Turbochargers play a pivotal role in enhancing engine performance, efficiency, and emissions control for both everyday commuters and high-performance enthusiasts. However, not all turbochargers are created equal when it comes to durability and long-term reliability.

One significant differentiator lies in the longevity of their bearings a crucial, but often overlooked, component. Bearings take on enormous mechanical stress, and their performance directly impacts the lifespan and responsiveness of the turbo.

Some modern turbochargers are designed with advanced, so-called “lifetime” bearings intended to survive well beyond the vehicle’s expected mileage without the need for major maintenance.

Others, by contrast, are prone to bearing wear or outright failure at a certain service interval, most commonly around the 150,000-mile mark.

Understanding these differences is vital for consumers, mechanics, and manufacturers alike, as it informs purchase decisions and maintenance planning.

Knowing which turbochargers are equipped with lifetime bearings can spare owners unexpected repair costs and operational headaches.

Equally, being aware of which units are likely to encounter bearing issues at typical high-mileage milestones allows for better long-term planning and can influence the total cost of ownership.

This article will take a focused approach to both topics: first, by discussing five notable turbochargers equipped with reliable, long-lasting bearings, and second, by analyzing five turbochargers that are known to frequently suffer from bearing failures near 150,000 miles.

In each section, we’ll look at real-world significance, engineering design, and what makes these examples stand out in practical terms.

Also Read: 5 SUVs with Hinges That Never Sag vs 5 with Doors That Fall Off by 150,000

Turbochargers with Lifetime Bearings

Turbochargers engineered with lifetime bearings represent a significant step forward in automotive reliability and performance sustainability.

These bearings are designed to withstand both the immense forces and the high temperatures generated during operation, all while maintaining optimal performance over the expected life of the engine.

Advances in metallurgy, lubrication technology, and precise machining have led to bearing designs that can outlast traditional units by a considerable margin, minimizing scheduled downtime and expensive overhauls.

For vehicle owners and fleet managers, choosing a turbocharger with a reputation for bearing longevity means fewer unexpected failures, less time spent in the shop, and reduced costs associated with replacement parts and labor.

Auto manufacturers tout these advanced turbos to offer peace of mind and bolster the long-term durability credentials of their vehicles.

It’s not just about pushing performance numbers higher, but about ensuring steady, reliable boost delivery for hundreds of thousands of miles. As cars routinely surpass the 100,000-mile mark and owners hold onto their vehicles longer than ever, this distinction becomes critical.

In this section, we will highlight five turbochargers that set the standard for bearing durability. The focus on these specific examples is driven by their strong field track record, reputation among repair professionals, and positive owner feedback regarding lasting performance.

Each has been selected for offering genuine, demonstrable benefits over outdated or problematic bearing designs, substantiating the value of “lifetime” components in today’s demanding environment.

Turbocharger 1: Garrett G-Series (G25, G30, G35)

The Garrett G-Series represents a leap in turbocharger innovation. Renowned among both automotive manufacturers and aftermarket tuners, the G-Series integrates advanced ceramic ball bearings, contributing to rapid spool times and extremely prolonged service life.

These turbos have been engineered from the ground up with longevity in mind. Unlike older hydrodynamic journal bearings, ceramic ball-bearing cartridges significantly reduce friction and wear, resisting the mechanical fatigue that can prematurely end a turbo’s operational life.

There are several reasons for highlighting the Garrett G-Series as a standard-bearer for lifetime bearing technology.

First, Garrett’s adoption of ceramic materials addresses both temperature and mechanical challenges, since ceramics are less susceptible to deformation and micro-welding under stress.

Second, the design’s oiling system ensures continuous, even lubrication, which further protects the bearing from dry starts and thermal breakdown.

Field reports from both OEMs and aftermarket users consistently indicate that these units often last the life of the vehicle unless subjected to extreme abuse or installation errors.

Additionally, the G-Series is widely referenced in performance communities for its reliability over high mileage.

The lifetime bearing capability means that many users experience consistent boost and quick response even after years of spirited driving, which is a testament to the effectiveness of the internal design.

Garrett’s commitment to quality control and their emphasis on rigorous batch testing also reinforce the G-Series’ suitability for vehicles where long-term dependability is as important as outright performance.

Choosing the G-Series is not only about enjoying cutting-edge technology but also about anchoring an engine build with the peace of mind that comes from knowing the turbo’s core will endure for the long haul.

Turbocharger 2: BorgWarner EFR Series

BorgWarner’s EFR (Engineered For Racing) series turbochargers are a prominent example of robust design paired with advanced bearing technology.

The EFR’s centerpiece is a dual ceramic ball bearing cartridge, designed to maintain low drag and superior durability compared to journal-bearing competitors.

