The automotive world has witnessed countless engine designs come and go, but only a select few have demonstrated the extraordinary durability to remain operational after half a century.

These legendary powerplants represent the pinnacle of mechanical engineering from their respective eras, built in times when overengineering and simplicity often trumped efficiency and complexity.

Their continued operation today stands as a testament to both their original design integrity and the dedicated owners who have preserved them through decades of careful maintenance.

From American V8s that powered muscle cars through the golden age of horsepower to European straight-sixes that propelled luxury sedans across continents, these engines have survived changing automotive trends, fuel formulations, and parts availability challenges.

What unites these diverse powerplants is their fundamental mechanical soundness robust bottom ends, generous tolerances, and straightforward designs that prioritize longevity over maximum performance.

As modern vehicles increasingly embrace disposability and planned obsolescence, these 50+ year-old engines continue to fire up reliably, connecting today’s enthusiasts with automotive history through the unmistakable sound and feel of classic internal combustion.

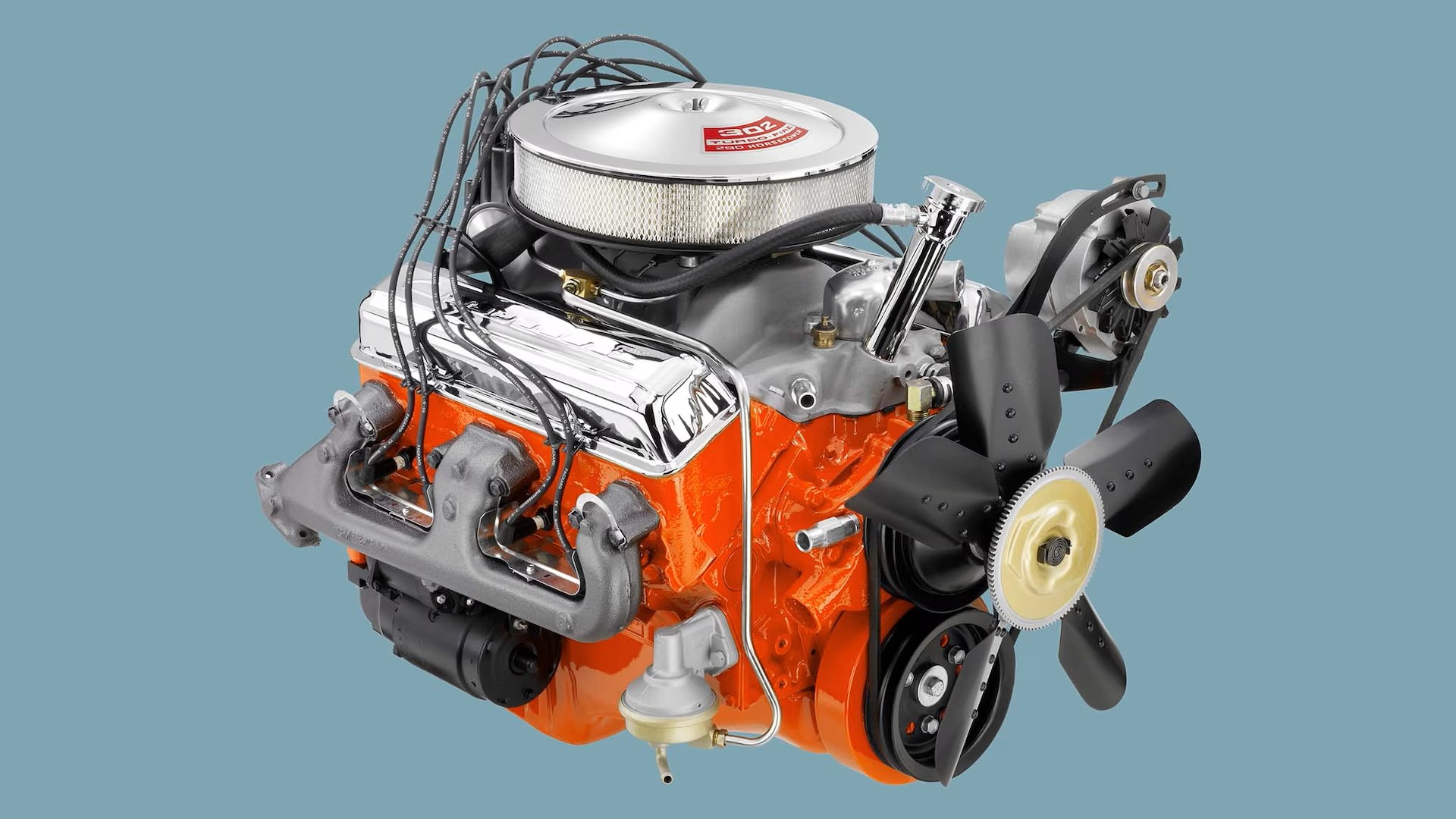

1. Chevrolet Small-Block V8

The Chevrolet Small-Block V8 stands as perhaps the most iconic and enduring American engine design ever created.

First introduced in 1955 as a 265 cubic inch powerplant for the redesigned Chevrolet passenger cars, this revolutionary engine architecture would go on to power millions of vehicles across eight decades of production.

What’s truly remarkable is how many of these original 1950s and 1960s engines continue to operate today, often with their original blocks and components still intact.

