When discussing the reliability and maintenance challenges of pickup trucks, cylinder head and head gasket issues often play a decisive role in shaping an owner’s long-term experience. For enthusiasts and buyers alike, engine durability and repair history remain among the most scrutinized factors.

Cylinder heads, in concert with head gaskets, are fundamental to maintaining proper engine compression and preventing the loss of coolant and oil into areas where they don’t belong. Successfully avoiding gasket trouble can make a significant difference in cost of ownership, engine longevity, and overall satisfaction with a truck.

Conversely, repeated head gasket failures by key mileage milestones increase repair costs and can tarnish the reputation of otherwise popular engines.

This article will focus on two closely connected sides of cylinder head reliability: first, five reputable pickup heads renowned for not succumbing to gasket problems, and then five commonly reported to have frequent failures, with the issue often surfacing by the 120,000-mile mark.

The engines showcased in each category have been selected based on a combination of owner testimony, mechanic records, and automotive technical analysis.

By charting which pickup powerplants shine in this area (and which stumble), readers will gain a grounded perspective on choosing trucks less likely to require costly top-end repairs as the odometer climbs, as well as insight into what makes some designs more resilient than others.

Also Read: 5 Cars With Original Exhaust Systems Still Working and 5 That Rust Out Fast

5 Pickup Heads with No Gasket Issues

For owners aiming to invest wisely, selecting a pickup with a proven track record for head gasket resilience is an important step.

Such engines inspire confidence, having demonstrated reliable sealing between the cylinder head and block over six-figure mileage spans.

Not improperly torqued, not made of questionable alloys, and not prone to the overheating that often precipitates gasket trouble, the cylinder heads highlighted in this section have helped build the reputations of their respective trucks.

Each of the following five was chosen due to minimal incidence of head gasket failures, low reported repair rates for top-end leaks, and widespread positive feedback from long-term owners and independent mechanics.

These engines are not only celebrated for their power and performance but also noted for sparing drivers the cost and frustration that often accompany gasket failure.

In analyzing why each has seen such success, this article intends to help readers recognize what to look for in head design, cooling passages, materials, and the manufacturing techniques used.

By emphasizing why these particular cylinder heads stand out, a fuller understanding will emerge on how trucks can go the distance without requiring major upper-engine repairs.

1. Chevrolet 5.3L Vortec V8 (Gen III/IV)

The Chevrolet 5.3L Vortec V8 enjoys a reputation for being trouble-free when it comes to head gasket concerns.

Manufactured as part of the LS-family architecture, it incorporates durable cast aluminum heads and multi-layered steel gaskets, carefully engineered for proper sealing under both daily driving and heavy loads.

The engine’s robust cooling system and uniform head bolt torque specifications further protect against localized overheating and uneven expansion, primary causes of gasket breakdown in less-proven designs.

Why highlight this particular head? The 5.3L has been found in millions of Chevrolet and GMC pickups for over two decades, and there is a considerable body of experiential data from owners, mechanics, and engine builders supporting its record.

Reports of head gasket seepage or failure before 200,000 miles are exceptionally rare, a testament to both GM’s engineering and timely improvements in head casting and coolant channel placement over multiple generations.

The 5.3L’s cylinder heads also benefit from a matched coefficient of expansion with the engine block, helping maintain a consistent seal during heating and cooling cycles.

Owners often cite the minimal oil and coolant loss, absence of white smoke at startup, and continued compression integrity as indicators of a solid design.

It is worth noting that while other parts of these engines, such as lifters and camshafts, can generate headlines for potential repairs, the cylinder heads themselves stand apart as a model of dependability in the pickup space.

For anyone seeking a time-tested V8 with fewer surprises as the odometer grows, the 5.3L Vortec’s top end remains a standout reason to invest with confidence.

2. Toyota 4.0L V6 1GR-FE

The Toyota 4.0L V6 engine, known as the 1GR-FE, is widely recognized for its durability and robust engineering, which extend to its cylinder head design and head gasket performance.

Introduced in the mid-2000s and found in vehicles like the Toyota Tacoma and 4Runner, this engine has earned praise for maintaining reliable sealing even under rigorous use and extended mileage.

