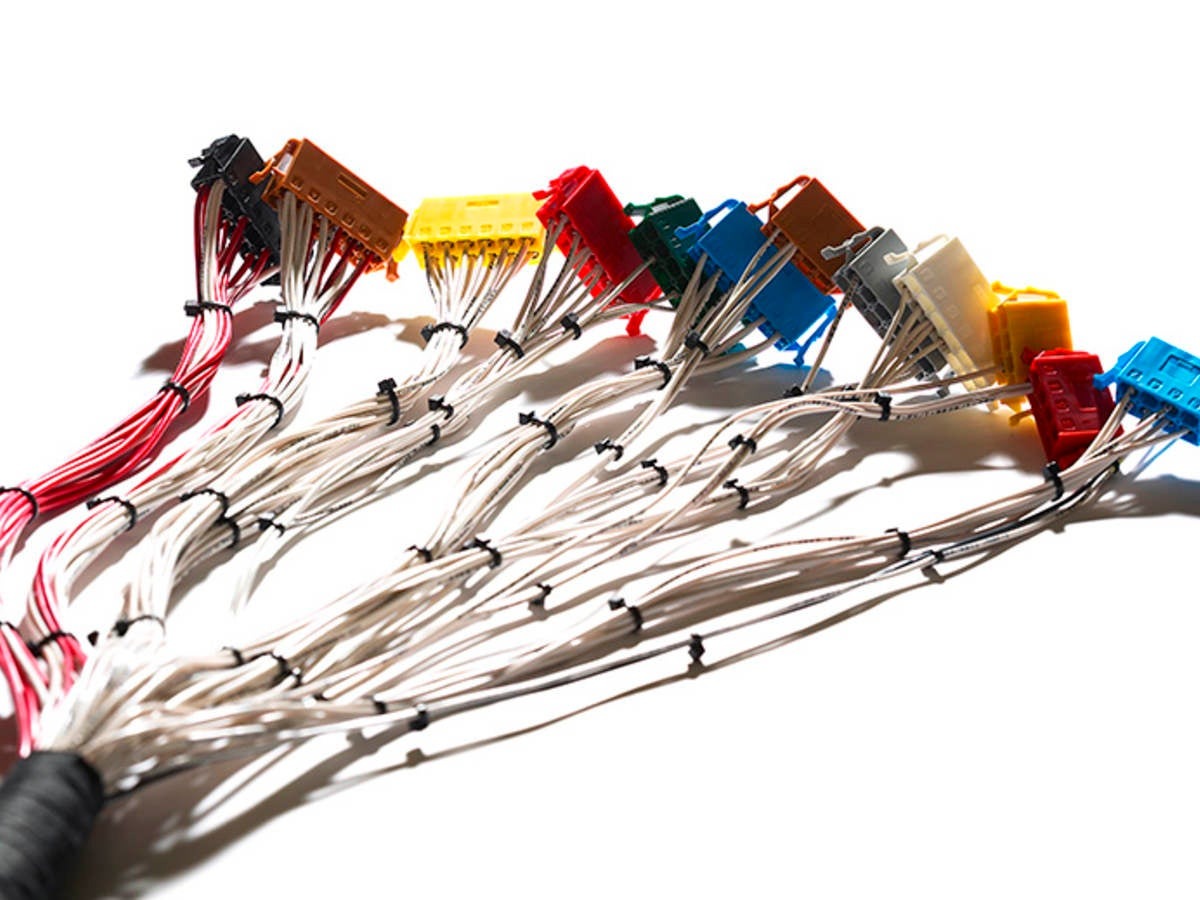

Automotive engineering has seen a series of improvements over the years, particularly in the areas of reliability and longevity. One important yet often ignored element is the wiring harness, which serves as the backbone of the car’s electrical network.

Whether it is about powering sensors, lighting, engine components, or infotainment systems, a well-designed wiring harness ensures every electronic feature operates without fail.

When this component is constructed using quality materials and protected against corrosion, moisture, and heat, it may last throughout the entire life of the vehicle. However, not every manufacturer achieves this feat, as some vehicles begin to develop wiring problems due to poor insulation or low-grade plastic coverings.

A durable wiring harness can help prevent frustrating and expensive electrical issues. But once insulation begins to degrade, it exposes wires to heat, friction, and water damage, leading to erratic behavior or complete failures in major systems.

