When drivers discuss the strength of diesel engines, it often comes down to two main things: how long they last and how dependable they are in daily use. Diesel engines have always carried a reputation for durability, and many owners proudly share stories of their trucks or cars running well beyond a million miles without any major trouble.

Some engines are so reliable that they continue performing strongly even after the vehicle’s body or frame has given up. At the same time, there are diesel engines that look promising on paper but bring constant trouble once put to the test in real conditions.

The difference between the two comes down to engineering quality, design, and how well manufacturers prepared them to handle stress, heat, and demanding road conditions.

For many drivers, especially those who depend on diesel trucks for work or long-distance travel, the engine is the heart of the investment. A strong diesel motor can make a truck or SUV last for decades, turning into a trusted machine that people refuse to part with.

Some of these engines were built so well that they became legends, often outliving the vehicles they were installed in. These engines earned respect not only for lasting long but also for keeping maintenance simple and affordable. However, not every diesel story ends well. Some engines turned out to be plagued by weak parts, poor engineering choices, or constant maintenance headaches.

Owners of these problem engines often felt betrayed, spending more time and money at the repair shop than actually driving. While diesel should be about strength, economy, and endurance, a poorly built motor quickly destroys that promise.

5 Diesel Engines That Outlast the Vehicle

1. Cummins 6BT 5.9

The Cummins 6BT 5.9 engine has become one of the most respected diesel engines in history. Produced during the late 1980s and 1990s, it earned a reputation for unmatched strength and dependability.

This engine is a straight-six turbocharged diesel that can run hundreds of thousands of miles without serious problems, provided that it is maintained properly. Owners often remark that the 6BT outlives the body of the truck it powers, which explains why so many old Dodge Rams with rusty frames still have a strong-running Cummins under the hood.

One of the reasons this engine lasts so long is its simple mechanical fuel system. Unlike newer engines that rely on complicated electronics, the 6BT uses mechanical injectors and a straightforward design.

This simplicity reduces the chance of electronic failures and makes it easier for mechanics to repair. Farmers, truckers, and off-road enthusiasts loved this feature because it meant the engine could keep running in conditions where high-tech systems might fail.

Durability also comes from the heavy-duty build of the 6BT. The engine block, pistons, and crankshaft are over-engineered to handle stress far above normal driving conditions. It was originally designed for medium-duty trucks and industrial use, so when placed in a pickup truck, it was naturally stronger than what most drivers needed.

That is why these engines regularly cross the 500,000-mile mark with little more than routine maintenance. Another reason for its legendary status is how easy it is to upgrade. Many owners modify the 6BT for extra power, and it still manages to handle the added strain without breaking down.

While the body and transmission of the truck may fail with age, the Cummins keeps running, often transplanted into other vehicles to continue its service. This reputation makes the 6BT one of the clearest examples of a diesel engine that truly outlasts the vehicle.

