The turbocharged V6 engines present a fascinating dichotomy between engineering excellence and costly complications. These powerplants have become increasingly popular across the automotive world, offering an attractive balance of performance and efficiency that appeals to manufacturers and consumers alike.

However, not all turbo V6s are created equal, and the difference between a well-engineered example and a problematic one can mean thousands of dollars in repair costs and countless hours of frustration.

On one side, we have the champions of reliable engines that have proven themselves through hundreds of thousands of miles with minimal issues beyond routine maintenance.

These power plants represent the pinnacle of modern engineering, where careful design, quality materials, and thorough testing have created engines that deliver both performance and dependability. They demonstrate that complexity doesn’t necessarily equate to unreliability when proper attention is paid to every detail.

Conversely, there are those turbo V6 engines that have earned notorious reputations for specific failure modes, particularly valve-related problems that can devastate both engine performance and owner wallets.

These engines serve as cautionary tales about the importance of proper engineering execution and the consequences when shortcuts are taken or design flaws are overlooked. Understanding both sides of this spectrum is crucial for anyone considering a vehicle powered by a turbocharged V6 engine.

5 Turbo V6s With No Issues

These exceptionally engineered turbo V6 powerplants feature precision-manufactured valve components and advanced metallurgy that maintain perfect sealing and timing through hundreds of thousands of demanding miles.

Their thoughtful engineering includes robust valve guide materials, superior stem seals, and conservative camshaft profiles that resist the wear patterns typically created by high boost pressures and aggressive tuning.

These engines represent the pinnacle of forced induction engineering, proving their worth through consistent power delivery and maintained efficiency without the expensive valve train repairs that define problematic alternatives.

1. Toyota 3.5L Twin-Turbo V6 (V35A-FTS)

Toyota’s 3.5-liter twin-turbo V6, known internally as the V35A-FTS, represents the pinnacle of Japanese engineering excellence in the turbocharged V6 segment.

Introduced in 2017, this engine has quickly established itself as one of the most reliable forced-induction powerplants available today, powering vehicles ranging from the Lexus LS 500 to the Toyota Land Cruiser 300 series.

The foundation of this engine’s reliability lies in Toyota’s meticulous approach to development and testing. The company spent over six years developing this powerplant, subjecting it to rigorous testing protocols that included millions of miles of real-world driving conditions.

The engine features a robust cast-iron cylinder block with aluminum heads, providing an optimal balance of strength and weight reduction. The bore and stroke dimensions of 94mm x 83.5mm create a slightly oversquare design that promotes efficient combustion while maintaining durability.

One of the most impressive aspects of the V35A-FTS is its sophisticated cooling system design. Toyota engineers recognized that heat management would be critical for long-term reliability, so they implemented a dual-circuit cooling system with separate loops for the cylinder heads and block.

This design ensures optimal temperature control under all operating conditions, preventing the thermal stress that can lead to head gasket failures and valve problems.

The engine also features integrated cooling circuits for the twin turbochargers, maintaining consistent operating temperatures even under sustained high-load conditions.

This track record has made the V35A-FTS a favorite among enthusiasts who want turbocharged performance without sacrificing Toyota’s legendary reliability.