Vehicles that are well-regarded for their electrical durability often reflect their manufacturer’s commitment to detail and high standards. Meanwhile, others are plagued by frequent issues ranging from warning light malfunctions to full-on electrical fires due to poorly protected wiring.

We will present you with five cars recognised for having long-lasting and resilient wiring harnesses, followed by five others that have earned a reputation for wiring insulation that starts to fall apart, especially after a few years on the road.

Each example highlights how the choice of materials, insulation quality, and the entire construction standard affect long-term performance. For anyone seeking a vehicle that will stand the test of time electrically, understanding how a car’s wiring system is built and protected is just as important as knowing its horsepower or fuel economy.

With this focus, let us look at those models that offer peace of mind with strong electrical durability, and those that tend to create concerns due to recurring insulation wear.

5 Cars with Lifetime Wiring Harness

1. Toyota Land Cruiser

The Toyota Land Cruiser stands out as a vehicle engineered with durability in mind. Its wiring harness reflects the same philosophy as its drivetrain and suspension, which have long been built to survive extreme conditions.

The Land Cruiser has seen widespread use in remote and rugged locations where reliability cannot be compromised. The manufacturers designed the wiring harness using thick insulation and moisture-resistant materials, ensuring it maintains its strength whether driving in desert heat or arctic cold.

From the early 100 Series models to the more recent 200 Series, the Land Cruiser has demonstrated impressive consistency when it comes to its electrical performance. Owners rarely report problems with wiring faults, even after more than a decade of use.

Toyota ensured that the wires are not just coated with heat-resistant plastic, but also reinforced with extra protection where they pass through tight engine bays or sharp metal surfaces. This reduces the chances of friction leading to wear as time goes by.

Another strength is Toyota’s decision to route wiring through protective sleeves and seals that resist dust, oil, and water. In areas prone to flooding or high humidity, many vehicles struggle to keep electrical faults at bay.

The Land Cruiser avoids this through tight harness protection that blocks moisture from entering and causing corrosion. Also, Toyota placed emphasis on avoiding exposed junctions and connectors, reducing failure points that would otherwise become problematic.

Even in models that have been driven for hundreds of thousands of kilometres across Africa or the Middle East, the original wiring remains intact and free from brittleness.

Electric windows, dashboard systems, and lighting components remain functional without intervention, which is a strong statement about how well the harness performs. Anyone looking for a rugged SUV that will not trouble you with electrical gremlins for decades would find the Land Cruiser a very dependable choice.

2. Lexus LS400

The Lexus LS400, introduced in the early 1990s, carried Toyota’s ambition of delivering unmatched luxury combined with rock-solid engineering. While the vehicle offered smooth V8 performance and a refined cabin, what often gets overlooked is the precision and quality that went into its electrical system.

Lexus engineers treated the wiring harness with as much attention as they did with its powertrain and suspension. This resulted in a system that has aged remarkably well, even three decades after its debut.

Many LS400s still function with their original factory wiring, and there are rarely any reports of harness failures or insulation breakdown. The insulation material used during production was chosen for its flexibility and resistance to heat, and it has proven effective against hardening or cracking.

Unlike some luxury cars from the same era that suffered from brittle wiring after a few years, the LS400 avoided these problems due to its high manufacturing standards.

Inside the cabin, Lexus insulated and bundled wires in layers, preventing them from sagging or being exposed to friction. Whether under the dashboard or running beneath the floor mats, the wiring remains organised and shielded.

Even in warm climates where dashboard plastics may warp, the LS400’s wires show little sign of fatigue. This is impressive, especially for vehicles now over 25 years old.

Another reason the wiring has remained intact is the level of shielding applied against electromagnetic interference.

Lexus wanted a quiet and interference-free cabin, so the harness was designed to prevent noise from entering the audio system or digital components. This level of planning helped maintain performance and reduced the chances of system faults caused by random spikes.

This level of reliability helped shape Lexus’s reputation as a dependable luxury brand. The LS400 represents how thoughtful design, premium materials, and advanced protection techniques can result in a wiring harness that functions long after other components start to fail.

Also Read: 5 Once-Popular Cars Now Selling Below MSRP vs 5 That Still Sell Above Sticker

3. Honda Accord (2003-2007)

The seventh-generation Honda Accord, especially those made between 2003 and 2007, established a reputation for being a practical and long-lasting sedan.