The small block’s legendary durability stems from its fundamentally sound design principles. Chief Engineer Ed Cole and his team created an engine with a robust deep-skirt block casting that provided exceptional structural rigidity.

The crankshaft rode on five main bearings overbuilt for the era while the forged connecting rods offered tremendous strength margins.

Perhaps most importantly, the block featured siamesed cylinder walls with substantial material between bores, preventing the cracking issues that plagued many competing designs.

The small block’s valvetrain employed a simple overhead valve arrangement with stamped steel rocker arms actuated by hydraulic lifters.

While not as sophisticated as overhead cam designs, this configuration proved remarkably durable and easily serviceable.

The engine’s cooling system featured large water jackets and efficient flow patterns that prevented hotspots, contributing to exceptional cylinder head gasket longevity.

What truly set the small block apart was its versatility. Available in displacements ranging from 265 to 400 cubic inches, these engines powered everything from family sedans to Corvettes.

This widespread application ensured parts availability that continues to this day, allowing owners to keep even the earliest examples operational.

The 283, 327, and 350 cubic inch variants proved particularly long-lived, with countless examples surpassing 200,000 miles without major overhauls.

Today, small blocks from the 1950s and 1960s continue to power classic Chevrolets, hot rods, and even boats across America.

Their continued operation is supported by a vast aftermarket that supplies everything from complete replacement blocks to the smallest gaskets.

Many have been upgraded with modern ignition systems, fuel delivery, and internal components while retaining their original architecture.

This combination of inherent durability and ongoing support ensures that the Chevrolet Small-Block V8 will likely remain a running, operational engine design well past its 100th birthday.