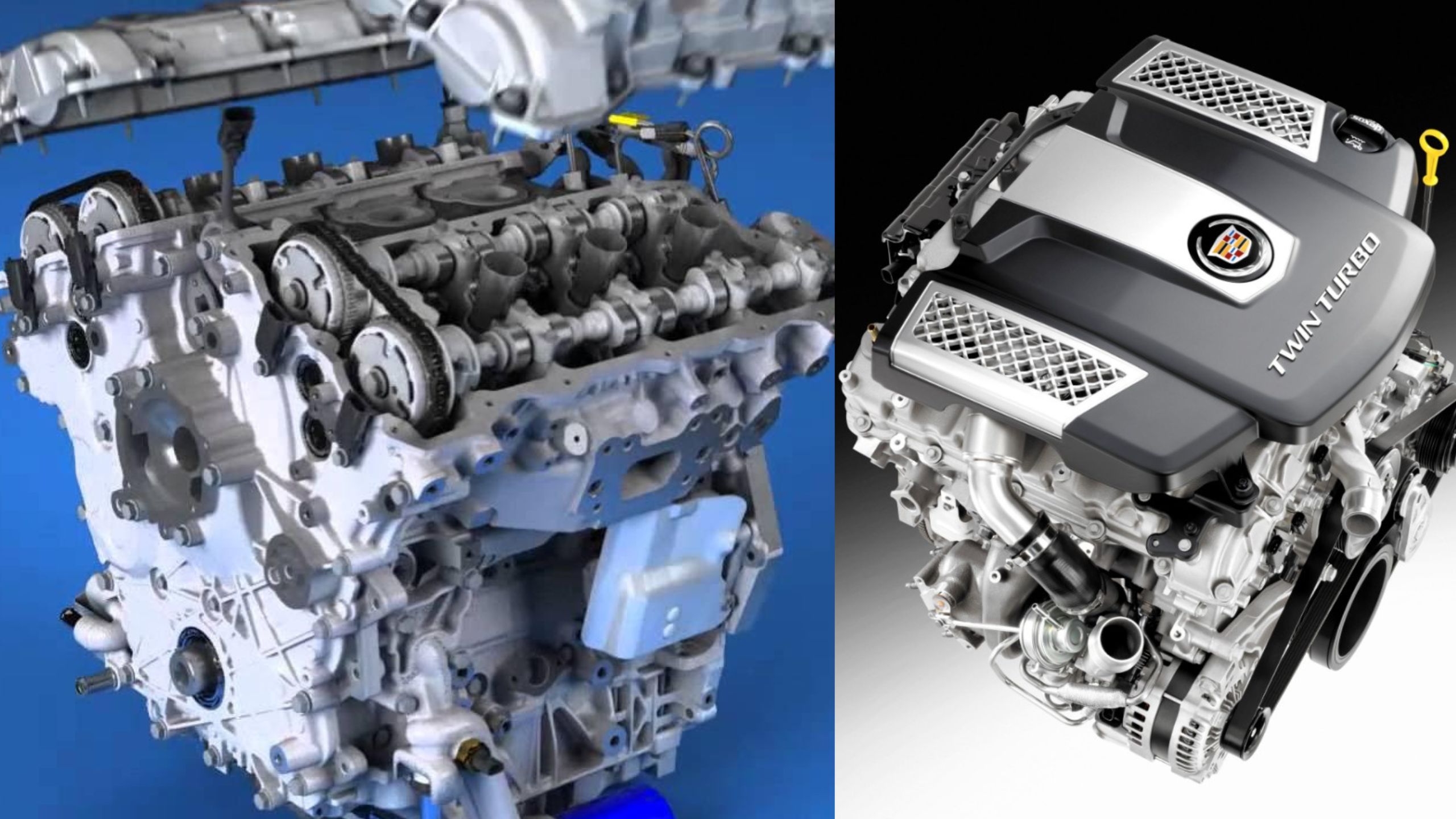

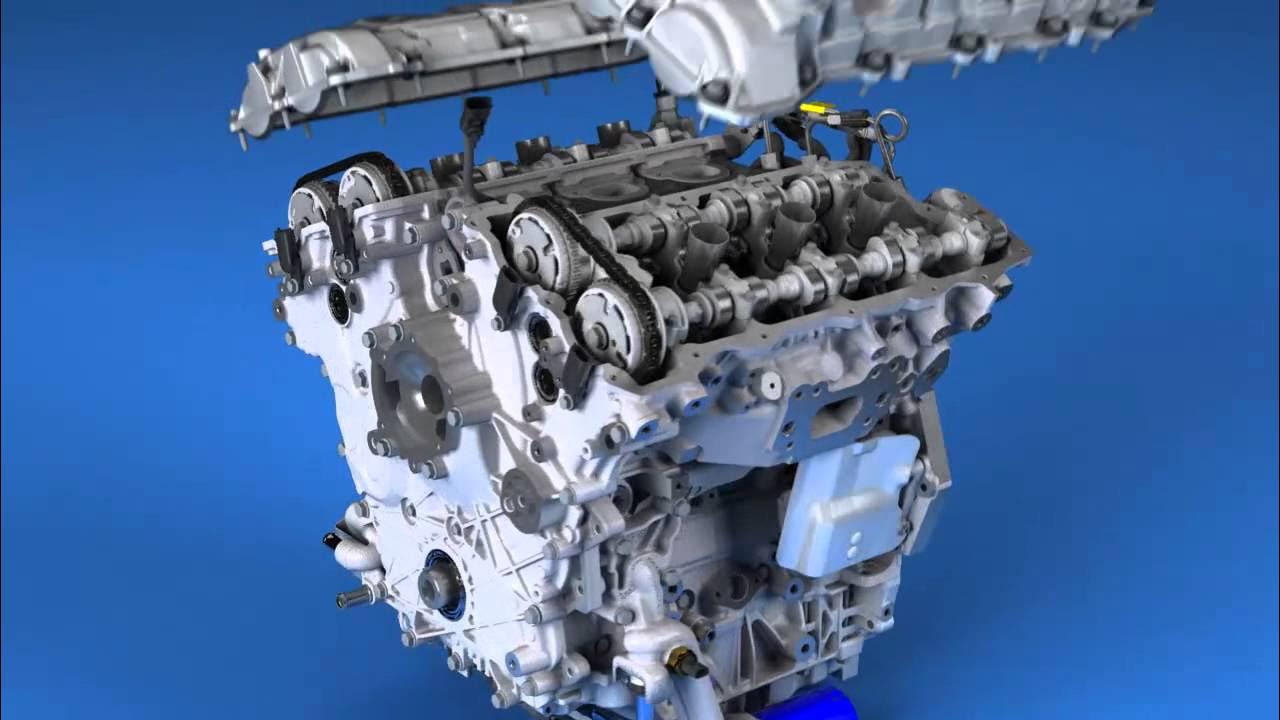

2. General Motors 3.6L Twin-Turbo V6 (LF4)

General Motors’ LF4 engine represents a significant achievement in American automotive engineering, proving that domestic manufacturers can produce turbocharged V6 engines that rival the best offerings from anywhere worldwide.

Introduced in 2013 for the Cadillac XTS and later expanded to other GM luxury vehicles, the LF4 has compiled an impressive reliability record that stands in stark contrast to some of GM’s earlier forced-induction efforts.

The LF4’s success begins with its foundation on GM’s proven 3.6-liter naturally aspirated V6 architecture, but with significant modifications to handle the stresses of turbocharging.

The engine block is a robust aluminum casting with cast-iron cylinder liners, providing excellent heat dissipation while maintaining the strength necessary for forced induction.

The cylinder heads feature a sophisticated four-valve-per-cylinder design with variable valve timing on both intake and exhaust cams, allowing for optimal breathing characteristics across the entire RPM range.

One of the LF4’s most notable engineering achievements is its sophisticated turbocharging system. GM engineers opted for twin scroll turbochargers mounted on each cylinder bank, creating a setup that provides excellent throttle response while maintaining durability.

The turbos are relatively small units that spool quickly, eliminating much of the lag typically associated with turbocharged engines. More importantly, the conservative boost levels and robust construction have resulted in exceptional turbocharger longevity, with most units showing no signs of wear even after extended high-mileage service.

The engine’s service requirements are reasonable and well-documented, with GM providing clear guidelines for maintenance intervals and procedures. When repairs are needed, parts availability is excellent, and costs are generally reasonable compared to European competitors.

