The steering rack represents one of the most critical components in modern automotive engineering, serving as the mechanical heart that translates driver input into directional control.

This precision-engineered assembly determines not only the responsiveness and feel of your vehicle’s steering but also plays a fundamental role in driving safety and comfort.

Understanding the distinction between steering racks that maintain their tight, precise operation for extended periods versus those that develop looseness prematurely is crucial for both automotive professionals and discerning vehicle owners.

The longevity and performance characteristics of steering racks vary dramatically based on several key factors, including manufacturing quality, materials used, design philosophy, and maintenance requirements.

While some steering racks are engineered to maintain their tight tolerances and responsive feel well beyond 150,000 miles, others begin showing signs of wear, developing play, and losing precision much earlier in their service life.

This disparity often stems from fundamental differences in construction methods, seal quality, internal component materials, and engineering approach.

Modern automotive manufacturers have developed distinctly different philosophies regarding steering rack design and construction. Some prioritize long-term durability and precision retention, investing in superior materials, advanced manufacturing processes, and rigorous quality control measures.

Others focus on cost reduction and initial performance, sometimes at the expense of long-term reliability. Understanding these differences becomes essential when selecting replacement parts or evaluating vehicles for purchase, as the steering rack’s condition significantly impacts both vehicle safety and driving experience.

Top 5 Steering Racks That Stay Tight

These exceptionally engineered steering systems feature precision-machined rack assemblies with hardened steel pinion gears and premium sealing systems that maintain perfect hydraulic pressure and mechanical tolerances through hundreds of thousands of miles of varied driving conditions.

Their sophisticated construction includes heavy-duty tie rod assemblies, reinforced mounting bushings, and advanced power steering pumps that prevent the fluid contamination and pressure loss typically associated with high-mileage operation and aggressive driving patterns.

From parking lot maneuvering that subjects racks to maximum steering lock stress to highway driving that tests sustained directional stability, these remarkable steering systems continue providing razor-sharp road feedback without developing play, wandering, or hydraulic leakage.

The meticulous manufacturing process includes computer-controlled machining tolerances, premium O-ring materials, and multi-stage pressure testing that ensures leak-free operation throughout extended service life.

Drivers report that these legendary steering systems become more communicative with age often delivering their most precise feel and response after 150,000+ miles as components settle and hydraulic systems stabilize, proving their worth through consistent steering accuracy and maintained driving confidence throughout ownership.

1. ZF Lenksysteme (ZF Group)

ZF Lenksysteme steering racks represent the pinnacle of German automotive engineering precision, consistently maintaining tight tolerances and responsive steering feel throughout their extended service life.

ZF is a worldwide leader of OE quality automotive safety products, known for driveline, chassis, and passive safety technology, with the company investing more than 6% of sales in research and development annually to ensure continuous improvement in its steering systems.

The construction methodology employed by ZF sets these units apart from conventional alternatives. Their steering racks feature precision-machined aluminum housings with advanced surface treatments that resist wear and corrosion over extended periods.

The internal rack gear utilizes high-grade steel alloys with specialized heat treatment processes that maintain dimensional stability under varying temperature and load conditions.

This attention to metallurgy ensures that the critical gear teeth maintain their precise engagement with the pinion, preventing the development of backlash that characterizes loosening steering systems.

ZF’s sealing technology represents another significant advantage in maintaining long-term tightness. Their multi-lip seal design incorporates advanced elastomeric compounds specifically formulated to resist power steering fluid degradation, temperature extremes, and contamination ingress.

Just about all problems with the rack and pinion happen when the boots fail and water and dirt get in, making ZF’s superior sealing system crucial for longevity.

The company’s proprietary seal materials maintain their flexibility and sealing effectiveness well beyond conventional seal materials, preventing the contamination and wear that typically leads to steering looseness.

The manufacturing precision achieved by ZF extends to their quality control processes, where each steering rack undergoes comprehensive testing, including pressure testing, dimensional verification, and operational testing under simulated driving conditions.

This rigorous approach ensures that only units meeting strict tolerances leave the factory, contributing to their reputation for maintaining tight steering feel throughout their service life.

Many automotive enthusiasts and professionals consider ZF steering racks to represent the benchmark against which other manufacturers’ products are measured, particularly in applications where steering precision and longevity are paramount considerations.

