For many American drivers, the V8 engine represents more than raw power it’s a trusted companion for the long haul. While downsized turbo engines and hybrids are gaining popularity, the V8 still holds strong in trucks, SUVs, and muscle cars.

However, not all V8s are built equally. Some shine early but fall apart before 150,000 miles. Others just keep going, delivering consistent performance with simple maintenance. Here are seven V8 engines that have built reputations for reliability, often lasting well beyond the 150K mark.

1. GM 5.3L V8 (Vortec and Ecotec3)

Found in everything from the Chevy Silverado and Suburban to the GMC Yukon and Sierra, the 5.3-liter V8 has become one of the most proven engines in the U.S. Whether in its older Vortec form or the newer direct-injection Ecotec3 variant, this engine consistently delivers reliable service over the long haul.

With millions produced and widespread availability of parts, it’s common to see these engines running strong at 200,000 to 300,000 miles. It’s especially popular among owners who need dependable power for towing, long commutes, or utility work.

The Vortec 5.3L V8 LMG was an engine developed by General Motors specifically for full-size SUVs. With a displacement of 5.3 liters in a V8 configuration, the LMG was part of the Vortec Generation IV Small Block engine family, later succeeded by the EcoTec3 Generation V Small Block engines.

The LMG is essentially the same as the 5.3-liter V8 Vortec LMF but comes equipped with Active Fuel Management (AFM)/Cylinder Deactivation technology.

It was produced for GM’s 2006–2014 GMT900-based SUVs, which include the Chevrolet Tahoe and Suburban, as well as the GMC Yukon and Yukon XL. When the 2015 models of the Tahoe/Suburban and Yukon/Yukon XL were introduced, the LMG was replaced by the all-new 5.3-liter V8 EcoTec3 L83.

The LMG is a technically advanced small-block V8 designed to offer a strong balance of power, torque, and efficiency, making it well-suited for full-size trucks and SUVs.

Its variable valve timing enhances both performance and fuel efficiency while also helping to reduce emissions. Additionally, GM’s Active Fuel Management system contributes to improved fuel economy in light-load driving scenarios. The engine is also E85-capable, allowing it to run on ethanol-based fuel.

Across all applications, the LMG is paired with GM’s Hydra-Matic 6L80 six-speed automatic transmission for smooth and efficient power delivery. Improved airflow plays a key role in the 5.3L’s performance, with an optimized intake path and improved exhaust port design contributing to greater efficiency and emissions control.

The engine highlights further showcase the LMG’s engineering excellence. The cylinder block and rotating assembly were designed using math-based tools and data from GM’s racing programs, resulting in a lightweight yet rigid structure that minimizes vibration and enhances smoothness.

Its deep-skirt design supports six-bolt, cross-bolted main-bearing caps to limit crank flex and stiffen the engine. The structural oil pan adds further rigidity, while the heavy-duty timing chain, validated for 200,000 miles, ensures quiet operation and long-term durability.

The high-flow cylinder heads feature cathedral-shaped intake ports that promote exceptional airflow, supporting high-rpm horsepower and strong low-rpm torque. The aluminum alloy heads use large intake and exhaust valves made from materials capable of meeting the demands of a truck engine. The intake and D-shaped exhaust ports are optimized for excellent high-rpm breathing.

The camshaft phasing system with variable valve timing allows the engine to adjust valve timing based on driving conditions, maximizing performance, drivability, and fuel economy. At idle, the cam remains fully advanced for smooth operation, while at high rpm it may retard timing to increase airflow and horsepower.

Under light loads, the timing can be retarded across the rev range to boost fuel efficiency. Flex-fuel capability allows the LMG to use E85, a clean-burning fuel consisting of 85% ethanol and 15% gasoline, which reduces greenhouse gas emissions and can be sourced from renewable materials like corn, wheat stalks, and agricultural waste.

GM’s Active Fuel Management technology improves fuel economy by around 6% under federal testing and potentially more during real-world conditions by deactivating four of the engine’s cylinders under light loads. The transition back to full power takes less than 20 milliseconds and is nearly undetectable to the driver.