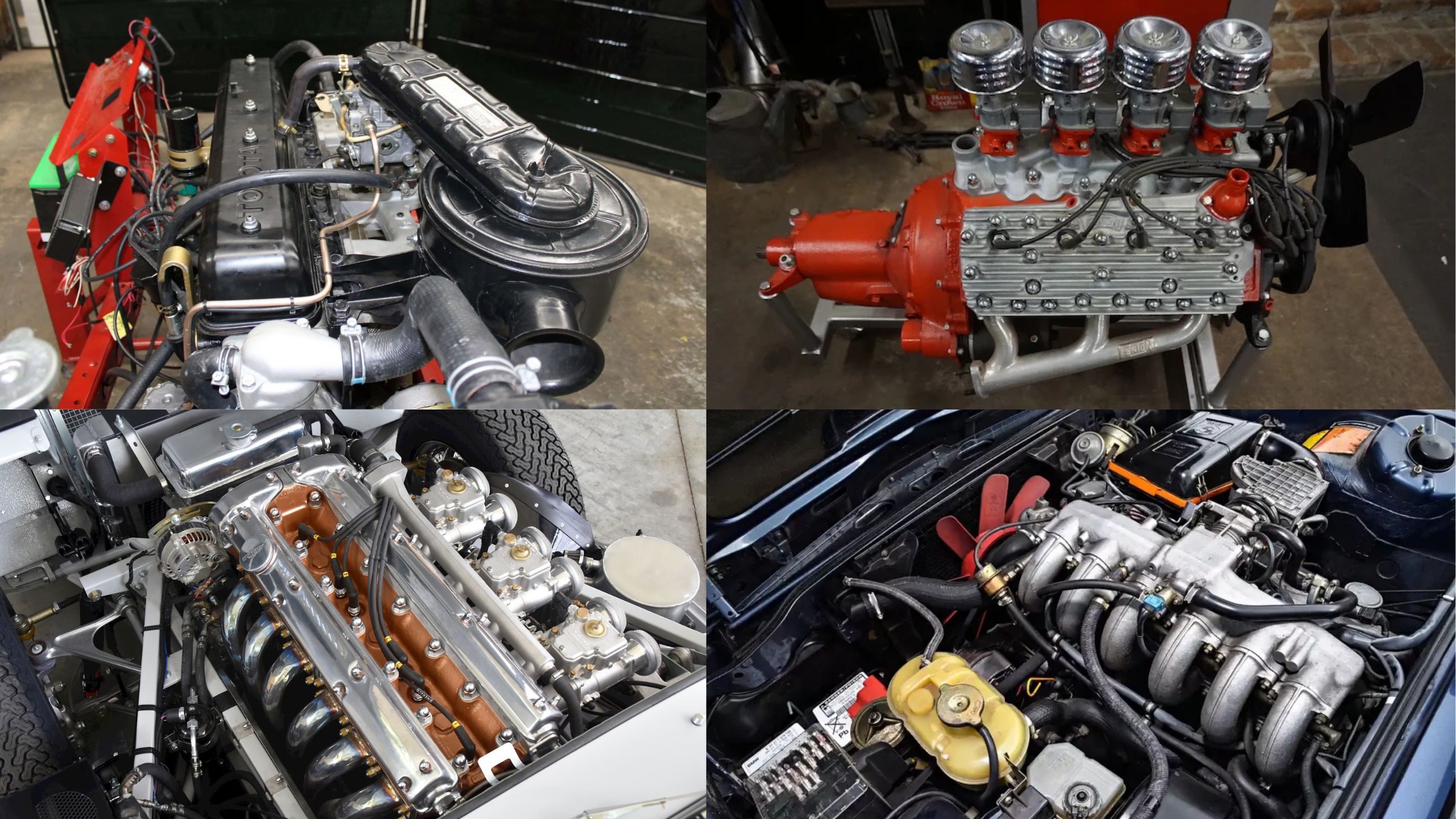

2. Mercedes-Benz M180 Inline-Six

The Mercedes-Benz M180 inline-six engine represents the epitome of German engineering excellence and has earned a well-deserved reputation as one of the most durable powerplants ever created.

First introduced in 1951 and produced through the early 1970s, this remarkable engine powered iconic Mercedes models including the 220, 230, and early 280 series.

What’s truly extraordinary is how many of these engines continue to operate flawlessly today, often with 500,000+ miles on their original components.

The M180’s exceptional longevity begins with its fundamental architecture. The engine features a deep-skirt cast iron block with seven main bearings supporting the forged steel crankshaft an overbuilt design that provides exceptional rigidity and durability.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary, though many engines have never required such attention.

The aluminum cylinder head featured overhead valves actuated by pushrods, a design that prioritized reliability over maximum performance.

Mercedes engineers designed the M180 with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions.

The cooling system was similarly overengineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the M180 maintained its reliability despite its relatively high specific output for the era. In its most powerful naturally aspirated form, the engine produced up to 150 horsepower from 2.8 liters respectable numbers for the 1960s.

This combination of performance and durability helped establish Mercedes-Benz’s reputation for building cars that could accumulate a million kilometers.

The M180’s longevity is further enhanced by its mechanical simplicity. The engine uses a single overhead camshaft with mechanical valves that require periodic adjustment but rarely develop serious issues.

