For vehicle owners, few issues can be as frustrating and expensive as a blown head gasket. This small but crucial component sits between the engine block and the cylinder head, sealing the combustion chambers and preventing coolant or oil from leaking into the cylinders.

When a head gasket fails, it can lead to overheating, loss of engine power, and in severe cases, complete engine damage. Repairing such damage often costs a considerable amount, and in many cases, the repair bill is high enough to make some owners consider replacing the entire engine.

The rate at which an engine experiences head gasket failure is influenced by its design, build quality, cooling system efficiency, and even the way it is driven and maintained. While some engines are engineered in such a way that gasket problems are rare, others are notorious for suffering this damage regularly, sometimes even before reaching moderate mileage.

These differences are often the result of choices made during manufacturing, such as the materials used, the head bolt torque design, or the cooling passage configuration. For some drivers, knowing which engines have a reliable track record with gaskets can help guide future vehicle purchases, while learning which ones are prone to the problem can save thousands of dollars in repairs.

We will review five engines that have proven to be durable in this aspect and are less likely to suffer a gasket failure, and then we will turn our attention to five engines known for experiencing the problem so often that some owners almost expect it. Each engine on both lists will be examined in detail, with attention given to its construction, performance, and common user experiences.

Engines That Rarely Blow Gaskets

1. Toyota 2UZ-FE V8

The Toyota 2UZ-FE V8 has gained a strong reputation for durability and resistance to common engine problems, including head gasket failure. Produced for various Toyota trucks and SUVs such as the Land Cruiser, Tundra, and Sequoia, this 4.7-litre engine is built with a cast-iron block and aluminium heads, which allows it to handle high temperatures and heavy loads without easily distorting. The combination of these materials provides strength while maintaining good heat dissipation, both of which are important for gasket health.

Its head bolts are designed to hold torque very well, which reduces the likelihood of the head lifting under extreme conditions. The cooling passages are also wide and well-positioned, ensuring that heat is managed efficiently even when towing heavy trailers or driving in hot weather.

Many owners have driven their 2UZ-FE-powered vehicles beyond 300,000 miles without experiencing any gasket problems, which is an impressive achievement for a petrol V8. Another contributing factor to its gasket reliability is the conservative tuning of the engine. It does not push extreme compression ratios or turbocharging, which means less strain on the sealing surfaces.

The 2UZ-FE’s engineering focuses on steady and consistent performance rather than squeezing out maximum horsepower, and that makes it more forgiving for the head gasket. Even when drivers neglect minor maintenance tasks, the engine can often tolerate the oversight without immediate failure.

Maintenance is still important, of course. Using the correct coolant and replacing it at the recommended intervals helps prevent corrosion in the head gasket area. Because of its robust design, even when overheating does occur due to external issues like a broken water pump, the 2UZ-FE is less likely to suffer permanent head gasket damage compared to many other engines in its class.

This combination of strong materials, careful engineering, and practical cooling design has allowed it to stand out as one of the most reliable V8s in this regard.

2. Honda K24

The Honda K24 engine series is widely respected for its balance of performance, efficiency, and reliability. Found in various Honda and Acura models, this four-cylinder powerplant is known for running hundreds of thousands of miles with minimal mechanical failures.

One of its strongest qualities is the way the cylinder head and block are engineered to work together under pressure, reducing the risk of head gasket leaks. The K24 is an aluminium-block engine with iron cylinder liners, giving it a lightweight structure without compromising durability.

Honda’s precision in machining the head gasket sealing surfaces ensures a very tight fit, and the use of high-quality multi-layer steel (MLS) gaskets further enhances resistance to failure. These gaskets are better at withstanding thermal cycling compared to cheaper composite types used in some other engines.

The engine’s cooling system is also highly efficient, keeping operating temperatures stable under both city driving and highway cruising. This stability is essential for preventing the expansion and contraction that can wear out a head gasket as time goes on. Even under performance tuning or track driving, the K24 holds up well when properly maintained.