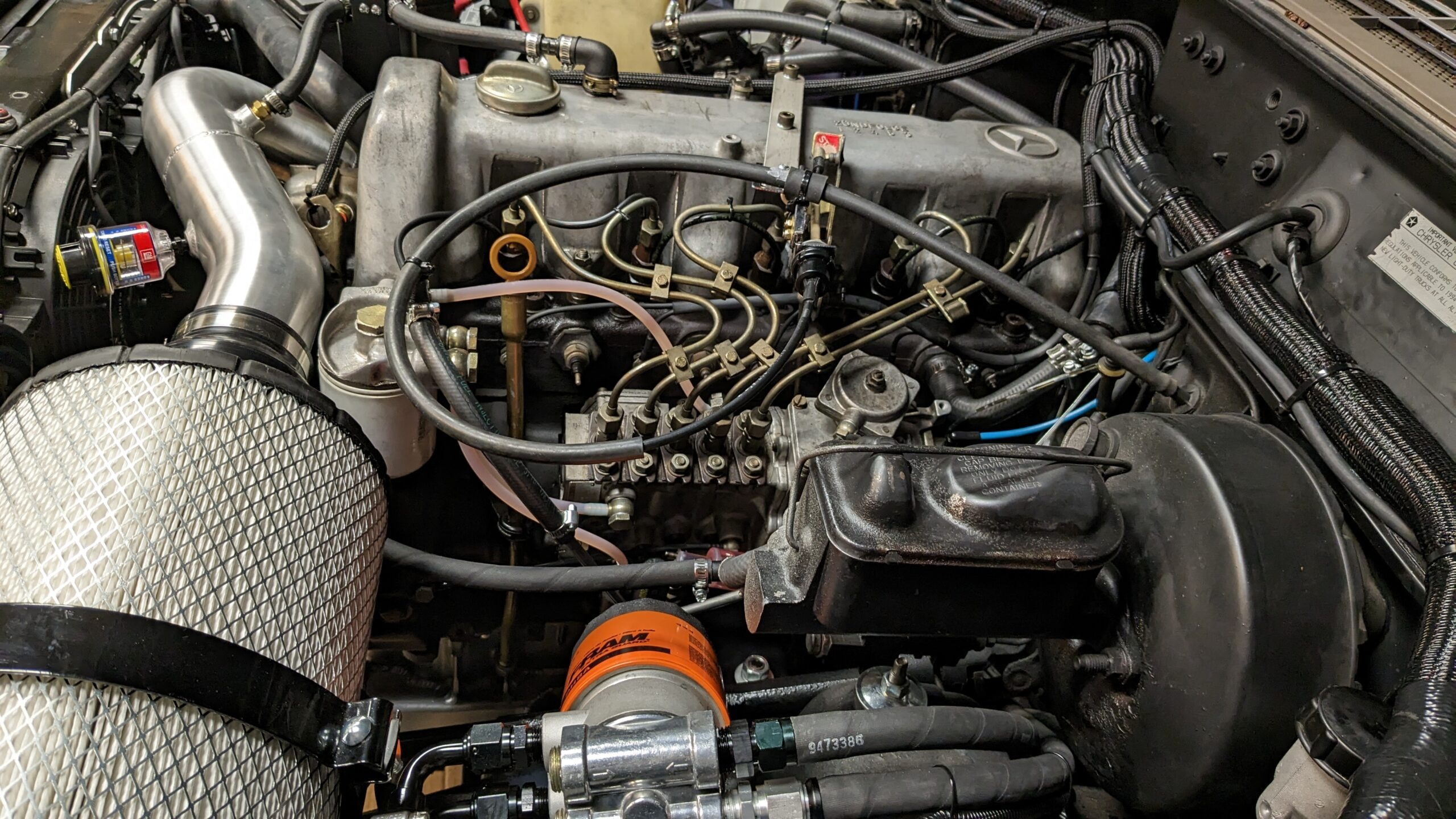

2. Mercedes-Benz OM617

Mercedes-Benz has long been known for building engines that last, but the OM617 diesel stands out even among its lineup. Produced from the mid-1970s through the 1980s, this five-cylinder diesel became famous for its ability to run nearly forever with minimal issues. Many owners still drive cars equipped with the OM617 today, some with mileage climbing past 600,000 miles.

One of the strongest points of the OM617 is its mechanical simplicity. Similar to the Cummins 6BT, this engine does not depend on complicated electronics. Its fuel injection system is straightforward and designed for steady reliability rather than high performance.

This makes it very forgiving, even if maintenance is not perfect. People often joke that the engine will still run even if the rest of the car has completely fallen apart. Another major advantage is the quality of materials Mercedes used during that era. The cast-iron block and robust internal components were designed to handle years of stress without wearing out.

Unlike some engines that struggle with weak gaskets or fragile parts, the OM617 rarely suffers from major failures. Instead, most problems that arise are small issues such as leaking seals or minor fuel pump adjustments, which are easy to fix.

The OM617 also proved itself in harsh environments around the world. These engines were commonly used in African and Middle Eastern countries where fuel quality and driving conditions were often less than ideal.

Despite poor roads, extreme heat, and limited maintenance, the OM617 continued to deliver reliable service. Its ability to run on low-quality diesel without major damage added to its reputation as nearly indestructible.