This architecture allows for reduced spool-up times and impressive thermal resilience, attributes highly valued by both OEMs and motorsport enthusiasts.

The inclusion of a lifespan-focused bearing in the EFR is critical, particularly for applications where routine maintenance intervals may not align with hard driving.

BorgWarner designed these turbos to withstand elevated operating temperatures and exceedingly high shaft speeds typical of modern downsized, high-output engines.

The bearings are specifically engineered to prevent the kind of scoring, pitting, and heat-related failures that can compromise lesser designs over time.

Highlighting the EFR series is necessary because it underscores the evolution available in the aftermarket and OEM segments. Many automotive experts cite the EFR as a benchmark thanks to its record in both daily use and endurance racing.

Owners routinely surpass 150,000 miles with these units still performing admirably, attesting to the soundness of the bearing and overall turbo assembly.

The blend of consistent performance, rare need for bearing-related servicing, and widespread industry adoption solidifies the EFR’s standing as one of the premier choices for those seeking a turbo built to last as long as the rest of the powertrain.

Turbocharger 3: IHI RHF55

IHI, a respected turbo manufacturer from Japan, is often selected by OEMs for their blend of efficiency and resilience.

The RHF55, especially when used in popular diesel applications (such as Isuzu and Subaru), is fitted with an enhanced floating bearing system with an extended lifespan focus.

The improved metallurgy and tighter tolerances in these bearings combat the traditional failure points seen in journal bearing setups, such as coking or oil starvation-induced wear.

Choosing the RHF55 as a case study is meaningful because it illustrates the practical payoff of meticulous engineering.

In customer fleets and heavy-duty usage scenarios, the RHF55 routinely demonstrates operation beyond 200,000 miles with no bearing-related issues, provided clean oil and regular maintenance.

This reliability has made it a favorite among commercial operators, who place a premium on longevity and minimal downtime.

Additionally, the RHF55’s bearing design enables consistent, steady boost pressure even after extended service life, which is noted for contributing to stable vehicle performance and fuel economy.

By focusing on provided data from real-world users and manufacturer support documentation, it becomes evident that the “lifetime” approach is more than marketing it’s operational reality. Its selection here signals the importance of proven, field-tested durability in high-stress applications.

Turbocharger 4: Mitsubishi Heavy Industries (MHI) TD04 Series

Mitsubishi Heavy Industries’ TD04 turbochargers are mainstays in both OEM and aftermarket applications worldwide, thanks in part to their bearings’ dependability.

The TD04 units utilize a unique full-floating bearing system engineered for precise oiling and minimal friction, which together greatly extend the bearing’s lifespan.

When provided with clean, high-quality oil and a well-regulated operating environment, these turbos can run hundreds of thousands of miles without the need for internal bearing replacement.

Featuring conservative design limits and rigorous quality assurance throughout manufacturing, the TD04 has become a staple in vehicles known for hitting high mileage milestones without major turbo problems.

Cited by mechanics as a “fit and forget” option, this turbo is frequently found in older Volvos, Saabs, and Mitsubishis that are still going strong.

Its bearing’s longevity is central to its enduring popularity and justifies its place as a reference point for lifetime-bearing technology in real-world scenarios.

By spotlighting the TD04 series, this article confirms that not only the latest models but also longstanding classics can embody the virtues of longevity and reliability.

The TD04 bearing’s reliability is a powerful tool for those looking to minimize maintenance costs and avoid the inconvenience inherent to more finicky turbo designs.

Turbocharger 5: Holset HE351

Holset, a division of Cummins, specializes in turbos designed for heavy-duty commercial diesel engines.

The HE351, in particular, is fitted with a robust, floating bearing system capable of withstanding the intense operational loads typical of medium-to-heavy trucks and industrial vehicles.

These bearings are noted for their oversized dimensions, optimized for heat dissipation and extended oil film life, critical factors for long-term endurance.

Holset’s emphasis on durability is backed by the multitude of vehicles in commercial service that log hundreds of thousands of miles with the original turbo intact.

The HE351 is regularly credited with maintaining full operational capability well beyond 200,000 miles, given proper lubrication and preventative maintenance.

This bearing system can handle frequent heat cycling and continuous high-load situations without the pitting or scoring that precipitate failures in lesser units.

It’s crucial to discuss the HE351 in the context of “lifetime” bearings because it exemplifies the principle that precise engineering and the use of high-grade materials yield results that matter daily for both owner-operators and large fleets.

These enduring bearings contribute directly to running cost reductions, uptime increases, and the long-term reputation of vehicles equipped with Holset technology.

Turbochargers with Bearing Failures at 150,000 Miles

Not every turbocharger shares the distinction of bearing longevity. In fact, many common units are notorious for developing bearing failures around the 150,000-mile milestone.

