Rust is not just a cosmetic issue that ages a vehicle’s appearance. It is a corrosive menace that, when left unchecked, can compromise a car’s structural integrity, endanger safety systems, and significantly shorten its lifespan. While modern vehicles are increasingly engineered with rust protection technologies, not all manufacturers treat this issue with the same level of seriousness.

Some brands have invested heavily in rust-proofing through galvanized steel, advanced coatings, and undercarriage seals. Others, however, have fallen short, leaving owners with repair bills and safety concerns stemming from frame rot or brake line corrosion.

This blog takes a closer look at ten vehicles, split between two groups: five that have demonstrated impressive rust resistance over time and five that unfortunately suffer from structural rust problems.

For each model, we will examine the materials, coatings, and engineering practices that either protect the car or leave it vulnerable. We’ll also explore real-world outcomes, including how rust impacts crash safety, resale value, and the overall driving experience.

Rust might not be as dramatic as engine failure or brake malfunction, but it can be just as dangerous. In extreme cases, rust can cause suspension mounts to separate or lead to brake line failure. Knowing which vehicles are equipped to resist this threat can help consumers make smarter, safer choices when buying or maintaining a vehicle. Read on to discover which cars are built to last and which ones crumble under the rust.

5 Cars with Rust Protection That Maintain Safety

Rust-resistant cars don’t just look better longer. They are often engineered with safety and longevity in mind, incorporating galvanized steel panels, rust-inhibiting primers, and sealed undercarriages.

These vehicles tend to perform well in long-term ownership studies, especially in regions where road salt is common in winter. The best-performing models have consistently shown little to no serious corrosion issues even after a decade of use, giving peace of mind to their owners and preserving crashworthiness.

Additionally, these cars often include factory warranties that cover corrosion for extended periods, reinforcing the manufacturer’s confidence in their design. In this section, we highlight five vehicles that stand out for their proactive approach to rust protection and how that effort supports long-term safety.

ALSO READ: 5 Vehicles People Drive Until the Wheels Fall Off and 5 They Trade ASAP

1. 2023 Toyota Camry

The Toyota Camry has long been known for its dependability, and the 2023 model continues that legacy with excellent rust protection built into its engineering. Toyota employs a combination of galvanized steel panels and high-grade anti-corrosion coatings throughout the body and undercarriage.

These materials are designed to withstand years of exposure to harsh elements like road salt, humidity, and acid rain, which commonly lead to rust in other vehicles. The Camry also benefits from strategic sealing around wheel wells, door sills, and underbody seams to prevent moisture from settling into vulnerable areas.

Beyond materials, Toyota’s production process includes an electro-deposition coating technique. This applies a rust-resistant primer to the entire body structure, reaching areas that traditional sprays often miss.

It is one of the reasons why Camrys sold in snow-prone regions like the Midwest and Northeast routinely last well over a decade with minimal signs of rust. Furthermore, the Camry’s 5-year corrosion warranty and available 7-year extended protection package offer peace of mind for long-term owners.

Owners have reported excellent durability even when driving in harsh winter conditions. Unlike some competitors, the Camry’s brake and fuel lines are also coated or shielded to prevent corrosion-related failures.

This not only preserves the car’s appearance but also ensures its structural safety remains intact. With routine maintenance and basic cleaning, the Camry continues to be one of the safest bets for rust resistance on the road today, reinforcing Toyota’s reputation for quality and longevity.

2. 2023 Honda CR-V

The 2023 Honda CR-V blends practicality, fuel efficiency, and standout corrosion resistance in a highly competitive SUV market. Honda has paid close attention to rust prevention, particularly in models destined for colder climates.

The CR-V’s body panels are made from galvanized steel, and the underbody receives multiple protective treatments, including a robust layer of undercoating that shields vital areas such as the frame rails and suspension mounts. This is critical for maintaining structural integrity over time, especially in snowy or coastal regions.

One of the key strengths of the CR-V’s rust prevention system is the integration of advanced sealants applied to weld seams and joints. These help to keep out moisture and road salt, two of the leading causes of corrosion in vehicles. Honda also equips the CR-V with plastic fender liners and splash guards to protect against rock chips and salt spray that could otherwise damage exposed metal.