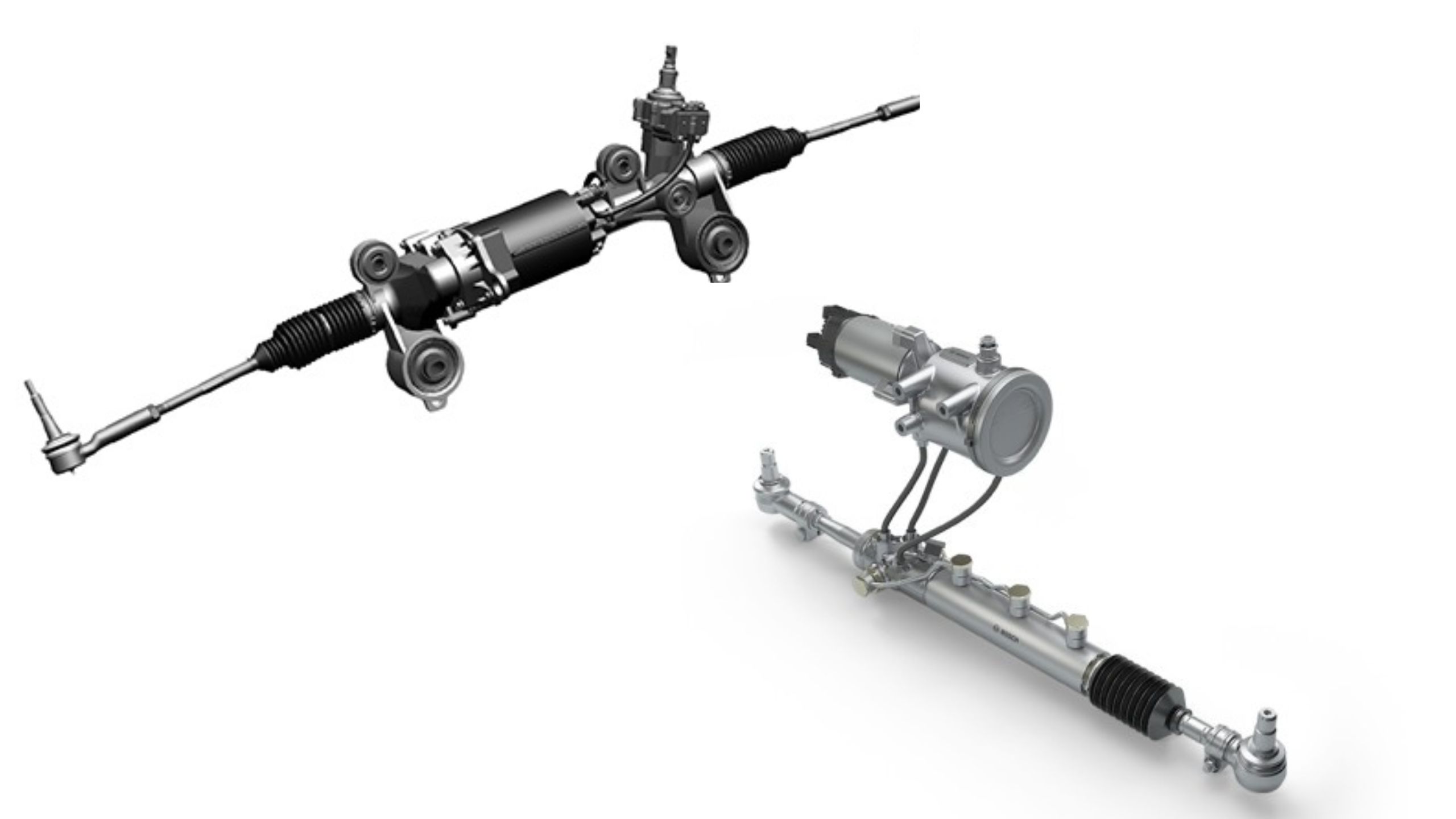

2. Bosch Automotive Steering

Bosch steering racks have earned recognition for their exceptional longevity and consistent performance characteristics, leveraging the company’s extensive experience in automotive systems integration and precision manufacturing.

