For decades, the Ford F-150 has stood as America’s best-selling pickup truck, known not just for its utility but for its ability to endure some of the harshest driving conditions in the country.

Whether hauling heavy loads across the plains, enduring blistering desert heat, or navigating icy backroads in the Midwest, the F-150 has earned its reputation through tough engineering and at the heart of that toughness lies the engine.

But not all F-150 engines are built the same. Over the years, Ford has experimented with V6s, V8s, EcoBoost turbos, and diesels, each designed for different needs.

Yet, only a few powerplants have proven themselves as true workhorses, surviving the harshest mashups of heavy towing, off-road punishment, and years of daily use.

This article looks at some of the most reliable and battle-tested F-150 engines that have proven their worth under extreme conditions.

From classic naturally aspirated V8s to modern twin-turbocharged powerplants, these are the engines that American truck owners continue to trust when the going gets tough.

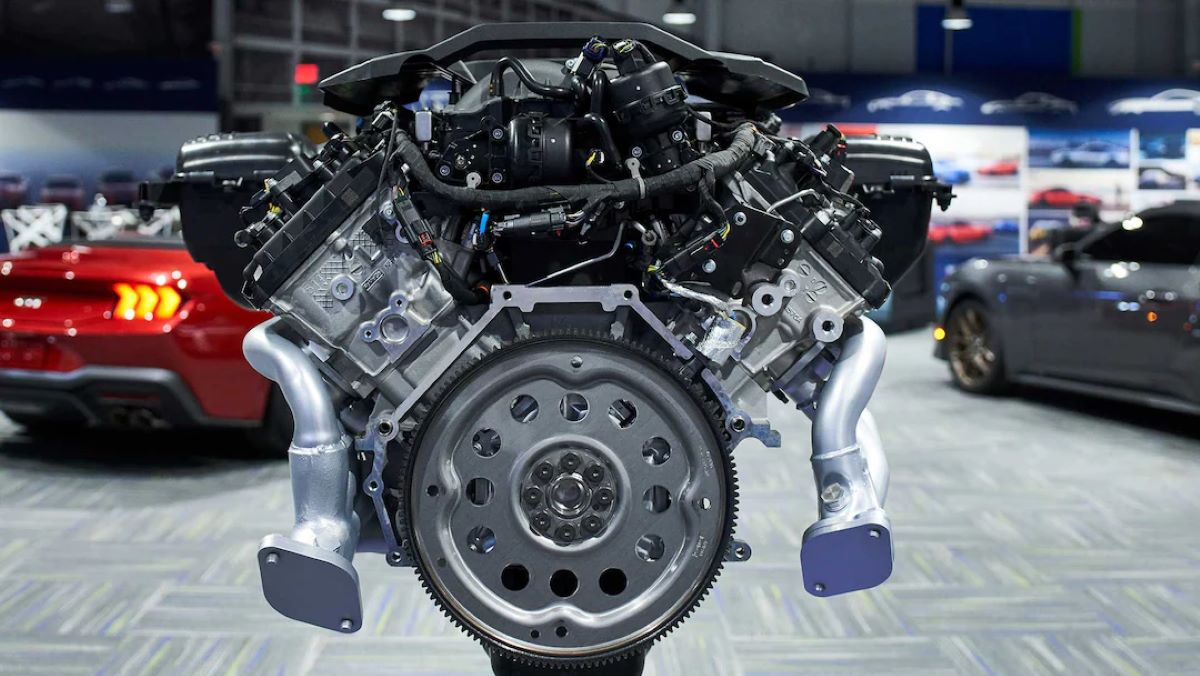

1. 5.0L Coyote V8 (2011–Present)

The Coyote V8 is a legend not just in Ford’s Mustang lineup but also in the F-150. Since its debut in 2011, the 5.0L has become the go-to engine for traditional truck buyers who prefer the reliability of a naturally aspirated V8 over the complexity of turbos.