Advanced electronic throttle control (ETC) eliminates the mechanical link between the accelerator pedal and the throttle body, using sensors and the engine control module to regulate throttle position precisely, resulting in smoother and more responsive performance.

Quiet exhaust manifolds, made from durable cast nodular iron, improve durability, sealing, and noise reduction. They feature triple-layer stainless steel heat shields that limit heat transfer, helping the engine reach operating temperature quickly while reducing engine bay heat.

Finally, the LMG is equipped with a sophisticated 58X ignition system, featuring a crankshaft position encoder that ensures precise ignition timing throughout the entire operating range.

This system allows the engine control module to adjust timing with high accuracy, optimizing both power output and fuel economy while also delivering consistent engine starts in all conditions. Overall, the Vortec 5.3L V8 LMG combines advanced engineering, efficiency technologies, and durable construction, making it a well-rounded powerplant that served GM SUVs effectively throughout its production years.

Also Read: 5 Forgotten Family Cars That Last vs 5 Bestseller Family Cars With Issues

2. Toyota 4.7L i-Force V8

Toyota’s 4.7L i-Force V8 powered the first-generation Tundra, Sequoia, and Lexus GX470, earning a reputation for nearly bulletproof reliability.

While it didn’t dominate on horsepower charts, this V8 was overbuilt and under-stressed, making it a favorite among drivers who value longevity over flash.

Routine maintenance especially replacing the timing belt at recommended intervals helps these engines routinely surpass 250K miles. They’re particularly popular in used truck markets where reliability is more important than the latest tech.

The 2UZ-FE is a 4.7-liter, 90º V8, 32-valve DOHC gasoline engine manufactured at Toyota’s engine plant in Tahara, Aichi Prefecture, Japan, as well as the company’s American TMM plant in Alabama.

During its design phase, Toyota studied American truck manufacturing practices and opted for a high-strength cast-iron block rather than an aluminum one. This decision was made to enhance durability since the engine was specifically intended for low-revving, high-torque applications in pickups and SUVs.

With a displacement of 284.6 cubic inches, the 2UZ-FE incorporates aluminum DOHC cylinder heads, multi-port fuel injection, four valves per cylinder with bucket tappets, four one-piece cast camshafts, and a cast aluminum intake manifold and runner.

In 2005, the engine’s valvetrain was upgraded to include cam-phasing through Toyota’s VVT-i (Variable Valve Timing – Intelligent) system, which improved overall performance.

Power output initially varied slightly depending on the application; when it first entered the U.S. market, the engine produced 240 horsepower with 315 lb-ft of torque. In its later versions equipped with VVT-i, the 2UZ-FE delivered an impressive 282 horsepower and could generate up to 325 lb-ft of torque.