The German manufacturer’s approach to steering rack design emphasizes the integration of advanced materials science with proven mechanical engineering principles, resulting in products that maintain their tight operational characteristics well into high-mileage service.

The internal architecture of Bosch steering racks incorporates several innovative features that contribute to their longevity. Their rack bars utilize a specialized nitriding process that creates an extremely hard surface layer while maintaining a tough, flexible core.

This treatment method significantly reduces wear rates at the critical gear interface points while providing resistance to the stress concentrations that can develop during heavy steering loads. The pinion gears feature similar surface treatments, ensuring matched wear characteristics that prevent the development of excessive play over time.

Bosch’s hydraulic power steering systems integrate sophisticated pressure control valves that maintain consistent assist levels while protecting internal components from excessive pressures that can accelerate wear.

Their electric power steering variants incorporate intelligent torque sensors and control algorithms that adapt to driving conditions, reducing unnecessary stress on mechanical components.

This adaptive approach helps preserve the mechanical integrity of the steering rack components, contributing to extended service life and maintained precision.

The company’s commitment to quality extends to its bearing and bushing systems, which utilize advanced polymer compositions and precision manufacturing techniques.

These components are designed to operate with minimal friction while maintaining precise positioning of the rack assembly within its housing. The reduced friction characteristics not only improve steering feel but also minimize wear rates, helping to preserve the tight tolerances that define premium steering system performance.

Many automotive manufacturers specify Bosch steering systems as original equipment specifically because of their proven ability to maintain performance characteristics throughout the vehicle’s intended service life.

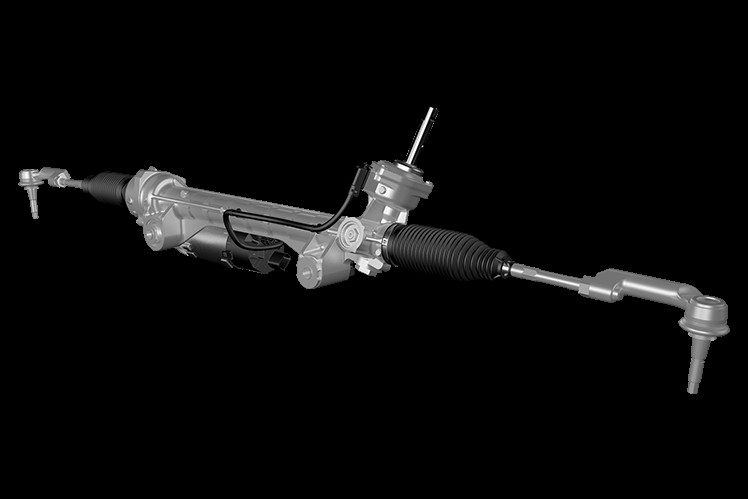

3. TRW Automotive (Now ZF-TRW)

TRW Automotive steering racks, now part of the ZF Group following acquisition, combine motorsport-derived engineering with street-focused durability requirements.

TRW is an Aftermarket Division of a large company, the ZF, benefiting from the combined expertise of both organizations in developing steering systems that maintain their precision over extended periods.

Their design philosophy emphasizes robust construction methods that resist the development of play and maintain responsive steering characteristics.

The manufacturing approach employed by TRW incorporates several features specifically designed to prevent common failure modes that lead to loose steering.

Their rack housings utilize precision-bore manufacturing with surface finishes that minimize friction while maintaining precise tolerances. The rack bars feature multi-stage machining processes that ensure consistent gear tooth profiles and surface finishes, critical factors in preventing wear-induced looseness.

These precision manufacturing techniques result in steering racks that maintain their intended clearances and operating characteristics well beyond typical replacement intervals.

TRW’s experience in motorsport applications has influenced their street product development, particularly in areas of stress analysis and fatigue resistance. Their steering racks incorporate design features that distribute loads more evenly across bearing surfaces, reducing stress concentrations that can lead to premature wear.

The company’s testing protocols include extended durability testing that simulates years of typical driving conditions, ensuring that their products maintain performance standards throughout their intended service life.

The hydraulic components within TRW steering systems feature an advanced materials selection that resists degradation from power steering fluid contact and temperature cycling.

Their seal systems incorporate multiple sealing stages with different seal materials optimized for specific functions, providing comprehensive protection against contamination while maintaining low friction operation.