Reports from long-term owners in the northern U.S. and Canada consistently highlight how well the CR-V holds up under heavy winter conditions. Brake lines, fuel systems, and the rear subframe all benefit from thoughtful design and protective measures. In crash safety terms, these protections ensure that the frame and suspension retain their integrity well into the vehicle’s lifespan.

With a 5-year corrosion warranty and solid rust resistance performance backed by real-world data, the 2023 CR-V is a safe and smart choice for drivers who value longevity and want to avoid the hidden dangers of structural rust.

3. 2023 Subaru Outback

The 2023 Subaru Outback stands as one of the most rugged, adventure-ready vehicles in its class. What many overlook, however, is the brand’s strong commitment to corrosion resistance.

Designed with off-road and all-weather driving in mind, the Outback features a fully galvanized steel body and a factory-applied undercoating that protects against road salt, slush, and dirt accumulation. These features are particularly valuable in snowbelt regions where rust can drastically reduce a vehicle’s lifespan.

Subaru also uses weld-seam sealers and heavy-duty rust-proofing treatments in wheel wells, rocker panels, and around suspension components. These high-risk areas are frequently targeted by road debris and moisture.

The Outback’s raised ride height further protects the undercarriage from constant exposure, and the inclusion of rubberized splash guards shields the paint and metal from sand, salt, and gravel.

Real-world reviews from owners in northern U.S. states and Canada consistently note how well the Outback resists corrosion even after many winters. Subaru also coats its brake and fuel lines to reduce vulnerability to rust-related failures that could impact safety systems. When combined with its symmetrical all-wheel drive system and reinforced frame, the Outback maintains its structural reliability for the long haul.

Backed by a 5-year unlimited mileage corrosion warranty, the 2023 Subaru Outback is a smart investment for those who drive in harsh conditions. It’s proof that rust protection can coexist with utility and off-road capability without compromising safety or comfort.

4. 2023 Mazda CX-5

Mazda has made enormous strides in both design and durability, and 2023 CX-5 is a standout example. Among compact SUVs, the CX-5 offers one of the most advanced rust protection systems available in its segment. The entire body structure is composed of galvanized high-tensile steel, and the chassis benefits from extensive sealing at joints, panel connections, and underbody seams to block moisture intrusion.

Mazda uses a multi-layer coating process on the CX-5 that includes electrodeposition primer, anti-chip coating on vulnerable body parts, and wax-based rustproofing in cavities. This three-stage defense system is highly effective against long-term corrosion. Brake and fuel lines are coated or wrapped to resist salt exposure, and wheel well liners are extended to block splash-back from winter roads.

In long-term ownership surveys, the CX-5 consistently ranks among the top in corrosion durability. Even in high-salt areas like New England or the Great Lakes region, these SUVs tend to hold up well with proper care. Mazda also supports its corrosion resistance claims with a 5-year unlimited mileage rust-through warranty.

Another factor that contributes to the CX-5’s rust resistance is its tight manufacturing tolerances. Water and road grime have fewer gaps to enter, which minimizes internal corrosion over time. When combined with excellent crash test scores and a sturdy build, the 2023 CX-5 emerges as a compact SUV that values both aesthetics and long-term safety.

5. 2023 Volvo XC90

The 2023 Volvo XC90 is a luxury SUV with advanced safety features and a model engineered with longevity in mind, including strong protection against rust. Volvo has long been known for its commitment to safety; corrosion resistance plays a vital role in that philosophy. The XC90 uses high-quality galvanized steel in both its body panels and frame, ensuring that the underlying structure remains solid well beyond the typical vehicle lifespan.

Volvo applies a comprehensive anti-corrosion coating process at its factories, which includes e-coat dipping, cavity wax treatments, and seam sealing across all structural junctions. These measures are especially important for preserving crash integrity and preventing structural weakening over time. Additionally, the XC90 comes with fully enclosed wheel arches and plastic cladding on lower body panels to prevent chipping from road debris.

