Honda Motor Company has built its reputation on a foundation of reliability, durability, and engineering excellence that spans over seven decades. Since Soichiro Honda founded the company in 1948, the Japanese automaker has become synonymous with vehicles that start every morning, run for hundreds of thousands of miles, and maintain their value better than most competitors.

This reputation didn’t emerge overnight it was carefully crafted through decades of meticulous engineering, rigorous testing, and an unwavering commitment to quality that became deeply embedded in Honda’s corporate DNA.

The brand’s reliability legend began in the motorcycle world, where Honda’s small, efficient engines proved incredibly durable and fuel-efficient. This engineering philosophy naturally transitioned to automobiles, where Honda applied the same principles of simplicity, efficiency, and longevity.

These problematic vehicles serve as important reminders that even the most trusted manufacturers can stumble, whether due to rushed development timelines, cost-cutting measures, or simply the complexity of modern automotive engineering.

Understanding both Honda’s greatest reliability successes and its notable failures provides valuable insight into what makes a vehicle truly dependable and what factors can undermine even the best intentions. This examination reveals the delicate balance between innovation, cost management, and quality control that defines the modern automotive industry.

5 Hondas with legendary reliability

These exceptional vehicles represent Honda engineering at its finest through proven powertrains, meticulous build quality, and a conservative design philosophy that enables decades of trouble-free operation while maintaining excellent resale value and owner satisfaction ratings.

Their robust construction incorporates time-tested engines, durable transmissions, and reliable electrical systems that resist premature failure, providing consistent performance across various driving conditions and climate environments over hundreds of thousands of miles.

Their legendary status includes engines that routinely exceed 300,000 miles, transmissions that provide smooth operation throughout their entire service life, and electrical systems that maintain functionality despite decades of use.

These Honda models consistently appear on reliability surveys and used car recommendation lists, with many examples still operating efficiently after 20+ years of service. They represent the gold standard of automotive reliability, proving that proper engineering and quality control can create vehicles that truly last a lifetime while maintaining Honda’s prestigious reputation for dependable transportation.