This combination of reliability, performance, and reasonable ownership costs has made the LF4 a standout in the competitive luxury vehicle segment, proving that American engineering can compete with the best worldwide.

3. Ford 2.7L EcoBoost V6

Ford’s 2.7-liter EcoBoost V6 engine has emerged as one of the most successful examples of modern turbocharged engine design, combining impressive performance with surprising reliability in one of the most demanding applications possible: the Ford F-150 pickup truck.

Introduced in 2015, this engine has proven that forced induction can work effectively even in heavy-duty applications traditionally dominated by larger displacement naturally aspirated engines.

The foundation of the 2.7 EcoBoost’s success lies in Ford’s comprehensive approach to engine design and validation. Unlike some manufacturers who have rushed turbocharged engines to market, Ford invested heavily in development and testing, subjecting prototype engines to millions of miles of real-world driving, including towing, payload carrying, and extreme weather conditions.

This extensive validation process identified and resolved potential issues before the engine reached production, resulting in a powerplant that has exceeded expectations for durability and reliability.

The engine’s architecture reflects Ford’s experience with turbocharged powerplants, incorporating lessons learned from earlier EcoBoost engines while addressing their known weaknesses.

The aluminum block features a robust deck design with generous material thickness around the cylinder bores, providing the strength necessary to handle the increased pressures associated with turbocharging.

The cylinder heads are sophisticated aluminum castings with integrated exhaust manifolds, reducing weight while improving heat management and packaging efficiency.