One standout aspect of the XC90’s rust protection is the quality of its paint and primer systems. Volvo uses a multi-layer paint application with UV and salt-resistant properties that protect even in extreme Scandinavian winters. Brake lines and underbody components are wrapped and shielded, further reinforcing safety systems against corrosion.

Volvo’s corrosion protection warranty spans 12 years with unlimited mileage, demonstrating the brand’s confidence in the XC90’s rust-proofing. For those investing in a premium SUV that offers long-term peace of mind and high safety standards, the XC90 proves that rust resistance is a key component of luxury engineering.

5 Cars That Suffer Structural Rust

While most vehicles will eventually show signs of age, some models are notorious for developing rust far earlier than expected. In these cases, the problem goes beyond surface blemishes and reaches the frame, subframe, or even suspension components, affecting safety-critical structures. Some vehicles lack proper undercoating or use poorly protected fasteners and weld points that become weak over time. In certain climates, especially those with heavy road salt use, these shortcomings become dangerous liabilities. Rust can weaken the chassis, compromise crash protection, or cause suspension and braking failures. In this section, we explore five cars known for chronic rust issues, focusing on how this problem impacts safety, reliability, and consumer trust.

ALSO READ: 5 Used Cars That Surprised Owners and 5 That Became Immediate Mistakes

1. 2007–2014 Chevrolet Silverado 1500

The Chevrolet Silverado 1500 is one of the most popular full-size pickups in the United States, but models produced between 2007 and 2014 have gained a troubling reputation for premature structural rust. While the Silverado is built for heavy use, especially in work and off-road environments, the rust issues reported during these model years go far beyond surface corrosion. Owners have commonly reported frame rust, deteriorating brake lines, and suspension component failure, especially in northern climates with heavy salt use.

One of the most concerning rust-prone areas is the frame itself. GM used a frame design during this period that lacked adequate rustproofing and drainage. Water and salt would accumulate in crevices, leading to rapid corrosion from the inside out. In numerous cases, trucks with less than 100,000 miles experienced significant rust-through in frame rails and cab mounts. This kind of structural compromise can undermine the vehicle’s crash protection and towing stability.

Another frequent failure point is the brake and fuel lines, which were often made of uncoated steel that quickly corroded. Several NHTSA complaints and user reports cite brake line ruptures from rust, a serious safety concern that can lead to sudden loss of braking power. Even with aftermarket coatings or treatments, many Silverado owners found the rust too advanced by the time problems became visible.

Despite its capability and strong engine lineup, the 2007–2014 Silverado suffers from rust-related problems that impact long-term reliability and, more importantly, driver safety. For buyers in snowbelt regions, this generation of Silverado can pose more risk than reward.

2. 2002–2006 Nissan Altima

The 2002–2006 Nissan Altima represents one of the most widespread examples of structural rust problems in a modern sedan. While these vehicles were praised for their styling and performance when new, owners quickly discovered a serious design flaw: the front subframe and floorboards were especially vulnerable to rust, often leading to dangerous and expensive repairs within a few years of ownership.

The most notorious issue was the floorboard rust-through, particularly on the driver’s side. Water would leak into the cabin from poorly sealed seams or air conditioning drains, soaking insulation and causing rust to spread from the inside out. In severe cases, holes the size of basketballs formed under the driver’s feet, directly compromising crash safety and occupant protection.

Additionally, the Altima’s front subframe was made of untreated or lightly coated steel. In snowbelt states, the subframe could deteriorate rapidly, leading to alignment issues or, in extreme cases, front suspension separation. Many owners were shocked to discover the extent of the damage during inspections, and dealerships frequently recommended subframe replacement, a job that could cost thousands.

Despite growing awareness, Nissan never issued a widespread recall for these rust issues. That left many owners with unsafe vehicles and no factory recourse. While the Altima from this era may appear mechanically sound on the surface, the rust underneath tells a different story. For those considering a used model from these years, a detailed inspection of the underbody and frame is absolutely essential.

