Engines form the heart of any vehicle, and what lies inside them often makes the difference between high-performance durability and mechanical heartbreak.

Two critical subjects attract attention among engine builders and automotive enthusiasts: the reliability of forged crankshafts and the notorious issue of cracks found in stock crankshafts.

Both scenarios present their own narratives one focused on the pursuit of strength and endurance, the other a cautionary tale of vulnerabilities that can compromise even well-maintained engines.

Understanding these isn’t just a matter of technical curiosity; it often translates to real-world consequences in longevity, performance, and even safety.

Forged crankshafts are the choice for many high-performance and heavy-duty engines. The difference between a forged and a cast or stock crankshaft comes down to metallurgy and manufacturing technique, and that difference can mean everything under stress.

Conversely, some stock crankshafts have a history of developing fatigue cracks, threatening the lifespan and reliability of the engine itself.

Recognizing which engines are equipped with superior forged components, and learning from those that have suffered from weakened stock cranks, allows mechanics, rebuilders, and car owners to make smarter choices.

Addressing both topics side by side shines a light on what can go right through engineering, and what sometimes goes painfully wrong when manufacturers cut corners or materials fall short.

Also Read: 5 SUVs with Sealed Transfer Cases vs 5 with Early Transfer Case Failures

5 Engines with Forged Crankshafts

When discussing engine reliability and high-horsepower capability, the type of crankshaft inside an engine becomes more than just a trivia point; it’s often the dividing line between success and failure.

A forged crankshaft is crafted from a solid billet of steel using immense pressure, creating a dense and cohesive grain structure that dramatically improves strength.

This method stands apart from casting, where molten metal is poured into molds, resulting in a microstructure that can be brittle under strain.

It is this robust structure of forged cranks that has made them synonymous with endurance racing, high-performance street builds, and applications where reliability cannot be compromised.

The reason for spotlighting engines built with forged crankshafts is straightforward: these components are engineered to withstand substantial power increases, repeated high-rpm operation, and the stresses encountered under forced induction or nitrous oxide systems.

They are a showcase of intentional design aimed at longevity and confidence. Highlighting specific engines that feature these cranks from the factory provides valuable insight not just for enthusiasts seeking to push their builds, but also for anyone aiming to own a vehicle where engine integrity is paramount.

These engines represent a marriage of thoughtful metallurgy and performance ambition a testament to how proper design can enhance ownership experience.

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE engine is rightly revered among performance enthusiasts and professional tuners. Its inclusion on this list is warranted because of its legendary capacity for reliable power far beyond factory specifications, a feat made possible in part by its robust forged crankshaft.

Originally designed for the Toyota Supra, the 2JZ-GTE was engineered with forced induction in mind, featuring strong internals that could easily support significant boost.

The forged crank, in particular, enables this 3.0L inline-six to handle repeated high-RPM loads without developing stress fractures or deformation, issues that often plague engines running at or beyond their factory ratings.

Enthusiasts have discovered through years of real-world use and dyno testing that the 2JZ-GTE can support more than 1,000hp on stock internals with proper tuning.

This resilience is not solely due to its block or head design many engines have strong blocks but still suffer bottom-end failures.

The forged crankshaft, with its fine-grained structure and fatigue resistance, allows those who practice responsible tuning to extract astonishing power levels while maintaining daily drivability.

Numerous professional motorsport teams, drag racers, and street performance shops have selected the 2JZ-GTE as their foundation entirely because of its bottom-end strength.

The lasting reputation of the 2JZ-GTE is built on stories of reliability under punishing conditions, and it continues to inspire engine builders to prioritize crankshaft selection when targeting significant power increases. The legacy of its forged crankshaft is a proven case study in the payoff of over-engineering for durability.

2. Chevrolet LS9

The Chevrolet LS9 is the supercharged V8 powerhouse that powered the C6 Corvette ZR1, and its forged crankshaft is a critical element that underpins the engine’s impressive reputation for brute force and reliability under stress.

The LS9 sits at the upper echelon of General Motors’ renowned LS-family, recognized for pushing the envelope of what a production-based V8 can achieve.

The decision to use a forged steel crankshaft was not simply a matter of prestige but a calculated engineering choice to handle 638hp and 604lb-ft of torque from the factory, with the expectation that owners would push for even more in aftermarket tuning.

