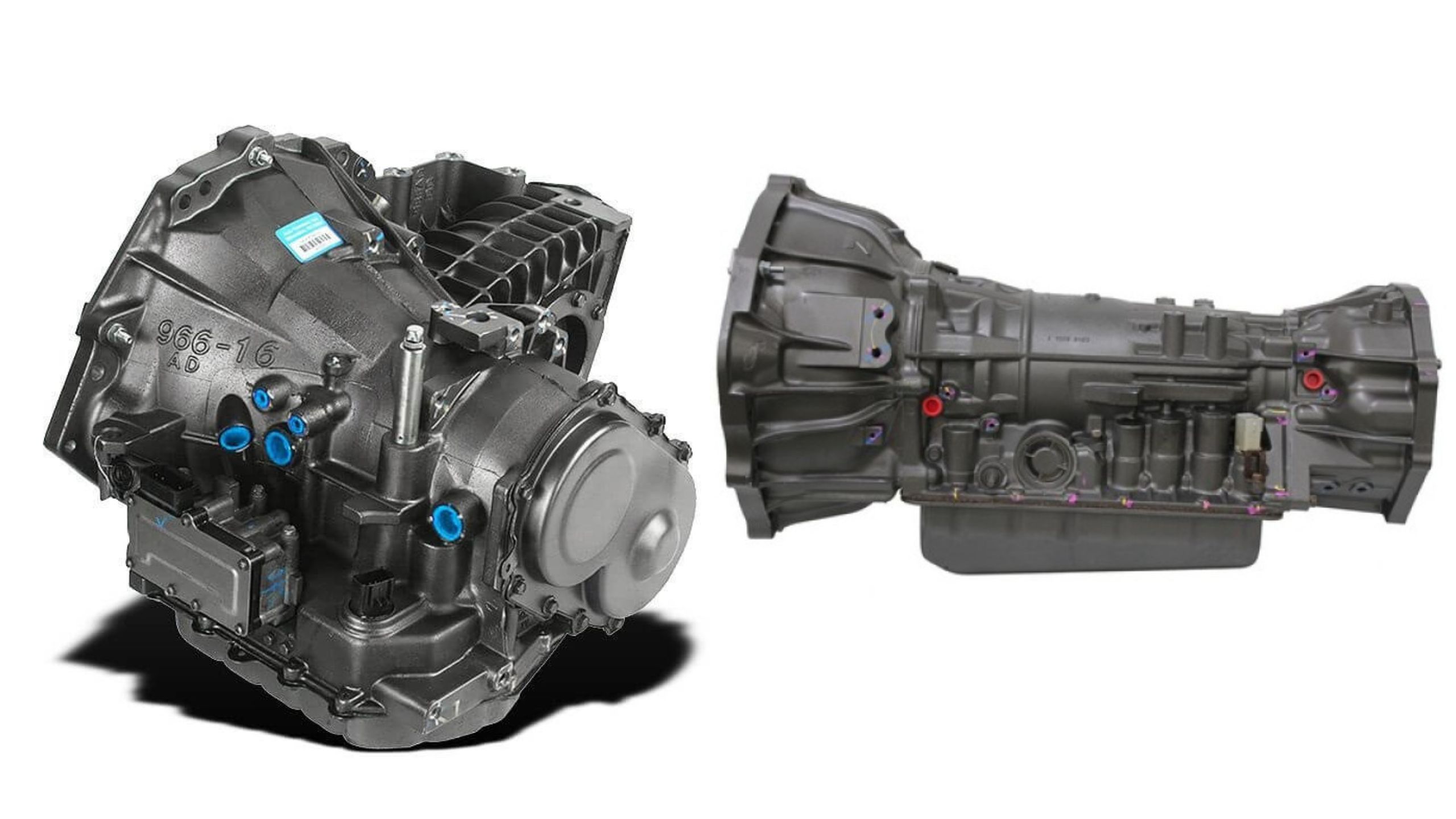

The automatic transmission stands as one of the most complex and crucial components in modern vehicles, serving as the mechanical bridge between engine power and wheel motion.

This intricate system of gears, clutches, bands, and hydraulic controls has evolved dramatically since its introduction in the 1940s, with some designs achieving legendary status for their longevity while others have earned notorious reputations for premature failure.

Understanding the reliability spectrum of automatic transmissions is essential for both car buyers and automotive enthusiasts. The difference between a transmission that runs smoothly for 300,000 miles and one that requires rebuilding at 80,000 miles often comes down to fundamental design philosophy, manufacturing quality, heat management, and hydraulic system robustness.