Another factor that works in favour of the K24’s gasket longevity is Honda’s tradition of designing engines with balanced internals. The smooth operation reduces vibration and stress on the sealing points. Owners have reported engines surpassing 250,000 to 300,000 miles without ever needing a head gasket replacement.

Proper maintenance habits, such as keeping the coolant fresh and using quality oil, are still necessary, but the K24’s forgiving design makes it less vulnerable to minor issues. This makes it an excellent choice for drivers seeking a dependable engine that will rarely give trouble in this area.

Also Read: 5 Trucks with Engine Block Heaters vs 5 without Cold-Start Support

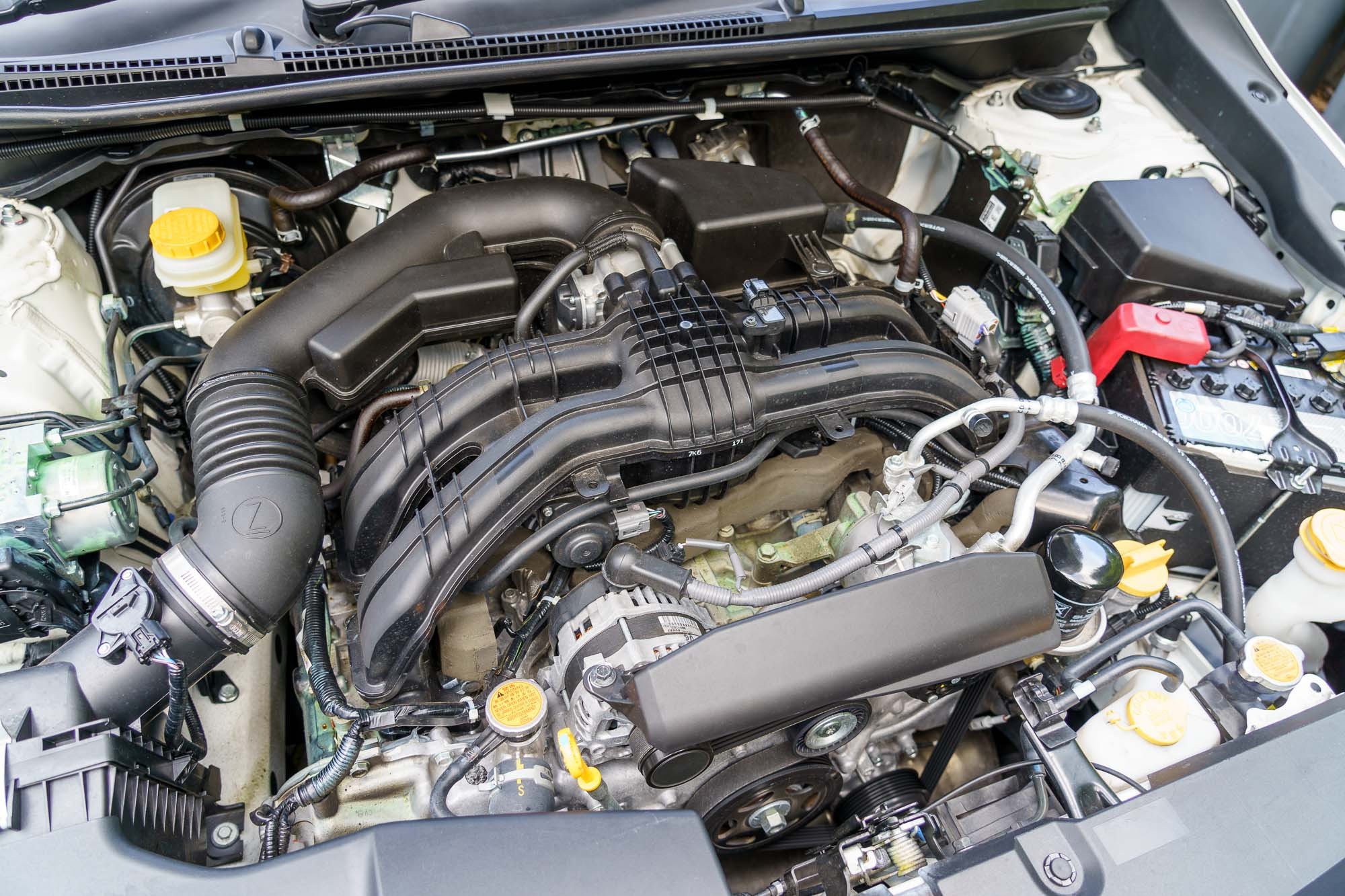

3. Lexus 1UZ-FE V8

The Lexus 1UZ-FE V8 is often regarded as one of the most dependable luxury car engines of its time, and one of the reasons it earned such praise is its resistance to head gasket failures. Introduced in the early 1990s, it powered vehicles like the Lexus LS 400 and SC 400, as well as some Toyota Crown and Celsior models.

Built with a strong aluminium block paired with aluminium heads, the 1UZ-FE benefits from Toyota’s meticulous engineering, which ensures precise tolerances between the block and head surfaces. The head gasket used in this engine is a robust, multi-layer steel design that maintains its seal even under heavy stress.

The cooling system is designed with generous flow capacity, keeping temperatures under control during extended high-speed cruising or stop-and-go urban driving. Unlike some engines that develop hot spots near the rear cylinders, the 1UZ-FE maintains an even temperature distribution, which prevents gasket warping.

One thing that sets this engine apart is its conservative compression ratio combined with naturally aspirated operation. Without forced induction, cylinder pressures remain moderate, reducing the load placed on the gasket. Lexus also designed the engine’s head bolts with exceptional holding strength, so the clamping force remains consistent for decades.

Owners of 1UZ-FE-powered cars often report surpassing 300,000 miles without head gasket issues, provided regular coolant changes and oil servicing are observed. Even if the engine is subjected to occasional overheating due to unrelated faults, its resilience often allows it to recover without catastrophic gasket failure. This long-lasting reliability has helped maintain its reputation as one of the most trouble-free V8s ever made.