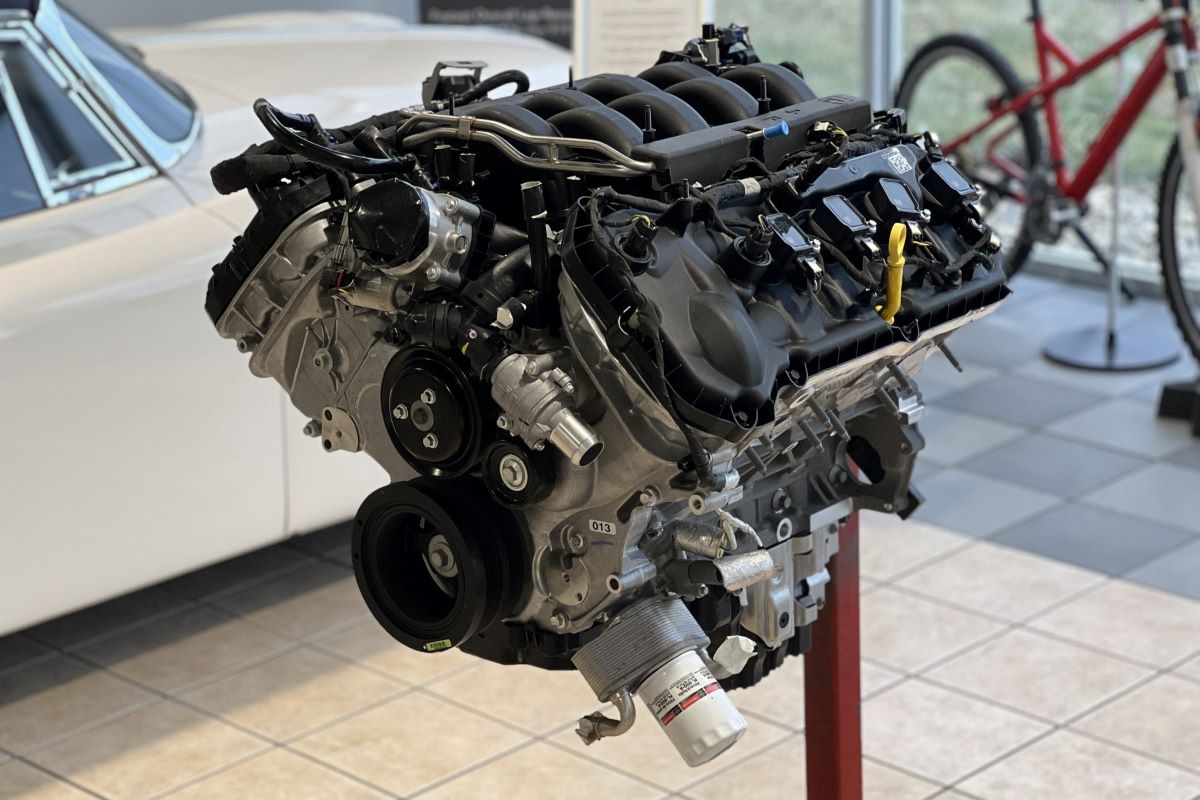

3. Ford 5.0L Coyote V8

The Coyote 5.0-liter V8, introduced in the Mustang GT and F-150 in 2011, is a rare modern V8 that balances high performance with impressive durability.

Known for its high-revving character and robust design with dual overhead cams and variable valve timing, it handles abuse better than most.

Whether under the hood of a track-day Mustang or a hard-working F-150, the Coyote has proven it can cross 200,000 miles with minimal issues if properly maintained especially with regular oil changes to support its high-RPM capability.

Ford vs. Chevy has long been the automotive equivalent of two heavyweight boxers trading blows in the ring. This rivalry has spanned decades, driving constant innovation and pushing the boundaries of everything from truck towing capacity to pony car performance.

In the 1990s, Ford sought an edge with its new line of modular V8 engines. However, when the pony car wars reignited with the reintroduction of the Chevy Camaro in 2010 and the Dodge Challenger in 2008, the Mustang responded with a new powerhouse: the Ford Coyote V8 engine family.

If you’ve followed anything about Velocity’s modernized Ford classics, or simply kept up with the Ford Mustang over the last thirteen years—you’ve undoubtedly heard of this engine. The Coyote V8’s evolution is a story of innovation and performance gains, culminating in the Gen IV version introduced with the all-new sixth-generation Mustang.

The Ford Coyote V8 traces its lineage back to the modular engine family that debuted in 1991, essentially serving as its second generation. These modular engines replaced the pushrod V8s that had powered nearly every Mustang since 1967, with the exceptions of the 1974, 1980, and 1981 model years. The 4.6L modular engine came in three versions: 16-valve, 24-valve, and 32-valve, appearing over a span of fourteen years.

The 16-valve version was offered between 1996 and 2004, producing between 215 hp and 265 hp depending on improvements. From 2005 through 2010, the 24-valve version delivered between 300 hp and 315 hp, while the 32-valve variant powered the SVT Cobra and Mustang Mach 1 from 1996 to 2004.