The timing chain design has proven exceptionally durable, with many engines reaching 300,000+ miles on the original components.

Even the fuel system, which evolved from carburetors to mechanical fuel injection, has demonstrated remarkable durability.

Today, M180 engines from the 1950s and 1960s continue to power classic Mercedes-Benz vehicles across the globe.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the half-million-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

3. Ford Flathead V8

The Ford Flathead V8 stands as one of the most historically significant and surprisingly durable engines in automotive history.

Introduced in 1932 and produced through 1953, this revolutionary powerplant brought affordable V8 power to the masses and transformed the American automotive world.

What’s truly remarkable is how many of these engines continue to operate today, nearly 70-90 years after they left the factory.

The Flathead’s enduring nature stems from its fundamental simplicity and overbuilt design. Henry Ford and his engineers created an engine with a robust cast iron block that featured unusually thick cylinder walls and substantial material throughout.

The crankshaft rode on three main bearings a design that proved more than adequate for the era’s power levels and driving conditions.

The engine’s distinctive side-valve configuration, with valves located in the block rather than the head, eliminated many of the complex components that could fail in overhead valve designs.

What truly set the Flathead apart was its accessibility and ease of repair. The engine could be completely disassembled with basic hand tools, allowing owners to perform repairs that would have required specialized equipment on more complex designs.

This simplicity encouraged regular maintenance and timely repairs, contributing to the engine’s longevity in real-world conditions.

The Flathead did have known weaknesses, particularly in its cooling system design. The complex water passages around the valves could lead to hotspots and overheating under severe conditions.

However, owners quickly learned to manage these issues through proper maintenance and driving habits.

Many engines were later modified with improved cooling systems, updated water pumps, and modern coolants that addressed these concerns.

Perhaps most impressively, the Flathead maintained excellent reliability despite becoming a favorite among hot rodders and performance enthusiasts.

The engine responded well to modifications, with many examples producing double their original horsepower through relatively simple upgrades.

This adaptability helped ensure the Flathead’s continued relevance long after it ceased production.

Today, Flathead V8s from the 1930s and 1940s continue to power classic Fords, hot rods, and custom vehicles across America.

Their continued operation is supported by a robust aftermarket that supplies everything from complete replacement blocks to the smallest gaskets.

Many have been upgraded with modern ignition systems, fuel delivery, and metallurgy while retaining their original architecture.

This combination of inherent durability and ongoing support ensures that the Ford Flathead V8 will likely remain an operational engine design well into its second century of existence.

4. Jaguar XK Inline-Six

The Jaguar XK inline-six engine represents the perfect union of elegant engineering and exceptional durability.

First introduced in 1949 and produced through 1992, this remarkable powerplant powered everything from Le Mans-winning race cars to luxury sedans.

What’s truly extraordinary is how many of these engines from the 1950s and 1960s continue to operate flawlessly today, often with their original blocks and components still intact.

The XK’s legendary longevity begins with its fundamental architecture. The engine features a robust cast iron block with seven main bearings supporting the crankshaft an overbuilt design that provides exceptional rigidity and durability.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary.

The aluminum cylinder head featured dual overhead camshafts at a time when most engines used simpler pushrod designs, yet this advanced configuration proved remarkably durable when properly maintained.

Jaguar engineers designed the XK with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions, including sustained high-speed running.

The cooling system was similarly well-engineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the XK maintained its reliability despite its high-performance nature. In its most powerful naturally aspirated form, the 4.2-liter version produced up to 265 horsepower exceptional output for the 1960s.

This combination of performance and durability helped establish Jaguar’s reputation for building sporting cars that could be driven hard yet remain reliable.

The XK’s longevity is further enhanced by its adaptability. Over its 43-year production run, the engine evolved from carburetors to fuel injection, increased in displacement from 3.4 to 4.2 liters, and found applications in diverse vehicles from the XK120 sports car to the Mark 2 sedan.

This widespread use ensured parts availability that continues to this day, allowing owners to keep even the earliest examples operational.