Some manufacturers prioritized durability and over-engineered their transmissions with robust internal components, effective cooling systems, and conservative shift programming. These transmissions were built during eras when longevity trumped fuel economy regulations and cost-cutting measures.

Additionally, the trend toward sealed transmissions with “lifetime” fluid has eliminated regular maintenance intervals that previously helped extend transmission life. This analysis examines ten automatic transmissions that represent opposite ends of the reliability spectrum.

The durable transmissions earned their reputations through decades of consistent performance across millions of vehicles, while the problematic units became cautionary tales that cost manufacturers billions in warranty claims and irreparable damage to their reputations.

5 Automatics Known For Lasting Decades

These unfortunately designed automatic transmissions suffer from fundamental engineering flaws including inadequate cooling capacity, undersized components, and overly complex control systems that create multiple failure points throughout normal operation.

Their compromised internal architecture features plastic components in high-stress applications, insufficient clutch material thickness, and valve bodies prone to sticking that cause erratic shifting behavior and complete transmission failure.

From routine acceleration that overwhelms weak clutch packs to simple fluid temperature spikes that damage delicate solenoids, these problematic transmissions begin showing symptoms within the first 50,000 miles and progress to complete failure.

The manufacturing shortcuts include inadequate quality control, substandard materials, and cost-cutting measures that eliminate critical redundancies in hydraulic circuits.

Owners frequently report catastrophic transmission failures requiring complete rebuilds often experiencing multiple failures before 150,000 miles, with repair costs exceeding vehicle value and creating dangerous situations when transmissions fail without warning during highway driving or emergency maneuvers.

1. Toyota A340E/A341E/A343F Series (1985-2009)

The Toyota A340E family represents the gold standard of automatic transmission reliability, serving as the backbone for countless Toyota and Lexus vehicles throughout the late 20th and early 21st centuries.

This four-speed automatic transmission was initially developed for Toyota’s rear-wheel-drive applications, later spawning variants like the A341E for four-wheel-drive vehicles and the A343F for front-wheel-drive applications.

The engineering philosophy behind this transmission family emphasized conservative design choices, robust construction, and extensive real-world testing.

The A340E’s legendary durability stems from several key design elements. Toyota employed a massive torque converter with excellent heat dissipation properties, reducing the thermal stress that plagues many automatic transmissions.

The planetary gear sets were manufactured from high-quality steel alloys with precise tolerances, ensuring smooth operation and minimal wear over hundreds of thousands of miles.

The hydraulic valve body featured simple, proven designs with redundant safety systems that prevented catastrophic failures even when minor components began wearing.

Toyota’s commitment to adequate cooling cannot be overstated in the A340E’s success story. Unlike many contemporary transmissions that relied on marginal cooling systems, the A340E featured generous fluid capacity and effective heat exchange with the engine cooling system.

The transmission’s oil pump was sized conservatively, ensuring consistent hydraulic pressure even as internal clearances increased with age. This approach meant that even high-mileage A340E transmissions maintained crisp shifts and proper clutch engagement.

The consistent availability of affordable rebuild kits and replacement parts has helped maintain these transmissions in service long after their original warranty periods expired.

2. General Motors TH350/TH400 (1969-1986)

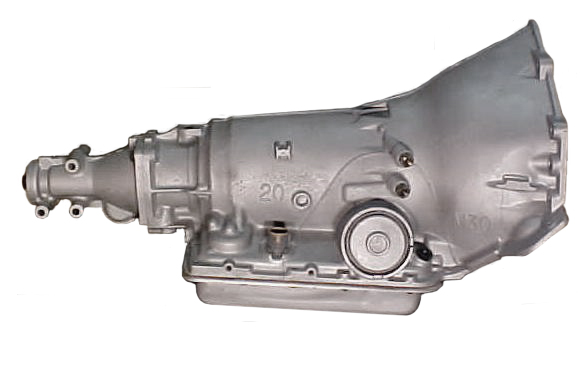

General Motors’ Turbo Hydra-Matic 350 and 400 series transmissions represent the pinnacle of traditional American automatic transmission engineering, embodying the “built like a tank” philosophy that characterized Detroit’s golden age of automotive manufacturing.

These three-speed automatics were designed during an era when durability and reliability were paramount concerns, long before fuel economy regulations and cost-cutting measures began influencing transmission design decisions.

The TH350, introduced in 1969, was designed as a lighter, more compact alternative to the massive TH400, while still maintaining exceptional durability.

Its cast iron case provided enormous strength and excellent heat dissipation, while the aluminum components were strategically placed to reduce weight without compromising structural integrity.