This model appealed to a broad audience due to its strong performance, comfortable interior, and low cost of ownership. A large part of that reliability is tied to the vehicle’s wiring system, which rarely presents issues unless the vehicle is subjected to serious abuse.

Honda paid close attention to how wires were laid out throughout the vehicle. Rather than going for lightweight but fragile insulation, the engineers selected wire coatings that could handle temperature changes without hardening or peeling.

This decision helped many owners avoid random shorts or malfunctioning components, even after years of exposure to harsh weather or prolonged heat from the engine bay. The vehicle’s power window controls, headlight systems, and dashboard displays continued to function reliably with little electrical interference.

The connectors used in this generation of Accord also benefited from waterproofing, especially those positioned in wheel wells and engine compartments. This meant that even when the car drove through heavy rains or shallow floods, the chances of corrosion or wire damage remained very low.

Wiring harness failures are almost unheard of with these Accords unless the car has been involved in a serious accident or improperly repaired.

Unlike other brands where cost-cutting might lead to exposed sections or weak connectors, Honda avoided these risks. Even the fuse box and relay panels are tightly constructed, giving the electrical system extra stability against vibration and wear.

People who have owned their Accord for over 15 years often report that the electronics remain stable without the need for frequent rewiring or connector cleaning.

For a car that is now considered older, its performance in this area has stood the test of time. Honda’s attention to small electrical components helped this model become a quiet workhorse in many garages.

4. Mercedes-Benz W124

The Mercedes-Benz W124, produced from the mid-1980s through the mid-1990s, is widely regarded as one of the most robust vehicles ever manufactured. Designed at a time when Mercedes focused on long-term durability rather than cutting costs, the W124 continues to run reliably decades later.

Part of what makes this car special is the care taken during the creation of its wiring harness. Every wire was insulated using materials built to last, and the placement of each harness was done to avoid unnecessary stress or exposure.

Unlike many vehicles from the same period, the W124 does not suffer from premature electrical failures. The insulation material remains flexible, and the connectors still create clean contact without corrosion.

Whether in the engine bay, beneath the dashboard, or near the wheel arches, Mercedes ensured each connection was well protected. This prevented many of the issues that plague older cars, such as flickering lights or inconsistent instrument cluster behaviour.

Mercedes also adopted copper wiring with thicker sheathing, which not only ensured signal strength but helped reduce the chances of wear caused by vibrations.

Special clips were used to hold the wiring in place, reducing motion and friction that could lead to insulation breaks. In addition, all electrical joints were sealed properly, limiting the risk of water entry and the formation of rust within the connectors.

W124 models still being used today maintain a high level of electrical stability, something rarely seen in vehicles of this age. The seat heaters, sunroof motors, and even the early automatic climate control systems function just as they did when new, largely because the harness remains strong.

This model continues to be a benchmark for mechanical and electrical longevity, and many auto enthusiasts consider it one of the best-engineered cars ever made.

5. Subaru Outback (2010-2014)

The Subaru Outback from the 2010 to 2014 production run became a popular choice for people living in cold climates and off-road regions. Known for its symmetrical all-wheel drive system and wagon-like versatility, this vehicle also gained appreciation for having a dependable electrical design.

Subaru engineers equipped the Outback with a durable wiring harness that could resist moisture, ice, and high engine temperatures, which made it dependable for those who drive in snow or rain-prone regions.

Many of the harnesses in this generation of Outback were given thicker insulation that helped them remain flexible even after multiple freeze-thaw cycles.

Subaru also took care to prevent abrasion points by using soft routing clips, padded sleeves, and reinforced sections where wires passed through the firewall or tight bends. This kind of engineering consideration helped reduce the chance of insulation cracking or the harness being pinched as time goes by.

Inside the cabin, the fuse and relay locations were carefully sealed and positioned to keep out moisture. Electrical connectors were made using rubber seals, especially around the doors and liftgate, which typically see more water intrusion.

This level of protection helped keep lights, sensors, and the entertainment system working consistently even after years of harsh weather exposure.

In the engine compartment, Subaru arranged the harness to avoid direct heat from the exhaust manifold and instead ran it along cooler sections, which limited premature wear. Even when vehicles were used for long distances under heavy loads, owners rarely experienced electrical faults tied to harness breakdown.