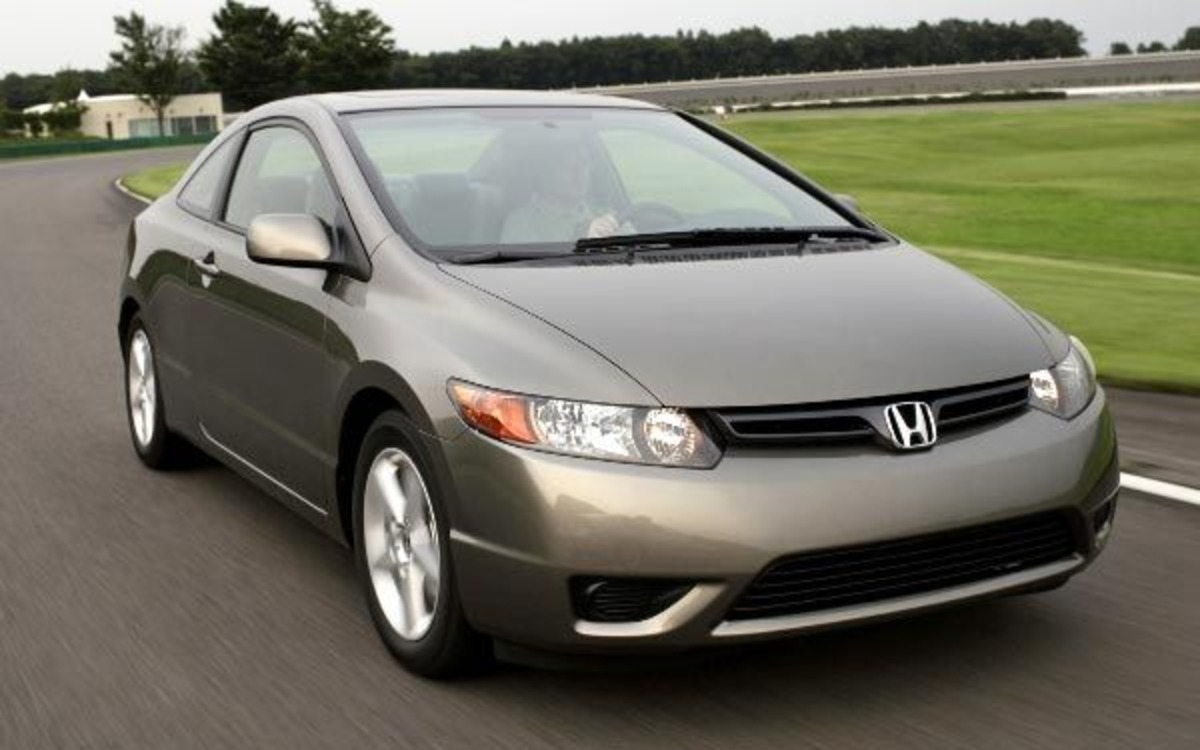

1. Honda Civic (1996-2000 Sixth Generation)

The sixth-generation Honda Civic stands as perhaps the most reliable compact car ever produced, representing the pinnacle of Honda’s engineering philosophy during the late 1990s.

This generation of Civic achieved legendary status not through flashy features or cutting-edge technology, but through an almost obsessive attention to build quality, component durability, and long-term reliability that has made these vehicles nearly indestructible even decades after production ended.

At the heart of this Civic’s legendary reliability lies Honda’s naturally aspirated engines, particularly the 1.6-liter D16Y7 and D16Y8 units. These power plants were engineered with conservative tuning, robust internal components, and proven technology that prioritized longevity over peak performance.

The engines featured Honda’s VTEC variable valve timing system in higher trims, but even the base engines were virtually bulletproof. With proper maintenance, often nothing more than regular oil changes and basic tune ups, these engines routinely exceeded 300,000 miles without major repairs.

The transmission options, whether the smooth five-speed manual or the reliable four-speed automatic, were equally robust and rarely required attention beyond routine fluid changes.

The build quality extended far beyond the powertrain. Honda used high-grade steel in critical structural areas, applied superior corrosion protection, and assembled these vehicles with tolerances that remained tight even after years of use.

The electrical systems were refreshingly simple and reliable, avoiding the complexity that would plague later generations. Interior components, while not luxurious, were built to withstand daily abuse without breaking, fading, or wearing prematurely.

These vehicles consistently rank at the top of used car reliability surveys, maintain strong resale values despite their age, and continue serving as daily drivers for owners who have accumulated astronomical mileage figures.

Many examples with original engines and transmissions have surpassed 400,000 miles with nothing more than routine maintenance, a testament to Honda’s engineering excellence during this golden era of automotive reliability.

2. Honda Accord (1998-2002 Sixth Generation)

The sixth-generation Honda Accord represents the perfect synthesis of Honda’s reliability engineering and mid-size sedan practicality, creating a vehicle that set new standards for long-term durability in the family car segment.

This generation of Accord built upon decades of refinement and represented Honda at its most confident, producing a sedan that would go on to become one of the most trusted and dependable vehicles ever manufactured.

The transmission systems matched the engines in terms of reliability and refinement. The five-speed manual transmission offered precise shifts and clutch longevity that impressed even the most demanding drivers, while the four-speed automatic transmission provided smooth operation and remarkable durability.

Honda’s transmission programming prioritized component longevity over aggressive shift patterns, resulting in units that rarely failed even under demanding conditions or high-mileage operation.

Honda’s attention to build quality during this era was exemplary, with paint systems that resisted fading and oxidation, body panels that maintained their fit and finish over decades, and interior materials that withstood daily use without significant deterioration.

The electrical systems were engineered with redundancy and simplicity, avoiding the complex modules and sensors that would later become sources of reliability issues in other vehicles.

The suspension and brake systems demonstrated Honda’s commitment to long-term durability, with components that maintained their performance characteristics well beyond typical replacement intervals.

The vehicles aged gracefully, maintaining their reliability characteristics even as odometers climbed well beyond 200,000 miles, making them favorites among used car buyers seeking dependable transportation.