Known for its smooth power delivery, robust internals, and long-lasting durability, the Coyote thrives in harsh mashups involving heavy towing, off-roading, and even long-distance hauling.

In the F-150, the Coyote delivers a balance of power and dependability, with owners reporting engines surpassing 200,000 miles with minimal issues. Its simple, proven design means fewer points of failure compared to EcoBoost alternatives.

For construction crews, ranchers, and outdoor adventurers who don’t want to second-guess their truck’s endurance, the 5.0L V8 continues to be a bulletproof option.

The Ford 5.0 Modular “Coyote” is a completely redesigned 5.0-liter gasoline V8 that took over from the 4.6L and 5.4L Modular engines in the Mustang GT and F-150 starting with the 2011 model year.

Ford created this engine with a clear goal in mind: to take on GM’s 6.2L V8 and Chrysler’s new 6.4L Hemi. Despite having a smaller displacement, Ford engineers succeeded in producing an engine that delivers the same power output as its rivals while running on regular 87-octane unleaded fuel.

Although the 5.0L shares no components with earlier Modular engines, it retains several critical dimensions: an 8.937 in (227.0 mm) deck height, a 3.937 in (100.0 mm) bore spacing, matching the 4.6L V8, and the same bell housing bolt pattern.

These carryovers allowed Ford to continue machining and assembling the new engine on existing Modular production lines without needing a complete retool.

At its core, the 5.0L Modular V8 uses a brand-new aluminum cylinder block with pressed-in cast-iron liners, a 90-degree V-angle, four-bolt main bearing caps, and a deep crankcase.

Inside, it carries a forged steel crankshaft paired with forged powdered-metal connecting rods, each measuring 5.933 in (150.7 mm) in length. The block also features piston-cooling jets for added durability.

Where the legendary 5.0/302 relied on a cam-in-block pushrod setup with two valves per cylinder, the Coyote introduces a far more advanced design.

It uses aluminum cylinder heads with dual overhead camshafts (DOHC), four valves per cylinder, and an independent timing chain for each head. A three-layer metal gasket seals the block to the heads.

Valve operation comes via roller finger followers with hydraulic lash adjusters. Most importantly, the Coyote debuted Ford’s cam-torque-actuated (CTA) Twin Independent Variable Cam Timing (Ti-VCT), a first for any Ford V8.

This same system also appeared in the 3.5L and 3.7L V6s launched in 2011. Additional design details include plastic cylinder head covers, a low-mounted plastic intake manifold plenum between the cylinder banks, and a “drive-by-wire” electronic throttle body with variable runner control.

From the start, the 5.0L Coyote was equipped with electronically controlled, sequential multi-port fuel injection and a coil-on-plug ignition system.

The Mustang GT variant received tubular stainless-steel exhaust headers, while the F-150 version came with more conventional cast-iron exhaust manifolds. In trucks, the 5.0 served as an alternative to the 3.5L EcoBoost V6, tuned differently to favor torque.

Compared to the high-revving Mustang GT setup, the F-150’s Coyote trades some peak horsepower for stronger low- and mid-range torque.