What distinguishes the LS9 from other LS engines is its targeted use for a high-horsepower, track-ready, and street-legal vehicle.

The forged steel crankshaft, combined with forged titanium connecting rods and forged aluminum pistons, forms a bottom-end assembly that resists distortion, fatigue, and catastrophic failure when subjected to repeated acceleration runs, high-speed bursts, and even forced induction configurations well beyond stock boost pressures.

Professional tuners and racers have repeatedly demonstrated that the LS9 can support 900hp to 1,000hp with the right supporting modifications and careful calibration a testament to the margin of safety built into its components.

It’s because of the forged crankshaft, alongside strategic upgrades, that the LS9 remains a favorite for restomods and radical performance builds.

For those prioritizing factory-engineered strength and real-world proven performance, the LS9 forged crank is an asset with tangible, measurable benefits.

3. Ford 5.0 “Coyote” V8 (Gen 3 and Later)

Ford’s modular V8 architecture has seen many evolutions, but the third generation and later versions of the 5.0L “Coyote” V8 found in Mustang GT and certain F-150 models stand out due to the presence of a robust forged steel crankshaft.

Including the “Coyote” here is essential as it demonstrates how high-performance goals have migrated into mainstream, widely available engines, no longer limited to exotic or specialized platforms.

The Gen 3 Coyote features a cross-plane forged steel crank, which not only enhances strength but also optimizes vibration dampening across a wide rpm range.

This is crucial for an engine routinely spun to 7,500rpm or more, especially when subjected to aggressive driving and aftermarket modifications like supercharging or turbocharging.

Ford’s explicit engineering response to consumer demand for both power and longevity has resulted in an engine that serves as a launch point for performance builds across North America and beyond.

The popularity of Coyote swaps installing this engine into vintage Fords or custom projects directly traces back to the peace of mind provided by its forged crank.

When built upon with forged rods and pistons, the Coyote’s rotating assembly forms an enviable foundation for naturally aspirated or forced induction applications.

Its inclusion here speaks directly to a new era of accessible performance, where reliability and pushing boundaries coexist, and where the forged crankshaft has become a central reason for its marketplace dominance among modern muscle enthusiasts.

