceed 300,000 miles in truck applications with basic maintenance, and even high-performance variants in Corvettes and Camaros demonstrate exceptional longevity when properly maintained.

The continued availability of factory and aftermarket parts, combined with straightforward serviceability, ensures these engines remain economically viable to maintain long after most vehicles would be considered at the end of their useful lives.

8. Volvo Redblock (B230) Inline-Four

The Volvo Redblock engine family, particularly the 2.3-liter B230 variant produced from 1985 to 1998, has earned cult status for its extraordinary durability.

This engine, which powered various 200, 700, and 900 series Volvo models, exemplifies the Swedish manufacturer’s philosophy of overbuilt engineering and safety-focused design principles applied to powertrain development.

The B230’s exceptional longevity begins with its basic architecture a cast iron block and head with generous wall thicknesses, providing superior rigidity and thermal stability compared to lighter but more flexible aluminum designs.

The siamese cylinder design (with no water jackets between cylinders) created an extremely strong block structure, while the seven main bearing crankshaft design provided exceptional support for the forged steel crankshaft an unusual feature in a four-cylinder engine and more commonly found in straight-six configurations.

What truly distinguished the B230 was Volvo’s approach to engineering safety margins.

While contemporary engines were being designed with increasingly tight tolerances and higher specific outputs, Volvo deliberately under-stressed the B230, typically running it far below its mechanical limits.

Even turbocharged variants maintained substantial headroom, with connecting rods and bearing surfaces designed to handle much more power than factory specifications.

This conservative approach meant that even under adverse conditions poor maintenance, extreme temperatures, or high loads the engine continued to function reliably.

The B230’s oiling system further contributed to its legendary status. The engine featured a high-capacity oil pump and generous oil galleys that maintained consistent pressure even in high-mileage examples.

The top-feed oiling design for the turbocharger (in forced induction variants) ensured proper lubrication during cold starts, preventing the premature turbo failures common in many turbocharged engines of the era.

Timing belt service represented the only major maintenance requirement, with 50,000-mile intervals being conservative considering the robust design.

Even if neglected, the non-interference design prevented catastrophic damage in case of belt failure.

The engine’s external components matched its internal durability, with electrical systems and accessories typically lasting as long as the core engine a rarity in the automotive world where peripheral components often fail long before the engine itself.

The B230’s reputation for durability was further enhanced by real-world performance in commercial applications.

Volvo 240 taxis routinely accumulated over 500,000 miles on original engines, with many documented cases exceeding one million miles with only basic rebuilds.

This performance in demanding service conditions cemented the engine’s legendary status among enthusiasts seeking bulletproof reliability.

Even decades after production ended, the B230 remains a popular choice for engine swaps and builds intended for extreme longevity, a testament to Volvo’s commitment to engineering robustness over marketing specifications.

9. Nissan RB Series Inline-Six

The Nissan RB series engines, particularly the 2.6-liter RB26DETT found in the iconic Skyline GT-R and the 3.0-liter RB30 used in Australian-market vehicles represent a perfect balance of high performance potential and extraordinary durability.

Produced from 1985 through 2002, these inline-six engines have developed a global cult following for their ability to handle immense power increases while maintaining remarkable reliability.

The RB’s exceptional longevity begins with its fundamental architecture an inline-six configuration that naturally balances primary and secondary forces, reducing vibration and stress on internal components.

The iron block provides superior rigidity and cylinder seal compared to aluminum designs, with thick cylinder walls that resist deformation even under high boost.

The seven main bearing crankshaft design ensures exceptional support for the rotating assembly, distributing loads evenly and reducing localized stress that leads to bearing failures in less robust engines.

What truly distinguishes the RB series, particularly the twin-turbocharged RB26DETT, is its substantial engineering margin.

Nissan officially rated the engine at 276 horsepower due to Japan’s “gentlemen’s agreement” limiting stated power, but the actual output was significantly higher, and the mechanical components were designed to handle much more.

The connecting rods, often the weak point in high-performance engines, feature extraordinary strength in stock form, while the oil pump provides generous pressure even at high RPMs, protecting bearings under extreme conditions.

The RB’s head design further contributes to its legendary status. The four-valve-per-cylinder layout with dual overhead cams provides excellent breathing capability, while the substantial material thickness prevents warping even under the increased thermal stress of forced induction.

The intake and exhaust port design prioritized flow consistency over maximum throughput, creating predictable performance characteristics that made the engine more manageable under various operating conditions.

The timing belt system, while requiring maintenance at 60,000-mile intervals, proved exceptionally reliable when serviced properly.

Unlike many performance engines that suffer from inadequate cooling, the RB series featured a well-designed water jacket system that prevented hot spots and maintained consistent cylinder head temperatures even under sustained high-load operation.

Most impressive is the RB’s tolerance for modifications and increased power. While many engines become problematic when pushed beyond factory specifications, the RB platform routinely handles double or triple its original output with basic supporting modifications.

