In the automotive world, engine longevity represents the ultimate test of engineering excellence. While most drivers consider 100,000 miles a respectable milestone and 200,000 miles exceptional, there exists a rare breed of powerplants that transcend these conventional boundaries, routinely delivering performance well beyond what most would consider possible.

These million-mile engines don’t just represent mechanical achievement they embody decades of refined engineering, meticulous maintenance, and sometimes, sheer luck.

The pursuit of extreme longevity in automotive engines reveals fascinating insights into materials science, lubrication technology, and design philosophy.

Some manufacturers have inadvertently created legends through conservative engineering approaches, while others have stumbled upon formulas for durability that they didn’t fully understand at the time.

These high-mileage champions often share common characteristics: robust construction, simple designs that minimize complexity, and forgiving tolerances that allow for gradual wear without catastrophic failure.

Conversely, the automotive industry has also produced engines that serve as cautionary tales powerplants that promised innovation but delivered disappointment, motors that looked impressive on paper but crumbled under real-world conditions.

These failures offer equally valuable lessons about the delicate balance between performance, complexity, and reliability. Understanding both extremes provides insight into what makes an engine truly exceptional and what factors contribute to premature failure in the unforgiving environment of daily driving.

5 Million-Mile Engines You’ve Never Heard Of

These exceptionally durable powerplants feature robust internal construction and precision-manufactured components that maintain optimal performance through decades of continuous operation and extreme mileage accumulation without developing the catastrophic failures that plague lesser engines.

Their thoughtful engineering includes reinforced crankshaft designs and durable valve train systems that resist the stress concentrations typically created by hundreds of thousands of combustion cycles, extreme temperature variations, and the demanding operational requirements of ultra-high-mileage service.

From cast-iron block construction that provides exceptional dimensional stability to conservative power outputs that reduce internal stress, these remarkable engines continue operating like new without developing bearing wear or compression loss.

Fleet operators report million-mile service intervals with these dependable powerplants an often-overlooked engineering achievement that proves its worth through consistent operation and maintained fuel efficiency throughout extraordinary ownership periods.

1. Mercedes-Benz OM617 Turbo Diesel (1974-1985)

The Mercedes-Benz OM617 turbo diesel engine stands as one of the most underappreciated powerplants in automotive history, yet it consistently delivers performance that would make modern engines envious.

This 3.0-liter five-cylinder diesel, found primarily in the W123 and W126 chassis, was engineered during an era when Mercedes-Benz prioritized durability above all else, resulting in a motor that routinely exceeds 500,000 miles with proper maintenance.

Displacing 2.7 liters in most applications, and sometimes 3.0 liters, the OM617 was a powerhouse with a lot of low-end torque, and its reputation for reliability stems from several key design elements.

The engine block, cast from high-quality iron, features thick cylinder walls and a robust crankcase that can withstand the high compression ratios inherent to diesel combustion. The five-cylinder configuration provides inherent balance advantages over four-cylinder designs while maintaining simplicity compared to six-cylinder alternatives.

The turbocharger system, while primitive by today’s standards, was remarkably durable due to its conservative boost levels and simple wastegate design. Unlike modern complex variable-geometry turbos, the OM617’s fixed-geometry turbo operated within safe parameters that rarely stressed the engine’s internals.

The fuel injection system, utilizing mechanical Bosch pumps, required no electronic components that could fail, instead relying on purely mechanical precision that could be serviced indefinitely.

What truly sets the OM617 apart is its forgiving nature regarding maintenance intervals. While the engine responds well to regular servicing, it can tolerate extended oil change intervals without catastrophic failure, a characteristic that has allowed many examples to accumulate massive mileage even under neglectful ownership.

The combustion chamber design promotes complete fuel burn, reducing carbon buildup that plagues many modern diesels. The cylinder head, constructed from aluminum, features large valves and ports that promote excellent breathing characteristics.

The valve train, utilizing hydraulic lifters, automatically adjusts for wear, eliminating the need for periodic valve adjustments that could lead to damage if neglected. This self-compensating design philosophy extends throughout the engine, creating a powerplant that improves with age as components wear into perfect harmony.

Many OM617 engines have exceeded one million miles with only routine maintenance, and some taxi examples have reportedly reached 1.5 million miles before requiring a major overhaul.