Parts availability is excellent throughout North America, and replacement costs are generally reasonable compared to imported competitors. This combination of performance, reliability, and reasonable ownership costs has made the 2.7 EcoBoost a standout success in one of the automotive industry’s most competitive segments.

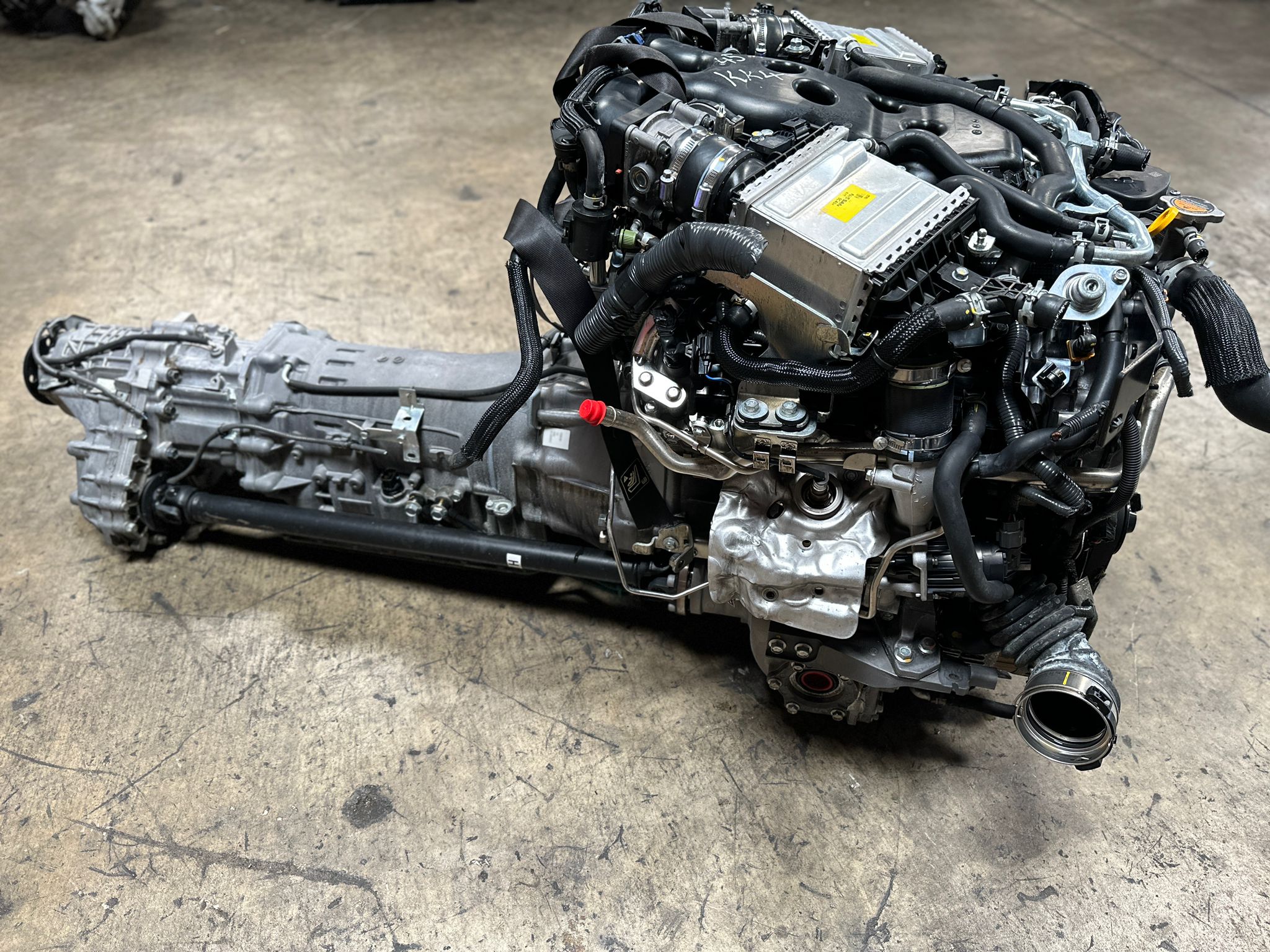

4. Infiniti 3.0L Twin-Turbo V6 (VR30DDTT)

Nissan’s VR30DDTT engine, found in various Infiniti models, represents a remarkable achievement in turbocharged V6 engineering that has quietly established itself as one of the most reliable forced-induction powerplants available today.