For many enthusiasts today, cars equipped with the OM617 are still highly valued. People restore old Mercedes sedans and coupes largely because of the strong engine inside. Just like the Cummins 6BT, the OM617 often outlasts the vehicle, and it remains one of the best examples of a diesel engine built for true longevity.

Also Read: 5 Engines That Go a Lifetime Without Rebuilds and 5 That Need One by 60K

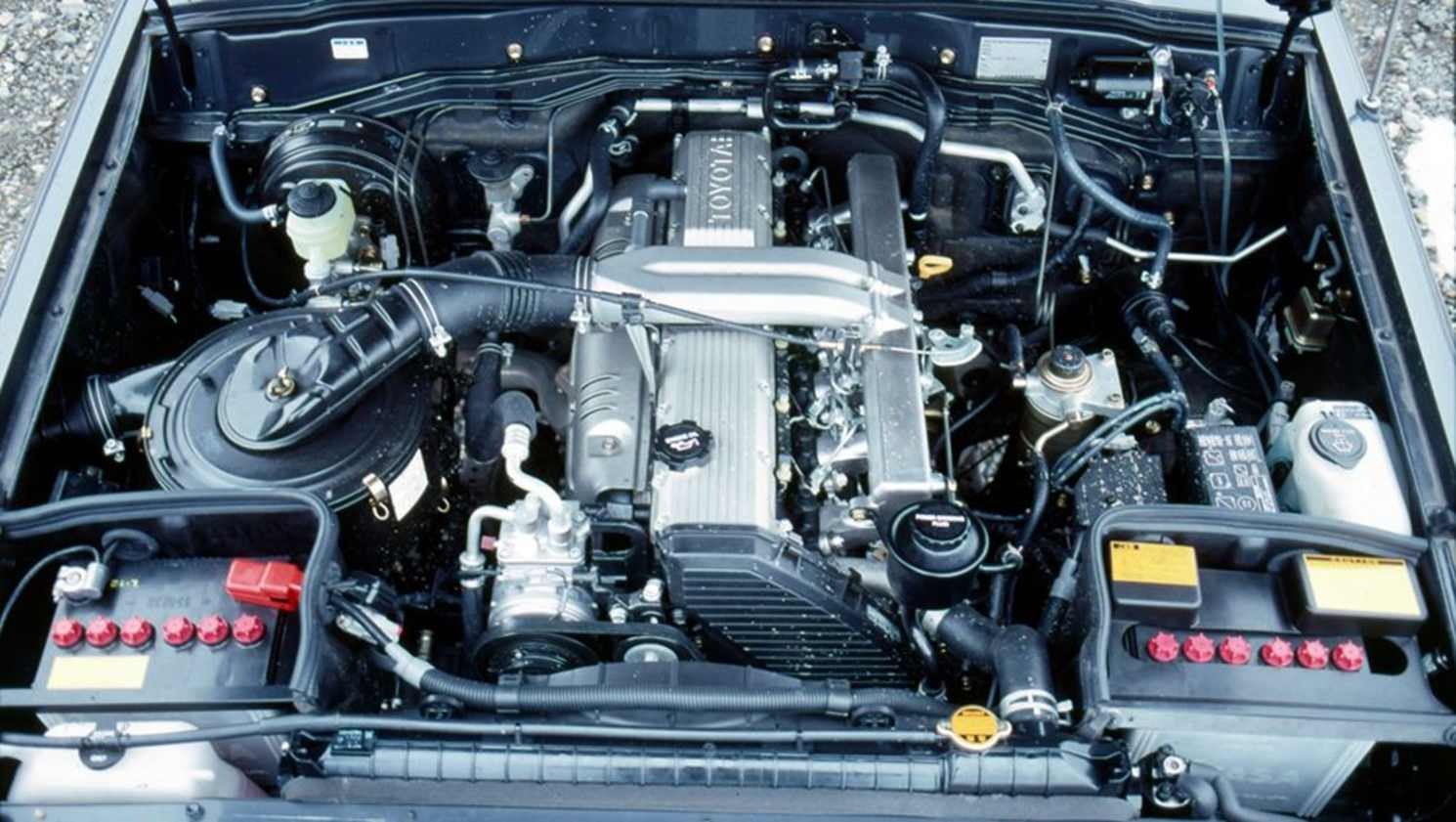

3. Toyota 1HZ

The Toyota 1HZ engine is another diesel that is known for lasting far beyond the vehicle itself. This naturally aspirated inline-six diesel is famous for its toughness, especially in off-road and utility vehicles like the Toyota Land Cruiser. Produced from the late 1980s onward, the 1HZ is beloved across Africa, Australia, and other regions where reliability is valued above all else.