Its cylinder heads are made from cast aluminum, optimized with reinforced cooling channels that help manage engine temperature effectively, a critical factor in preventing head gasket degradation.

The multi-layer steel gaskets used in this engine are precision molded to fit tightly between the cylinder head and block, reducing the likelihood of leaks caused by thermal expansion and contraction.

Toyota’s focus on consistent head bolt torque and using quality materials contributes to the 1GR-FE’s reputation for resistance to gasket failure.

This engine is worth spotlighting because owners frequently report minimal coolant or oil mixing issues after 120,000 miles and beyond.

The absence of overheating problems, due in part to Toyota’s efficient cooling design, plays a significant role in preventing gasket compromise.

While some other engines from its era may develop gasket issues as a maintenance challenge, the 1GR-FE typically sustains its head seal integrity without requiring costly repairs or diagnostic headaches.

Highlighting this engine helps clarify what good gasket performance looks like in a modern pickup engine, providing a benchmark for what owners might expect when prioritizing long-term reliability in heads and gaskets.

3. Ford 5.0L Coyote V8

The Ford 5.0L Coyote V8, a mainstay in the F-150 lineup since 2011, stands out for its exceptional head and gasket reliability.

The Coyote’s cylinder heads are crafted from high-strength aluminum, designed with advanced cooling passages and flat, well-machined surfaces which enhance gasket sealing.

Ford employs multi-layer steel gaskets in this engine, a significant improvement over older composite styles, resulting in fewer reports of blowouts or leaks even as mileage accumulates.

Writing about the Coyote is important because, despite being a modern, high-revving V8 with dual overhead cams and variable valve timing, it has demonstrated remarkable resistance to failures that typically afflict more complex cylinder head designs.

Ford’s insistence on strict quality control standards, especially regarding head bolt clamping force and surface finish, further reduces the risk of gasket failure.

Owners of F-150 pickups commonly share experiences of surpassing 200,000 miles without encountering coolant in the oil, unexplained oil consumption, or white exhaust smoke all telltale signs of a solid seal between head and block.

The Coyote’s reputation is not just rooted in engineering, but in extensive real-world longevity shown by both commercial and recreational users.

Mechanics often suggest that when properly maintained, the Coyote’s heads and gaskets remain nearly trouble-free, with repair rates considerably lower than those found in earlier Ford V8s.

This reliability, coupled with strong aftermarket support and parts availability, positions the Coyote as a pillar of trustworthiness for anyone considering a long-term investment in a gasoline-powered pickup.

4. Dodge/RAM 5.7L Hemi V8 (post-2009 design)

The 5.7L Hemi V8, used in Dodge and RAM trucks, is another example of a cylinder head and gasket design that fares extremely well over high mileage. Key head design updates especially those introduced starting in 2009 included improved aluminum alloy, more precise head machining, and re-engineered cooling passages.

The Hemi’s cylinder head also uses a robust multi-layer steel gasket, an upgrade from earlier single-layer materials, specifically to combat failures that plagued some earlier models.

Focusing on this engine is relevant because the post-2009 Hemi has consistently delivered reliable performance in pickup trucks subjected to heavy towing, stop-and-go driving, and tough environmental conditions.

The combination of improved cooling, better gasket materials, and strict torque sequence procedures during assembly has all but eliminated premature leaks and blowouts associated with earlier Hemis.

Unlike many engines where increased displacement and power output often lead to head seal issues, the 5.7L Hemi has proven that smart engineering and quality components can deliver both power and durability.

Drivers and fleet operators regularly register high mileage sometimes beyond 250,000 miles, without head gasket incidents, further cementing the modern Hemi’s reputation.

Highlighting the 5.7L Hemi informs readers how design evolutions within the same engine family can drastically improve reliability outcomes and reduce long-term maintenance worries for owners.