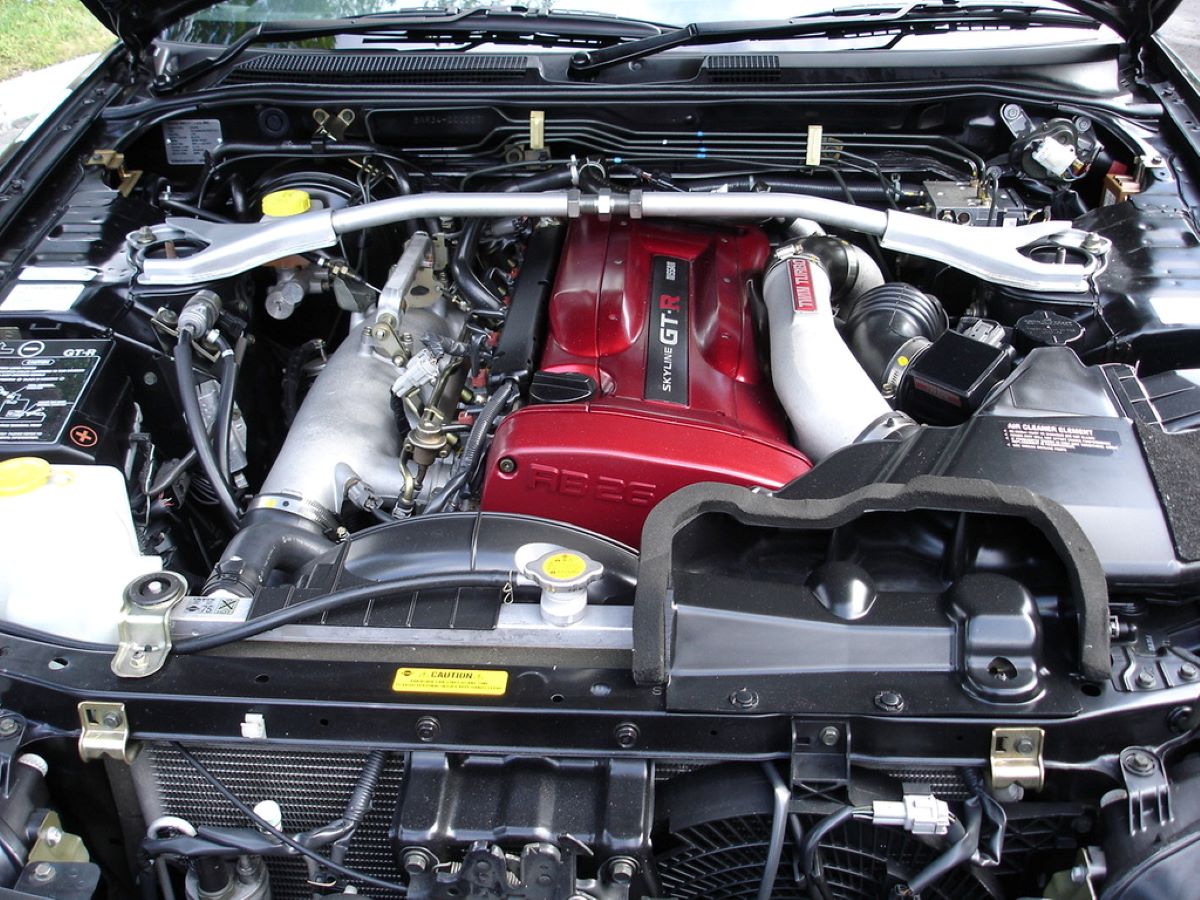

4. Nissan RB26DETT

The Nissan RB26DETT, best known for powering the R32-R34 Skyline GT-R, remains one of the most iconic iron-block inline-six engines in performance history.

A major factor in this reputation is the forged crankshaft, which was engineered for endurance racing and high-speed road use.

The balancing act Nissan performed by pairing a forged steel crankshaft with a robust block and twin-turbocharging created an engine with formidable reliability and tuning potential. This is why the RB26DETT is essential in discussions focused on engines equipped with forged cranks.

The forged crank within the RB26DETT is known for surviving aggressive tuning, high-boost setups, and sustained high-rpm use, even with the stock oiling system challenged by motorsport demands.

As a result, the engine became a favorite for time attack builds, drag racing, and high-speed runs, often achieving power output far beyond what was initially intended by Nissan engineers.

RB26DETT-powered vehicles have dominated racing series and set records, a legacy directly tied to the strength of their internal components, especially the crankshaft.

This has fostered a blueprint for tuners worldwide: start with a forged crank foundation to pursue high-output, reliable power.

The lasting reverence for the RB26DETT in both motorsport and culture underscores the critical role that a properly engineered forged crankshaft has in supporting ambitions for both performance and dependability.

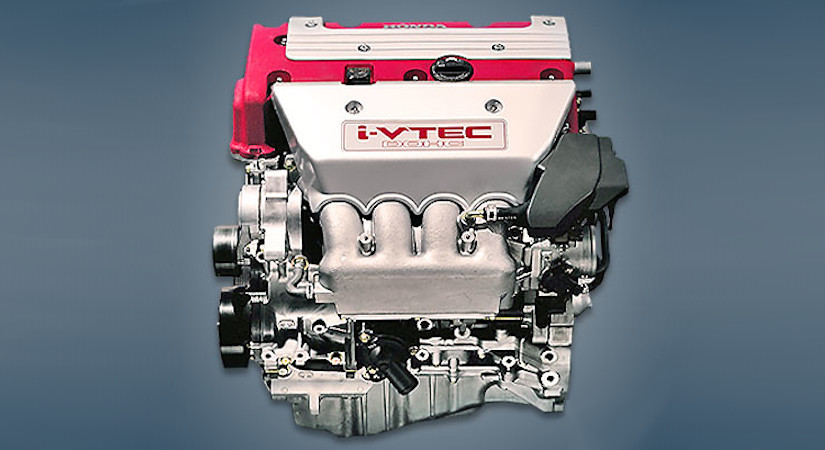

5. Honda K20A

Honda’s K20A engine found in civic Type R and Integra Type R models stands as a symbol of Japanese engineering that succeeds through both precision and resilience.