Today, XK engines from the 1950s and 1960s continue to power classic Jaguars across the globe.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the 200,000-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

Also Read: 12 Sports Sedans That Can Outrun Supercars in Raw Performance

5. Buick/Oldsmobile/Pontiac (BOP) V8

The Buick/Oldsmobile/Pontiac (BOP) V8 engines represent some of the most durable and long-lived American powerplants ever produced.

Introduced in the mid-1950s and produced through the 1970s, these distinct but related engine families powered everything from family sedans to muscle cars.

What’s truly remarkable is how many of these engines continue to operate flawlessly today, often with their original blocks and components still intact after more than half a century.

The BOP V8s’ exceptional longevity begins with their fundamental architecture. All three divisions created engines with deep-skirt cast iron blocks that provided exceptional structural rigidity.

The crankshafts rode on five main bearings overbuilt for the era while the connecting rods offered tremendous strength margins.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary, though many engines have never required such attention.

These engines employed overhead valve arrangements with hydraulic lifters that maintained proper valve lash automatically, reducing maintenance requirements and ensuring consistent operation throughout the engine’s life.

The cooling systems featured large water jackets and efficient flow patterns that prevented hotspots, contributing to exceptional cylinder head gasket longevity.

What truly set the BOP V8s apart was their build quality. General Motors divisions during this era operated with considerable independence, and each took pride in their engineering.

Buick’s “nailhead” V8 (named for its small valve size) became renowned for its torque and durability. Oldsmobile’s “Rocket” V8 established new standards for smoothness and longevity.

Pontiac’s V8, with its distinctive wide-deck block design, delivered exceptional performance while maintaining remarkable reliability.

Perhaps most impressively, these engines maintained their reliability despite their high-performance applications.

The Buick 401/425, Oldsmobile 394/425, and Pontiac 389/400 powered some of the most iconic muscle cars of the 1960s, yet continued to deliver hundreds of thousands of miles of service when properly maintained.

This combination of performance and durability helped establish these divisions’ reputations for building cars that could be driven hard yet remain reliable.

Today, BOP V8s from the 1950s and 1960s continue to power classic General Motors vehicles across America.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the 200,000-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