As competition from the Chevrolet Camaro and Dodge Challenger intensified, Ford recognized the need for a more powerful engine for the Mustang GT. This is where the Coyote V8 came into play.

Debuting for the 2011 model year, the Coyote V8 delivered the Mustang GT the performance boost it needed to take on the 426-hp Camaro SS and the 375-hp Challenger R/T.

Built with an all-aluminum construction and a 32-valve DOHC setup, the Coyote stood apart thanks to its Twin Independent Variable Cam Timing (Ti-VCT), a feature that optimized both performance and efficiency. Another defining aspect of its design was its 5.0L displacement, a nod to Ford’s heritage that allowed the Mustang to once again wear the iconic “5.0” badge after a fifteen-year absence.

Beyond powering factory models like the Mustang and F-150, Ford also offers the Coyote as a crate engine, making it a favorite for custom builds. Since its launch, the 5.0L Coyote V8 has evolved through four distinct generations, each delivering significant horsepower gains, while also inspiring other performance variants with larger displacements.

4. Chrysler HEMI 5.7L V8

Chrysler’s 5.7L HEMI V8 brought real muscle back into the American mainstream when it launched in the early 2000s. It’s been powering Ram trucks, Dodge Chargers and Challengers, and Jeep Grand Cherokees ever since.

While earlier versions had a few issues, including potential lifter problems with the MDS system, later models are much improved.

Properly maintained HEMIs routinely cross the 150,000-mile threshold with ease. Many owners report their engines still pulling strong even after 200K miles, especially in highway-driven Rams and muscle sedans.

Chrysler’s Hemi series of V8 engines stands as an enduring icon of American automotive engineering, with a legacy dating back to the 1950s and continuing strongly into the present. After decades of evolution, the Hemi made a major comeback in 2003 as a redesigned, modern version, first appearing in the Dodge Ram truck.

The name “Hemi,” trademarked by Chrysler and often stylized in all caps, highlights the engine’s signature feature: its hemispherical combustion chambers. This domed design enhances the flow of gases within the chamber, resulting in improved efficiency and greater power output.

Over the years, the Hemi V8 has taken on several forms, but one standout is the 5.7-liter version of the third-generation engine. This variant has powered a wide array of models from the early 2000s through today, showcasing its versatility and performance across the lineup.

The 5.7L Hemi earned recognition by making the Ward’s 10 Best Engines list from 2003 through 2007 and once again in 2009. Although it is now in the process of being phased out, this engine remains an integral part of Stellantis’ heritage and continues to drive select vehicles currently on the market.

5. Lexus 4.6L 1UR-FE V8

This 4.6-liter V8, found in vehicles like the Lexus GX460 and LS460, blends quiet performance with bulletproof construction.

A successor to the beloved 4.7L i-Force, it brings more power while retaining Toyota’s famous reliability.

While it’s more common in luxury sedans and premium SUVs than work trucks, it can still handle off-road use and long-distance travel with ease.

With routine oil changes and minimal abuse, these engines often last well into the 200,000-mile range especially in Lexus models known for conservative driving. One of the defining features of the 1UR-FE engine is its new aluminum alloy cylinder block equipped with spiny-type cast iron liners, replacing the traditional cast iron block used in the 2UZ.

This updated block maintains the same 90-degree ‘V’ angle, a 105.5 mm bore pitch, and a 21.0 mm cylinder bank offset. The bore size remains at 94.0 mm, while the stroke was slightly shortened to 83.0 mm. Additionally, the engine incorporates a new forged steel crankshaft that uses only six balance weights, compared to the eight found in its predecessor.

This reduction slightly compromises operational smoothness, so Toyota countered the issue by equipping the 1UR crankshaft pulley with a torsional rubber damper to minimize noise and vibration. The engine also features forged connecting rods, aluminum pistons with a resin coating, and four oil jets within the cylinder block to cool the pistons with oil.

The cylinder head design was completely overhauled for the 1UR-FE. It now uses aluminum alloy cylinder heads with separated camshaft housings. Each cylinder bank houses two camshafts, supporting four valves per cylinder. Another significant improvement is the use of timing chains rather than the less reliable timing belts.