3. Honda CR-V (1997-2001 First Generation)

The first-generation Honda CR-V revolutionized the compact SUV segment not through aggressive styling or powerful engines, but through an unwavering commitment to reliability and practical design that established the template for dependable crossover vehicles.

This pioneering SUV proved that Honda’s legendary reliability could successfully transition from cars to utility vehicles, creating a new category of family-friendly SUVs that prioritized dependability over ruggedness.

Built on Honda’s proven Civic platform, the original CR-V inherited decades of refinement and reliability engineering that had made Honda’s compact cars legendary for their durability.

The 2.0-liter naturally aspirated four-cylinder engine, designated B20B, represented Honda’s conservative approach to SUV powertrains, delivering adequate performance while maintaining the exceptional reliability characteristics that defined Honda’s reputation. This engine featured Honda’s proven design elements, including a robust bottom end, conservative tuning, and materials that prioritized longevity over peak performance.

The Real Time 4WD system developed for the CR-V demonstrated Honda’s ability to engineer complex systems with reliability as the primary objective. Unlike traditional four-wheel-drive systems that relied on complicated transfer cases and locking differentials, Honda’s system used a simple viscous coupling that engaged the rear wheels automatically when traction was needed.

This system eliminated the maintenance requirements and potential failure points associated with conventional 4WD systems while providing adequate capability for most drivers’ needs.

Honda’s attention to build quality extended throughout the first-generation CR-V, with body construction that resisted corrosion, paint systems that maintained their appearance over decades, and interior materials that withstood family use without significant deterioration.

What truly distinguished the first-generation CR-V was its ability to deliver SUV capability without compromising Honda’s reliability standards. These vehicles routinely exceeded 200,000 miles with minimal major repairs, maintained their mechanical integrity even in demanding climates, and provided hassle-free ownership experiences that converted countless families to the Honda brand.

4. Honda Pilot (2003-2008 First Generation)

The first-generation Honda Pilot marked Honda’s successful entry into the three-row SUV segment, demonstrating that the company’s reliability engineering could scale up to larger, more complex vehicles without compromising the dependability that defined the Honda brand.

This full-size SUV proved that families didn’t need to sacrifice reliability for space and capability, establishing Honda as a serious competitor in the competitive family SUV market.

The foundation of the Pilot’s reliability lay in Honda’s 3.5-liter V6 engine, the J35A4, which represented a mature evolution of Honda’s V6 technology.

This powerplant delivered robust performance while maintaining Honda’s characteristic conservative tuning and robust internal construction. The engine featured Honda’s VTEC variable valve timing system, aluminum construction for weight reduction, and internal components sized for longevity rather than peak performance.

Regular maintenance requirements were straightforward, with oil change intervals and service procedures that didn’t burden owners with excessive complexity or cost.

The five-speed automatic transmission paired with this engine proved equally reliable, providing smooth shifts and exceptional durability even under the demanding conditions of three-row SUV operation. Honda’s transmission programming prioritized component longevity over aggressive performance, resulting in a unit that rarely failed even when subjected to regular towing or fully-loaded operation.

The Variable Torque Management 4WD system provided capable all-weather traction while maintaining simplicity and reliability that avoided the complexity and potential failure points of more sophisticated systems.

Honda’s attention to build quality extended throughout the first-generation Pilot, with body construction that utilized high-strength steel in critical areas, paint systems that resisted environmental degradation, and assembly quality that maintained tight tolerances over decades of use.

The interior materials, while not luxurious, were selected for durability and resistance to wear, with controls and switches that continued functioning properly even after years of family use.

These vehicles routinely exceeded 200,000 miles with their original powertrains intact, maintained their mechanical integrity even in demanding operating conditions, and provided the hassle-free ownership experience that Honda owners had come to expect from smaller vehicles.

Also Read: 5 Turbo Engines Known For Longevity vs 5 That Fail Early

5. Honda Ridgeline (2006-2014 First Generation)

The first-generation Honda Ridgeline represented Honda’s unconventional approach to the pickup truck market, prioritizing car-like reliability and refinement over traditional truck ruggedness.