This attention to hydraulic system integrity helps preserve the mechanical components by preventing contamination-induced wear, a common cause of steering looseness in lesser quality units.

4. Koyo Steering Systems (JTEKT Corporation)

Koyo steering racks, manufactured by JTEKT Corporation, represent Japanese automotive engineering precision applied to steering system design and manufacturing.

Known for their exceptional build quality and consistent performance characteristics, Koyo units maintain tight steering feel through innovative design approaches and meticulous manufacturing processes.

Their products have earned recognition among automotive professionals for reliable long-term performance and resistance to the wear patterns that typically lead to steering looseness.

The design philosophy behind Koyo steering systems emphasizes preventive engineering, incorporating features that address potential failure modes before they can develop into problems.

Their rack and pinion assemblies utilize advanced gear cutting techniques that produce extremely precise tooth profiles with optimized contact patterns.

These manufacturing methods ensure even load distribution across gear teeth, minimizing localized wear that can develop into excessive backlash over time. The precision of their gear manufacturing processes contributes significantly to their reputation for maintaining tight steering characteristics.

Koyo’s bearing technology represents another significant advantage in longevity and precision retention. Their steering racks incorporate precision ball bearings and specialized bushings manufactured to extremely tight tolerances using advanced materials.

These components are designed to operate with minimal clearances while maintaining smooth operation under varying load conditions. The reduced clearances help maintain precise rack positioning within the housing, preventing the development of play that characterizes worn steering systems.

The company’s approach to power steering integration focuses on system optimization rather than individual component performance. Their electric power steering systems incorporate sophisticated control algorithms that work in harmony with the mechanical steering components, reducing unnecessary stress and wear while providing consistent steering assistance.

This integrated approach helps preserve mechanical component integrity while delivering enhanced performance characteristics. Many Japanese automotive manufacturers rely on Koyo steering systems as original equipment specifically because of their proven ability to maintain precision and reliability throughout extended service intervals.

Also Read: 5 Sports Cars Fun to Drive After 250K Miles vs. 5 That Fall Apart

5. Delphi Automotive (Now Nexteer Automotive)

Delphi steering racks, now produced by Nexteer Automotive following corporate restructuring, have established a reputation for maintaining tight steering characteristics through innovative design approaches and advanced manufacturing techniques.

The company’s focus on technological advancement has resulted in steering systems that address traditional weaknesses in rack and pinion design while maintaining the precision and responsiveness demanded by modern vehicles.

The engineering approach employed by Nexteer emphasizes the elimination of wear-prone design elements through innovative solutions. Their steering racks incorporate advanced bushing systems that utilize self-lubricating materials, reducing friction and wear while maintaining precise positioning.

These bushings are designed to accommodate normal thermal expansion and contraction without developing play, a common source of looseness in conventional designs.

The company’s research into materials science has produced bearing surfaces that maintain their properties under extended use, contributing to a consistent steering feel over time.

Nexteer’s electric power steering systems represent significant advances in steering technology integration. Their systems incorporate variable assist algorithms that adapt to vehicle speed and driving conditions, reducing unnecessary stress on mechanical components while optimizing steering response.

The electronic control units monitor system performance continuously, adjusting parameters to maintain optimal operation while protecting mechanical components from excessive loads. This intelligent approach to steering system management helps preserve component integrity and extend service life.

The manufacturing quality control processes employed by Nexteer include comprehensive testing of critical dimensions and operational parameters.

Each steering rack undergoes precision measurement of internal clearances, seal effectiveness, and operational smoothness before approval for shipment.

Their testing protocols include accelerated wear testing that simulates extended service conditions, ensuring that products meet durability standards before reaching customer vehicles.

This commitment to quality control contributes to their reputation for producing steering systems that maintain their intended performance characteristics throughout their service life.

Top 5 Steering Racks That Get Loose Fast

These unfortunately designed steering systems suffer from inadequate internal sealing, including cheap O-rings that shrink and crack, undersized rack bushings that allow excessive movement, and poorly designed pressure relief valves that cause premature hydraulic system failure and steering looseness.

Their compromised construction features lightweight tie rod components that bend under load, inadequate power steering fluid filtration that allows contamination buildup, and insufficient rack housing rigidity that permits flexing under normal steering forces.