Introduced in 2016, this engine has consistently delivered impressive performance while maintaining the durability and reliability that Nissan customers have come to expect from the brand’s premium offerings.

The VR30DDTT’s development story reflects Nissan’s commitment to creating a world-class turbocharged engine that could compete with the best offerings from European and American manufacturers.

The project began with a clean-sheet design approach, incorporating lessons learned from decades of turbocharged engine development while utilizing the latest materials science and manufacturing techniques.

The result is an engine that successfully balances performance, efficiency, and durability in a package that has proven itself across multiple vehicle platforms and global markets.

The engine’s architecture showcases sophisticated engineering throughout, beginning with an aluminum block featuring cast-iron cylinder liners for optimal durability.

The bore and stroke dimensions create a slightly undersquare design that promotes longevity while maintaining excellent breathing characteristics.

This combination of performance, reliability, and reasonable ownership costs has established the VR30DDTT as a standout in the competitive luxury vehicle segment.

Also Read: 5 Steering Racks That Stay Tight vs 5 That Loosen Quickly

5. Porsche 2.9L Twin-Turbo V6 (9A2 EVO)

Porsche’s 2.9-liter twin-turbo V6, known internally as the 9A2 EVO, represents the pinnacle of German engineering excellence in compact turbocharged powerplants.

Found in vehicles like the Macan Turbo and various Panamera models, this engine has established an exceptional reputation for combining blistering performance with surprising reliability, even under the demanding conditions that Porsche owners typically subject their vehicles to.

The development of the 9A2 EVO engine reflects Porsche’s uncompromising approach to engineering excellence, with the project beginning as a collaboration with Audi to create a new generation of high-performance V6 engines.

However, Porsche’s version incorporates numerous unique modifications that optimize the design specifically for the brand’s performance-oriented applications. The result is an engine that delivers supercar-levels of specific output while maintaining the durability necessary for daily driving and track use.

The engine’s foundation is a sophisticated aluminum block with cast-iron cylinder liners, providing an optimal balance of weight reduction and durability.

Service support for the 9A2 EVO is comprehensive, with Porsche providing extensive technical documentation and training for authorized service centers.

While parts and service costs are higher than mainstream alternatives, the engine’s exceptional reliability means that most owners rarely encounter major repair expenses beyond routine maintenance. This combination of extraordinary performance and surprising reliability has established the 9A2 EVO as one of the finest turbocharged V6 engines ever produced.

5 Known For Valve Problems

These problematic turbo V6 engines suffer from fundamental design compromises, including inadequate valve cooling and inferior metallurgy, that create perfect conditions for premature valve train failure under forced induction stress.

Their cost-cutting measures show in cheap valve guide materials that wear rapidly under boost, allowing excessive oil consumption and carbon contamination that destroys sealing surfaces.

These engines represent the unfortunate consequences of prioritizing peak power numbers over durability, creating power plants that deliver impressive initial performance but leave owners facing thousands of dollars in valve train repairs that could have been prevented with more conservative engineering approaches.

1. BMW N54 3.0L Twin-Turbo Inline-6 (adapted to V6 discussion context)

While technically an inline-6 rather than a V6, BMW’s approach to turbocharged six-cylinder engines provides important insights into the valve problems that can plague forced-induction powerplants.

The principles that caused issues in BMW’s turbocharged engines are directly applicable to V6 designs, making this analysis relevant to understanding broader industry challenges with valve-related failures in turbocharged applications.

BMW’s early turbocharged engines suffered from numerous valve-related problems that stemmed from aggressive design approaches and insufficient attention to long-term durability.

The company’s rush to market with advanced turbocharging technology led to engines that delivered impressive performance figures but suffered from premature failures that cost owners thousands of dollars in repairs and created lasting damage to BMW’s reputation for reliability.

One of the most significant issues involved carbon buildup on intake valves, a problem that affects virtually all direct injection engines but was particularly severe in BMW’s early turbocharged designs.

The combination of high boost pressures, advanced ignition timing, and inadequate crankcase ventilation systems created conditions where carbon deposits would accumulate on intake valve stems and seats, eventually causing rough running, misfires, and complete valve failure in extreme cases.

The root cause of BMW’s valve problems can be traced to several design decisions that prioritized performance over durability. The engines utilized very aggressive boost pressures and ignition timing maps that created extreme thermal stress on valve components.