Also Read: 5 Affordable Engines That Can Be Tuned and 5 That Can’t Take Mods

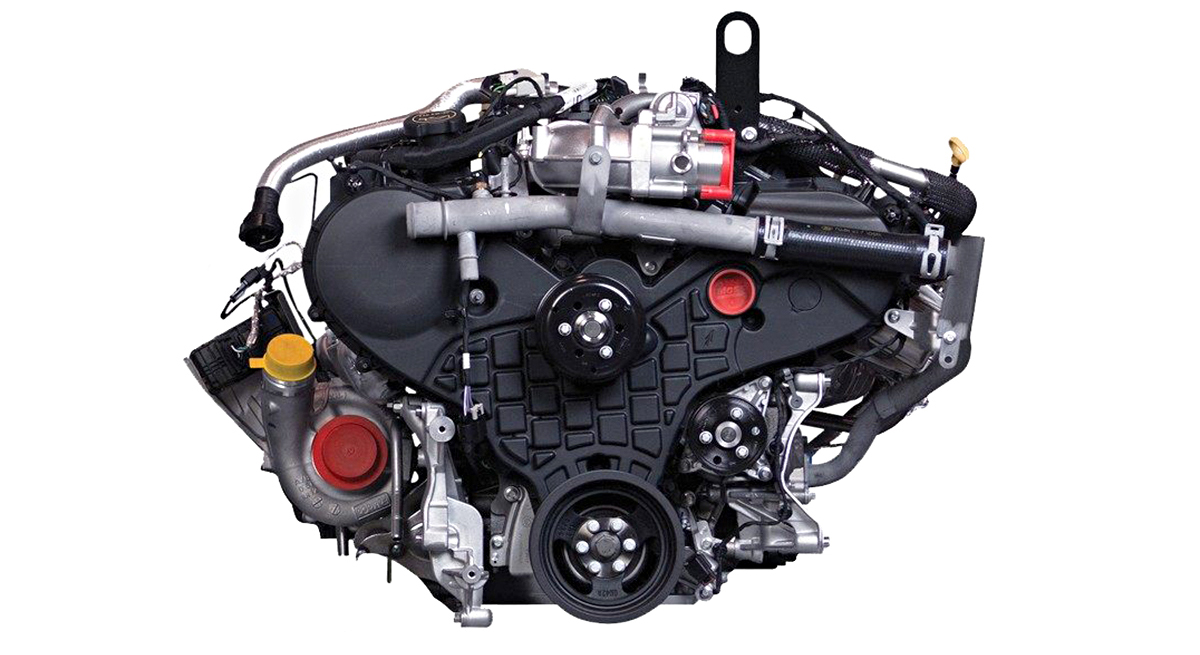

2. 3.5L EcoBoost V6 (2011–Present)

When Ford introduced the twin-turbocharged 3.5L EcoBoost, many skeptics doubted whether a turbo V6 could replace a V8 in America’s favorite truck.

Fast forward a decade, and the EcoBoost has silenced critics by proving it can handle the toughest conditions. Offering massive low-end torque, excellent towing ability, and surprising fuel efficiency, the 3.5L has become a fan favorite for both work and play.

Owners who tow RVs, horse trailers, or heavy equipment often favor this engine because of its torque-rich performance. Despite being more complex than the Coyote, the 3.5L EcoBoost has held up well in high-mileage scenarios.

With proper maintenance especially regular oil changes and turbo care this engine has been documented to cross the 250,000-mile mark while still pulling strong. In harsh mashups like steep mountain towing or desert hauling, it has proven itself time and time again.

The 3.5L EcoBoost is a turbocharged, direct-injected 3.5-liter V6 gasoline engine that first debuted in 2007 under the name “TwinForce.” Ford designed it as a practical alternative to large-displacement V8s, including the Coyote V8.

The concept was simple: deliver the same power and torque as a naturally aspirated 6.0L V8, but with significantly lower fuel consumption and reduced emissions. Production officially began in 2009, and as the engine rolled out across Ford’s lineup, it quickly found its most popular application in the brand’s best-seller, the Ford F-150.

This was no surprise; EcoBoost-equipped F-150s came with a lower price tag while avoiding the usual drawbacks of small-displacement, naturally aspirated six-cylinder engines, making them a compelling option alongside the V8 models.

At its core, the 3.5L EcoBoost is based on the Duratec 35 (Ford Cyclone V6) architecture, sharing the same bore and stroke dimensions. The block is aluminum with an open-deck design and reinforced with high-strength steel cylinder sleeves.

Internally, it carries forged steel I-beam connecting rods, a forged steel crankshaft, and six-bolt main bearing caps for strength. The pistons are high-strength aluminum, CNC-machined, and feature a low-friction coating on the skirts.