One of the strengths of the 1HZ is that it was built with durability as the top priority. It may not produce as much power as turbocharged engines, but its slower and steadier operation keeps stress low on internal parts.

The cast-iron block and strong crankshaft mean the engine can handle years of abuse without failing. Owners often report driving their Land Cruisers through deserts, forests, and remote regions with no major engine issues even after decades of use.

Another reason the 1HZ is so dependable is its ability to tolerate poor maintenance and low-quality fuel. Drivers in remote areas often cannot access premium diesel or high-end service centers, yet the 1HZ keeps running. Its simple mechanical fuel system does not depend on sensitive electronics, making it easier to repair in the field with basic tools.

This engine also benefits from Toyota’s global reputation for building vehicles that endure hard conditions. The 1HZ was designed to support humanitarian work, military operations, and heavy off-road use.

In all these cases, the engine proved itself as one that will not give up easily. Even when the body of the vehicle rusts or the suspension wears out, the engine usually remains strong enough to be swapped into another chassis.

Because of these traits, the Toyota 1HZ is considered one of the most dependable diesel engines ever made. It represents the kind of powerplant that outlasts the vehicle, keeping Toyota’s reputation for durability alive in some of the toughest places on earth.

4. Detroit Diesel Series 60

The Detroit Diesel Series 60 is one of the most respected engines in the heavy-duty truck industry. Introduced in the late 1980s, this inline-six turbo diesel quickly became a favorite among fleet operators and long-haul drivers. It was known for both its durability and its efficiency, often lasting more than a million miles before requiring major rebuilds.

One of the reasons the Series 60 stood out was that it was among the first electronically controlled heavy-duty diesels. While some electronics in engines have been a problem, Detroit Diesel engineered this system well, making it both reliable and fuel-efficient. The balance between mechanical toughness and smart electronics made it a pioneer in modern diesel design.

The Series 60 was built with a strong block and internals, designed to handle the extreme stress of long-distance hauling. Trucking companies valued it because downtime was reduced, and maintenance costs were kept under control. Many of these engines are still running today, decades after they were first installed in big rigs.

Another reason for its reputation is how well it performed in different applications. It was not limited to long-haul trucks but also used in buses, construction equipment, and even boats. This versatility proved that the Series 60 was engineered to a very high standard.

For many drivers, the Detroit Diesel Series 60 became synonymous with reliability on the highway. Even when the truck’s body and suspension wore out, the engine often remained in good condition. Rebuilding or transplanting the Series 60 into another vehicle was common, showing just how much life the engine carried beyond the original truck.

Because of its proven strength and dependability, the Series 60 stands as one of the diesel engines that truly outlasts the vehicle it powers.

5. Caterpillar C15

The Caterpillar C15 engine is another diesel that is remembered for its strength and endurance. Used mainly in heavy-duty trucks, construction equipment, and industrial machines, the C15 earned a reputation for running long and hard without major failures. Introduced in the early 2000s, it carried on Caterpillar’s tradition of producing engines built to handle extreme stress.

One of the strongest qualities of the C15 is its tough construction. The block, pistons, and other components were engineered for very demanding work. This engine was never about saving weight or cutting corners.

It was designed to handle heavy loads and long-distance hauling across rough terrain. Because of this, many C15 engines are still running strong even after hundreds of thousands of miles. Another reason the C15 became a legend is its flexibility.

It could be tuned for different applications, from highway trucks to construction machinery. No matter where it was used, the engine proved itself reliable. Even when emissions rules forced changes to the design, the basic C15 remained respected for its durability.

Owners often point out that while maintenance is necessary, the C15 rarely suffers from catastrophic failures. Small problems can appear, but the engine as a whole remains strong and dependable. Many drivers report that the truck’s frame or body wears out before the C15 gives up.