The TH400, meanwhile, was engineered as GM’s heavy-duty transmission, capable of handling the massive torque outputs of big-block V8 engines while maintaining smooth operation and long service life.

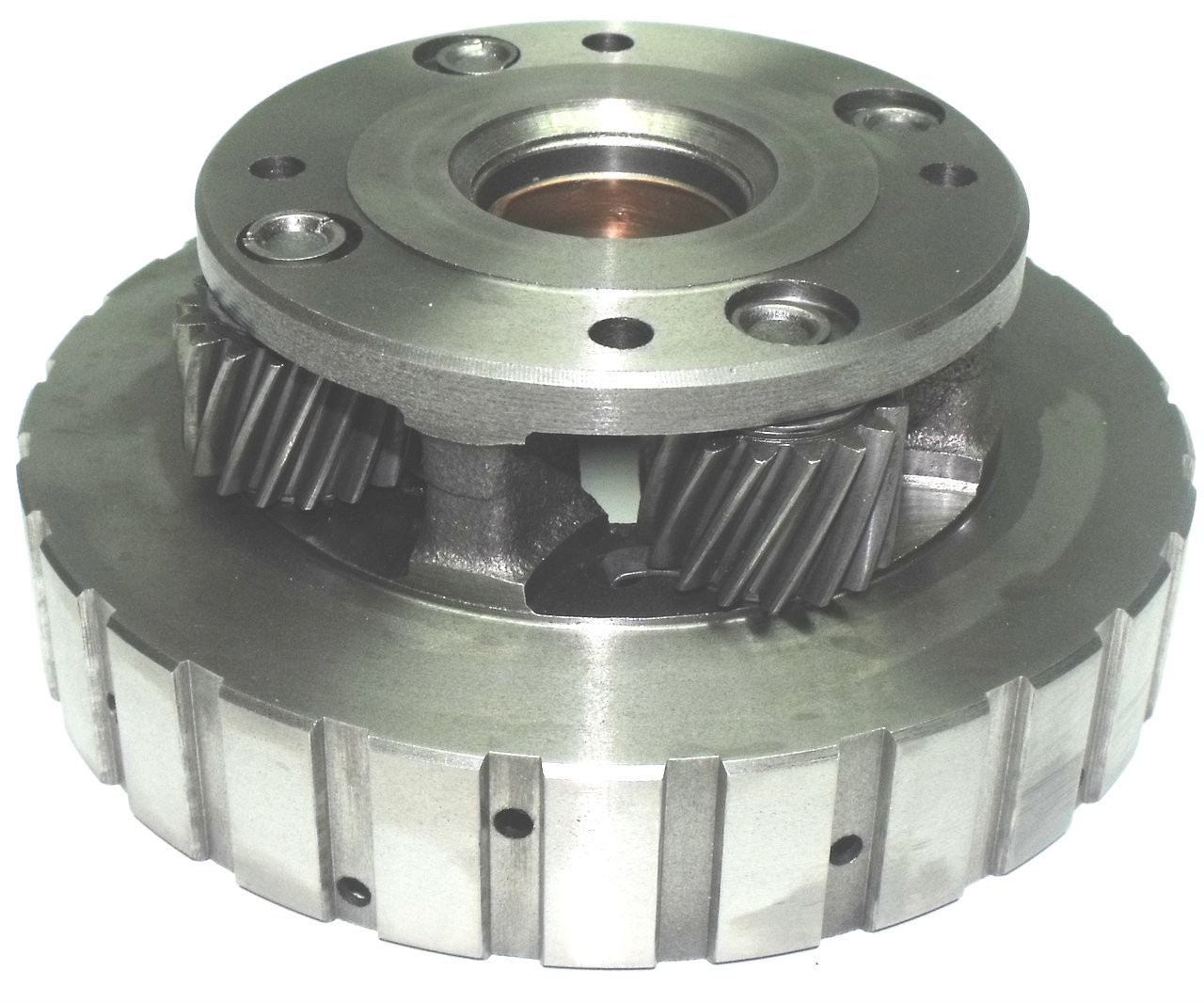

Both transmissions featured robust Simpson planetary gear sets with widely spaced gear ratios that reduced stress on individual components. The clutch packs were generously sized, featuring multiple friction and steel plates, which provided an enormous holding capacity and excellent heat dissipation.

The bands were substantial units with effective servo systems that applied consistent pressure without the complexity that plagued later designs. The torque converters were large, heavy units with excellent multiplication characteristics and superior heat management properties.