Their crown design is specifically engineered to promote efficient combustion. To manage heat, the block includes oil squirters that spray the underside of the pistons, helping them stay cool under heavy loads. The oil pan, like the block, is made of aluminum.

3. 4.6L Triton V8 (1997–2010)

The late ’90s and early 2000s brought us the Triton V8, which powered millions of F-150s across the United States. While not the most powerful engine in Ford’s history, the 4.6L Triton earned its place on this list by being one of the most reliable and long-lasting options of its era.

Farmers, contractors, and weekend warriors all leaned on this engine to handle tough workloads, and many are still on the road today with over 300,000 miles.

One reason the 4.6L Triton stands out is its simplicity. Its naturally aspirated design, sturdy block, and proven track record made it an engine that could take abuse without flinching.

From towing boats in Florida’s humidity to enduring frigid Minnesota winters, this powerplant was a workhorse through and through.

The Ford 4.6L V8 was the very first engine in Ford’s Modular overhead camshaft family to enter production, debuting in the 1991 Lincoln Town Car. This 4.6-liter gasoline engine used a 90-degree V-angle layout with two valves per cylinder and a SOHC (single overhead camshaft) design. Before long, it became the standard V8 for the Mustang GT.

Ford also engineered a 4-valve DOHC version, best known for powering the SVT Cobra and Mach 1. This higher-performance 32-valve engine first appeared in the 1993 Lincoln Mark VIII, marketed as the 4.6L Four-Cam V8. With the introduction of the Modular lineup, Ford retired its long-running pushrod-based Small Block 5.0 H.O. V8.

The 4.6L V8 was offered with either a deep-skirt aluminum or cast-iron cylinder block, depending on model year and vehicle application. These blocks came from two plants, Romeo and Windsor, and could be distinguished by certain details.

Windsor iron blocks featured a “W” marking along with dowel pins at the cross-bolted main caps, while Romeo blocks used jackscrew cross-bolted main caps and were sometimes marked with an “R” (though not all of them were).

Aluminum blocks were generally produced at the Windsor Aluminum Plant (WAP), except for the highly regarded Teksid aluminum blocks of the 1990s, which were cast in Turin, Italy. Aluminum versions were equipped with six-bolt main bearing caps.

The engine’s geometry carried a 90-degree bank angle, an 8.937 in (227.0 mm) deck height, and a 3.937 in (100.0 mm) bore spacing. With its nearly square bore-to-stroke ratio, the 4.6 achieved a well-balanced blend of performance and refinement, positively affecting noise, vibration, and harshness characteristics.

Connecting rods measured 5.933 in (150.7 mm) in length. Ford built these Modular engines with either six- or eight-bolt crankshafts, eight-bolt forged steel versions appearing in trucks and high-performance models, while six-bolt cranks were usually found in Romeo-built passenger car applications. From the factory, all engines included forged pistons and cracked powdered-metal connecting rods.

Cylinder head designs varied across the 4.6’s long production run. Engines could be equipped with 2-valve heads (1990–2014), 3-valve heads (2005–2010) with a SOHC layout, or 4-valve heads using a DOHC setup. In every configuration, camshafts were driven by two timing chains, one for each head.

The valvetrain incorporated roller rocker arms with hydraulic lash adjusters for reduced friction. The 3-valve heads were particularly notable, featuring apex-shaped combustion chambers with centrally located spark plugs, two intake valves, and one oversized exhaust valve designed to maximize airflow velocity and volume.

4. 3.0L Power Stroke Diesel V6 (2018–2021)

For truck owners who wanted diesel torque without stepping into a Super Duty, the 3.0L Power Stroke offered the perfect middle ground.

Although short-lived in the F-150 lineup, this diesel engine earned respect for its ability to handle long hauls and tough towing jobs with ease.

Delivering 440 lb-ft of torque and impressive fuel economy, it excelled in scenarios where constant heavy loads were involved.

The 3.0L Power Stroke was particularly popular among RV owners and those hauling equipment across states. Its diesel durability, combined with Ford’s F-150 chassis, made it a serious contender for anyone needing longevity under tough conditions.