This reputation for outlasting the vehicle made the Caterpillar C15 a favorite among truckers and construction operators. Just like the Cummins 6BT and Detroit Diesel Series 60, it belongs to the list of engines that built trust through long-lasting performance.

5 Diesel Engines That Constantly Fail

1. Ford 6.0 Power Stroke

When Ford introduced the 6.0 Power Stroke diesel in the early 2000s, many buyers expected it to continue the strong reputation built by the 7.3 Power Stroke before it. Instead, the 6.0 turned out to be one of the most troublesome diesel engines ever installed in heavy-duty pickups. Despite offering more power and modern features, this engine became known for frequent breakdowns and expensive repairs.

One of the biggest problems with the 6.0 Power Stroke is its poor head gasket design. The engine is very prone to blowing head gaskets under heavy load, especially when towing or after simple modifications.

The weak head bolts could not hold the pressure created by the turbocharger, leading to coolant leaks and engine failure. Replacing head gaskets on this engine is extremely costly, which frustrated owners who expected long-lasting performance.

The engine’s EGR (Exhaust Gas Recirculation) system also caused endless headaches. The cooler used in the EGR system often failed, leaking coolant and leading to overheating. Once that happened, other parts such as the turbocharger and oil cooler were affected, creating a chain reaction of failures. Many truck owners ended up spending thousands of dollars just to keep their engines running.

Electrical and sensor problems also added to the poor reputation of the 6.0. The injectors were known to clog, the turbo vanes stuck often, and the high-pressure oil system failed repeatedly. For a truck marketed as a workhorse, this level of unreliability was unacceptable.

Ford eventually replaced the 6.0 with the 6.4 Power Stroke, but by then, the damage was done. Many owners lost trust in Ford’s diesel pickups during that time. The 6.0 remains an example of an engine that looked good on paper but failed in real-world performance.

While a few modified versions can be made reliable, the majority of stock 6.0 Power Strokes are remembered for constant failure, making it one of the most disappointing diesel engines ever offered in the US market.