While initially controversial among traditional truck buyers, the Ridgeline’s unique design philosophy and Honda’s reliability engineering created a pickup that delivered exceptional dependability and longevity in a segment often plagued by mechanical issues and high maintenance requirements.

Built on Honda’s proven SUV platform and sharing components with the Pilot, the Ridgeline inherited decades of reliability engineering and component development that had proven successful in Honda’s passenger car and SUV lines.

The 3.5-liter V6 engine, Honda’s J35A9, provided adequate power for most truck duties while maintaining the conservative tuning and robust construction that characterized Honda’s approach to powertrain development.

This engine featured Honda’s VTEC system, aluminum construction, and internal components sized for longevity rather than peak performance numbers.

The five-speed automatic transmission demonstrated Honda’s ability to adapt proven components to truck applications without compromising reliability.

Unlike many pickup trucks that suffered from transmission problems under heavy-duty use, the Ridgeline’s transmission proved remarkably durable even when regularly loaded or used for towing within its rated capacity.

The Variable Torque Management 4WD system provided adequate capability for most users while avoiding the complexity and maintenance requirements of traditional truck four-wheel-drive systems.

Honda’s independent rear suspension, while unusual for a pickup truck, contributed significantly to the Ridgeline’s reliability and refinement. This system eliminated the maintenance requirements and potential problems associated with solid rear axles while providing a comfortable ride quality that distinguished the Ridgeline from conventional trucks.

What truly distinguished the first-generation Ridgeline was its ability to provide truck capability with Honda reliability, creating a unique ownership experience that prioritized dependability over traditional truck attributes.

These vehicles routinely exceeded 200,000 miles with minimal major repairs, maintained their mechanical integrity even under demanding conditions, and provided the hassle-free ownership that Honda buyers expected from their vehicles.

5 That Faced Major Issues

These disappointing vehicles undermine Honda’s reliability reputation through premature failures, widespread component problems, and quality control lapses that contradict the brand’s legendary status while creating expensive repair scenarios for unsuspecting owners.

Their compromised construction incorporates problematic engines, defective transmissions, and unreliable systems that generate endless repair headaches despite Honda positioning that suggests superior engineering excellence and build quality over mainstream competitors.

The combination of frequent breakdowns, expensive replacement components, and recurring failures creates ownership disasters as buyers discover that Honda badges cannot prevent fundamental engineering mistakes that prioritize cost reduction or rushed development over basic reliability standards.

These Honda models frequently appear in technical service bulletins, class-action lawsuits, and reliability complaint databases that destroy both owner confidence and the brand’s hard-earned reputation for dependability.

They represent everything that can go wrong when even excellent manufacturers make critical engineering mistakes, transforming Honda’s reliable transportation into expensive repair burdens requiring constant professional attention and major component replacement.

1. Honda Civic (2006-2011 – Eighth Generation)

The eighth-generation Honda Civic marked a significant departure from Honda’s traditional reliability-first approach, representing one of the most problematic periods in the model’s otherwise stellar history.

This generation suffered from multiple design flaws, cost-cutting measures, and quality control issues that damaged Honda’s reputation and disappointed loyal customers who expected the legendary reliability that had defined previous Civic generations.

The most notorious problem plaguing this generation involved the engine block cracking, particularly in the 1.8-liter R18A1 engine. Unlike previous Honda engines that were renowned for their durability, this powerplant suffered from a fundamental design flaw where the engine block would develop cracks around the cylinder sleeves, leading to coolant leaks, overheating, and eventually complete engine failure.

The problem was widespread enough to generate multiple class-action lawsuits and forced Honda to extend warranties on affected vehicles. The root cause appeared to be inadequate material thickness and poor metallurgy in critical areas of the engine block, suggesting cost-cutting measures had compromised Honda’s traditional engineering standards.

Transmission problems also plagued this generation, with both manual and automatic transmissions experiencing premature failures and operational issues.

The five-speed automatic transmission, in particular, suffered from harsh shifting, slipping, and complete failure at relatively low mileages. Many owners reported transmission problems beginning as early as 50,000 miles, with some requiring complete transmission replacement under warranty.