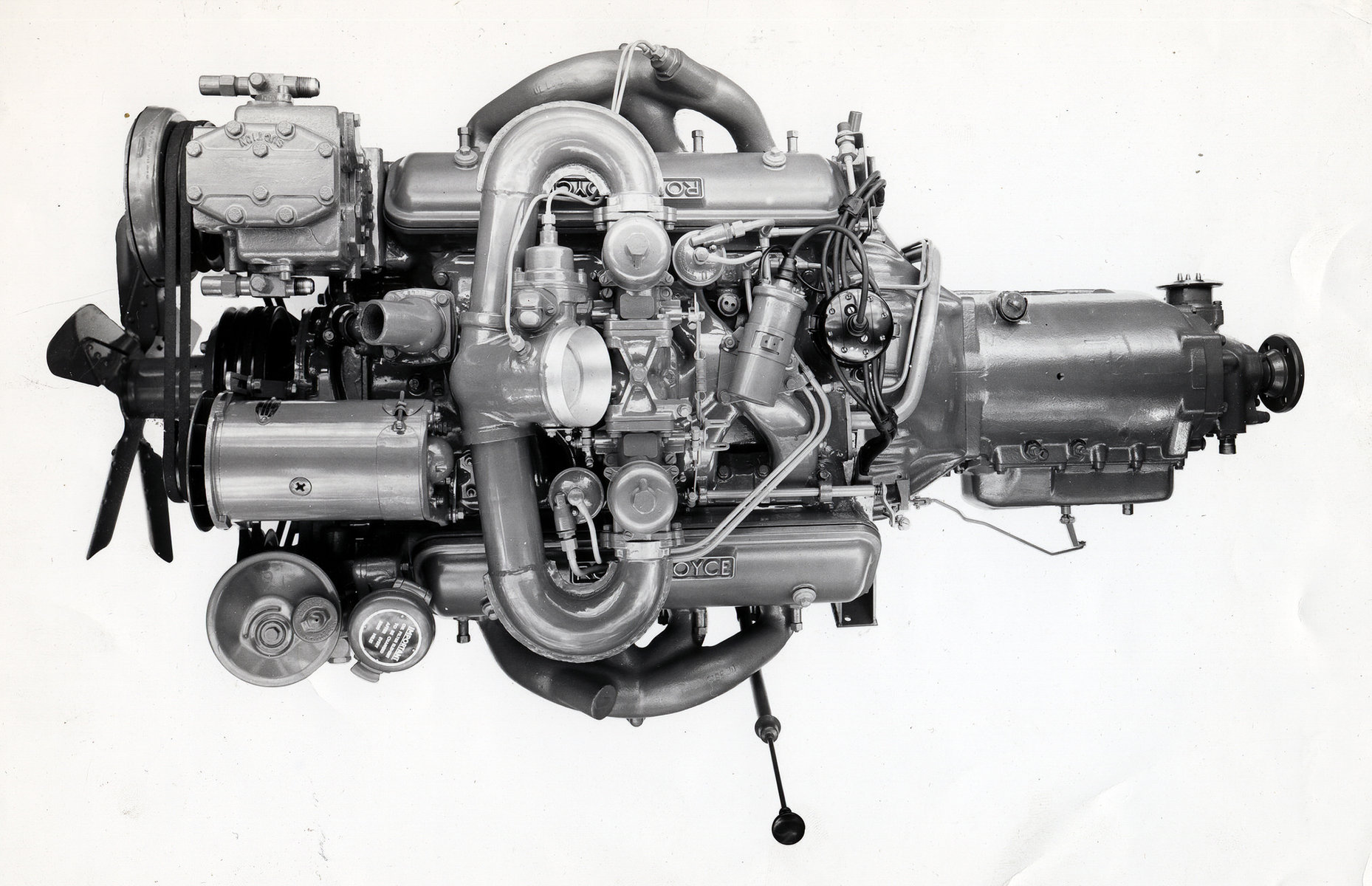

6. Rolls-Royce/Bentley L-Series V8

The Rolls-Royce/Bentley L-Series V8 stands as one of the most extraordinary examples of automotive engineering longevity in history.

First introduced in 1959 and remarkably still in production (in highly evolved form) over six decades later, this magnificent powerplant has powered the world’s most prestigious luxury automobiles through multiple eras.

What’s truly exceptional is how many of these original engines from the 1960s continue to operate flawlessly today, often accumulating hundreds of thousands of miles while maintaining their legendary smoothness and refinement.

The L-Series’ extraordinary durability begins with its fundamental architecture. The engine features a deep-skirt aluminum block with wet cylinder liners and a rigid crankcase structure that provides exceptional stability.

The crankshaft rides on five main bearings with generous dimensions that ensure minimal wear even after decades of operation.

The cylinder heads, also aluminum, feature overhead valves actuated by hydraulic lifters, a design that prioritized silent operation and reliability over maximum performance.

Rolls-Royce engineers designed the L-Series with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions.

The cooling system was similarly overengineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the L-Series maintained its reliability despite its complexity for the era.

Originally designed as a 6.25-liter (later expanded to 6.75 liters), this substantial engine incorporated advanced features like aluminum construction, hydraulic valve lifters, and precise fuel delivery systems.

Yet these sophisticated elements were executed with such precision that they rarely created reliability issues, even as the engine aged.

The L-Series’ longevity is further enhanced by its conservative tuning. While exact power figures were never officially published (Rolls-Royce famously described output as “adequate”), the engine operated well within its mechanical limits, extending component life dramatically.

Even when later turbocharged versions dramatically increased power output, the fundamental strength of the original design proved more than adequate.

Today, L-Series engines from the 1960s continue to power classic Rolls-Royce and Bentley motorcars across the globe.

Their continued operation is supported by dedicated specialists and factory heritage programs, allowing owners to maintain these engines indefinitely.