4. Toyota 1GR-FE V6

Toyota’s 1GR-FE V6, found in vehicles such as the Tacoma, 4Runner, and FJ Cruiser, is another strong performer when it comes to gasket reliability. Built with a cast-aluminium block and aluminium heads, this 4.0-litre engine is designed for heavy-duty use in off-road and work settings. Its engineers paid careful attention to head gasket sealing, using high-grade materials and machining precision to avoid leaks.

The 1GR-FE also features a simple, effective cooling system with large coolant passages that promote consistent temperature control across the entire head and block. This even cooling reduces the likelihood of thermal distortion, which is a major contributor to gasket wear in other engines. The use of head bolts with high tensile strength ensures the clamping pressure stays constant for years, preventing the head from lifting under high load.

Its naturally aspirated design with moderate compression allows it to handle extreme driving conditions without putting excessive strain on the head gasket. This is particularly valuable for drivers who use their trucks for towing or extended highway trips in hot weather. Many reports from long-term owners show these engines reaching well over 250,000 miles without gasket trouble.

Routine maintenance, such as timely coolant replacement and use of the correct coolant type, is still required, but the 1GR-FE is forgiving even when owners occasionally delay minor servicing. It stands as a practical choice for anyone needing a tough and dependable V6 that will not be a constant source of gasket concerns.

5. GM LS3 V8

The GM LS3 V8, used in vehicles like the Chevrolet Corvette, Camaro SS, and some performance sedans, is a modern engine with excellent resistance to head gasket failure. Built on the proven LS platform, it uses an aluminium block with aluminium heads and multi-layer steel gaskets. These gaskets are specifically engineered to withstand the high combustion pressures produced by the LS3’s relatively high horsepower output.

One of the LS3’s strengths lies in its head bolt arrangement and torque pattern. The bolts are positioned to ensure even distribution of clamping force across the gasket surface. This, combined with precision-machined mating surfaces, reduces the risk of blowouts even under aggressive driving. The LS3 also benefits from a well-designed cooling system that prevents hot spots, which are a common cause of gasket degradation.