The engine’s reputation in developing countries, where it powers countless Mercedes-Benz vehicles in extreme conditions, speaks to its exceptional durability. Even today, these engines command premium prices in the used market, with high-mileage examples often worth more than the vehicles they power.

2. Toyota 22R/22RE (1981-1995)

The Toyota 22R and its fuel-injected sibling, the 22RE, represent the pinnacle of four-cylinder engine reliability, consistently delivering service life that exceeds 400,000 miles with proper maintenance.

Found in the Toyota Pickup (later Tacoma), 4Runner, and various other models, these 2.4-liter engines have achieved legendary status among enthusiasts and professionals alike for their ability to function reliably under extreme conditions.

The 22R’s design philosophy emphasized simplicity and durability over peak performance, resulting in an engine that could withstand decades of abuse while maintaining acceptable power output.

The iron block construction provided exceptional strength and thermal stability, while the aluminum cylinder head offered good heat dissipation without the complexity of modern multi-valve designs.

The two-valve-per-cylinder configuration, while not optimal for power production, created large, robust valves that rarely failed and were easy to service.

The carburetor-equipped 22R featured a simple Aisin two-barrel carburetor that, while not sophisticated by modern standards, provided reliable fuel delivery with minimal maintenance requirements.

The later 22RE’s electronic fuel injection system, while more complex, utilized Toyota’s proven L-Jetronic system that demonstrated exceptional longevity. Both variants featured timing chains rather than belts, eliminating the need for timing belt replacement and the catastrophic engine damage that could result from belt failure.

The engine’s conservative design included understressed components throughout. The crankshaft, forged from high-quality steel, featured large bearing surfaces that distributed loads effectively.

The connecting rods, while not exotic, were designed with generous safety margins that allowed the engine to tolerate occasional over-revving without failure. The pistons, cast from aluminum, featured thick ring lands that resisted cracking even under extreme thermal cycling.

One of the 22R’s most remarkable characteristics is its ability to maintain compression even at extremely high mileage. The cylinder bore finish and ring package were designed to wear gradually and evenly, allowing the engine to maintain acceptable compression ratios well beyond 300,000 miles.

This gradual wear pattern, combined with the engine’s forgiving tolerances, means that high-mileage 22R engines often still provide adequate power and fuel economy.

Professional mechanics often cite the 22R/22RE as the benchmark for four-cylinder reliability, with many examples serving in commercial applications for decades without major failure.

The engine’s reputation for durability has made it a favorite for expedition vehicles, where reliability is paramount and repair facilities may be thousands of miles away.

3. Cummins 12-Valve 5.9L (1989-1998)

The Cummins 12-valve 5.9L diesel engine, found in Dodge Ram pickups from 1989 to 1998, represents the gold standard for diesel engine durability in light-duty applications.

This inline-six powerplant has achieved legendary status among diesel enthusiasts, with countless examples exceeding 500,000 miles and many documented cases surpassing one million miles of service.

The engine’s exceptional longevity stems from its industrial heritage, as Cummins designed the 5.9L for medium-duty commercial applications before adapting it for pickup truck use.

This industrial foundation provided the engine with construction standards far exceeding typical automotive requirements, resulting in a powerplant that could withstand decades of hard use while maintaining reliability.

The engine block, cast from high-strength iron, features exceptionally thick cylinder walls and a robust crankcase design that can handle the enormous forces generated by diesel combustion.

The wet-sleeve cylinder design allows for complete engine rebuilds without replacing the block, contributing to the engine’s reputation for longevity.

The main bearing caps, secured with four bolts each, provide exceptional strength that prevents bearing cap walking, a common failure mode in lesser engines.

These diesels are known for their durability for good reason. The first engine got to 400,000 miles before requiring major attention, and many examples have exceeded twice that mileage with only routine maintenance.

The engine’s reputation in commercial applications, where it powers countless work trucks in extreme conditions, speaks to its exceptional durability.