Many have crossed the 300,000-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

7. Chrysler Slant-Six

The Chrysler Slant-Six engine represents one of the most durable and reliable powerplants in automotive history.

First introduced in 1959 and produced through 1991, this remarkable inline-six powered everything from compact Valiants to full-size Dodge trucks.

What’s truly extraordinary is how many of these engines from the 1960s and early 1970s continue to operate flawlessly today, often with minimal maintenance and original components still intact after more than five decades.

The Slant-Six’s legendary longevity begins with its fundamental architecture. The engine features a deep-skirt cast iron block with seven main bearings supporting the crankshaft an overbuilt design that provides exceptional rigidity and durability.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary, though many engines have never required such attention.

The engine’s distinctive 30-degree tilt (which gave it its “slant” name) allowed for a lower hood line while creating excellent oil return paths that enhanced lubrication.

Chrysler engineers designed the Slant-Six with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions.

The cooling system was similarly well-engineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the Slant-Six maintained its reliability despite its relatively simple design.

The engine uses an overhead valve arrangement with solid lifters that require periodic adjustment but rarely develop serious issues.

The timing chain design has proven exceptionally durable, with many engines reaching 300,000+ miles on the original components.

Even the carburetion system, often a weakness in older engines, proved remarkably trouble-free in the Slant-Six.

The engine earned the nickname “the leaning tower of power” not just for its tilted design but for its surprising durability in commercial applications.

Taxi companies and delivery services routinely saw these engines exceed 500,000 miles with basic maintenance.

The 225 cubic inch version (3.7 liters) proved particularly long-lived, with countless examples continuing to operate decades after production.

This combination of simplicity and durability helped establish Chrysler’s reputation for building engines that could withstand tremendous abuse.

Today, Slant-Six engines from the 1960s continue to power classic Mopar vehicles across America.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the half-million-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants, which many mechanics consider the most reliable American engine ever made.

8. Porsche Type 901/911 Flat-Six

The Porsche Type 901/911 flat-six engine represents one of the most enduring and evolutionarily successful powerplants in automotive history.

First introduced in 1963 and produced in air-cooled form through 1998, this remarkable boxer engine powered the iconic 911 sports car through multiple generations.

What’s truly extraordinary is how many of these engines from the 1960s and early 1970s continue to operate flawlessly today, often with their original cases and components still intact after more than five decades.

The 911 engine’s exceptional longevity begins with its fundamental architecture. The engine features a horizontally opposed six-cylinder layout with a lightweight but robust aluminum crankcase.

The crankshaft rides on eight main bearings an overbuilt design that provides exceptional rigidity and durability.

The cylinder barrels were initially made of cast iron (later replaced by aluminum with Nikasil linings), offering excellent wear characteristics and thermal stability.

Porsche engineers designed the flat-six with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions, including sustained high-speed running and track use.

The air-cooling system was similarly well-engineered, with precisely directed airflow and large cooling fins that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to overheating issues that plagued many contemporaries.

Perhaps most impressively, the flat-six maintained its reliability despite its high-performance nature.

The engine uses an overhead camshaft arrangement with a complex chain-driven valvetrain that proved remarkably durable when properly maintained.

The timing chain design has proven exceptionally long-lived, with many engines reaching 200,000+ miles on the original components.

Even the unique Bosch mechanical fuel injection system on later models demonstrated remarkable durability.

The engine’s longevity is further enhanced by its adaptability. Over its 35-year air-cooled production run, the engine evolved from 2.0 to 3.8 liters, incorporated fuel injection and electronic engine management, and saw power outputs increase from 130 to over 400 horsepower.

This continuous refinement addressed weak points while maintaining the fundamental design integrity that made the engine so durable.

Today, flat-six engines from the 1960s and 1970s continue to power classic Porsche 911s across the globe.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the 300,000-mile threshold while retaining their original cases a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

9. Toyota F-Series Inline-Six

The Toyota F-Series inline-six engine stands as one of the most durable and reliable powerplants ever created.

First introduced in 1955 and produced through 1992, this remarkable engine powered iconic Toyota vehicles including the Land Cruiser FJ40, FJ55, and FJ60 series.