Even though the LS3 delivers strong performance, it avoids the extremes of turbocharging or very high compression ratios, which can increase stress on the gasket. Many owners use these engines for spirited driving or even track use without encountering gasket failures. When maintained with proper coolant and oil changes, it is common to see them exceed 200,000 miles without a head gasket replacement.

For enthusiasts who want performance without the frequent worry of gasket repairs, the LS3 offers an excellent balance of power and dependability. Its combination of advanced materials, strong clamping hardware, and efficient cooling makes it a reliable choice in both daily driving and demanding conditions.

Engines That Wear Out Gaskets Frequently

1. Subaru EJ25

The Subaru EJ25, used in various Legacy, Outback, Forester, and Impreza models, has developed a long-standing reputation for head gasket problems. This horizontally opposed 2.5-litre four-cylinder engine is known for its smoothness and low centre of gravity, but its gasket design and cooling characteristics have often let it down.

A major issue stems from the fact that the EJ25’s gasket sealing surfaces can suffer from uneven heating. The flat-four layout allows certain areas of the head to retain more heat than others, and as time goes on this leads to warping and loss of gasket seal. Subaru originally used a single-layer composite gasket in many of these engines, which was more prone to deterioration compared to multi-layer steel designs.

Coolant and oil leaks at the head gasket are common, sometimes appearing before 100,000 miles. In some cases, external leaks occur first, with coolant dripping outside the block, while in others, internal leaks develop, allowing coolant to enter the combustion chamber and cause white exhaust smoke.

Subaru addressed the problem in later years with improved gaskets, but even updated versions can fail prematurely if the engine is overheated or not maintained properly. Owners often budget for a head gasket job as part of long-term EJ25 ownership. While the engine offers good drivability and performance, its gasket reliability has been a consistent weak point for many years.

2. Chrysler 2.7L V6

The Chrysler 2.7-litre V6, fitted in models like the Dodge Intrepid, Chrysler Sebring, and Concorde, is remembered as an engine with more than its fair share of mechanical troubles. Among the most common complaints from owners is head gasket failure, which can occur far earlier than many would expect.

The design of this engine contributes heavily to the problem, starting with its relatively narrow cooling passages. Because of these restricted pathways, even slight neglect in coolant maintenance can lead to overheating, and once overheating begins, the head gasket’s sealing ability is quickly compromised.

Another long-standing weakness of the 2.7L V6 is its tendency toward oil sludge buildup. If oil changes are delayed or the wrong oil type is used, thick sludge forms within the engine, obstructing oil flow and creating hot spots.

These hot spots upgrade engine temperatures, putting even more stress on the head gasket. Once the gasket is damaged, coolant often mixes with the engine oil, creating a milky, sludge-like mixture that speeds up internal wear and can ruin the bearings.

Reports from owners indicate that head gasket issues have occurred as early as 70,000 to 90,000 miles, particularly in vehicles used primarily for city driving, where frequent starts and stops put extra load on the cooling system. Repairing the gasket is often costly, and without fixing the underlying causes, such as clearing sludge and improving coolant circulation, the problem can return in a short time.

This history of repeated failures and expensive repairs has hurt the reputation of vehicles equipped with the 2.7L V6 in the used market. Many buyers actively avoid them, knowing that unless the engine has been meticulously maintained and inspected, there is a considerable chance of facing major head gasket repairs sooner than desired.

3. Ford 6.0L Power Stroke Diesel

The Ford 6.0-litre Power Stroke diesel V8, used in Ford Super Duty trucks between the early and mid-2000s, is well known for delivering strong pulling power and quick throttle response for its size. However, it has also gained a reputation for being prone to head gasket problems, especially in trucks that are worked hard or modified for higher performance.

This engine’s issues are often traced back to its factory head bolt design, which is not strong enough to withstand the extreme pressures generated under certain conditions. When the 6.0L is subjected to heavy towing, aggressive driving, or increased turbo boost through aftermarket tuning, cylinder pressures rise sharply.

The original head bolts can stretch slightly under this load, reducing the clamping force that keeps the head gasket sealed. Once that seal is compromised, combustion gases can leak into the cooling system, coolant can escape, and the gasket can deteriorate rapidly.