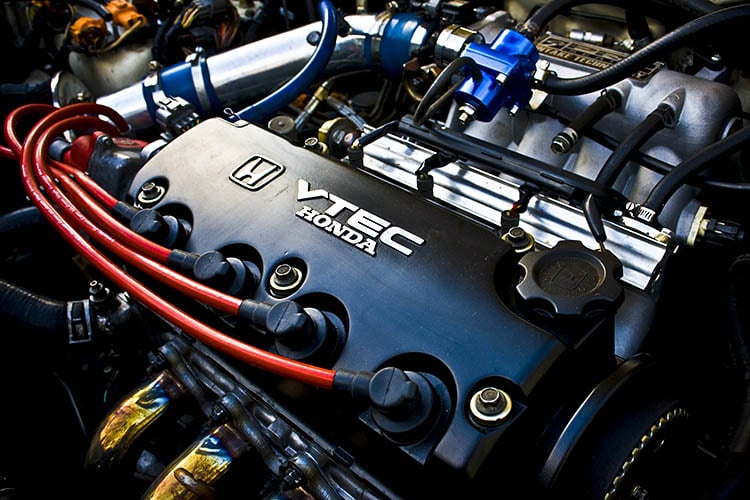

4. Honda D15/D16 Series (1984-2005)

The Honda D15 and D16 series engines, found in Civic, Del Sol, and CRX models, represent the pinnacle of compact engine reliability, consistently delivering service life that exceeds 300,000 miles with proper maintenance.

These 1.5L and 1.6L four-cylinder engines have achieved legendary status among economy car enthusiasts for their ability to function reliably while providing excellent fuel economy.

The D-series engines’ design philosophy emphasized efficiency and durability through simplicity, resulting in powerplants that could withstand decades of daily driving while maintaining acceptable performance.

The aluminum block construction provided excellent weight savings while maintaining adequate strength for the engine’s modest power output.

The aluminum cylinder head, featuring a simple two-valve-per-cylinder design, provided good thermal characteristics without the complexity of modern multi-valve arrangements.

The SOHC (Single Overhead Cam) design, while not optimal for peak power production, created a robust valve train that rarely failed and was easy to service.

The timing belt system, while requiring periodic replacement, was simple and accessible, with failure typically non-interfering, meaning belt failure wouldn’t cause valve damage. The hydraulic lifters automatically compensated for wear, eliminating the need for periodic valve adjustments.

Professional mechanics often cite the D-series engines as examples of Honda’s engineering excellence during the 1980s and 1990s, when the company prioritized reliability and efficiency over peak performance.

The engine’s reputation for durability has made it a favorite for budget builds and economy-focused applications, where long-term reliability is more important than maximum power.

Also Read: 5 Cars That Handle 120°F and -30°F Equally Well and 5 That Die in Either