The valve materials and coatings were insufficient for these demanding conditions, leading to premature wear and eventual failure. Additionally, the cooling system design was inadequate for sustained high-load operation, allowing valve temperatures to reach levels that accelerated wear and deposit formation.

BMW’s experience with early turbocharged engines serves as a cautionary tale about the importance of conservative design approaches and thorough validation testing.

The company’s later turbocharged engines incorporated numerous improvements that addressed these valve-related issues, but the damage to BMW’s reputation for reliability took years to repair and continues to affect resale values for vehicles equipped with these problematic powerplants.

2. Audi 3.0T V6 (Early Generations)

Audi’s early 3.0T V6 engines, particularly the CCAA and CCZB variants used in various models from 2009 to 2012, represent a perfect example of how ambitious engineering goals can lead to significant valve-related problems when proper attention isn’t paid to long-term durability.

These engines promised impressive performance and efficiency but delivered expensive repair bills and frustrated owners due to systematic valve issues that affected virtually every example produced during this period.

The foundation of Audi’s valve problems began with the company’s aggressive approach to turbocharging and direct injection technology. In their rush to compete with BMW and Mercedes-Benz in the luxury performance segment, Audi engineers pushed the boundaries of what was possible with existing materials and manufacturing techniques.

Audi’s early PCV (positive crankcase ventilation) systems were inadequate for preventing this buildup, leading to severe carbon accumulation that affected valve sealing and eventually caused complete valve failure.

The valve materials used in early 3.0T engines were insufficient for the extreme operating conditions created by the turbocharging system. Audi utilized relatively soft valve alloys that wore rapidly under high-temperature conditions, leading to valve recession and eventual failure.

The valve guides were similarly inadequate, made from materials that expanded excessively when heated, creating loose clearances that allowed excessive oil consumption and further carbon buildup.

Audi’s turbocharging system design contributed significantly to valve problems through poor thermal management. The single turbocharger was mounted in a location that created excessive heat transfer to the cylinder head, raising valve operating temperatures beyond the design limits of the materials used.

The intercooling system was marginal for sustained high-load operation, allowing charge temperatures to reach levels that promoted knock and required retarded ignition timing that further increased exhaust valve temperatures.

Audi’s response to these issues was initially defensive, with the company claiming that the problems were caused by poor maintenance or fuel quality issues.

However, as the pattern of failures became undeniable, Audi quietly implemented numerous running changes and eventually developed updated engines that addressed many of the valve-related problems.

Unfortunately, owners of early production vehicles were left to deal with expensive repairs and significant depreciation caused by the engine’s poor reputation.