3. 1999–2004 Ford F-150

The 1999–2004 Ford F-150 is another full-size truck with widespread structural rust issues, especially among owners in cold-weather and high-salt regions. Despite being America’s best-selling vehicle, this generation of the F-150 has become synonymous with premature rust damage, particularly on the frame, rear leaf spring mounts, and brake line systems.

One of the most dangerous problems reported with this truck is frame rot near the rear axle and spare tire area. In many cases, the frame would rust through so badly that the spare tire could fall off while driving. Ford eventually issued a recall in 2011, but it only addressed a small number of affected vehicles, leaving many owners without a fix. Even trucks that were regularly washed and maintained saw rust develop in structural points critical to safety.

Brake and fuel lines, especially on four-wheel-drive models, were also prone to rapid corrosion. These steel lines were not adequately coated or shielded, making them vulnerable to rust-induced leaks. Several reports describe sudden brake failure due to ruptured lines, a significant safety risk under normal driving conditions.

Body rust was also common, particularly around the wheel arches, cab corners, and rocker panels. While cosmetic rust is often accepted on trucks, the extent and location of corrosion on these F-150s often extended into frame and suspension components. For truck owners who depend on durability and towing capability, this generation of the F-150 presented a troubling flaw in its long-term safety.

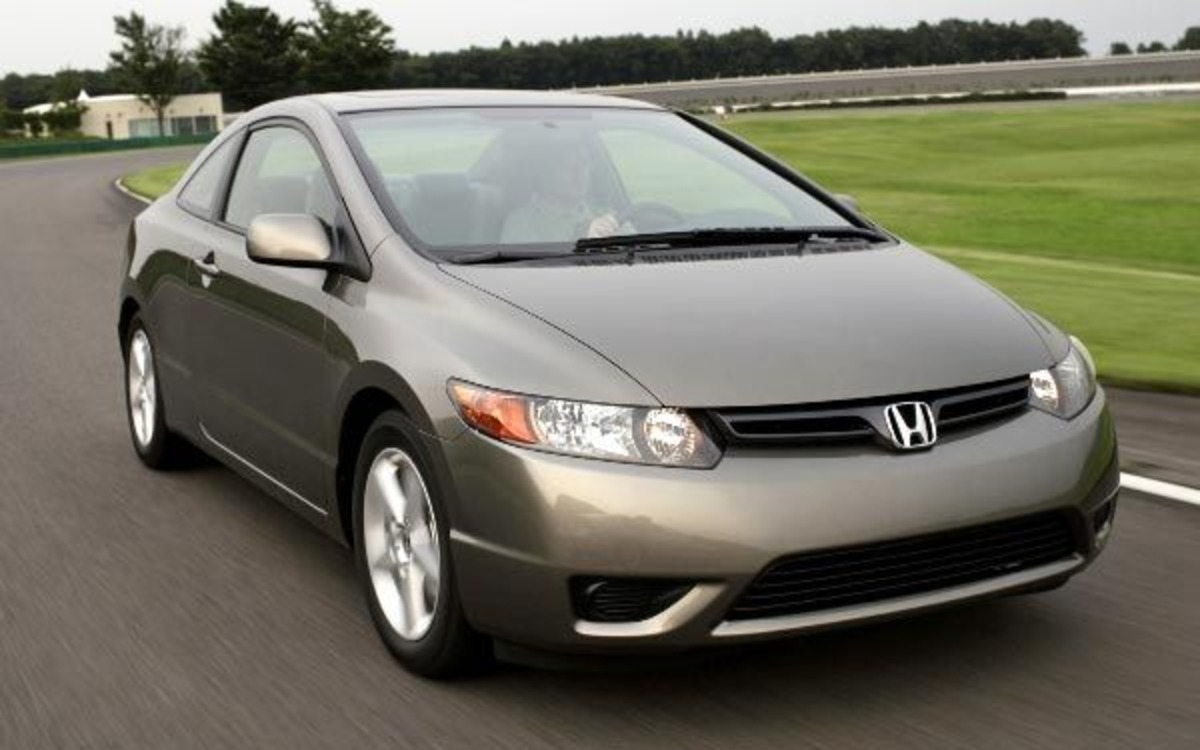

4. 2006–2011 Honda Civic

Though Honda is typically regarded as a reliable brand, the 2006–2011 Honda Civic has been flagged by owners and mechanics for serious rust-related issues. While surface rust is common in older vehicles, the Civic of this era has been criticized for frame and underbody corrosion that occurs too quickly, particularly in northern climates.