Primary timing chains drive the intake camshafts, while each exhaust camshaft is powered by a secondary chain. The valves are now operated through roller rocker arms, and the valvetrain employs hydraulic lifters, eliminating the need for manual valve clearance adjustments. For enhanced durability, a three-layer steel-laminate type gasket is placed between the cylinder block and each head.

The exhaust setup features four-into-one (4-1) stainless steel headers, stainless steel exhaust pipes, and catalytic converters on both cylinder banks. To lower emissions, the engine uses a water-cooled Exhaust Gas Recirculation (EGR) system along with an air injection system designed to accelerate the warm-up process of the catalytic converters.

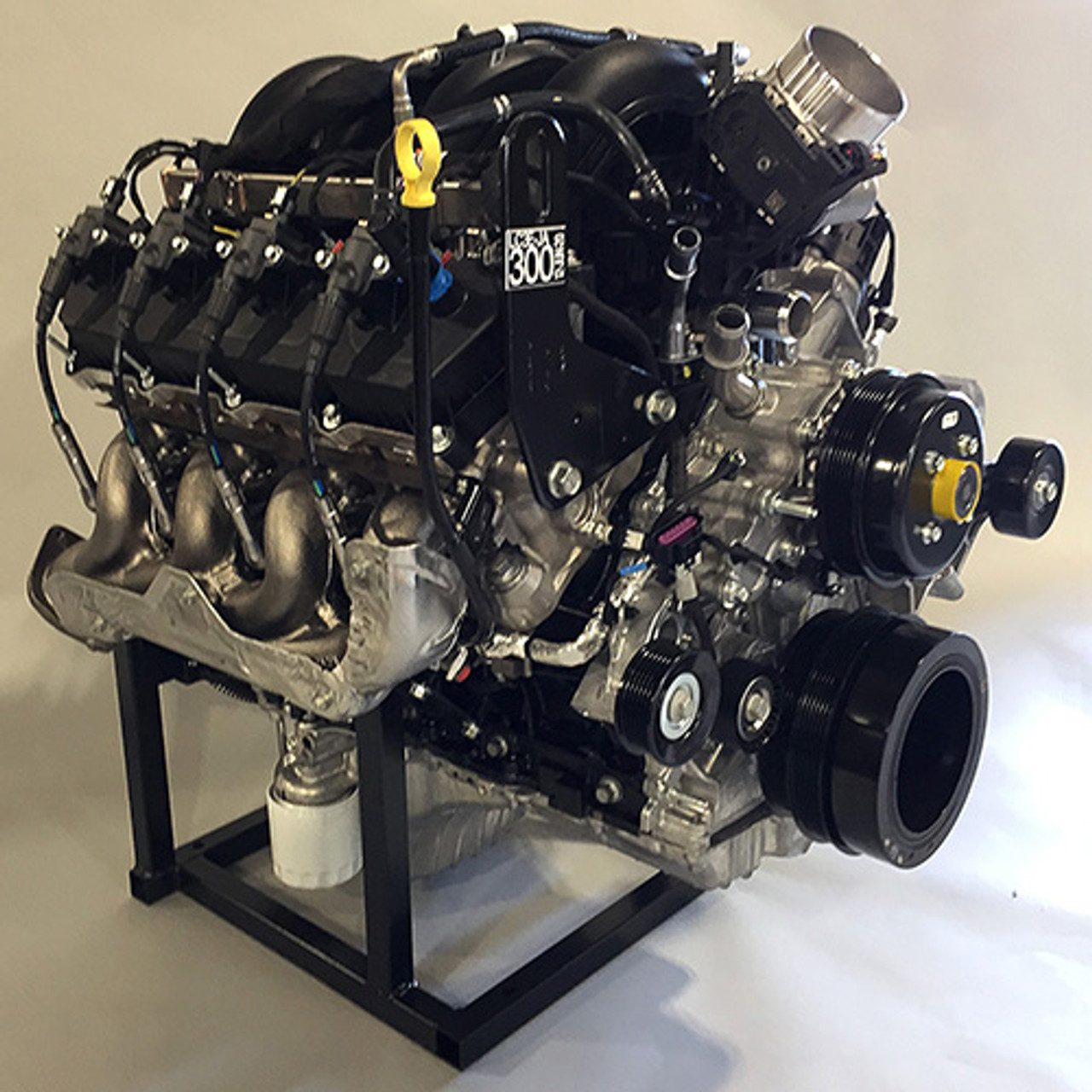

6. GM 6.0L V8 (Vortec 6000)

Used extensively in heavy-duty GM trucks and vans, the 6.0L Vortec is built like a tank. It doesn’t boast high fuel economy or groundbreaking technology, but it’s a known quantity: simple, dependable, and easy to fix.

This V8 was a staple in commercial fleets, including ambulances, utility trucks, and delivery vans, because it could be trusted to keep running under harsh conditions. It’s not unusual to see these engines push well past 300,000 miles, particularly in highway-driven or fleet-maintained vehicles.

The L96 is designed as a heavy-duty workhorse, built to deliver both durability and performance. Variable valve timing technology allows the engine to optimize power, efficiency, and emissions control under various driving conditions.

Its performance is enhanced by improved airflow; the intake flow has been streamlined from the manifold to the cylinder heads, while the exhaust ports are engineered for superior flow. These airflow improvements not only boost power but also contribute to better emissions performance.