The manual transmission wasn’t immune to problems either, with reports of difficult shifting, gear grinding, and premature clutch wear that suggested fundamental design or manufacturing issues.

The interior quality represented another significant departure from Honda’s traditional standards, with numerous reports of premature wear, component failures, and poor build quality.

Dashboard materials would crack and fade prematurely, seat fabrics would wear through unusually quickly, and various interior trim pieces would break or become loose with normal use.

The climate control systems proved particularly problematic, with frequent failures of air conditioning compressors, heating systems, and electronic controls that required expensive repairs.

The widespread nature of the engine block cracking issue, in particular, suggested systematic quality control problems that went beyond isolated manufacturing defects, yet Honda was slow to acknowledge the scope of the problems and implement comprehensive solutions for affected customers.

2. Honda Accord (2003-2007 Seventh Generation)

The seventh-generation Honda Accord represented a troubling period in the model’s otherwise exemplary reliability record, suffering from multiple serious defects that contradicted Honda’s reputation for dependable engineering.

This generation became notorious for transmission failures, engine problems, and build quality issues that forced Honda to implement multiple recalls and extended warranty programs while damaging customer confidence in the Accord nameplate.

Engine problems also plagued this generation, with reports of premature engine failure, excessive oil consumption, and cylinder head issues that required major repairs.

The V6 engines were particularly problematic, suffering from timing belt tensioner failures that could lead to catastrophic engine damage if the timing belt failed. Unlike previous Honda engines known for their longevity and reliability, these powerplants often required significant repairs well before reaching typical replacement intervals.

Electrical system problems became increasingly common in this generation, with reports of premature alternator failures, starter problems, and various electronic control module failures that resulted in expensive repairs and unreliable operation.

The complexity of the electrical systems had increased significantly compared to previous generations, but the reliability hadn’t kept pace with the added sophistication.

Suspension component failures occurred more frequently than in previous generations, with reports of premature strut failures, control arm problems, and other suspension-related issues that required expensive repairs and affected vehicle safety and handling.

The cumulative effect of these problems created a significant reliability crisis for Honda, forcing the company to implement numerous recalls, extended warranty programs, and customer satisfaction initiatives to address the widespread defects affecting this generation of Accord.

3. Honda Pilot (2009-2015 Second Generation)

The second-generation Honda Pilot marked a significant decline in reliability compared to its predecessor, suffering from multiple serious defects that contradicted Honda’s reputation for dependable SUVs.

This generation became notorious for Variable Cylinder Management (VCM) engine problems, transmission issues, and various component failures that required expensive repairs and damaged Honda’s standing in the competitive three-row SUV segment.

The most serious and widespread problem involved Honda’s Variable Cylinder Management system, which was designed to improve fuel economy by deactivating cylinders under light load conditions.

However, the VCM system proved fundamentally flawed, causing excessive engine vibration, premature engine mount failure, and eventual internal engine damage.

The constant cycling between different cylinder configurations created unusual stress patterns that Honda’s engines weren’t adequately designed to handle, leading to premature wear of critical internal components.

Engine problems extended beyond the VCM system, with reports of excessive oil consumption, timing belt tensioner failures, and various internal engine problems that required major repairs. Many owners reported engines consuming a quart of oil every 1,000 miles or less, well beyond normal consumption rates and requiring constant monitoring and frequent oil additions.

The timing belt tensioner problems were particularly serious, as failure could result in catastrophic engine damage requiring complete engine replacement.

Transmission problems plagued this generation, with reports of harsh shifting, slipping, premature failure, and various operational issues that required expensive repairs or complete transmission replacement.

The six-speed automatic transmission proved less reliable than the simpler five-speed unit used in the previous generation, suggesting that increased complexity had compromised durability and long-term reliability.

Air conditioning system failures became increasingly common, with reports of premature compressor failures, refrigerant leaks, and various system malfunctions that required expensive repairs.

Paint quality issues and premature rust formation became more prevalent in this generation, with reports of clear coat failure, paint oxidation, and rust formation that occurred well before such problems typically manifest.