The most affected components include the rear wheel wells and the subframe that supports the rear suspension. Due to limited undercoating and poorly sealed welds, moisture easily collects in hidden areas and begins to degrade the metal. This is especially dangerous when it begins affecting suspension mounting points. Several owners reported creaking sounds or misaligned wheels, only to discover the subframe or control arms were separating due to rust.

Additionally, many 8th-generation Civics suffer from rotting floor pans and corroded rocker panels, which can reduce overall structural integrity. Rust damage has been observed in Civics with under 100,000 miles, which is particularly troubling for a car known for its long-term reliability.

There have been no broad recalls for corrosion on these models, despite hundreds of documented cases across online forums and NHTSA complaints. Though the engine and transmission remain reliable, rust in structural areas can lead to alignment problems, weakened crash safety, and high repair costs.

If you’re in the market for a used Civic from this generation, a detailed inspection of the wheel wells, undercarriage, and rear frame should be a top priority. Even otherwise well-maintained examples can have dangerous corrosion hidden underneath.

5. 2005–2010 Jeep Liberty

The 2005–2010 Jeep Liberty may offer off-road appeal and a rugged appearance, but it is widely regarded as one of the most rust-prone SUVs of the mid-2000s. While some body rust is expected in older vehicles, the Liberty goes far beyond cosmetic issues. Frame rot and suspension rust were common and severe enough to prompt multiple recalls by the National Highway Traffic Safety Administration (NHTSA).

One of the most alarming issues involved the rear lower control arms rusting and fracturing. Jeep issued a recall in 2012 for this defect, which affected tens of thousands of vehicles. A failed control arm can lead to unpredictable handling, suspension collapse, or loss of control at highway speeds, making it a serious safety concern.

In addition to suspension rust, the unibody frame of the Liberty is particularly vulnerable in areas around the rocker panels and wheel wells. These locations often corrode from the inside out, leaving structural weak spots that compromise crash safety and towing capacity. Even with regular washing and rustproofing, many owners reported significant frame damage within 5 to 7 years of ownership.

Rust on the Liberty is not limited to northern regions. Owners in more temperate areas also reported premature corrosion, pointing to flaws in the vehicle’s design and factory coatings. Despite its off-road branding, the Jeep Liberty struggles to hold up structurally over time, especially when used in the environments it was supposedly built for.

Rust may not grab headline-grabbing engineering foresight with advanced coatings and sealed joints, but others like the Nissan Altima or Ford F-150 suffer from widespread, often dangerous corrosion.

The difference comes down to issues like engine recalls or airbag failures, but it poses a quiet and potentially deadly threat to your vehicle’s integrity. Structural rust doesn’t just affect appearance; it weakens frames, undermines suspension systems, and jeopardizes crash safety.

As this blog illustrates, not all cars are created equal when it comes to long-term rust resistance. While models like the Toyota Camry, Honda CR-V, and Volvo XC90 demonstrate impressive manufacturer commitment to corrosion protection.

High-quality materials, smart design, and factory-applied sealants go a long way in preventing damage. On the other hand, cost-cutting measures or outdated rustproofing practices can lead to expensive repairs, or worse, compromised safety on the road.

For buyers, especially in snowbelt regions or coastal climates, rust protection should be a top consideration when purchasing a new or used vehicle. Thorough inspections, maintenance routines like undercarriage washing, and researching manufacturer history can help you avoid models with a history of premature rust.

Remember that airbags and crash test scores don’t just measure a car’s safety. Structural durability matters just as much.

In the long run, investing in a vehicle with solid rust resistance is not only smart, it’s safer. It means fewer repair bills, a better resale value, and most importantly, confidence that your car will protect you and your passengers for years to come.