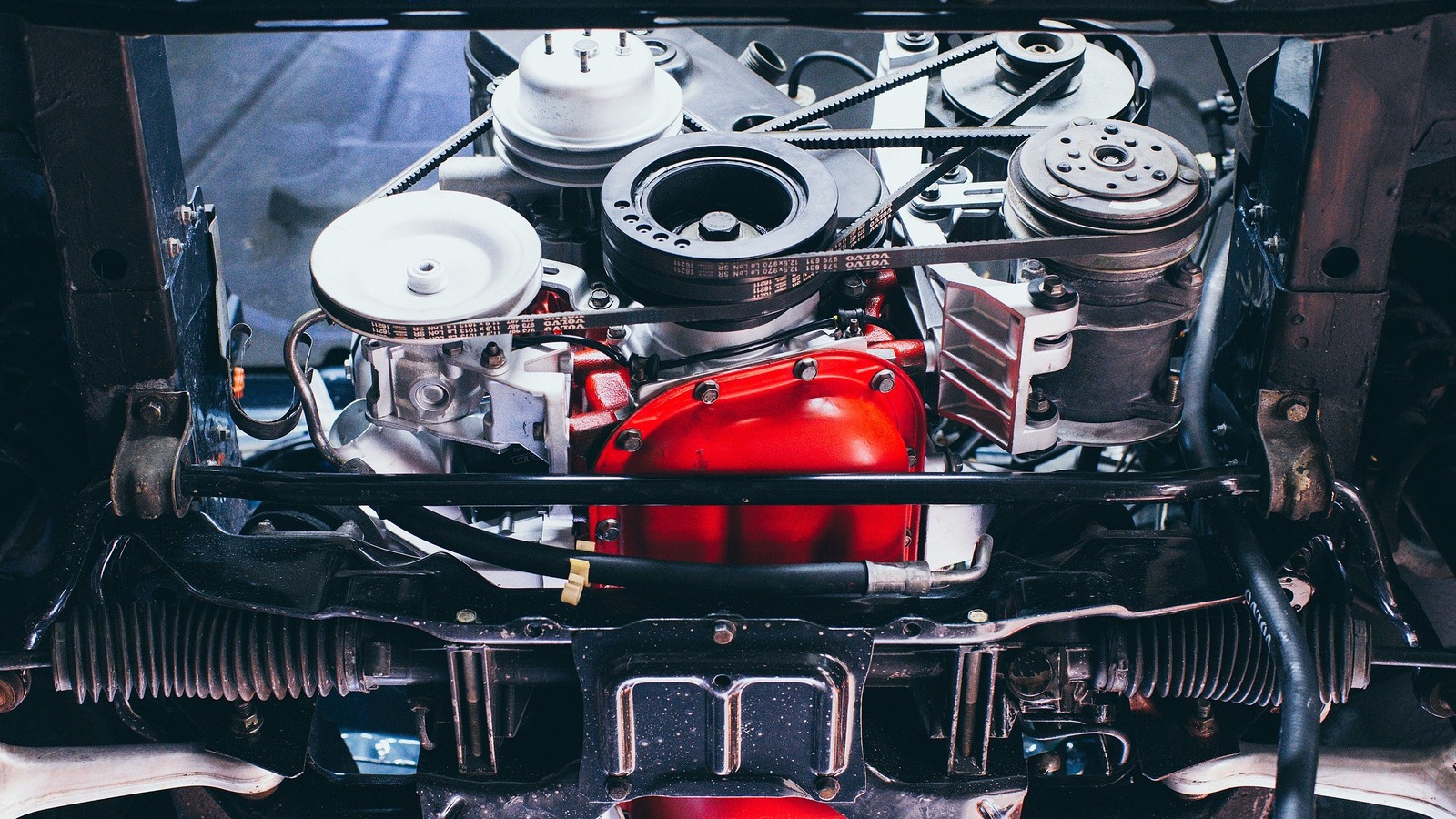

5. Volvo B230F Red Block (1982-1993)

The Volvo B230F, known affectionately as the “Red Block” due to its distinctive red paint scheme, represents Swedish engineering at its finest, routinely delivering service life that exceeds 400,000 miles with proper maintenance. Some cars make the monstrous million mile marker seem trivial, but there is one that has set an almost unbeatable record; the Volvo P1800S.

This 2.3-liter four-cylinder engine, found in 240, 740, and 940 series vehicles, has achieved legendary status among Volvo enthusiasts for its exceptional durability and serviceability.

The B230F’s design philosophy emphasized robust construction and conservative engineering, resulting in an engine that could withstand decades of Scandinavian weather conditions while maintaining reliable performance.

The cast iron block construction provided exceptional strength and thermal stability, while the aluminum cylinder head offered good heat dissipation and reduced weight.

The oversquare bore and stroke configuration promoted good breathing characteristics while maintaining reasonable piston speeds. The fuel injection system, utilizing Bosch LH-Jetronic technology, provided excellent fuel delivery with minimal maintenance requirements.

The electronic control unit, while not sophisticated by modern standards, was remarkably reliable and could function properly for decades without failure.

The air-mass meter system, while more complex than throttle-position-based systems, provided accurate fuel delivery across a wide range of operating conditions.

Professional mechanics often cite the B230F as an example of how conservative engineering can produce exceptional results. The engine’s reputation for durability has made it a favorite for high-mileage applications, where long-term reliability is more important than peak performance.

Many examples have exceeded 500,000 miles with only routine maintenance, and some documented cases have surpassed one million miles of service.

5 That Die in Obscurity

These problematic powerplants demonstrate recurring catastrophic failures that cause premature engine death and expensive replacement scenarios during normal service life, creating costly ownership nightmares that frustrate drivers and generate devastating repair bills.

Their compromised engineering includes inadequate bearing designs prone to premature failure, creating ongoing reliability disasters that destroy engines and generate complete powertrain replacement costs.

From timing chain systems that stretch and fail catastrophically to oil pump failures that cause complete engine seizure, these unreliable engines generate extensive warranty claims and expensive emergency replacement requirements.