Despite its rugged capabilities, the 6.0L L96 is remarkably refined. Noise-reducing features are integrated throughout the engine and work alongside an improved engine cradle and mounting system to minimize vibrations transmitted into the passenger cabin, resulting in a quieter and smoother ride.

The engine block was developed using advanced math-based tools and insights from GM’s racing programs, resulting in a lightweight yet rigid foundation for smooth operation. Its deep-skirt design maximizes strength and reduces vibration. Six-bolt, cross-bolted main-bearing caps minimize crankshaft flex and strengthen the engine structure.

A structural oil pan adds further rigidity. The rotating assembly is engineered for optimal strength and longevity while incorporating features that reduce noise and enhance smoothness. The L96 also uses a heavy-duty timing chain designed specifically for quiet operation, validated for 200,000 miles, and fitted with a leaf-spring-type dampener.

The cylinder heads of the L96 feature “cathedral”-shaped intake ports, derived from the high-performance heads of the “C5” Chevrolet Corvette Z06. These promote exceptional airflow at high rpm for a wide horsepower band while maintaining robust low-end torque. Both the intake and the D-shaped exhaust ports are designed to deliver excellent high-rpm airflow.

Variable valve timing (VVT) enables the L96 to adjust camshaft timing according to engine demands. At idle, the cam is fully advanced for smooth operation. Under different conditions, the phaser adapts to achieve optimal timing for power, drivability, and fuel efficiency.

