When it comes to automotive engineering, the heart of every vehicle lies beneath the hood. The engine serves as the powerhouse that transforms fuel into motion, and its reliability can make the difference between years of trouble-free driving and countless visits to the mechanic’s shop.

Car enthusiasts and everyday drivers alike recognize the importance of selecting a vehicle with a dependable powertrain, as this decision affects not only their wallet but also their peace of mind. Engineering excellence typically favors simplicity in design, with fewer moving parts translating to fewer potential failure points.

This principle has guided automotive manufacturers for decades as they balance performance demands with long-term durability. Some engines have earned legendary status for their ability to accumulate hundreds of thousands of miles with minimal maintenance requirements, while others have become infamous for their premature failures and expensive repair bills.

The automotive industry has produced both mechanical marvels and engineering disasters throughout its history. Certain engines demonstrate exceptional build quality, robust design, and materials that withstand the test of time.

These reliable units often feature straightforward architectures, proven technologies, and conservative engineering approaches that prioritize longevity over peak performance figures. Some engines are known to run well above 300,000 miles with proper maintenance.

Other engines have gained notoriety for their tendency to develop problems well before reaching reasonable mileage milestones. These problematic engines often suffer from design flaws, inadequate cooling systems, poor materials selection, or manufacturing defects that lead to premature wear and catastrophic failures.

Understanding which engines fall into each category can save drivers money and frustration while helping them make informed purchasing decisions. This examination will identify five engines celebrated for their exceptional reliability alongside five engines notorious for their tendency to develop serious problems.

Each engine’s strengths and weaknesses will be discussed to provide valuable insights for potential car buyers and current owners seeking to understand their vehicle’s long-term prospects.