The hydraulic systems in both transmissions were marvels of simplicity and effectiveness. The valve bodies featured large passages with minimal restrictions, ensuring adequate flow even as pumps wore and clearances increased.

The governor systems were mechanical units that provided consistent shift points without the electronic complexity that would later introduce new failure modes. The modulator systems responded predictably to engine vacuum, providing smooth shifts under varying load conditions.

Performance enthusiasts continue building high-power versions of these transmissions for racing applications, testament to their fundamental strength and design excellence. Rebuild parts remain widely available and affordable, ensuring these transmissions can continue serving reliably for decades to come.

3. Ford AOD/AODE/4R70W Series (1980-2011)

Ford’s Automatic Overdrive (AOD) transmission family represents one of the most successful attempts at combining durability with fuel-saving overdrive technology.

Introduced in 1980 as Ford’s answer to the fuel crises of the late 1970s, the AOD featured a unique four-speed design that incorporated both hydraulic and mechanical controls, later evolving into the electronically controlled AODE and eventually the refined 4R70W that served Ford faithfully into the 21st century.

The AOD’s innovative design featured a split-torque concept where engine torque was transmitted through both the torque converter and a direct mechanical connection in certain gears.

This approach reduced slippage losses while maintaining the smooth operation characteristics of a traditional automatic. The planetary gear arrangement was more complex than contemporary three-speed automatics, but Ford’s engineers created a robust system that could handle the additional stresses imposed by the overdrive function.

One of the AOD family’s greatest strengths was its progressive development over three decades. Ford continuously refined the design, addressing weaknesses and incorporating improvements based on real-world experience.

Early AOD units suffered from some reliability issues, particularly with the direct clutch drum and intermediate band, but these problems were systematically resolved in later iterations.

The AODE brought electronic controls that improved shift quality and timing, while the 4R70W represented the culmination of Ford’s refinement process.

The mechanical aspects of these transmissions were generally robust. The case was cast aluminum with steel inserts in high-stress areas, providing good strength-to-weight ratio and effective heat dissipation.

The gear trains featured adequately sized components with conservative load ratings. The clutch packs, while not as generous as some contemporary GM transmissions, were appropriately sized for their intended applications and responded well to proper maintenance.

Cooling system design evolved significantly throughout the AOD family’s production run. Early units relied primarily on the radiator-mounted heat exchanger, but Ford gradually improved the cooling capacity and added auxiliary coolers for heavy-duty applications.

Many examples have exceeded 250,000 miles with proper maintenance, and the transmission’s relatively simple electronic controls have proven reliable over time. The availability of aftermarket performance parts and rebuild components ensures continued serviceability for enthusiasts and fleet operators.

4. Chrysler A727 TorqueFlite (1962-1991)

The Chrysler A727 TorqueFlite stands as perhaps the most respected automatic transmission in American automotive history, earning legendary status among both automotive professionals and enthusiasts for its exceptional durability, smooth operation, and remarkable ability to handle high-power applications.

Introduced in 1962 as an evolution of Chrysler’s earlier PowerFlite transmission, the A727 represented the culmination of decades of automatic transmission development and established design principles that influenced the industry for generations.

The TorqueFlite’s legendary reliability stemmed from Chrysler’s conservative engineering approach and extensive use of premium materials. The transmission case was cast from high-quality aluminum alloy with steel reinforcements in critical areas, providing excellent strength while maintaining reasonable weight.

The internal components were manufactured to exceptionally tight tolerances using premium steel alloys, ensuring smooth operation and minimal wear even under severe operating conditions.

The planetary gear arrangement in the A727 was a masterpiece of mechanical engineering. Chrysler employed a simple, robust Simpson gear set with widely spaced ratios that minimized stress on individual components.

The sun gears, planetary carriers, and ring gears were manufactured from case-hardened steel with precise tooth geometry that promoted smooth power transfer and exceptional longevity. The clutch packs featured multiple friction plates with generous surface area and excellent heat dissipation characteristics.

Hydraulic system design was another area where the TorqueFlite excelled. The valve body was machined from high-quality aluminum with large, smooth passages that promoted good fluid flow and minimal pressure losses.

The pump assembly featured a robust design with conservative operating pressures that ensured consistent performance throughout the transmission’s service life. The governor system was entirely mechanical, eliminating the complexity and potential failure points associated with electronic controls.

The kickdown linkage required occasional adjustment, but this was a simple mechanical operation that could be performed with basic tools. Even severely neglected TorqueFlite transmissions often continued functioning adequately, a testament to the robustness of Chrysler’s design.