From routine city driving that reveals inadequate component strength to simple temperature cycling that causes seal deterioration, these problematic steering systems begin showing play and looseness within the first 75,000 miles and progress to dangerous steering wander.

The manufacturing shortcuts include plastic components in high-stress applications, the elimination of redundant sealing systems, and substandard rack machining that creates premature wear patterns.

Drivers frequently report complete loss of steering precision, requiring expensive rack replacement often experiencing dangerous on-center play, fluid leaks that contaminate driveways, and steering effort variations that make highway driving unpredictable, creating safety hazards and repair costs that exceed reasonable maintenance expectations while destroying the fundamental connection between driver and vehicle.

1. Generic Aftermarket Units (Various Manufacturers)

Generic aftermarket steering racks represent the most problematic category in terms of maintaining tight steering characteristics over time. These units, manufactured by various suppliers primarily focused on cost reduction rather than quality retention, typically develop looseness and play significantly earlier than OEM or premium aftermarket alternatives.

A steering rack typically lasts between 100,000 and 150,000 miles under normal driving conditions, but generic units often fall well short of these expectations.

The fundamental issue with generic aftermarket steering racks lies in their manufacturing approach, which prioritizes initial cost over long-term performance. These units often utilize lower-grade materials in critical areas such as gear teeth, bearing surfaces, and sealing systems.

The rack bars may be manufactured from less expensive steel alloys that lack the surface hardening treatments found in premium units, resulting in accelerated wear at gear contact points.

This wear progression leads to increasing backlash between the rack and pinion, manifesting as looseness in steering feel and reduced precision in vehicle control.

The sealing systems employed in generic steering racks frequently represent the weakest link in their durability chain. Most problems with rack and pinion happen when the boots fail and water and dirt get in, and generic units typically utilize inferior seal materials that degrade rapidly under normal operating conditions.

Once contamination enters the steering rack housing, accelerated wear of internal components occurs, leading to rapid development of play and looseness. The combination of poor initial quality and inadequate contamination protection makes generic aftermarket steering racks particularly susceptible to early failure and performance degradation.

2. Cardone Remanufactured Units

Cardone Remanufactured steering racks, while offering cost advantages over new OEM units, present inherent challenges in maintaining long-term tightness due to the limitations of the remanufacturing process.

The company’s approach involves rebuilding used steering rack cores with replacement seals and selected internal components, but the fundamental wear on critical surfaces often cannot be fully addressed through conventional remanufacturing techniques.

The remanufacturing process typically involves disassembly of used steering racks, cleaning of components, replacement of obvious wear items such as seals and O-rings, and reassembly with testing.

However, the critical gear surfaces that determine steering tightness often show microscopic wear patterns that cannot be economically addressed in remanufacturing.

These existing wear patterns serve as stress concentrators that accelerate future wear, leading to more rapid development of looseness compared to new units with pristine gear surfaces.

Cardone’s quality control processes, while adequate for ensuring basic functionality, may not detect subtle wear conditions that will affect long-term performance.

The dimensional tolerances that determine steering tightness require extremely precise measurement equipment and techniques that may not be economically feasible in remanufacturing operations.

Consequently, remanufactured units may have acceptable initial performance while harboring wear conditions that will manifest as looseness relatively quickly in service.

The mixed nature of core units processed by Cardone means that quality can vary significantly between individual steering racks. Some cores may have experienced minimal wear and provide good long-term service, while others may have accumulated damage that compromises their ability to maintain tight operation.

This variability makes it difficult to predict the longevity of any individual remanufactured unit, contributing to their reputation for inconsistent performance characteristics and premature looseness development.

3. Beck/Arnley Steering Racks

Beck/Arnley steering racks, manufactured by various overseas suppliers and distributed under the Beck/Arnley brand, have gained a reputation for developing looseness prematurely compared to premium alternatives.

These units represent the challenges faced by import brands attempting to balance cost competitiveness with performance requirements, often resulting in compromises that affect long-term steering tightness and precision.

The manufacturing standards employed by Beck/Arnley’s overseas suppliers may not match those of premium manufacturers, particularly in areas critical to long-term performance.

The gear cutting processes used to manufacture rack and pinion components may lack the precision required for maintaining tight tolerances over extended periods.