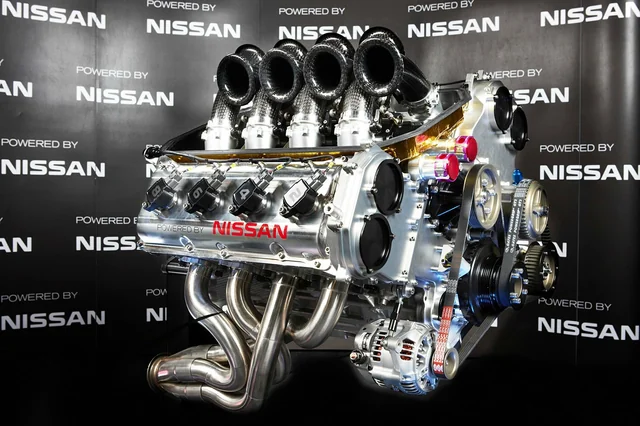

5. Nissan 5.6L Endurance V8

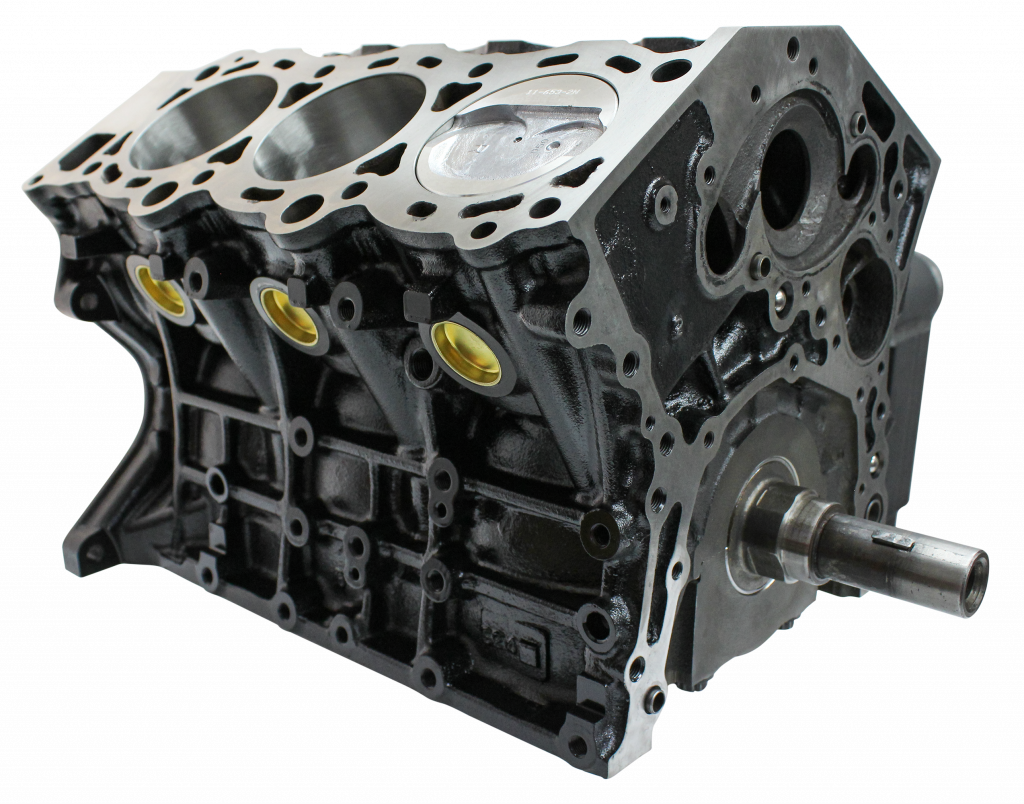

Completing this set is the Nissan 5.6L Endurance V8, a workhorse found in the Titan and earlier Armada models. This engine features a cast aluminum head, carefully matched to its iron block with high-grade steel head gaskets.

Nissan’s tight manufacturing tolerances, especially at the head-to-block interface, reduce hot spots and distortion that sometimes afflict other pickup engines.

Discussing the Endurance V8 here matters because it helps highlight the benefits of conservative engineering: rather than radical new technologies or untested designs, Nissan focused on perfecting the basics.

As a result, there are very few major head gasket complaints even at high mileage, and instances of coolant or oil mixing remain extremely rare.

The Endurance V8 avoids common pitfalls by utilizing thicker head gaskets, a proven torque-to-yield fastener strategy, and more effective coolant circulation in the upper engine.

Owners routinely note that after 150,000 miles or more, there are minimal leaks or overheating incidents stemming from the head area, fostering long-term trust in the engine’s resilience.