Also Read: 5 Turbo Engines Known For Longevity vs 5 That Fail Early

5. Mercedes-Benz W4A040/W5A330/722.6 Series (1996-2011)

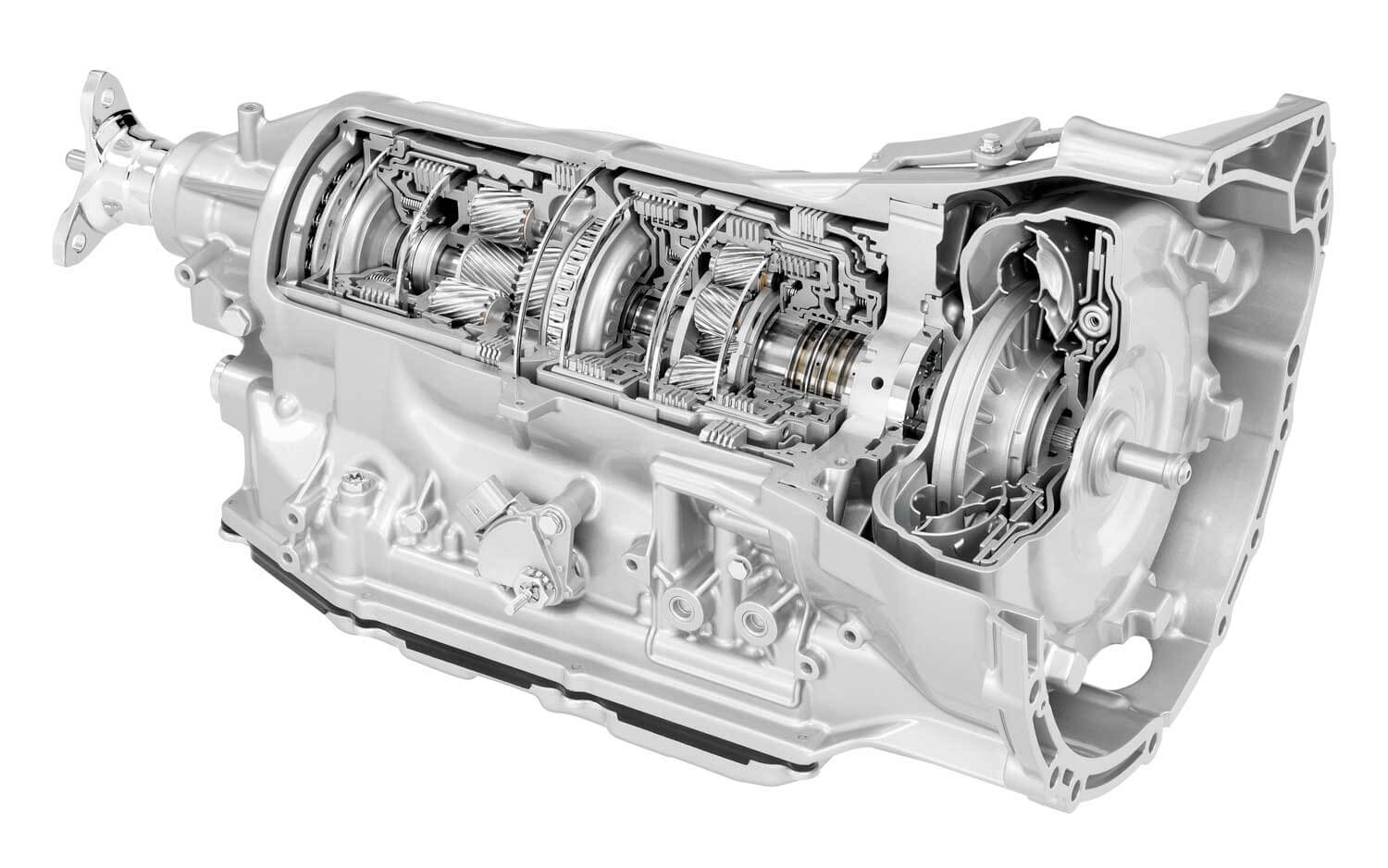

Mercedes-Benz’s 722.6 series automatic transmission, developed in collaboration with automotive supplier ZF, represents the pinnacle of European automatic transmission engineering and stands as one of the most durable and sophisticated automatics ever produced.

This five-speed electronic transmission was designed to Mercedes-Benz’s exacting standards for luxury, refinement, and longevity, incorporating advanced technologies and premium materials that set new benchmarks for automatic transmission performance.