Owners frequently report complete engine failure and total loss scenarios with these short-lived machines, a reflection of design shortcuts and inadequate testing that prioritize manufacturing cost reduction over long-term durability and engine survival.

1. Cadillac 8-6-4 V8 (1981)

The Cadillac 8-6-4 V8 engine represents one of the most ambitious engineering failures in automotive history, promising revolutionary fuel economy improvements but delivering reliability nightmares that lasted mere months rather than the decades expected from premium luxury vehicles.

This 6.0-liter V8, exclusive to 1981 Cadillacs, featured groundbreaking cylinder deactivation technology that was decades ahead of its time unfortunately, the execution was equally decades behind what was needed for reliable operation.

General Motors’ engineers conceived the 8-6-4 system as a solution to increasingly stringent fuel economy regulations while maintaining the V8 performance that Cadillac customers expected.

The concept was brilliant: during light load conditions, the engine would shut down two or four cylinders by closing their intake and exhaust valves, effectively transforming the V8 into a V6 or V4 as needed.

This variable displacement technology promised to deliver V8 power when needed and four-cylinder economy when cruising. The system’s complexity, however, far exceeded the technological capabilities of 1981.

The cylinder deactivation mechanism relied on solenoid-controlled hydraulic actuators that would collapse the rocker arms, preventing valve operation in the deactivated cylinders.

This system required precise hydraulic pressure control, sophisticated electronic management, and flawless integration with the engine’s fuel and ignition systems all areas where early 1980s technology fell short. The 8-6-4’s failure had lasting implications for GM’s reputation and the development of variable displacement technology.

The debacle made manufacturers extremely cautious about implementing similar systems, delaying the widespread adoption of cylinder deactivation technology by more than two decades. Modern variable displacement engines, while successful, still face skepticism from consumers who remember the 8-6-4’s spectacular failure.

2. Oldsmobile 5.7L Diesel V8 (1978-1985)

The Oldsmobile 5.7L diesel V8 engine stands as one of the most notorious engineering disasters in American automotive history, promising European-style fuel economy with American V8 smoothness but delivering catastrophic reliability problems that destroyed consumer confidence in diesel passenger cars for decades.

This 350 cubic inch diesel, found in various GM vehicles from 1978 to 1985, was hastily developed during the fuel crisis era and represented GM’s attempt to quickly enter the diesel passenger car market.

The engine’s fundamental problems stemmed from GM’s decision to convert its existing 5.7L gasoline V8 architecture to diesel operation rather than designing a purpose-built diesel engine.

This cost-cutting approach created a powerplant that was fundamentally unsuited to the demands of diesel combustion, with catastrophic results that became apparent within the first few thousand miles of operation.

The engine block, originally designed for gasoline’s lower combustion pressures, lacked the structural integrity required for diesel operation. The thin cylinder walls and inadequate main bearing support created a structure that couldn’t handle the massive forces generated by diesel combustion.

The head gasket design, adequate for gasoline engines, failed repeatedly under the higher pressures and temperatures of diesel operation, leading to coolant contamination and overheating.

The fuel injection system proved even more problematic than the mechanical components. GM contracted with Stanadyne to develop a rotary injection pump suitable for automotive use, but the resulting system was plagued with reliability issues.

The injection pump, sensitive to fuel quality and contamination, failed frequently and catastrophically. When the pump failed, metal particles would circulate throughout the fuel system, contaminating injectors and requiring complete system replacement.

The engine’s failure rate was so high that GM extended the warranty to 5 years/50,000 miles specifically for the diesel V8, an unprecedented move that acknowledged the engine’s fundamental problems.

Despite this extension, many owners faced multiple engine replacements within the warranty period, creating a customer relations nightmare that damaged GM’s reputation for decades.