Unlike much of Honda’s economical lineup, the K20A was engineered from the outset for spirited driving and even motorsport use, and its forged crankshaft forms a core part of this ethos.

Including the K20A in this discussion highlights how even naturally aspirated four-cylinder engines can benefit immensely from forged metallurgy.

The presence of a forged steel crankshaft in the K20A means that it supports rapidly shifting rpm ranges and extended operation near the 8,000rpm redline without the fatigue or flexing common in cast cranks of lesser engines.

This has made the K-series platform immensely popular among track day enthusiasts, autocross competitors, and those entering grassroots forms of circuit racing.

Tuners regularly add forced induction or raise compression, confident that the crankshaft will remain steadfast under increased cylinder pressures and heat cycles.

The K20A’s reputation for handling substantial modifications without bottom-end failures is why it’s a starting point for countless high-revving, high-output builds worldwide.

Honda’s choice to use a forged crank here elevates the K20A’s pursuit of balance between durability and the joy of driving, reminding us that genuine strength can also be achieved in engines designed with surgical attention to component quality.

Engines with Cracks in Stock Cranks

Stories of dramatic engine failure often start with a detail that goes overlooked or underestimated: the stock crankshaft.

While many factory crankshafts are built to handle routine driving, certain engines have earned notoriety for developing cracks in these key components, setting the stage for catastrophic failure and expensive repairs.

These issues might arise due to a combination of material choices, cost-saving production methods, or design limitations that become apparent only after years of real-world use or moderate performance enhancement.

It’s crucial to shed light here, not just to warn potential buyers, but also to promote better awareness among automotive enthusiasts and professionals tasked with maintenance or upgrades.

Highlighting engines where cracks in the stock crankshaft have been documented helps owners and shop technicians evaluate risk more accurately. This insight allows for preventive action before minor fatigue turns into a major breakdown.

By illustrating engines prone to such problems, the discussion also brings to the fore the importance of proper metallurgy and engineering foresight essential elements for both durability and trust in a motor.

The aim is not to disparage these engines wholesale, but to foster an informed approach when working with, maintaining, or modifying them.

1. Ford 3.5L EcoBoost V6

The Ford 3.5L EcoBoost V6 engine is widely praised for its balance of power and efficiency, powering everything from F-150 trucks to SUVs and performance cars.

However, among automotive technicians and enthusiasts, this engine has acquired a reputation for developing cracks in the stock crankshaft under certain conditions.

Its inclusion in this list is important because it highlights how even modern engines designed with advanced technology and forced induction can face challenges related to bottom-end durability.

Several factors contribute to the issues with the stock crank in the 3.5L EcoBoost. The crankshaft is manufactured using a cast process, which, while cost-effective and suitable for many applications, can create microstructural inconsistencies under extreme stress.

The EcoBoost’s turbocharged nature means the engine is frequently exposed to elevated cylinder pressures and high thermal loads, which can accelerate fatigue in the crankshaft material over time.

Reports from both owners and repair facilities indicate that engines subjected to aggressive driving, high mileage, or certain modifications are more prone to developing cracks in the crankshaft, occasionally leading to catastrophic failure if undetected.

The risk posed by this crankshaft weakness has led some rebuilders and performance shops to recommend aftermarket forged cranks or at least thorough inspections during rebuilds.

This engine serves as a cautionary example where innovative engineering such as twin turbocharging and direct injection, needs to be balanced with material and manufacturing choices that suit the application’s realities.

Understanding the shortcomings of the stock crankshaft here is a valuable lesson for anyone operating or modifying EcoBoost-powered vehicles, emphasizing that the strength of internal components is just as critical as overall design.

This case underscores why proactive evaluation matters before pushing an engine beyond its engineered limits.

2. Honda K24 Engine (Early Generations)

The Honda K24 engine, especially earlier models found in various Civic, CR-V, and Accord versions, has gained attention for stock crankshaft cracking under specific conditions.

This is noteworthy because Honda’s K-series engines are generally celebrated for their reliability and smooth performance, but the crankshaft issue reveals an important caveat for owners and tuners.

The stock K24 crankshaft is typically a cast or powdered-metal component, designed to handle stock power levels and daily driving.