Examining this Nissan V8 further demonstrates how quality control and straightforward engineering choices still yield excellent reliability, especially for those seeking minimal maintenance headaches in a pickup.

5 Pickup Heads with Head Gasket Failures by 120,000 Miles

Head gasket failure is one of the most dreaded issues in any pickup truck, often signaling expensive repairs, potential engine damage, and vehicle downtime.

In some engines, design compromises, material flaws, or insufficient cooling play a significant role in the higher likelihood of these failures, especially as trucks cover more miles or face demanding use.

The cost of replacing a failed gasket can be steep, and recurring problems destroy confidence in what should otherwise be long-lasting vehicles.

This section centers on five pickup heads and engines that have become associated with head gasket trouble, most commonly surfacing by the 120,000-mile mark. Including these is crucial because it sheds light on design flaws and cautions buyers about well-documented risks.

For current and prospective owners, knowing which engines tend to develop gasket problems empowers them to plan for possible repairs or to make better-informed purchase decisions.

By examining why these pickup engines experience such acute trouble, the article hopes to clarify not just “which ones fail?” but also “why do they fail, and how might owners reduce their chances of facing these repairs?”

Understanding weaker points in head and gasket designs guides not only truck enthusiasts but also engineers and manufacturers toward building more durable engines in the future.

1. Ford 4.2L V6 Essex

The Ford 4.2L V6 Essex, used in F-150s in the late 1990s and early 2000s, has been a frequent source of head gasket failures, often well before 120,000 miles.

This track record stems primarily from early gasket material issues, plus susceptibility to coolant leaks at specific points along the head-block interface. Poor coolant passage designs aggravate the problem, frequently allowing hot spots to develop and leading to premature weakening of the gasket.

Focusing on this engine in the discussion is important because the Essex V6’s high failure rate is instructive not just for Ford loyalists but for anyone considering an older, high-mileage pickup.

Anecdotal evidence and mechanic records converge on the same story: trucks with the Essex V6 are regularly brought in for misfires, rough running, and coolant loss, which, upon inspection, are traced back to blown gaskets or warped heads.

Many owners report needing extensive repairs like resurfacing or outright head replacement, sometimes more than once in a truck’s service life.

Including the 4.2L Essex as a cautionary case makes it clear how engineering or cost-saving in one area can have large ripple effects in terms of reliability. It guides readers in understanding what weaknesses to avoid and what preventive steps might limit damage if this engine is already under their hood.

2. Chevrolet 4.3L Vortec V6 (Pre-2002)

A mainstay in various GM trucks, the Chevrolet 4.3L Vortec V6, especially in models prior to 2002, suffers from recurring head gasket complaints.

The most significant problems link to head material expansion differences, dated gasket designs, and recurring issues with casting porosity.

Premature gasket failures report as loss of coolant, external leaks, and sometimes milkiness in the oil, often occurring just as trucks approach or surpass the 100,000-mile threshold.

Examining the pre-2002 4.3L Vortec underscores how manufacturing advancements benefit reliability.

Prior to redesigns in the early 2000s, many trucks faced expensive head jobs or gasket replacements, with mechanics pointing to inherent weaknesses in the head and block interface. The relative frequency of failures also made this engine a less desirable choice in the used pickup market versus its reworked successors.

Writing about this engine advises individuals to be alert to warning signs, such as unexplained coolant loss or sludgy oil.

For DIYers and budget-minded buyers, understanding the risk factors associated with this V6 can encourage them toward either more carefully maintained examples or later models blessed with more robust gaskets and improved assembly techniques.

3. Dodge 3.7L Magnum V6

The Dodge 3.7L Magnum V6, launched in the early 2000s for use in Dodge Dakotas and Ram 1500s, quickly acquired a reputation for persistent head gasket difficulties.

One cause stems from the head’s susceptibility to warping under even moderate overheating, partly due to thin aluminum castings and insufficient coolant distribution in the original design. Consequently, many owners discovered head gasket issues either external leaks or loss of compression, well before the 120,000-mile mark.

This engine is significant to this topic because, despite its decent performance and presence across numerous trucks, its higher-than-average rate of upper engine repairs became a common complaint.

The costs, frequently running into the thousands, imposed a considerable burden on owners, especially those who relied on their pickups for daily work or hauling.