The build quality seemed to have declined compared to previous generations, with various fit and finish issues that detracted from the vehicle’s quality and durability.

4. Honda CR-V (2007-2011 Third Generation)

The third-generation Honda CR-V represented a significant departure from Honda’s traditionally reliable compact SUV formula, suffering from multiple serious defects that damaged the model’s reputation for dependability.

This generation became notorious for engine problems, air conditioning failures, and various component issues that required expensive repairs and contradicted Honda’s reputation for building reliable crossover vehicles.

The most serious problem involved engine block cracking in the 2.4-liter K24Z1 engine, similar to issues affecting the contemporary Civic. The engine blocks would develop cracks that allowed coolant to leak into the combustion chambers or external environment, leading to overheating, white exhaust smoke, and eventually complete engine failure.

The problem was serious enough to generate class-action lawsuits and force Honda to extend engine warranties on affected vehicles, acknowledging the systematic nature of the defect.

Air conditioning system failures became epidemic in this generation, with reports of premature compressor failures, refrigerant leaks, and complete system malfunctions that left owners without climate control during hot weather.

The air conditioning problems were so widespread that Honda implemented multiple service campaigns and extended warranties to address the issues, but many owners faced repeated repairs and significant expense to maintain functional climate control systems.

Real Time 4WD system problems created safety and reliability concerns, with reports of system failures, unusual noises, and operational issues that affected the vehicle’s all-weather capability.

The 4WD system, which had been remarkably reliable in previous generations, seemed to suffer from component failures and design issues that required expensive repairs and reduced the vehicle’s utility in adverse weather conditions.

Engine oil consumption problems plagued many examples of this generation, with reports of excessive oil burning that required frequent oil additions and monitoring.

The suspension systems seemed to lack the durability that had characterized previous CR-V generations, requiring more frequent repairs and maintenance.

The cumulative effect of these problems created a reliability crisis for the CR-V nameplate, forcing Honda to implement numerous recalls, extended warranty programs, and service campaigns to address the widespread defects affecting this generation of their popular compact SUV.

5. Honda Ridgeline (2017-2023 Second Generation)

The second-generation Honda Ridgeline, while addressing some issues from its predecessor, introduced new reliability concerns that affected Honda’s reputation in the pickup truck segment.

This generation suffered from various engine, transmission, and component problems that contradicted Honda’s traditional reliability standards and created expensive repair issues for owners who expected Honda-level dependability from their trucks.

Engine problems became a significant concern, with reports of excessive oil consumption, timing belt issues, and various internal engine problems that required major repairs.

The 3.5-liter V6 engine, while sharing basic architecture with proven Honda powerplants, seemed to suffer from quality control issues and component problems that affected its reliability and longevity. Some owners reported engines consuming oil at rates well beyond normal specifications, requiring constant monitoring and frequent oil additions.

The nine-speed automatic transmission proved problematic, with reports of harsh shifting, hesitation, premature failure, and various operational issues that affected drivability and required expensive repairs.

The increased complexity of the transmission system didn’t translate to improved reliability, and many owners experienced multiple transmission-related problems that required dealer visits and extended repair periods.

Infotainment system problems became increasingly common, with reports of system crashes, software glitches, and hardware failures that left owners without essential vehicle functions.

The touchscreen-based systems proved less reliable than traditional controls, requiring software updates, component replacements, and various repairs that weren’t typically associated with Honda vehicles.

Bed and tailgate mechanism problems affected the truck’s primary utility, with reports of tailgate failures, bed drainage issues, and various mechanical problems that compromised the vehicle’s functionality as a pickup truck.

The innovative tailgate design, while offering unique features, proved less reliable than traditional tailgate systems and required more frequent repairs and adjustments.

Paint quality issues and premature rust formation became concerns for some owners, with reports of clear coat failure, paint oxidation, and rust development that occurred earlier than expected.

The increased complexity of modern vehicle electrical systems created multiple potential failure points that hadn’t been adequately addressed in the design and manufacturing process.

Also Read: 5 Electric Vehicles With Battery Packs That Don’t Degrade Vs 5 That Need Early Replacements