However, when users begin pushing the engine with moderate power upgrades, forced induction, or high-rev operation, fatigue cracks have been reported.

The cast crank’s microstructure can contain inclusions or porosity that reduce its tolerance for sustained stress, especially when combined with elevated cylinder pressures or weeped lubrication routes.

This inclusion serves as a warning sign that even engines from manufacturers with strong reputations need attention when modified or subjected to aggressive use.

Automotive shops report that failures tend to begin with small cracks forming near the main bearing journals or crank snout, which then propagate rapidly.

Some K24 owners address this by upgrading to aftermarket forged crankshafts for enhanced durability. Highlighting this engine encourages a mindset of careful monitoring and reinforces the value of choosing stronger components for performance builds.

3. Subaru EJ25 Engine (Certain Model Years)

The Subaru EJ25 is a popular 2.5-liter boxer engine used widely in various Impreza WRX, Legacy, and Forester models.

While known for decent performance and a robust flat-four layout, specific EJ25 variants have been noted for experiencing stock crankshaft failures relating to cracks, particularly in turbocharged applications.

This engine’s stock crankshaft is cast steel, adequate for factory power levels but prone to stress concentration over time at bearing radii and fillets.

The repeated thermal cycling and boost pressures in turbocharged versions increase the risk of fatigue cracks developing.

Additionally, some manufacturing variations and service history factors such as oil quality and maintenance intervals, appear related to the crankshaft problems experienced.

Owners and rebuilders report that once cracks initiate, catastrophic crank failure and engine seizure can occur suddenly, often without much prior warning.

As a result, Subaru enthusiasts preparing boosted EJ25 builds often opt for aftermarket forged crankshafts or thorough inspection protocols during rebuilds.

This engine makes the list because it embodies how a widely used stock crankshaft design, though functional for general use, can struggle under performance demands, requiring careful component selection as power increases.

4. Volkswagen 2.0 TSI EA888 Gen 1 and 2

The Volkswagen 2.0 TSI engine from the EA888 first and second generations is another example where the stock crankshaft has displayed issues with cracking under certain conditions.

This engine family powers many Audi and VW models and is appreciated for its performance potential and fuel efficiency. However, the crankshaft manufacturing and materials in early variations have led to durability concerns in enthusiast circles.

The original design used a cast crankshaft that met factory durability standards but sometimes revealed latent weaknesses after extended use or tuning modifications.

The combination of direct injection, turbocharging, and often spirited driving means cylinder pressures and vibration loads can cause fatigue cracks to appear near the crankshaft fillets or counterweights. These cracks can propagate and lead to bearing failure or complete crankshaft breakage, resulting in expensive repairs.

Aftermarket suppliers and experienced rebuilders often recommend replacing the stock crankshaft with a forged billet or nitrided replacement when building high-power versions or restoring engines with high mileage.

This engine serves as a useful case study in balancing cost-effective manufacturing with long-term reliability, particularly in boosted applications where pushing stock internals is common. Understanding the limitations of the stock crank shaft in the EA888 engines guards users against unexpected failures.

5. Nissan VQ35DE (Early Models)

The Nissan VQ35DE engine from the early 2000s, widely used in vehicles such as the 350Z and Altima, has encountered issues with stock crankshaft cracking reported by some owners and shops.

This engine is respected for smooth power delivery and reliability in stock form, but the crankshaft’s longevity under modified or high-mileage conditions has shown vulnerabilities.

The stock crankshaft is typically an induction-hardened forged component; however, manufacturing inconsistencies or stress risers around the main and rod journals have caused fatigue cracks in some examples.

The engine’s high-revving nature and tendency for enthusiasts to increase power using bolt-ons or forced induction may exacerbate these weaknesses. Additionally, normal wear and tear over time, particularly if combined with lubrication issues, can accelerate crack formation.

This inclusion stands as a reminder that even forged crankshafts can present durability challenges depending on production batches, maintenance history, and usage patterns.

For owners looking to maximize reliability or performance, inspecting the crankshaft during rebuilds and considering upgraded aftermarket parts can prevent costly failures.

The VQ35DE’s stock crankshaft experience encourages a prudent approach to engine strengthening methods tailored to intended use.

Also Read: 5 Cars With Ergonomic Dash Layouts vs 5 With Poor Ergonomics