Examples of producing 600-800 horsepower on the stock block and internals are common in the tuning community, often accumulating substantial mileage despite the increased stress.

This extraordinary headroom has made the RB series one of the most sought-after engines for performance builds worldwide, with many examples continuing to deliver reliable performance decades after manufacture despite operation well beyond their original design parameters.

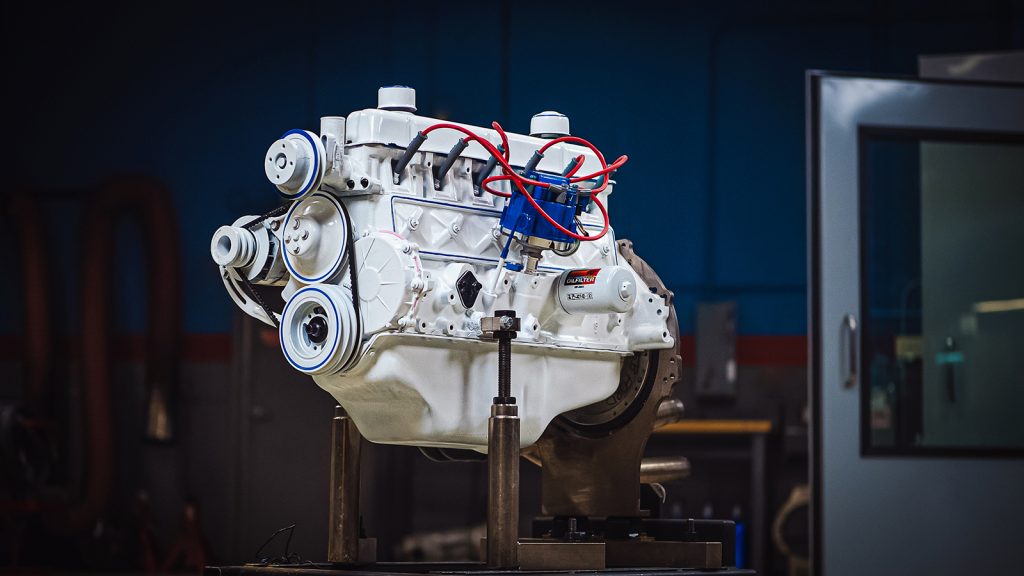

10. Ford 300 Inline-Six

The Ford 300 cubic inch (4.9-liter) inline-six engine, produced from 1965 through 1996, stands as perhaps the most durable American light-duty truck engine ever manufactured.

This remarkably long production run spanning over three decades with minimal fundamental changes speaks to the engine’s exceptional design and Ford’s recognition of its irreplaceable combination of reliability, torque, and simplicity.

The 300’s extraordinary longevity begins with its architecture an undersquare design with a long stroke that prioritized low-end torque over high-RPM horsepower.

This focus on torque production meant the engine rarely needed to work hard in typical use, operating well below its stress limits even when pulling substantial loads.

The seven main bearing crankshaft unusual for an inline-six and more commonly found in V8 engines provided exceptional support for the rotating assembly, distributing loads evenly and preventing localized bearing wear.

What truly distinguished the Ford 300 was its absolute mechanical simplicity.

With an overhead valve design featuring a gear-driven camshaft (no timing chain or belt to fail), mechanical fuel pump, and straightforward cooling system, the engine had remarkably few failure points.

The cast iron block and head offered exceptional durability and thermal stability, while the large displacement spread heat generation across six substantial cylinders, preventing the hot spots and cylinder wall distortion common in smaller, higher-stress engines.

The oiling system further contributed to the engine’s legendary status. Ford engineered a high-volume oil pump and generously sized oil galleys that maintained consistent pressure even in high-mileage examples.

The engine’s relatively low operating RPM meant reduced bearing loads and oil shearing compared to higher-revving designs, extending oil life and reducing wear on critical components.

Perhaps most impressive was the 300’s tolerance for neglect and poor maintenance.

These engines routinely survived extended oil change intervals, compromised cooling systems, and various forms of abuse that would destroy most modern engines.

In fleet service, agricultural applications, and industrial uses (where the engine was often repurposed for stationary power), the 300 cubic inch six developed a reputation for running virtually indefinitely with only basic maintenance.

The engine’s longevity was further enhanced by its valve arrangement, which used solid lifters rather than hydraulic ones in many applications, eliminating a common failure point.

While this design required periodic valve lash adjustment, it provided superior reliability in challenging environments and prevented the oil pressure-related valvetrain issues that plague many engines as they age.

Even as emission controls were added throughout its production run, the core mechanical integrity remained unchanged, allowing the engine to maintain its legendary reliability while meeting increasingly stringent regulations.

For many F-series truck owners, the 300 inline-six provided hundreds of thousands of miles of trouble-free service, often outlasting the vehicle body and requiring little more than basic maintenance throughout its operational life.

Also Read: 10 SUVs That Retain Their Value Better Than Any Other Vehicles