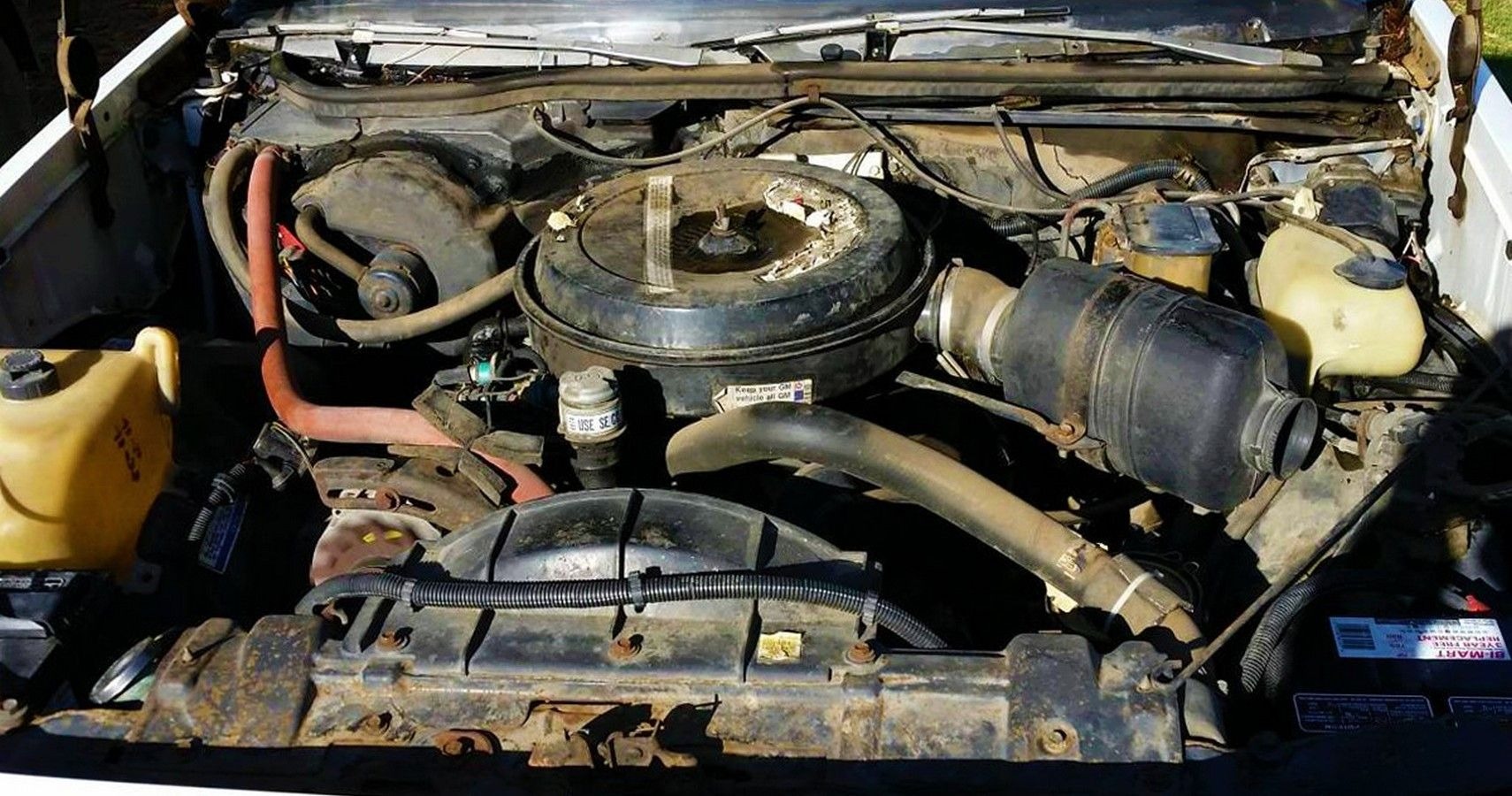

2. GM 5.7 Oldsmobile Diesel V8

During the late 1970s and early 1980s, General Motors decided to produce a diesel version of its popular gasoline V8 engines to meet growing fuel economy demands. The result was the 5.7 Oldsmobile Diesel V8, which quickly became one of the most disastrous diesel engines in history. Instead of designing a true diesel from the ground up, GM modified an existing gas engine, and the results were catastrophic.

The first problem was the weak engine block and head bolts. Because the 5.7 was originally designed for gasoline combustion, it could not handle the much higher compression ratios of a diesel engine. This led to frequent head gasket failures and cracked blocks. Owners found themselves stuck with major engine damage within a few years of ownership.

Fuel system problems also plagued the 5.7 diesel. The injection pump and injectors were not designed with durability in mind, and they often failed long before expected. Combined with the poor quality of diesel fuel in the US at the time, the engine suffered from clogged systems and constant misfires.

Another serious issue was reliability under daily use. These engines were installed in passenger cars such as Oldsmobile, Buick, and Cadillac sedans, but they could not handle regular highway driving without developing serious problems. Instead of lasting hundreds of thousands of miles like a diesel should, the 5.7 often failed before 100,000 miles.

The poor reputation of this engine damaged the entire diesel market in the United States. Many American drivers who bought their first diesel car during this era swore never to buy diesel again.

The 5.7 Oldsmobile Diesel V8 became the face of unreliability, and it is still remembered today as a major failure in automotive history. While GM hoped to offer better fuel economy, the decision to cut corners in design created one of the worst diesel engines ever produced.

3. Ford 6.4 Power Stroke

After the disaster of the 6.0 Power Stroke, Ford attempted to fix its reputation with the 6.4 Power Stroke introduced in 2008. While it improved in some areas, it still turned out to be another headache for truck owners. The engine delivered more horsepower and cleaner emissions, but reliability remained poor, and maintenance costs were even higher.

One of the main problems with the 6.4 is its fuel system. The high-pressure fuel pump was prone to failure, and when it broke, metal shavings would spread through the entire fuel system. This often required replacing the pump, injectors, and fuel lines all at once, leading to repair bills in the thousands.