While it didn’t stay in production for long, the trucks equipped with it remain sought-after in the used market for their resilience.

Also Read: 12 Cars That Went From Unpopular to Everyday Sight

5. 5.4L Triton V8 (1997–2010)

Though the 5.4L Triton had its fair share of critics due to spark plug issues, when maintained properly, it proved to be one of Ford’s most enduring engines.

Used in millions of F-150s, it was the workhorse of its generation, delivering plenty of torque for towing and long-haul jobs. Many owners still swear by it, with examples hitting 250,000 miles and beyond.

The reason it survives harsh mashups comes down to its sheer toughness. Despite its quirks, the 5.4L’s iron block and proven design allowed it to withstand years of abuse.

For many families, contractors, and outdoor workers, this engine represented the backbone of Ford’s pickup dominance in the early 2000s.

The Ford 5.4 Triton V8 is part of the Modular engine family, a naturally aspirated 5.4-liter gasoline V8 first introduced in the 1997 Ford F-150. Essentially a stroked version of the 4.6L Modular V8, it shares much of its design architecture with its smaller sibling.

Over its production run, the 5.4 was built in three main versions: the SOHC V8 with 2-valve or 3-valve cylinder heads, and the higher-performance DOHC 4-valve V8.

The 2V and 3V variants were used mainly in Ford’s F-Series pickups, while the 4V version powered some of Ford’s most iconic performance and luxury models, including the Ford GT supercar, Shelby GT500, Mustang SVT Cobra R, and several Lincoln vehicles.

The first 5.4, released in 1997, was a SOHC 2-valve V8 built around a cast-iron block. While it retained the same bore diameter as the 4.6L, the longer stroke required a taller deck height — 10.079 in (256.0 mm) compared to the 4.6’s 8.937 in (227.0 mm).

Inside, the engine featured fracture-split powdered-metal connecting rods paired with lightweight aluminum pistons, with some later versions receiving a forged steel crankshaft for added strength. Each bank carried SOHC aluminum heads with two valves per cylinder, driven by a pair of timing chains at the front of the engine (one for each camshaft).

The valvetrain used roller finger followers with hydraulic lash adjusters, while aluminum valve covers and a composite intake manifold rounded out the top end. Like all 5.4L V8s, the 2V was equipped with coil-on-plug ignition and electronic sequential multi-port fuel injection. Production of the 5.4 2V took place at the Windsor Engine Plant in Ontario, Canada.

The 5.4 3-valve version debuted first in Australia in the 2002 Ford Fairmont under the name “Bara 220,” and arrived in North America with the redesigned 2004 Ford F-150. This version introduced new cylinder heads with two intake valves and a large single exhaust valve per cylinder.

Ford also added variable camshaft timing (VCT), which significantly boosted power, torque, and fuel efficiency compared to the 2V SOHC design. Other internal updates included a higher 9.8:1 compression ratio and increased oil capacity.

Production of the 5.4 3V began at the Essex Engine Plant in Windsor, Ontario, before shifting back to the Windsor Engine Plant after the last Essex-built Triton 3V rolled off the line in 2008.

6. High-Output 3.5L EcoBoost (Raptor, 2017–Present)

For those who demand extreme off-road performance, the high-output version of the 3.5L EcoBoost found in the F-150 Raptor has become legendary.

Pushing well over 400 horsepower and delivering brutal torque, this engine is tuned for desert runs, mud pits, and high-speed off-road adventures.

Despite its aggressive nature, the high-output EcoBoost has proven surprisingly durable. Raptor owners often subject their trucks to harsh mashups that would cripple lesser powertrains yet the engine consistently delivers.

Whether bombing across sand dunes in Nevada or crawling rocky trails in Colorado, this motor thrives under punishment.

Every gearhead dreams of squeezing more performance out of their engine. Whether it’s something simple, like swapping out the factory air filter for a cold air intake, or going all-in with a full-blown engine swap, the goal never changes, more power.