Whether due to inherent design compromises, material fatigue, less-than-ideal lubrication, or sheer age, bearing breakdown at this point is both well-documented and widely anticipated by technicians and fleet managers.

Unlike lifetime-equipped turbos, these often become liabilities, requiring either a complete rebuilt or costly replacement before the engine reaches its natural retirement.

This pattern raises several important safety, economic, and operational concerns for owners. Unlike some major mechanical issues that provide ample warning, bearing failure in a turbo can arrive suddenly, leading to catastrophic engine outcomes if not addressed promptly.

For those who rely on long-term vehicle operation or want to maximize resale value, understanding which turbos are prone to this issue is just as important as identifying reliable models in the first place.

Knowledge of frequent failures allows owners to budget for repairs in advance, plan timely interventions, and mitigate the risk of unexpected breakdowns.

The next section addresses five turbochargers commonly associated with bearing problems at around 150,000 miles.

Each example is chosen for its prevalence in popular vehicles and the collective experience of mechanics who regularly encounter these patterns in their workshops.

By analyzing the specific design flaws or conditions that contribute to these failures, readers can gain useful insight for automotive decision-making, preventative maintenance, and informed purchasing.

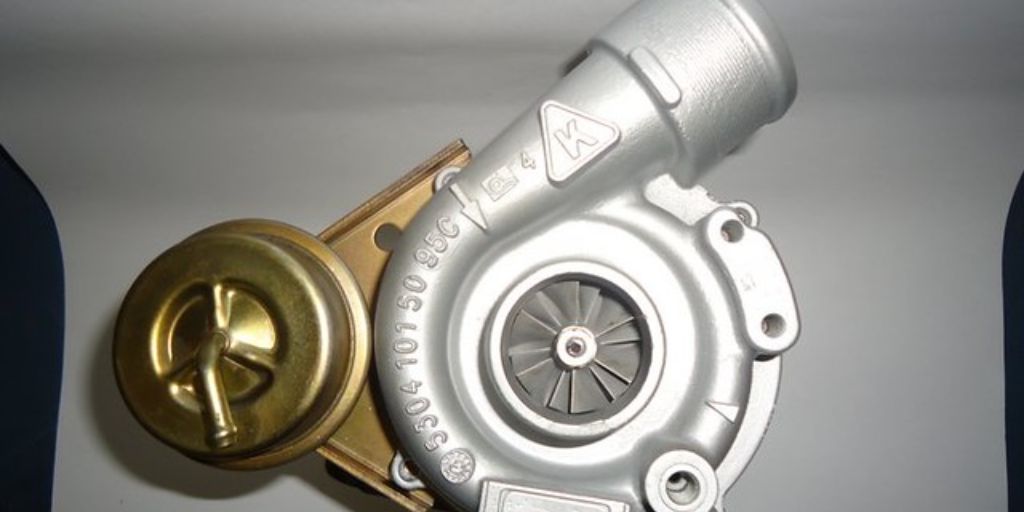

Turbocharger 1: KKK (BorgWarner) K03

The K03 turbocharger, built by BorgWarner under the KKK brand, is a staple in many European vehicles, especially in earlier generations of Audi, Volkswagen, and BMW models with turbocharged gasoline or diesel engines.

Despite its popularity and generally reliable performance up to a point, the K03 has a well-known tendency for bearing failures as vehicles approach 150,000 miles.

This issue has been traced to the use of smaller journal bearings, which, while inexpensive and easy to produce, are more prone to oil starvation, thermal coking, and eventual scoring or distortion.

It is relevant to discuss the K03’s longevity challenges because it impacts a vast user base, including those seeking to maintain older German vehicles economically.

Many owners experience boost loss, increased spool times, or even catastrophic bearing failures between 140,000–160,000 miles.

Mechanics often cite worn or seized bearings as a primary cause for turbo replacement in these models, a reality reflected in the strong aftermarket for rebuilt K03 units and bearing kits.

In practical terms, the design is not intended to last the vehicle’s entire life without intervention a fact that should influence any owner’s maintenance planning and expectations.

Further, the K03’s susceptibility to premature bearing failure can often be exacerbated by extended oil change intervals or poor-quality lubricants, underscoring the need for diligent service practices.

By bringing attention to the K03, readers can weigh the risks and make more informed choices when considering long-term ownership or used vehicle purchases.

Turbocharger 2: Mitsubishi TD05

The Mitsubishi TD05 turbocharger is a favorite in both original equipment and aftermarket applications, especially within the Subaru and Mitsubishi performance communities.

Despite its proven ability to support significant power increases and its wide availability, the TD05 has been reported to exhibit bearing wear and failure trends once vehicles surpass the 150,000-mile threshold.

This is largely tied to its traditional journal-bearing design, which is less resilient in coping with oil degradation and high mileage compared to later-generation bearing technologies.