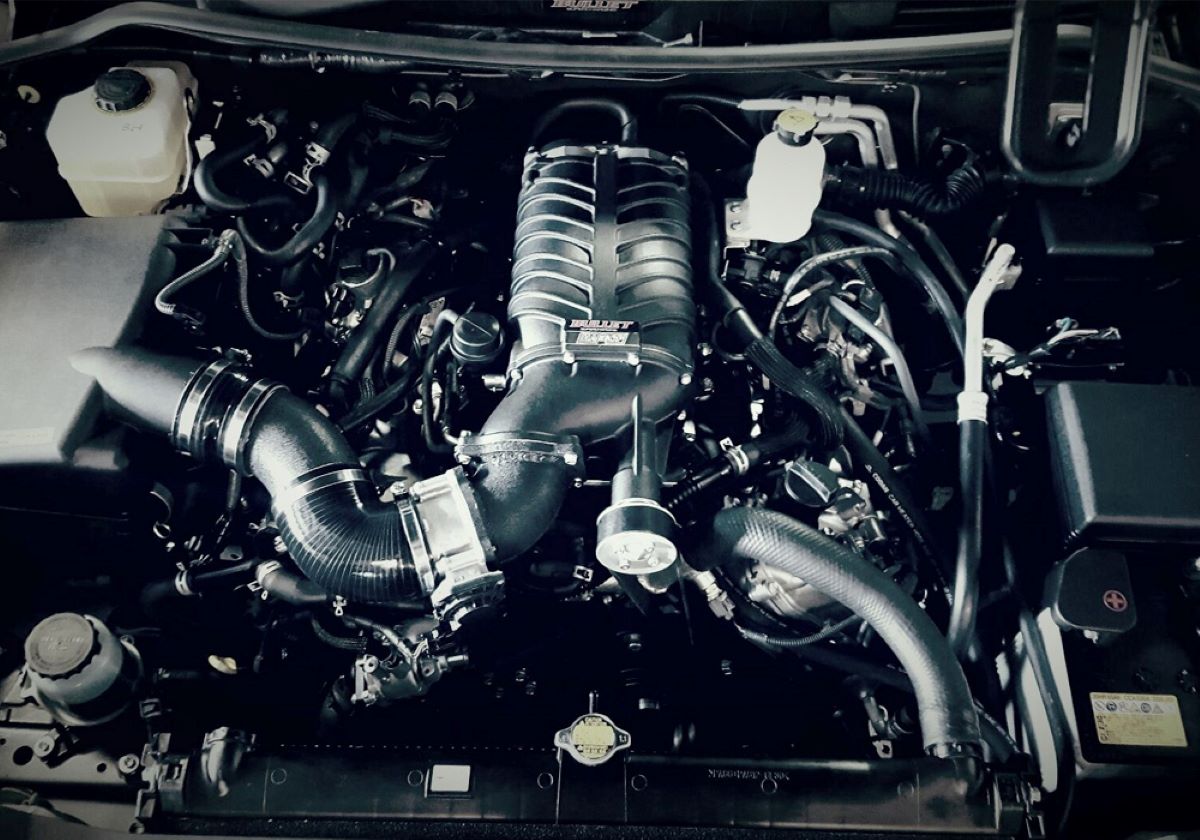

7. Ford 7.3L V8 (Godzilla)

Introduced in 2020, the Ford 7.3L “Godzilla” V8 may be new, but it was designed with the same old-school durability as legacy pushrod V8s.

Built for Super Duty trucks and commercial platforms, this engine features a cast-iron block, forged internals, and a focus on low-end torque and serviceability.

While it’s too early to judge it by decades of use, early reports suggest that Godzilla is living up to its name, regularly surpassing 150K miles with no signs of letting up.

When non-car enthusiasts hear the word “Godzilla,” they immediately picture the giant monster from the movies. In the automotive enthusiast world, however, the name is more commonly tied to the legendary Nissan GT-R. Regardless of the context, the term “Godzilla” carries the same weight—it represents something fierce, strong, and undeniably powerful.

Ford has captured that very essence with a crate engine worthy of the name: the Godzilla. This engine introduces a new family of pushrod V8s, a configuration that has become rare in modern cars. Ford moved away from pushrod designs in the 1990s, favoring overhead camshaft technology for its engines.

Today, only a handful of automakers, like Dodge with its HEMI and Chevrolet with the LS series, continue to use pushrod engines. Ford’s decision to bring back this design with the Godzilla marks a bold move—one that may turn out to be one of their best. This article dives into what makes this crate engine tick, why it works so well, and why it’s quickly becoming a top choice for engine swaps.

To provide the most current and accurate information, details here are drawn from multiple manufacturer sources, including Ford Performance.

At 7.3 liters, the Godzilla engine holds the title of being the largest displacement engine currently offered by Ford. It made its debut in 2020 under the hood of Ford Super Duty trucks, replacing the outgoing 6.2-liter Hurricane V8 that had powered Ford trucks from 2010 to 2022. That older engine served a wide range of vehicles, from the F-150 Raptor to the F-350 Super Duty lineup..