Ford’s 3.5-liter EcoBoost V6 has built a reputation as the perfect middle ground between power and efficiency, thanks to its direct injection, variable camshaft timing, and twin turbochargers.

In fact, “EcoBoost” is Ford’s trademark for its family of turbocharged, direct-injection V6 engines designed to deliver both performance and fuel economy, the best of both worlds.

Ford dropped the 3.5-liter EcoBoost into a wide range of vehicles, from the best-selling F-150 and hardcore Raptor to the halo car Ford GT.

In stock form, this twin-turbo V6 generates 400 hp and 500 lb-ft of torque in standard-output trim, and 450 hp with 510 lb-ft of torque in high-output versions like the Raptor.

If you’re a gearhead with a 3.5-liter EcoBoost under the hood, chances are you’ve wondered if basic bolt-on mods could unlock more power.

The answer is yes, with upgrades like a cold air intake, a larger intercooler, freer-flowing downpipes, and the right ECU tune, the EcoBoost can gain as much as 100 extra horsepower without opening up the engine.

For most owners, the balance between reliability, drivability, and power gains lies in stage 1 or 2 modifications. These usually include a high-flow intake, catless downpipes, an upgraded intercooler, and a proper custom ECU tune.

His 2017 Ford F-150 3.5L EcoBoost received both cosmetic and performance improvements, the first being a Ram Air Hood with functional heat extractor vents and inlet ducts to channel cool air into the intake system.

He then added an oil separator, a smart move especially for earlier direct-injection EcoBoosts, as it helps reduce carbon buildup on the intake valves.

To round out the build, Justin installed an aftermarket downpipe while retaining the stock cat-back exhaust, cutting back pressure and sharpening turbo spool noise.

On the dyno, the baseline pull with 93-octane fuel showed 305 hp and 352 lb-ft of torque at the rear wheels. After applying a 93-octane tune, the truck put down 352 hp and 415 lb-ft — a gain of 50 hp and 60 lb-ft from tuning alone.

With the intake and downpipe added, the final run delivered 379 hp and 422 lb-ft. The net result was an extra 88 hp and 98 lb-ft of torque, all achieved in a single day with a handful of mods.

While stage 1 and 2 mods deliver strong, safe gains, the 3.5L EcoBoost has the headroom for far more, but it comes at a price.

Pushing into serious power territory means upgraded turbos, forged pistons, strengthened fuel systems, and often methanol injection kits. Builds like this can easily run upwards of $10,000 once parts and labor are factored in, but the rewards can be huge.

Unlike bolt-ons, big-power setups require extensive work: full engine teardowns, forged bottom ends, precision tuning, and upgraded fueling. These projects take time, money, and expertise, and often compromise daily drivability. Maintenance demands increase, emissions legality becomes an issue in some regions, and reliability can suffer if corners are cut.

Still, for those willing to commit, the 3.5-liter EcoBoost is capable of putting down well over 700 wheel horsepower. Just be mindful of model year quirks and known issues before diving in.

Why These Engines Stand Out

What separates these engines from the rest isn’t just their performance numbers it’s their resilience in the real world.

Engines like the Coyote V8 and 3.5L EcoBoost thrive because they balance power with longevity, while classics like the Triton V8s remind us that simplicity often equals durability. Even the short-lived Power Stroke diesel proved its mettle in towing-heavy environments.

The F-150’s engine legacy reflects the truck’s broader reputation: built tough, built for America, and built to last. Each of these engines has earned its place not just in Ford’s lineup but in the lives of millions of truck owners who rely on them every day.

In the world of pickup trucks, few things matter more than an engine that can endure punishment. Ford F-150s have faced harsh mashups of heat, cold, towing, and off-roading for decades, and these engines stand as proof of what true engineering resilience looks like.

For anyone shopping for a used F-150 or just appreciating the engines that made the truck an icon these powerplants are the ones to watch.