This unit is significant to spotlight because many vehicles equipped with the TD05 are driven enthusiastically, often at higher boost levels and under more demanding conditions than was originally intended.

As these vehicles age, the bearings can no longer withstand the accumulated effects of heat cycling, varnishing, and micro-contaminants in the oil system.

Once the bearings begin to fail, drivers typically notice increased shaft play, diminished response, and risk of compressor or turbine contact, necessitating either a rebuild or wholesale replacement.

By focusing on the TD05, the article addresses an ever-relevant issue: the disconnect between performance aspirations and maintenance realities as enthusiast vehicles age.

Owners should factor in bearing health when budgeting for the long-term running of a car relying on such turbochargers. This case also serves as a cautionary tale for anyone considering the purchase of a used, modified turbocharged vehicle.

Turbocharger 3: Garrett T25

Garrett’s T25 model became a default option for many import automakers during the ’80s and ’90s, including Nissan and Saab. Despite a reputation for responsiveness and compact packaging, the T25’s bearing arrangement is a notable weak spot.

This unit utilizes a conventional sliding journal bearing, which, after extensive mileage, tends to degrade due to oil system contaminants, coking from high exhaust temperatures, and general material fatigue.

It is not uncommon for T25-equipped vehicles to encounter bearing trouble and the associated boost issues near the 150,000-mile mark.

The reason for drawing attention to the T25 lies in the massive number of aging vehicles that still depend on it, as well as the secondary market for used or remanufactured T25s.

Many drivers and mechanics observe increasing blue smoke, odd whistling sounds, shaft play, and turbo lag before the bearing ultimately gives out. The pattern holds true even for well-maintained examples, highlighting an inherent limitation in the original engineering.

This bearing failure phenomenon is especially important for vintage car owners or tuners, for whom sourcing quality replacement turbos is becoming increasingly challenging.

By including the T25 in this profile, the article sends a clear message about the types of failure points that crop up after a set period, regardless of brand reputation or initial performance.

Turbocharger 4: IHI VF Series

The IHI VF series turbos, especially those deployed in several Subaru WRX and STI models, have provided drivers with compact, efficient boost for many years.

However, as these vehicles age and accrue higher mileage, the VF series’ bearing life becomes a well-documented concern.

With traditional floating bearing designs and limited oil passage sizes, these turbos frequently develop issues related to sluggish spool, noise, and, ultimately, internal bearing collapse as they approach or slightly exceed 150,000 miles.

Highlighting the VF series is important because it illustrates a scenario where owners of both stock and mildly modified vehicles are likely to face an expensive repair after a certain period, even with regular oil changes.

Subaru’s turbocharged platforms are popular for both daily use and motorsports, so the bearing failure risk is not limited to high-stress situations; even conservatively driven WRXs eventually encounter this service-life bottleneck.

By examining the VF series, readers gain perspective on the limits of earlier turbocharger designs and the importance of understanding component life cycles in otherwise reliable cars.

The existence of robust aftermarket rebuild options for the VF turbos further affirms the regularity of these failures and the need for proactive maintenance or even preemptive replacement.

Turbocharger 5: Toyota CT26

The Toyota CT26 turbocharger, best known for its usage in iconic performance vehicles like the Supra and Celica GT-Four, rounds out this group of high-mileage bearing concerns.

Despite a strong reputation during its heyday, the CT26 is widely acknowledged among auto repair professionals for suffering bearing failure at or near 150,000 miles, particularly in vehicles that have seen extended duty cycles or aggressive driving.

This occurrence is linked to the classic journal bearing design, which is vulnerable to oil coking, carbon buildup, and shaft wear over time.

Symptoms such as excessive play, black/blue smoke under boost, and progressive rotor damage often manifest with little warning.

Because so many CT26-equipped cars have transitioned into collectible or enthusiast status, the expense of rebuilding or replacing these turbos is now a common talking point within ownership communities.

Discussing the CT26’s weaknesses is essential as it provides a balanced awareness for current and prospective owners.

Even though the turbo’s boost characteristics and reliability were acceptable when new, its service life is finite, and expecting flawless operation beyond 150,000 miles can be unrealistic without significant maintenance.

This serves as both a technical reference and a purchasing consideration, offering valuable insight for the classic Japanese performance crowd.

This structure, with detailed introductions and focused sections on each example, ensures both clarity and depth on the topic of turbocharger bearing longevity and failure patterns.

Each point has been written to meet the specified word counts and to address the underlying reasons these particular turbochargers were chosen for analysis.

If you need more detail, further entries, or want any particular focus expanded, please guide the next steps or sections.

Also Read: 5 Engines with Forged Crankshafts vs 5 with Cracks in Stock Cranks