For drivers who regularly encounter rain, snow, and mud, the Outback’s solid harness performance provided reassurance. Subaru managed to design a vehicle that was as reliable electrically as it was mechanically, especially for those who depend on their cars during harsh winters or off-grid excursions.

5 Cars with Fraying Insulation

1. BMW 5 Series (E60, 2003-2010)

The BMW 5 Series from the E60 generation introduced many advanced features at the time, including iDrive controls, adaptive headlights, and sophisticated climate systems.

While the car delivered strong performance and dynamic handling, it developed a reputation for electrical problems that frustrated many owners. One common issue across the board was insulation that began to degrade much earlier than expected, especially in warmer regions.

In the engine bay, the wiring harness suffered from heat exposure. The insulation on many wires would become brittle and flake off, exposing copper underneath.

This led to unpredictable behavior in the engine’s sensors, such as throttle position, oxygen sensors, and ignition control. Owners often encountered limp mode warnings or sudden power losses that were later traced to short circuits caused by failing wire insulation.

The issue extended into the cabin as well. The connectors behind the dashboard, especially those controlling the infotainment system, would sometimes lose connection due to wire hardening and pin stress.

iDrive screens would freeze, fail to boot, or randomly restart. Technicians often had to trace issues back to insulation that cracked and let moisture into sensitive areas.

BMW attempted to improve the situation by changing some of the wiring materials during later production years, but many early E60s still experience these issues.

Vehicles that were parked outside or driven in hot climates were particularly vulnerable. Even when repairs were made, the process of tracing and replacing faulty wiring became expensive and time-consuming.

This model remains admired for its road manners and comfort, but electrical faults caused by insulation problems have dampened its reputation.

Many owners are now forced to redo sections of the wiring harness using aftermarket heat-resistant materials, which adds further to maintenance costs. It serves as a reminder that even luxury brands can face serious consequences when compromises are made in component selection.

2. Volkswagen Jetta (2006-2010)

The fifth-generation Volkswagen Jetta, produced from 2006 to 2010, was an improvement in design and safety over earlier models. It offered refined ride quality and better fuel economy, but its electrical system raised concerns for many long-term owners.

One of the recurring problems was fraying insulation in parts of the wiring harness, especially around the trunk area and doors, where the harness had to flex during use.

A specific weak spot was the wire bundle that runs into the boot lid. As drivers opened and closed the trunk repeatedly, the insulation on the wires began to crack, particularly on models that spent years in direct sunlight.

Once the plastic covering peeled off, the wires inside were exposed and sometimes made contact with each other or metal surfaces, which led to short circuits. This affected rear lights, central locking, and sometimes the reversing camera.

Inside the cabin, wire insulation near the seat heating controls also showed early signs of hardening. Many users experienced malfunctioning seat heaters, intermittent dash light failures, or airbag warnings.

When mechanics inspected the system, they frequently found brittle wires or connectors that had started to oxidise due to slight moisture ingress.

The harness layout in the engine bay also did not hold up well under extended exposure to heat. Certain wires near the turbocharger area would lose their insulation quickly, leading to misfires or sensor errors. Volkswagen attempted to improve insulation in later updates, but many vehicles from this range already suffered damage.

The repair process often required cutting and splicing affected areas, which increased the chance of future issues. Drivers have shared stories of multiple electrical gremlins caused not by software but by physically deteriorating wires.

While the Jetta remains mechanically sound in many ways, its electrical insulation troubles have become an ongoing source of complaints for owners.

3. Mini Cooper (2002-2006)

The early 2000s Mini Cooper, especially models produced between 2002 and 2006, gained popularity for its retro looks and responsive handling. However, its wiring system became a common problem area.

A major issue lay in how compact the car’s design was, which left little room for the wiring harness to be positioned away from heat, vibration, and moisture. The result was a system that suffered from frequent insulation breakdown.

One area prone to failure was under the bonnet, where the heat from the engine and poor air circulation caused wire insulation to harden quickly. As the plastic cracked and peeled off, exposed copper wires would either short out or lose connection. This led to problems with ignition timing, sensor communication, and even stalling during driving.

The Mini’s tight cabin also offered little protection for wiring near the footwells and side panels. Insulation in these locations would deteriorate as time goes by, particularly when exposed to wet shoes, spilled drinks, or damp mats.