The 722.6’s exceptional durability begins with its fundamental architecture. The transmission case is constructed from high-strength aluminum alloy with reinforced mounting points and optimized ribbing for maximum structural integrity.

Internal components are manufactured from premium steel alloys with specialized heat treatments and surface coatings that dramatically extend service life. The planetary gear sets feature helical-cut teeth with precise geometry that promotes smooth, quiet operation while distributing loads effectively across all contact surfaces.

Electronic control systems in the 722.6 represent a quantum leap in transmission management technology. The transmission control module continuously monitors dozens of parameters, including throttle position, engine load, vehicle speed, transmission temperature, and even road grade to optimize shift timing and clutch engagement.

The adaptive shift logic learns driver preferences and adjusts shift characteristics accordingly, while also compensating for component wear as the transmission ages. This sophisticated control system prevents many of the harsh shifts and premature wear patterns that plague simpler transmissions.

Heat management was engineered to exceptional standards in the 722.6 series. The transmission features a large, efficient heat exchanger integrated into the radiator assembly, supplemented by an electric auxiliary cooling fan in many applications.

The fluid capacity is generous, and Mercedes specified their proprietary MB 236.14 transmission fluid with superior thermal stability and lubrication properties. The transmission’s operating temperature is continuously monitored, with the control system modifying shift patterns to prevent overheating under severe conditions.

The transmission’s sophisticated diagnostic capabilities allow technicians to identify and address minor issues before they develop into major problems, further extending service life through predictive maintenance strategies.

5 That Need Rebuilds fast

These unfortunately designed automatic transmissions suffer from fundamental engineering flaws, including inadequate cooling capacity, undersized components, and overly complex control systems that create multiple failure points throughout normal operation.

Their compromised internal architecture features plastic components in high-stress applications, insufficient clutch material thickness, and valve bodies prone to sticking, which cause erratic shifting behavior and complete transmission failure.

From routine acceleration that overwhelms weak clutch packs to simple fluid temperature spikes that damage delicate solenoids, these problematic transmissions begin showing symptoms within the first 50,000 miles and progress to complete failure.

The manufacturing shortcuts include inadequate quality control, substandard materials, and cost-cutting measures that eliminate critical redundancies in hydraulic circuits.

Owners frequently report catastrophic transmission failures requiring complete rebuilds, often experiencing multiple failures before 150,000 miles, with repair costs exceeding vehicle value and creating dangerous situations when transmissions fail without warning during highway driving or emergency maneuvers.

1. Nissan CVT (Jatco CVT7/CVT8) (2003-Present)

Nissan’s adoption of continuously variable transmission (CVT) technology represents one of the most problematic reliability decisions in modern automotive history.

The Jatco CVT7 and CVT8 units, used extensively across Nissan’s lineup since 2003, have earned notoriety for premature failures, expensive repairs, and fundamental design flaws that have resulted in multiple class-action lawsuits and extended warranty programs covering hundreds of thousands of vehicles.

The fundamental problem with Nissan’s CVT implementation lies in the inherent limitations of the technology when applied to mainstream automotive applications.

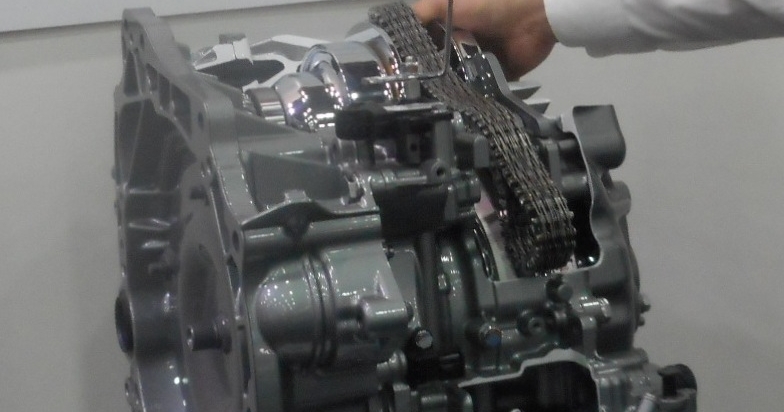

Unlike traditional automatics that use discrete gear ratios with robust clutch packs and bands, CVTs rely on a steel belt or chain running between two variable-diameter pulleys.

This system provides infinite gear ratios and improved fuel economy, but the contact pressures between the belt and pulleys are enormous, creating wear patterns and heat generation that traditional transmissions don’t experience.

Nissan’s specific CVT implementations suffer from multiple systemic issues. The steel belt, manufactured by various suppliers including Bosch and Jatco, experiences premature stretching and wear that leads to slipping, jerky operation, and eventual failure.