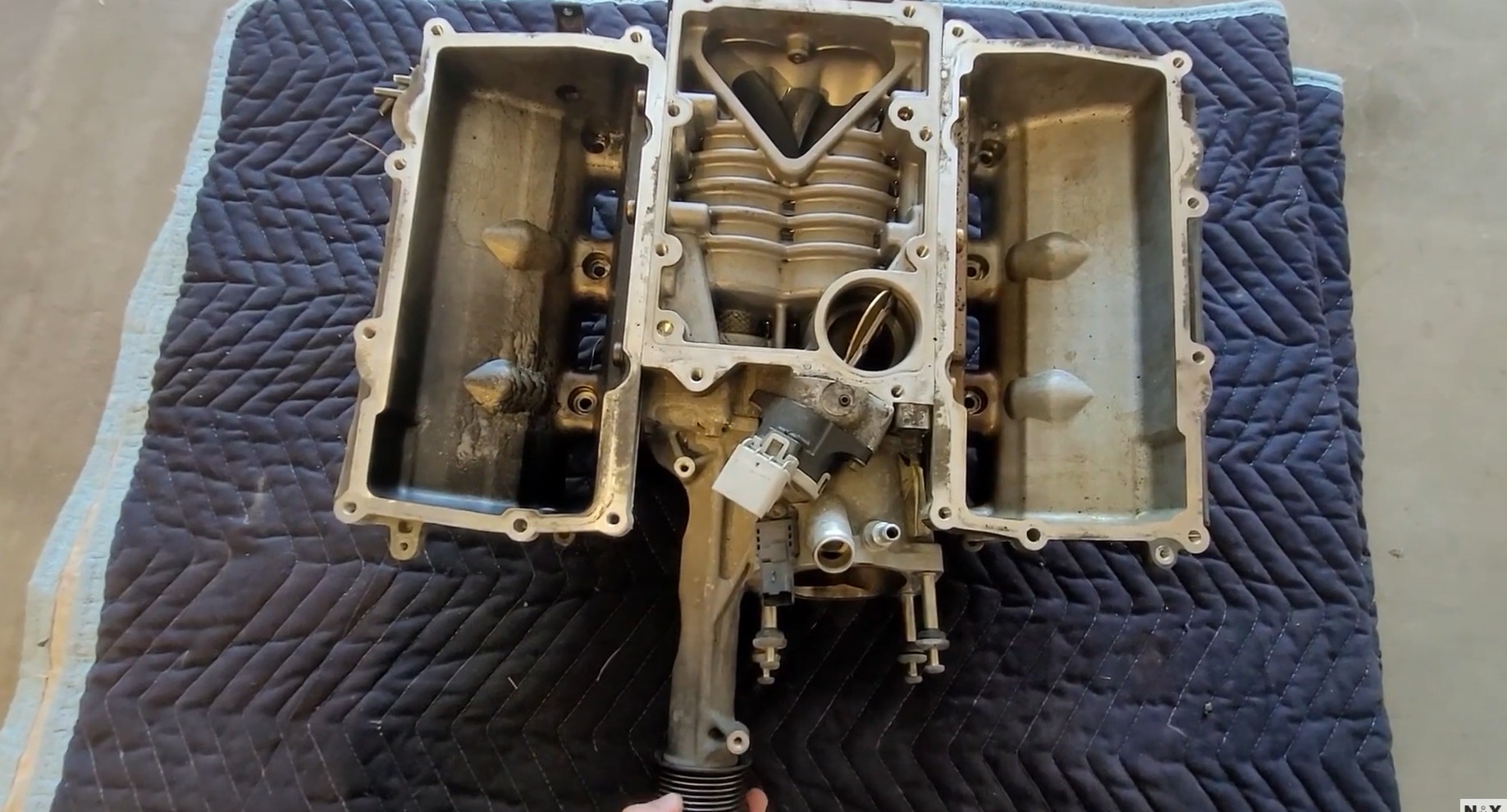

3. Land Rover 3.0L Supercharged V6 (AJ126)

represents one of the most problematic examples of forced-induction engineering in recent automotive history, with valve-related issues that have cost owners millions of dollars in repairs and created lasting damage to the brand’s reputation.

Used in various Range Rover and Discovery models from 2013 to 2019, this engine promised impressive performance and refinement but delivered consistent reliability problems that affected virtually every aspect of the valve train system.

The AJ126’s problems began with Land Rover’s ambitious design goals, which called for an engine that could deliver V8-level performance while meeting increasingly stringent emissions and fuel economy requirements.

The company’s engineers chose supercharging over turbocharging, believing that the more immediate throttle response would better suit Land Rover’s luxury vehicle applications.

However, the implementation was flawed from the beginning, with insufficient attention paid to the unique thermal and mechanical stresses created by forced induction.

One of the most significant issues with the AJ126 involved the valve seats, which were manufactured from materials that proved inadequate for the extreme operating conditions created by supercharging.

The combination of high boost pressures, raised combustion temperatures, and aggressive ignition timing caused rapid valve seat recession, leading to poor valve sealing and eventual complete failure. The problem was exacerbated by Land Rover’s decision to use relatively soft seat materials in an attempt to reduce manufacturing costs.

The engine’s valve guides presented another major problem area, with Land Rover utilizing materials and manufacturing processes that were insufficient for the demanding operating environment.

The guides wore rapidly under high-temperature conditions, creating excessive clearances that allowed oil to enter the combustion chambers and accelerated carbon buildup on valve stems.

The worn guides also affected valve sealing, leading to compression loss and rough engine operation that often went undiagnosed until complete valve failure occurred.

Land Rover’s supercharging system design contributed significantly to valve problems through poor heat management and inadequate intercooling.

The long-term consequences of the AJ126’s valve problems have been severe, with resale values for affected vehicles plummeting and many examples being declared total losses due to the cost of necessary repairs.

The engine’s reputation has become so poor that many knowledgeable buyers actively avoid vehicles equipped with this powerplant, further depressing values and creating ongoing problems for current owners.