A common solution among owners is to replace the factory bolts with stronger head studs. This upgrade provides greater clamping strength and resists stretching, improving gasket reliability. Unfortunately, installing head studs is not a simple or cheap job. It often requires lifting the cab off the truck’s frame, which adds substantial labour cost to the repair.

The 6.0L Power Stroke’s cooling system is also sensitive to blockages or restrictions. Even minor coolant flow issues can raise operating temperatures and worsen gasket problems. While the engine can deliver impressive torque for towing and hauling, its vulnerability under heavy load has made it a controversial choice.

Many diesel enthusiasts advise avoiding this engine unless it has already been upgraded with head studs and other reliability modifications. For those willing to invest in preventive upgrades, the 6.0L can be a capable workhorse, but without them, gasket failure is a frequent concern.

4. Mitsubishi 4G63T

The turbocharged Mitsubishi 4G63T has earned a lasting place in automotive history thanks to its performance in the Lancer Evolution and Mitsubishi Eclipse. It is celebrated for its tuning potential and motorsport achievements, yet it also carries a known weakness in head gasket durability when subjected to extreme modifications.

In its original factory setup, the 4G63T can be dependable for everyday driving, but many owners rarely leave it stock, often increasing boost levels and demanding more power than it was initially designed to handle.

When boost pressure is raised, cylinder pressures climb sharply, placing much greater stress on the head gasket. The factory composite gasket, while adequate for standard power levels, may not hold up well under these elevated conditions.

Aggressive driving without sufficient cooling upgrades can also cause excessive heat buildup. This heat can warp the cylinder head slightly, which in turn disrupts the seal between the head and block, creating a path for coolant or combustion gases to escape.

A failed head gasket on the 4G63T often leads to coolant and oil mixing, producing a thick, milky fluid inside the engine. Drivers may also notice heavy white smoke coming from the exhaust, which is a clear indicator of coolant entering the combustion chambers. For enthusiasts who plan to push the engine’s limits, upgrading to a multi-layer steel gasket and installing stronger head studs is often considered a preventive measure rather than an optional upgrade.

When used as a daily driver in stock form and maintained properly, the 4G63T can last for many years without gasket trouble. However, in tuned setups or motorsport applications, replacing the head gasket can become a regular part of ownership. The engine remains a favourite for its performance potential, but its gasket reliability is highly dependent on how it is treated.

Also Read: 5 Engines with Oversized Oil Pans vs 5 with Stock Pans That Crack

5. BMW N54

The BMW N54 twin-turbocharged inline-six, found in models such as the 335i, 135i, and early Z4 variants, is praised for its strong acceleration, smooth delivery, and tuning potential. However, while it delivers outstanding performance for its size, it has also gained a reputation for experiencing head gasket issues, particularly in vehicles driven aggressively or modified for higher output.

The core challenge with this engine lies in the stress placed on the head gasket by its twin turbochargers. These turbos produce high cylinder pressures, which increase the mechanical load on the gasket. Alongside that, heat management plays a crucial role in the N54’s reliability.

Turbocharger heat soak often causes uneven temperature distribution across the cylinder head. As certain sections heat and expand more than others, the risk of the gasket losing its seal becomes greater.

The original gasket design is of high quality, but repeated cycles of heating and cooling, especially during spirited driving or extended track sessions, gradually weaken it. Once the gasket starts to fail, symptoms can vary.

Some drivers first notice a steady loss of coolant or occasional white exhaust smoke, while others encounter more severe cases where coolant and combustion gases mix, requiring expensive repairs, including head resurfacing. The N54 is particularly popular among performance enthusiasts due to its ability to handle large power increases through tuning.

Unfortunately, raising boost levels and adding power without reinforcing the head gasket setup often shortens its life considerably. To prevent such failures, many tuners install upgraded multi-layer steel gaskets combined with stronger head studs, which improve clamping force and withstand higher pressures.

Without these preventive measures, it is not uncommon for gasket problems to arise well before 150,000 miles, especially in modified vehicles. While the N54 remains a highly enjoyable engine to drive, its head gasket vulnerability is a factor every owner should keep in mind.