The primary and secondary pulleys develop scoring and wear patterns that prevent proper belt engagement, while the hydraulic system responsible for controlling pulley pressure often fails prematurely due to contamination and overheating.

Heat management has proven to be a critical weakness in Nissan’s CVT designs. The friction generated by the belt-pulley interface creates substantial heat that must be dissipated effectively to prevent premature component failure.

Many Nissan CVT applications feature inadequate cooling systems with marginal heat exchanger capacity and insufficient fluid circulation. The transmission fluid itself, while specially formulated for CVT applications, breaks down rapidly under the high temperatures and pressures inherent in the system.

The electronic control systems governing Nissan’s CVTs have also proven problematic. The transmission control module must precisely manage pulley pressures, belt tension, and gear ratios while preventing slippage and overheating.

Early control algorithms were poorly calibrated, leading to harsh operation, premature wear, and inconsistent performance. Software updates have addressed some issues, but fundamental hardware limitations remain.

The fluid specification is critical; using the incorrect fluid can cause immediate damage. Despite these requirements, many Nissan CVTs fail well before 100,000 miles, with some experiencing problems as early as 40,000-60,000 miles, even with proper maintenance.

2. Ford PowerShift DPS6 (2011-2019)

Ford’s PowerShift DPS6 dual-clutch transmission represents one of the most catastrophic automatic transmission failures in modern automotive history, resulting in billions of dollars in warranty costs, countless customer complaints, and irreparable damage to Ford’s reputation for reliability.

This six-speed dual-clutch automatic was designed to provide the fuel economy benefits of a manual transmission with the convenience of an automatic, but fundamental design flaws and inadequate testing led to widespread premature failures across multiple vehicle platforms.

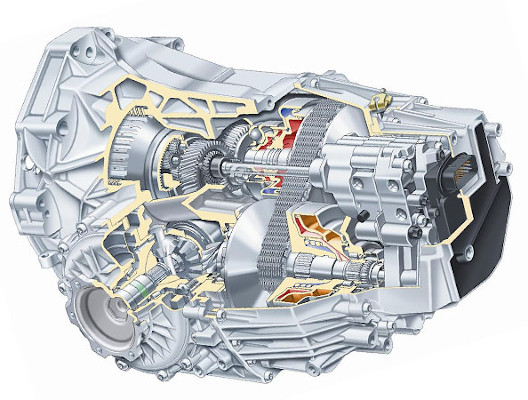

The PowerShift transmission’s problems stem from its dual-clutch architecture, which uses two separate clutch assemblies to pre-select gears and enable seamless shifts without power interruption.

While this technology works well in high-performance applications and commercial vehicles, Ford’s implementation for mass-market vehicles proved problematic from the outset. The clutches were inadequately sized for the intended applications and operating conditions, leading to premature wear, slippage, and eventual failure.

Clutch overheating became the PowerShift’s primary failure mode. The transmission’s computer-controlled clutch engagement system often failed to modulate pressure correctly, causing excessive slippage during engagement and generating destructive heat levels.

This problem was particularly severe during low-speed maneuvering, stop-and-go traffic, and parking lot operations where traditional automatics excel. The resulting heat would quickly degrade the clutch friction materials and contaminate the transmission fluid with debris.

The electronic control systems proved equally problematic. The transmission control module struggled to properly modulate clutch engagement, often causing harsh shifts, shuddering, hesitation, and complete loss of power transmission.

The company ultimately discontinued the transmission and reverted to conventional automatics for affected vehicle lines. The PowerShift failure highlighted the risks of introducing complex new technologies without adequate testing and validation, particularly in cost-sensitive mass-market applications where durability and reliability are paramount concerns.

3. Chrysler A604 UltraDrive (1989-2002)

Chrysler’s A604 UltraDrive transmission stands as a cautionary tale of ambitious engineering undermined by premature market introduction and inadequate development resources.

This four-speed electronic automatic was designed to be Chrysler’s technological showcase, featuring advanced electronic controls and adaptive shift logic that promised superior performance and fuel economy.

Instead, the A604 became synonymous with reliability problems, expensive repairs, and customer dissatisfaction that damaged Chrysler’s reputation for decades.

The A604’s problems began with its rushed development schedule. Chrysler was under intense competitive pressure to introduce a modern four-speed automatic to compete with offerings from General Motors and Ford.

The company accelerated the A604’s development timeline, reducing the extensive testing and validation that complex transmissions require. This decision would prove costly as real-world operation revealed numerous design weaknesses that should have been identified and corrected during development.