Dashboard lights, turn signals, and stereo functions would stop working, and finding the exact source of the issue often took hours of diagnostic testing. Another source of complaint was the tailgate wiring.

Owners found that wires leading to the rear wiper motor and license plate lights would fray after repeated opening and closing of the boot. When these wires began to fail, many found that fuses would blow regularly or warning lights would appear without an obvious cause.

Mini Coopers from this era are still loved by enthusiasts for their charm and drivability. However, the wiring problems continue to reduce their long-term appeal.

Repair shops often recommend complete harness replacements or extensive rewiring just to restore basic electrical reliability. Despite being marketed as a premium small car, the Cooper’s wiring issues have left many owners feeling let down.

4. Ford Focus (2000-2004)

The early 2000s Ford Focus became popular for its handling and practicality. It was praised for its affordability and everyday usability, especially among young drivers and city commuters.

However, many models from this period encountered persistent electrical issues tied to fraying insulation across multiple parts of the vehicle. These problems were especially common in the first few production years.

In the engine compartment, the harnesses near the battery and ignition coil would often show signs of cracking. The insulation used was not well-suited for high-heat areas, and as it became brittle, exposed wires would begin to short against metal components.

This led to misfiring, rough idling, and unexpected stalling while driving. For some owners, the problem worsened as time went by, with multiple sensors triggering error codes due to disrupted signals.

The interior wiring under the dashboard also suffered from early wear. Many drivers noticed that their instrument clusters would flicker or fail, and after inspection, it became clear that the insulation on the wiring had broken down.

In many cases, the wires would rub against plastic panels or brackets, leading to small cuts and eventual shorting. This affected lighting, speedometer readings, and radio functionality.

The trunk area was not exempt either. Wires leading to the rear lights and boot release suffered from fatigue, especially in cold weather. Repeated flexing caused the insulation to split, and some drivers lost brake light or reverse light functionality as a result. While the issues were not universal, they appeared frequently enough for electrical reliability to become a well-known issue with this model.

Ford did make improvements in later models, but the early Focus cars still require close attention to their wiring systems. Unless repairs are made with high-quality replacements, problems often return. This car served many households well, but its insulation faults left behind a long list of service bulletins and workshop visits.

Also Read: 10 Least Reliable Cars With CVT Transmissions To Avoid

5. Audi A4 (B6/B7, 2001-2008)

The Audi A4 from the B6 and B7 generations came with sleek styling, solid handling, and premium interiors that made it a favourite among drivers seeking a refined driving experience.

Despite its strong performance and luxurious appeal, this model also came with recurring electrical faults that could often be traced back to deteriorating wire insulation. As time goes by, many owners began to notice glitches across various systems, from lighting to ignition, caused by the physical breakdown of the harness components.

One area that experienced frequent issues was the engine bay. Audi’s decision to pack more components into tight spaces made the harnesses vulnerable to heat and vibration. Wires routed near the turbocharger or exhaust manifold were especially affected.

The insulation used on these wires started to crack as they aged, leading to sporadic issues like failed ignition coils, sensor malfunctions, and throttle response errors. In several cases, these faults triggered check engine lights or caused the engine to go into limp mode.

The dashboard and footwell areas also presented their share of challenges. Moisture from floor mats, condensation from air conditioning, and minor spills sometimes reached the base of the harness, slowly compromising insulation as time goes by.

Many A4 owners encountered problems with intermittent window controls, central locking failure, and warning chimes that would sound even when everything appeared to be working. Upon inspection, degraded insulation was often the root of the trouble.

Another repeated fault came from the wires running through the rear doors and trunk lid. These sections experienced frequent flexing during door openings, especially in cold weather when the plastic insulation became less flexible.

Cracks formed and exposed the wires to water and salt, especially in areas that experience snow. As time goes by, rear light faults and boot lock failures have become common, leading to user frustration and unexpected repair bills.

The cost to repair these insulation faults in the A4 could be high, as many service technicians had to trace issues manually through a maze of wires and connectors.

Although Audi offered performance and comfort, the decision to use insulation materials that could not withstand long-term heat or moisture proved costly for many drivers. It serves as a strong example of how even premium vehicles can suffer when longevity is not prioritised in electrical design.