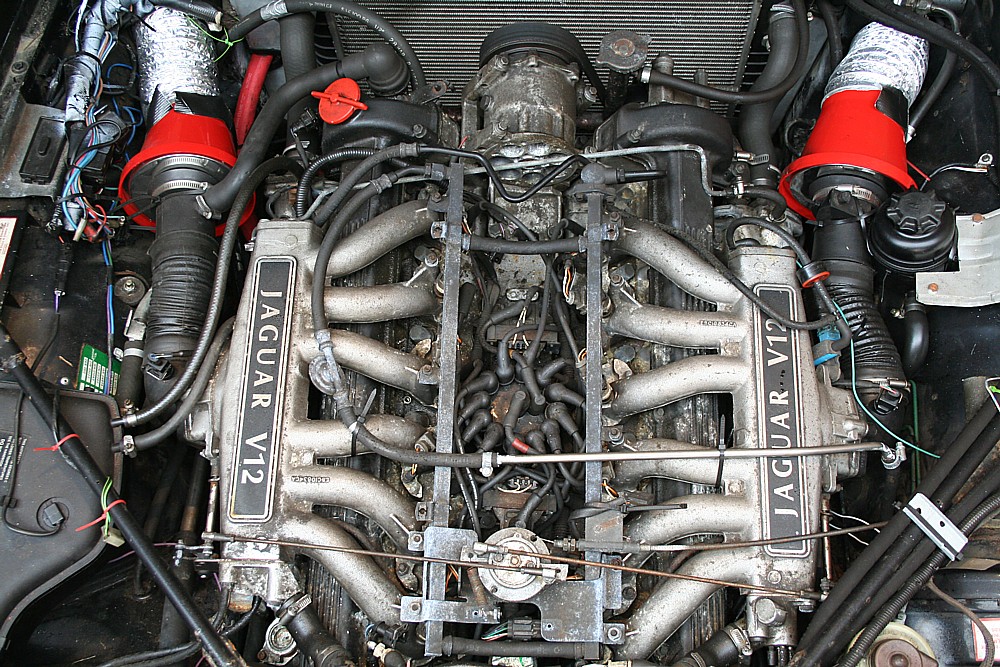

3. Jaguar 5.3L V12 (1971-1997)

The Jaguar 5.3L V12 engine represents the tragic dichotomy between engineering ambition and practical reliability, delivering spectacular performance and refinement when functioning properly but requiring such intensive maintenance and expensive repairs that it became synonymous with automotive unreliability.

This 5.3-liter aluminum V12, found in E-Type, XJS, and XJ12 models, embodied Jaguar’s commitment to performance and luxury while simultaneously demonstrating the company’s inability to engineer long-term reliability.

Maybe it is not fair to say the Jaguar V12 is the worst. The engine itself is relatively robust, but keeping it running can lead to costly repairs and undue stress.

The engine’s fundamental design was quite sound, featuring an aluminum block and heads that provided excellent weight distribution and thermal characteristics.

The SOHC design, while not optimal for peak power production, created a smooth, refined powerplant that delivered linear power delivery and exceptional refinement.

The V12’s problems stemmed not from fundamental design flaws but from component quality issues and complex systems that required precise maintenance.

The fuel injection system, utilizing Lucas mechanical injection, was notoriously sensitive to fuel quality and contamination. The injection pumps, manufactured to tight tolerances, would fail when exposed to poor fuel quality or extended service intervals, creating rich or lean running conditions that could damage the engine.

The cooling system represented the engine’s most critical weakness. The aluminum construction, while providing weight savings, created galvanic corrosion issues when mixed metals were present in the cooling system.

The complex cooling system, featuring multiple thermostats and a intricate routing system, was prone to air pockets and uneven cooling that could cause localized overheating and head gasket failure.

The electrical system, predominantly Lucas-manufactured, earned its reputation for unreliability. The complex ignition system, featuring dual distributors and multiple coils, was sensitive to moisture and component degradation.

The wiring harnesses, often poorly routed and inadequately protected, would deteriorate over time, causing intermittent failures that were difficult to diagnose and repair.

The V12’s legacy is complex: it represented Jaguar’s engineering capabilities at their peak while simultaneously demonstrating the company’s inability to create practical, reliable powerplants.

The engine’s failure contributed to Jaguar’s reputation for unreliability that persisted for decades, even after the company addressed many of the fundamental issues.

4. Chrysler 2.7L V6 (1998-2010)

The Chrysler 2.7L V6 engine, found in Dodge Intrepid, Chrysler Concorde, and various other vehicles, represents a masterclass in how cost-cutting and poor engineering decisions can create an engine that fails predictably and catastrophically, often before reaching 100,000 miles.