Electronic control system problems plagued the A604 throughout its production run. The transmission control module was one of the first fully electronic automotive transmission controllers, featuring complex algorithms for shift timing, pressure modulation, and adaptive learning.

However, the early control modules were unreliable, suffering from component failures, software glitches, and poor environmental durability. Many A604 failures were traced to control module problems rather than mechanical issues.

Maintenance requirements for the A604 were more stringent than many customers and service technicians realized. The transmission required specific fluid types and precise service procedures, but this information was not always communicated effectively.

The adaptive learning capability, while advanced for its time, often required reset procedures after service that many technicians were unfamiliar with. Improper service frequently resulted in operational problems that were difficult to diagnose and correct.

4. General Motors 4L60E (1992-2013)

General Motors’ 4L60E transmission presents a complex reliability story, representing both the potential and pitfalls of electronic transmission control technology.

While not as universally problematic as some transmissions on this list, the 4L60E earned a reputation for specific, predictable failure modes that affected hundreds of thousands of vehicles across GM’s truck and SUV lineup.

The transmission’s problems were particularly frustrating because they often occurred in otherwise reliable vehicles, leaving customers with expensive repair bills and reduced confidence in GM’s engineering capabilities.

The 4L60E was essentially an electronically controlled version of GM’s proven 4L60 hydraulic automatic, which itself evolved from the legendary TH700R4.

While the base mechanical design was sound, the addition of electronic controls introduced new complexity and potential failure points. The transmission control module managed shift timing, line pressure, and torque converter lockup through a series of computer-controlled solenoids and valves.

When these systems worked properly, the 4L60E provided smooth shifts and good fuel economy. When they failed, the results were often catastrophic.

The most common 4L60E failure mode involved the 3-4 clutch pack, which was inadequately designed for the transmission’s intended applications.

This clutch pack controlled the engagement of fourth gear and suffered from insufficient capacity and poor heat dissipation. Under normal driving conditions, the 3-4 clutches would gradually wear and begin slipping, eventually leading to complete failure and loss of overdrive. Heavy towing, aggressive driving, or inadequate cooling accelerated this failure mode significantly.

Cooling system adequacy varied significantly across 4L60E applications. While some installations featured robust cooling systems appropriate for the transmission’s thermal load, others were marginal at best.

Trucks and SUVs used for towing were particularly vulnerable to overheating-related failures, as the 4L60E’s cooling requirements exceeded the capacity of many OEM heat exchangers under severe operating conditions.

5. Audi/Volkswagen 01J Multitronic CVT (2000-2014)

Audi and Volkswagen’s 01J Multitronic continuously variable transmission represents a fascinating but ultimately flawed attempt to bring advanced CVT technology to premium automotive applications.

Unlike conventional CVTs that use belts or chains, the Multitronic employed a sophisticated chain-and-pulley system designed to handle higher torque loads while providing the smooth, stepless acceleration characteristic of CVT operation.

Despite its technical innovation, the 01J became notorious for expensive failures and complex repair requirements that made it one of the most problematic transmissions in European automotive history.

The Multitronic’s unique design featured a steel chain running between two variable-diameter cone pulleys, similar to other CVTs but with several important distinctions.

The chain was constructed from hundreds of small steel links designed to provide flexible operation while maintaining the strength necessary for higher-performance applications.

The pulleys were hydraulically actuated with precise electronic control, allowing infinite variation of gear ratios within the transmission’s operating range.

Chain wear became the Multitronic’s primary failure mode, typically manifesting between 80,000 and 120,000 miles depending on driving conditions and maintenance history.

The steel chain would gradually stretch due to the enormous contact pressures between the chain links and pulley surfaces. As the chain stretched, it would begin slipping on the pulleys, creating metal debris that contaminated the transmission fluid and accelerated component wear throughout the system.

The hydraulic control system proved equally problematic. The Multitronic required extremely precise hydraulic pressure control to maintain proper chain tension and prevent slippage.

The system employed multiple solenoids and pressure regulators that frequently failed due to contamination from chain wear debris. When these control components failed, the transmission often entered emergency mode with severely limited functionality, sometimes leaving vehicles completely inoperable.

The fluid specification was critical using incorrect fluid would cause immediate damage. Despite these maintenance requirements, many Multitronic transmissions failed well before reaching high mileage, often requiring complete replacement rather than repair due to the complexity and cost of internal components.

Also Read: 5 Electric Vehicles With Battery Packs That Don’t Degrade Vs 5 That Need Early Replacements