Highlighting the 3.7L Magnum helps illustrate how a promising engine can be hampered by fundamental design faults which, if unaddressed, overshadow its positive qualities.

It also reminds the reader that even within reputable brands, not every engine generation is equal savvy truck buyers should learn about such pain points before committing to a high-mileage V6.

4. Toyota 3.0L V6 3VZE

Despite Toyota’s broader reputation for reliability, the 3.0L V6 3VZE used in pickups during the 1980s and early 1990s is a well-known outlier where head gasket failures have been alarmingly common.

The problems can be traced to head gasket composition and cooling system limitations, which combined to create chronic risks at moderate to high mileage.

Many owners report head gasket issues surfacing as low as 80,000 miles, with symptoms such as overheating, white smoke, and coolant loss.

Discussing the 3VZE in this context is necessary to help clarify that even manufacturers praised for their dependability can produce engines with chronic weaknesses.

For vintage truck enthusiasts or budget-conscious buyers, this engine’s well-documented gasket issues highlight the importance of targeted preventive maintenance and the need to verify repair records when considering older Toyota pickups.

By spotlighting the 3VZE, readers gain insight into the ways material choice and cooling system design interact—and how a single persistent issue can linger across multiple years and models.

5. Nissan 3.3L VG33E V6

Completing this set, the Nissan 3.3L VG33E V6, used in Frontier and Xterra pickups from the late 1990s through early 2000s, has a notable reputation for head gasket failures.

Cast iron blocks paired with aluminum heads often develop problems due to differing rates of thermal expansion and sometimes lead to head gasket stress and ultimate failure.

Owners frequently encountered gasket trouble just prior to or just after crossing 120,000 miles, often prompted by even minor overheating events.

Detailing this engine is essential for demonstrating how success in one design era does not guarantee seamless results when dimensions or alloys change in later iterations.

Many Nissan owners were caught off guard by repair bills, as the external symptoms sometimes remained subtle until significant damage was already done.

Writing about the VG33E cautions would-be buyers and long-term owners to monitor for mild overheating events, ensure regular coolant service, and consider early replacement of tired gaskets.

It also serves as a reminder that comprehensive knowledge of an engine’s weak points is crucial for anyone looking to maximize a truck’s service life.

This article examines two contrasting categories of pickup truck engines based on their cylinder head and head gasket reliability.

It first highlights five pickup engines known for their robust cylinder heads that avoid head gasket issues, even beyond 120,000 miles.

These include the Chevrolet 5.3L Vortec V8, Toyota 4.0L V6 1GR-FE, Ford 5.0L Coyote V8, Dodge/RAM 5.7L Hemi V8 (post-2009), and Nissan 5.6L Endurance V8.

Each engine benefits from advanced materials such as cast aluminum heads, multi-layer steel gaskets, and optimized cooling designs that minimize thermal stress and maintain tight seals.

Their consistent manufacturing quality, well-planned cooling passages, and proper torque specifications reduce the risk of overheating a common cause of gasket failure, thus ensuring long-term durability.

These engines are widely praised by owners and mechanics for preserving compression integrity and avoiding coolant or oil leaks over high mileage, making them strong candidates for buyers seeking reliability and lower maintenance costs.

Conversely, the article also spotlights five engines with a history of head gasket failures frequently surfacing before 120,000 miles.

These include the Ford 4.2L V6 Essex, Chevrolet 4.3L Vortec V6 (pre-2002), Dodge 3.7L Magnum V6, Toyota 3.0L V6 3VZE, and Nissan 3.3L VG33E V6. Common issues arise from design flaws, such as inferior gasket materials, inadequate cooling passages, and thermal expansion mismatches between heads and blocks.

These factors contribute to premature gasket deterioration, overheating, and coolant leaks, which often result in costly repairs and engine damage.

Recognizing these problem engines aids owners and buyers in understanding potential risks, planning maintenance accordingly, and making informed decisions to reduce unexpected breakdowns and repair costs.

Overall, the contrasting cases reveal the engineering factors critical to gasket longevity and underscore how design improvements can significantly enhance pickup truck reliability.

Also Read: 5 Cars With Original Exhaust Systems Still Working and 5 That Rust Out Fast