Variations in gear tooth profiles and surface finishes can lead to uneven wear patterns that accelerate the development of backlash and steering looseness.

Material selection represents another area where cost pressures may compromise long-term performance in Beck/Arnley units. The steel alloys used for rack bars and pinion gears may lack the advanced metallurgy found in premium units, resulting in higher wear rates under normal operating conditions.

The absence of specialized surface treatments such as nitriding or case hardening further compromises wear resistance, leading to more rapid deterioration of the precise tolerances required for tight steering operation.

Quality control processes in overseas manufacturing facilities may not match the rigorous standards employed by premium manufacturers. The inspection procedures and testing protocols that ensure consistent quality and long-term performance require significant investment in equipment and training that may be compromised in cost-focused manufacturing operations.

This reduced quality oversight can result in units that meet basic functional requirements while harboring defects that will lead to premature looseness and performance degradation.

4. Duralast (AutoZone Brand) Steering Racks

Duralast steering racks, distributed through AutoZone’s retail network, represent the challenges faced by retail chain brands in balancing cost competitiveness with performance requirements.

These units, manufactured by various suppliers to meet aggressive price points, often develop steering looseness earlier than premium alternatives due to compromises in materials, manufacturing processes, and quality control standards.

The economic model driving Duralast steering rack development prioritizes initial affordability over long-term performance, resulting in design and manufacturing compromises that affect durability.

The suppliers contracted to manufacture these units must meet strict cost targets that may preclude the use of premium materials and advanced manufacturing processes required for maintaining tight steering characteristics over extended periods.

This cost pressure often translates into reduced material grades, simplified manufacturing processes, and abbreviated quality control procedures. The gear manufacturing processes employed in Duralast steering racks may lack the precision required for long-term tightness retention.

The cutting tools, machine maintenance, and process control standards that ensure consistent gear quality require significant ongoing investment that may be compromised when meeting aggressive cost targets.

Variations in gear tooth geometry and surface finish quality can lead to accelerated wear and rapid development of backlash that manifests as steering looseness.

The assembly and testing procedures used for Duralast units may not detect subtle quality issues that affect long-term performance. The equipment and time required for comprehensive dimensional inspection and functional testing represent costs that may be reduced to meet price targets.

Consequently, units may pass basic functionality tests while harboring tolerance variations that will lead to premature looseness development in service.

The retail distribution model further complicates quality control, as units may experience extended storage periods and handling conditions that can affect seal integrity and component condition before installation.

5. A1 Cardone “New” Units

A1 Cardone “new” steering racks, despite being marketed as new rather than remanufactured products, have developed a reputation for developing looseness prematurely compared to OEM and premium aftermarket alternatives.

These units represent the challenges faced when attempting to manufacture new steering racks to compete with OEM pricing while maintaining profitability, often resulting in compromises that affect long-term performance characteristics.

The manufacturing approach employed by A1 Cardone for their “new” steering rack line appears to prioritize cost competitiveness over long-term durability, resulting in units that may function adequately initially but develop looseness relatively quickly in service.

The materials selection process may favor lower-cost alternatives to the premium steel alloys and specialized treatments used by OEM manufacturers, leading to accelerated wear rates under normal operating conditions.

The precision manufacturing requirements for maintaining tight steering tolerances demand significant investment in machine tool accuracy, cutting tool quality, and process control systems.

A1 Cardone’s approach to manufacturing new units may involve compromises in these areas to achieve competitive pricing, resulting in products that lack the dimensional precision required for long-term tightness retention.

Variations in critical dimensions such as gear tooth spacing, bearing fits, and housing tolerances can contribute to the premature development of play and looseness.

Quality control processes for A1 Cardone’s new units may not match the comprehensive testing and inspection procedures employed by premium manufacturers.

The time and equipment required for thorough dimensional inspection, seal testing, and operational verification represent costs that may be reduced to maintain competitive pricing.

This abbreviated quality control can allow units with marginal tolerance conditions to reach the market, where they may provide initially acceptable performance before developing looseness prematurely.

The combination of manufacturing compromises and reduced quality oversight contributes to their reputation for inconsistent long-term performance compared to premium alternatives.

Also Read: 5 Minivans That Survive Families Vs. 5 That Break Under Kid Chaos