What’s truly extraordinary is how many of these engines from the 1960s and 1970s continue to operate flawlessly today, often in the harshest environments on Earth with minimal maintenance.

The F-Series’ legendary longevity begins with its fundamental architecture. The engine features a deep-skirt cast iron block with seven main bearings supporting the forged steel crankshaft an overbuilt design that provides exceptional rigidity and durability.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary, though many engines have never required such attention.

The cylinder head featured overhead valves actuated by pushrods, a design that prioritized reliability over maximum performance.

Toyota engineers designed the F-Series with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions, including extreme angles encountered during off-road use.

The cooling system was similarly overengineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the F-Series maintained its reliability despite being used in some of the most demanding conditions imaginable.

These engines powered vehicles in the Australian Outback, African deserts, and Arctic tundra, routinely operating in extreme temperatures and dusty environments.

The engine’s relatively low compression ratio and conservative tuning ensured it could run on poor-quality fuel often found in remote regions, while its mechanical simplicity meant repairs could be accomplished with basic tools.

The F-Series’ longevity is further enhanced by its adaptability. Over its 37-year production run, the engine evolved from the original 3.9-liter F engine to the 4.2-liter 2F and finally the fuel-injected 4.0-liter 3F, each maintaining the same fundamental architecture while incorporating refinements.

This continuous improvement addressed weak points while maintaining the bulletproof reliability that made the engine famous.

Today, F-Series engines from the 1960s and 1970s continue to power classic Land Cruisers across the globe.

Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the 500,000-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants.

10. BMW M30 Inline-Six

The BMW M30 inline-six engine represents one of the most elegant and enduring powerplants in automotive history.

First introduced in 1968 and produced through 1994, this remarkable engine powered iconic BMW models including the E3, E9, E12, E24, E28, and E34 series.

What’s truly extraordinary is how many of these engines from the 1970s continue to operate flawlessly today, often with their original blocks and components still intact after more than five decades.

The M30’s exceptional longevity begins with its fundamental architecture. The engine features a robust cast iron block with seven main bearings supporting the forged steel crankshaft an overbuilt design that provides exceptional rigidity and durability.

The cylinder walls were cast with substantial thickness, allowing for multiple rebuilds if necessary, though many engines have never required such attention.

The aluminum cylinder head featured an overhead camshaft design that provided excellent performance while maintaining remarkable reliability.

BMW engineers designed the M30 with precision oil passages and a high-capacity oil pump that ensured proper lubrication under all operating conditions, including sustained high-speed running on the Autobahn.

The cooling system was similarly well-engineered, with properly sized water jackets and efficient flow patterns that prevented hotspots.

These fundamental design elements contributed to the engine’s remarkable resistance to head gasket failures and overheating issues that plagued many contemporaries.

Perhaps most impressively, the M30 maintained its reliability despite its high-performance nature.

In its most powerful naturally aspirated form, the 3.5-liter M30B35 produced 218 horsepower impressive output for the era.

The engine’s timing chain design has proven exceptionally durable, with many engines reaching 300,000+ miles on the original components.

Even the fuel injection systems, which evolved from mechanical Bosch D-Jetronic to more sophisticated electronic management, demonstrated remarkable longevity.

The M30’s enduring nature is further enhanced by its adaptability. Over its 26-year production run, the engine evolved from 2.5 to 3.5 liters, incorporated increasingly sophisticated fuel injection and engine management systems, and found applications in diverse vehicles from luxury sedans to sports coupes.

This widespread use ensured parts availability that continues to this day, allowing owners to keep even the earliest examples operational.

Today, M30 engines from the 1970s continue to power classic BMWs across the globe. Their continued operation is supported by dedicated specialists and a healthy parts supply, allowing owners to maintain these engines indefinitely.

Many have crossed the 300,000-mile threshold while retaining their original blocks and heads a testament to the extraordinary engineering and build quality that went into these legendary powerplants that many enthusiasts consider the finest inline-six ever produced.

Also Read: 10 Fastest Manual Transmission Cars You Can Still Buy