This aluminum V6, designed to provide smooth operation and adequate power in mid-size applications, became notorious for oil sludge formation and timing chain failures that would destroy the engine without warning.

The engine’s primary problem stemmed from its inadequate oiling system design. The oil passages, designed to minimize material costs, were too small to provide adequate lubrication to critical components, particularly the timing chain tensioners and upper valve train components.

This marginal oiling system, combined with extended oil change intervals promoted by Chrysler, created conditions perfect for oil sludge formation.

The timing chain system proved to be the engine’s Achilles’ heel. The primary timing chain, responsible for driving the camshafts, was tensioned by hydraulic tensioners that required adequate oil pressure to function properly.

When oil sludge formed in the narrow oil passages, the tensioners would lose pressure, allowing the timing chain to skip teeth or break entirely. This failure was typically catastrophic, bending valves and often requiring complete engine replacement.

The engine’s aluminum construction, while providing weight savings, created thermal expansion issues that contributed to oil system problems. The aluminum block and heads expanded at different rates from the iron liners, creating sealing issues that allowed oil to leak into the cooling system.

This oil contamination would thicken the coolant and reduce its ability to transfer heat, contributing to overheating problems. The cooling system design compounded the engine’s problems.

The water pump, driven by the timing chain, was located inside the engine and required major disassembly to replace. When the water pump failed, coolant would contaminate the oil system, creating a cascade of failures that often destroyed the entire engine. The thermostat location, deep within the engine, made this crucial component difficult to service.

The crankcase ventilation system, designed to reduce emissions, actually contributed to oil sludge formation. The PCV system would draw oil vapors from the crankcase, but inadequate separation would allow oil to accumulate in the intake manifold, where it would cook and form deposits. These deposits would then be drawn back into the engine, contributing to sludge formation throughout the oil system.

The 2.7L’s legacy damaged Chrysler’s reputation for engine reliability for years. The high failure rate, combined with expensive repairs and poor owner experience, made consumers wary of Chrysler products.

The engine’s problems contributed to declining sales and damaged the company’s relationship with customers who had previously been loyal to the brand.

5. BMW N47 2.0L Diesel (2007-2011)

The BMW N47 2.0L diesel engine, found in various BMW models including the 1-Series, 3-Series, and X1, represents a perfect example of how advanced engineering can create spectacular failures when fundamental design decisions prove flawed.

This aluminum four-cylinder diesel, designed to provide excellent fuel economy and performance, became infamous for timing chain failures that would destroy the engine without warning, often before reaching 60,000 miles.

However, some engines rattle more than others, and this is especially the case when it comes to the family of BMW N47 engines. One of the reasons these motors are so loud and deserve their place on the list of worst engines is significant timing chain wear and almost inevitable failure.

The engine’s fundamental problem stemmed from BMW’s decision to locate the timing chain at the rear of the engine, where it was difficult to access and inadequately lubricated.

The timing chain system, designed to be maintenance-free, actually required careful monitoring and eventual replacement something BMW failed to communicate to owners. The chain tensioner, operated by oil pressure, would gradually lose effectiveness as the engine aged, allowing the chain to stretch and eventually skip teeth. This failure was often catastrophic, bending valves and requiring complete engine replacement.

The engine’s aluminum construction, while providing excellent performance characteristics, created thermal expansion issues that contributed to timing chain problems.

The aluminum block would expand more than the timing chain during warm-up, creating additional stress on the chain and tensioner system. This thermal cycling, repeated thousands of times over the engine’s life, would gradually weaken the timing chain system.

The fuel injection system, while advanced, created its reliability problems. The high-pressure fuel pump, operated by the camshaft, was prone to failure and expensive to replace.

When the pump failed, metal particles would contaminate the entire fuel system, requiring replacement of injectors, fuel lines, and filters. The common rail system, operating at extremely high pressures, was sensitive to fuel quality and contamination.

The legacy of the N47 engine serves as a cautionary tale about the risks of advanced engineering without adequate long-term testing. While the engine provided excellent performance and fuel economy when functioning properly, its fundamental design flaws created reliability problems that overshadowed its technical achievements. The engine’s failure contributed to skepticism about BMW’s diesel technology and influenced the company’s subsequent engine development programs.

Also Read: 5 Engines That Never Knock and 5 That Ping With Every Tank