The engine also suffered from excessive fuel dilution in the oil. During regeneration of the diesel particulate filter (DPF), raw fuel would wash down into the crankcase, thinning the engine oil and causing premature wear. This design flaw reduced engine life and required frequent oil changes just to keep things under control.

The twin turbocharger setup was another point of trouble. While it provided good power, the turbos were known to fail often, especially if the truck was tuned or heavily used for towing. Replacing or repairing the turbo system was extremely expensive, and many owners faced repeated failures.

Cooling issues also haunted the 6.4. The EGR system created additional stress on the cooling system, leading to overheating and head gasket problems. Many drivers discovered that even when properly maintained, the engine struggled to stay reliable.

Because of these issues, the 6.4 Power Stroke did not last long in Ford’s lineup. It was replaced by the 6.7 Power Stroke, which was designed completely in-house and finally restored Ford’s diesel reputation. Still, the 6.4 remains on the list of diesel engines that constantly fail, remembered for high costs, poor reliability, and disappointing performance.

4. Chrysler 2.7 CRD (Mercedes-Based)

In the early 2000s, Chrysler offered a 2.7 CRD diesel engine in some of its European and international models. This engine was based on a Mercedes-Benz design but produced under Chrysler’s supervision. Unfortunately, it never lived up to expectations and quickly became known for constant failures.

The 2.7 CRD suffered from timing chain problems that often led to catastrophic engine failure. The chain tensioners were poorly designed, and once they failed, the timing chain would slip or break. This caused major internal damage, often requiring a complete engine replacement.

Oil sludge buildup was another recurring issue. The engine’s lubrication system was not well designed, and when maintenance was less than perfect, sludge would clog oil passages. This starved critical components of oil, leading to worn bearings and seized engines. Many owners faced engine destruction even with regular oil changes.

The turbocharger also had a reputation for failing prematurely. Because the engine was often installed in heavier vehicles like the Chrysler 300C or Jeep Grand Cherokee, the turbo had to work harder than expected. This extra strain led to breakdowns, leaving drivers with costly repair bills.

Another frustration was the lack of durability compared to other diesels of the same size. While a Mercedes diesel is usually associated with long life, the 2.7 CRD was the opposite. Many engines failed well before 150,000 miles, far earlier than buyers anticipated.

Because of these repeated issues, the 2.7 CRD is remembered as one of the weakest diesel engines Chrysler ever offered. It damaged confidence in Chrysler’s diesel options, especially for customers outside the US who expected the same long-lasting reputation as traditional Mercedes diesels. Instead, they got an engine that failed far too often and left a negative mark on the brand.

Also Read: 5 Engines That Stay Quiet at High Miles and 5 That Sound Like Tractors

5. Navistar VT365 (International DT 365)

The Navistar VT365, also known as the International DT 365, was another diesel engine that left a trail of disappointed owners. Used in International trucks and some buses, this engine was essentially a version of Ford’s troubled 6.0 Power Stroke, since Navistar was responsible for building those engines during the partnership. Unsurprisingly, many of the same problems carried over to the VT365.

One of the major complaints was poor head gasket durability. Just like the Ford 6.0, the VT365 suffered from weak head bolts that allowed pressure to escape under load. This led to blown gaskets, coolant leaks, and overheating issues that were expensive to repair.

The EGR system also created endless trouble. The EGR cooler often failed, causing coolant to leak into the intake system. Once this happened, the engine was prone to white smoke, loss of power, and eventual failure. Replacing the EGR system was costly, and many owners had to do it multiple times during the life of the engine.

Fuel injection problems also plagued the VT365. The injectors were controlled by a high-pressure oil system that was unreliable and often failed without warning. When the injection system went bad, the engine would not start or would run poorly, leaving drivers stranded.

The VT365’s reputation suffered especially in commercial use. Bus operators and trucking companies could not afford the constant downtime and expensive repairs. Many fleets began replacing the VT365 engines long before their expected service life ended.

Because of its weak design and constant failures, the Navistar VT365 is remembered as one of the worst diesel engines used in medium-duty trucks. It shares the same flaws as the Ford 6.0 Power Stroke and remains an example of poor engineering in the diesel industry.