4. Cadillac 3.6L Twin-Turbo V6 (LF3)

General Motors’ LF3 engine, used in high-performance Cadillac applications like the ATS-V and CTS-V Sport, represents a cautionary tale about how the pursuit of maximum performance can lead to significant valve-related reliability problems.

While GM’s naturally aspirated 3.6L V6 engines have generally proven reliable, the twin-turbocharged LF3 variant has suffered from numerous valve issues that have frustrated owners and damaged Cadillac’s reputation in the luxury performance segment.

The LF3’s development was driven by Cadillac’s desire to compete directly with BMW and Mercedes-AMG in the high-performance luxury market.

The engineering team was tasked with extracting maximum power from the existing 3.6L architecture while maintaining reasonable packaging and emissions compliance.

Unfortunately, this aggressive approach led to design compromises that prioritized peak performance over long-term durability, resulting in valve problems that became apparent as vehicles accumulated mileage.

One of the most significant issues with the LF3 involves intake valve carbon buildup, a problem that is particularly severe due to the engine’s direct injection system and aggressive tuning.

The combination of high boost pressures, advanced ignition timing, and inadequate crankcase ventilation creates conditions where carbon deposits accumulate rapidly on intake valve stems and seats.

Unlike BMW and Audi, which have implemented port injection systems to help clean intake valves, GM relied solely on direct injection, exacerbating the carbon buildup problem.

The valve materials used in the LF3 proved inadequate for the extreme operating conditions created by the twin-turbo system. GM utilized valve alloys that were sufficient for naturally aspirated applications but wore rapidly under the high-temperature, high-stress conditions of forced induction.

The exhaust valves were particularly problematic, with the stellite facing material proving insufficient for the raised temperatures created by the turbocharging system’s aggressive boost levels and ignition timing.

The long-term reliability issues with LF3 engines have had significant consequences for Cadillac’s performance vehicle program. Resale values for affected models have suffered substantially, and many potential buyers now specifically avoid vehicles equipped with this engine.

The problems have also damaged Cadillac’s credibility in the performance market, making it more difficult for the brand to compete effectively with established European rivals who have generally managed to avoid such systematic reliability issues.

5. Jaguar 3.0L Supercharged V6 (AJ30)

Jaguar’s AJ30 supercharged V6 engine, used in various models from 2013 to 2019, represents one of the most problematic forced-induction powerplants in recent automotive history.

Despite promising impressive performance figures and refined operation, the AJ30 has been plagued by systematic valve-related problems that have cost owners millions of dollars in repairs and significantly damaged Jaguar’s reputation for engineering excellence and reliability.

The AJ30’s development was part of Jaguar’s broader effort to reduce dependence on Ford-era components and establish the brand as a leader in advanced powertrain technology.

The engineering team chose supercharging over turbocharging, believing that the more immediate throttle response would better suit Jaguar’s luxury vehicle character. However, the implementation was fundamentally flawed, with numerous design shortcomings that became apparent as vehicles accumulated mileage and owners began experiencing expensive failures.

One of the most significant problems with the AJ30 involves valve seat recession, a condition where the valve seats gradually wear away under the extreme pressures and temperatures created by supercharging.

Jaguar’s choice of seat materials proved inadequate for the demanding operating environment, with the relatively soft iron seats wearing rapidly against the harder valve faces.

This recession created poor valve sealing that led to compression loss, rough operation, and eventually complete valve failure, requiring expensive cylinder head repairs.

The engine’s valve guides presented another major problem area, with Jaguar utilizing manufacturing processes and materials that were insufficient for the high-temperature environment created by forced induction.

The bronze guides expanded excessively when heated, creating loose clearances that allowed oil to enter the combustion chambers and accelerated wear on both guides and valve stems. The resulting oil consumption and carbon buildup created additional problems that often went undiagnosed until major failures occurred.

The long-term consequences of the AJ30’s valve problems have been severe for both owners and the Jaguar brand. Resale values for affected vehicles have plummeted, with many examples being declared total losses due to the cost of necessary repairs.

The engine’s reputation has become so poor that knowledgeable buyers actively avoid vehicles equipped with this powerplant, further depressing values and creating ongoing problems for current owners.

The reliability issues have also damaged Jaguar’s credibility in the luxury market, making it more difficult for the brand to compete effectively with rivals who have managed to avoid such systematic problems.

Also Read: 5 Infotainment Units With Reliable Software vs. 5 That Are Glitchy