5 Engines That Stay Tight

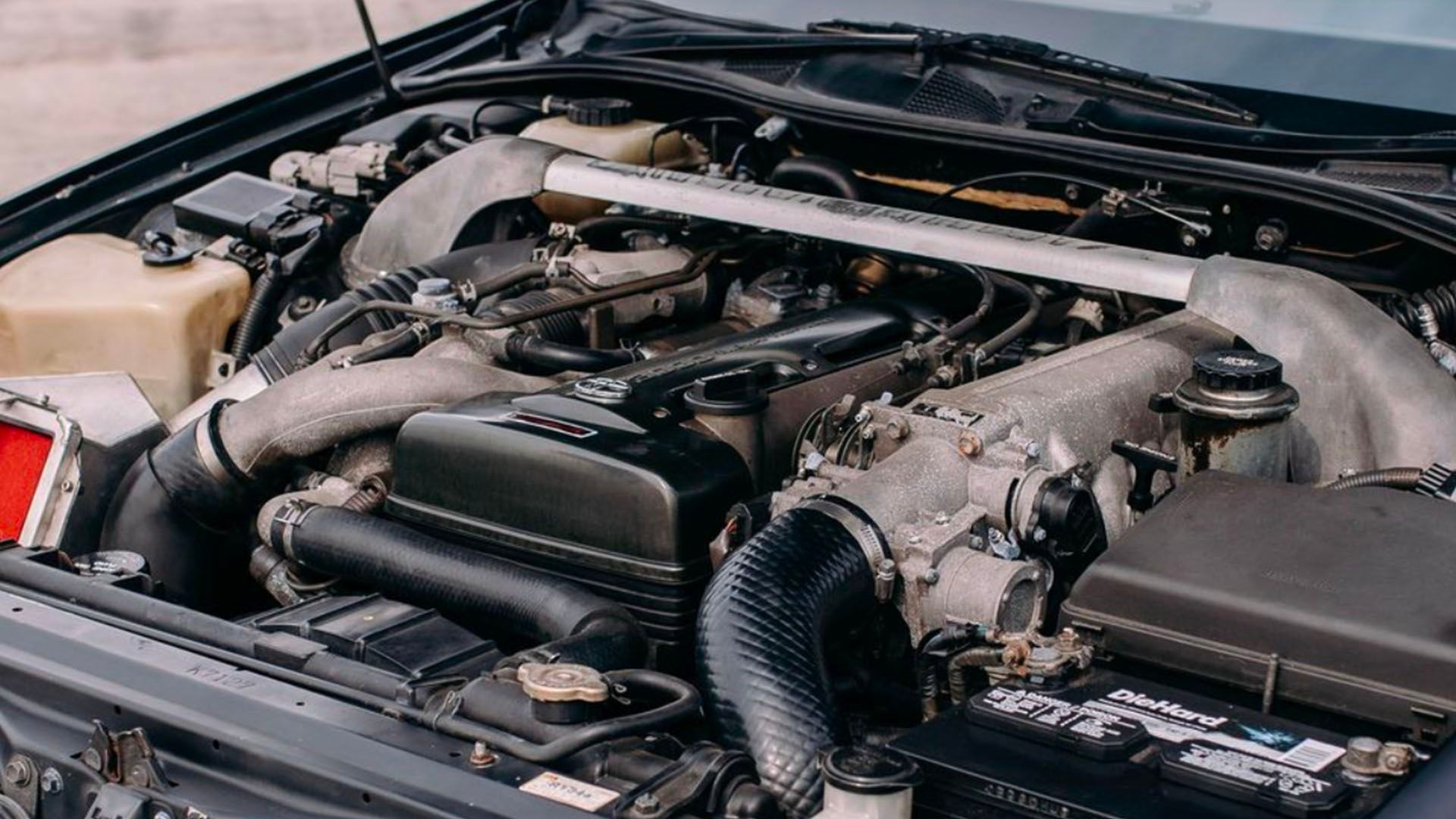

1. Toyota 2JZ-GTE

The Toyota 2JZ-GTE stands as one of the most revered engines in automotive history, earning its reputation through decades of reliable service and extraordinary performance potential. This inline-six turbocharged engine debuted in the 1990s and quickly became the benchmark for durability and tunability.

Engineers at Toyota constructed this engine with a cast-iron block featuring extremely thick cylinder walls, forged internals, and robust components capable of handling far more power than the factory specifications suggested.

The engine’s exceptional strength stems from its conservative factory tune, which utilizes only a fraction of its true potential. Toyota equipped the 2JZ-GTE with sequential twin turbochargers, sophisticated fuel injection systems, and advanced engine management technology that was ahead of its time.

The closed-deck block design provides exceptional rigidity, while the deep skirt construction ensures proper crankshaft support even under extreme loads. These engineering decisions resulted in an engine capable of producing reliable power for hundreds of thousands of miles.

Maintenance requirements for the 2JZ-GTE remain refreshingly simple despite its advanced technology. Regular oil changes using high-quality lubricants, periodic coolant system service, and attention to the turbocharger’s cooling needs keep these engines running reliably for an extended period.

The robust construction means internal components rarely wear out under normal driving conditions, and even modified examples producing double the factory power often achieve remarkable longevity when properly maintained. The aftermarket support for the 2JZ-GTE is unparalleled, with countless companies producing performance parts, replacement components, and upgrade options.

This extensive support network means owners can easily find parts and knowledgeable technicians familiar with the engine’s characteristics. The engine’s legendary status in motorsports and tuning communities has created a wealth of knowledge and expertise that benefits all owners, regardless of their performance goals.

Modern automotive journalists and mechanics consistently rank the 2JZ-GTE among the most reliable engines ever produced. Its combination of strength, simplicity, and engineering excellence created an engine that continues to impress decades after its initial release. For drivers seeking maximum reliability with performance potential, few engines can match the proven track record of Toyota’s masterpiece.

2. Honda B18C

Honda’s B18C engine represents the pinnacle of naturally aspirated four-cylinder engineering, combining exceptional reliability with thrilling high-rpm performance characteristics. This VTEC-equipped engine powered some of Honda’s most celebrated performance cars during the 1990s and early 2000s, establishing a reputation for bulletproof reliability even under demanding driving conditions.

The engine’s aluminum construction keeps weight low while providing excellent heat dissipation properties that contribute to its longevity. The B18C’s legendary reliability stems from Honda’s meticulous attention to detail and conservative engineering approach.

The engine features forged internals, precision-balanced rotating assemblies, and exceptional manufacturing tolerances that ensure smooth operation throughout its rev range. Honda’s VTEC system adds performance without compromising reliability, using mechanical actuation that rarely fails even after hundreds of thousands of miles of operation.

The sophisticated engine management system monitors all critical parameters to protect the engine from damage while maximizing performance. Oil circulation in the B18C deserves special recognition for its role in the engine’s durability.

Honda designed an excellent oiling system that maintains proper lubrication even during extended high-rpm operation, protecting bearing surfaces and valve train components from premature wear. The engine’s relatively simple design means fewer components can fail, while the high-quality materials and construction ensure that normal wear occurs very slowly over many years of service.

Maintenance requirements for the B18C are minimal and straightforward, making it an ideal choice for drivers who want performance without constant mechanical attention. Regular oil changes, periodic valve adjustments, and attention to the cooling system keep these engines running flawlessly for decades.

The timing belt requires replacement at specified intervals, but this routine maintenance task prevents any possibility of interference damage while keeping costs reasonable. The B18C’s reputation extends far beyond its original applications, with engine swaps and conversions bringing this reliable engine to countless other vehicles.

Its compact size, light weight, and exceptional power-to-weight ratio make it a popular choice for performance builds, while its proven reliability provides peace of mind for daily drivers. Honda’s engineering excellence shines through in every aspect of this remarkable engine.

Also Read: 5 Engines With Legendary Lifespans and 5 That Barely Make It

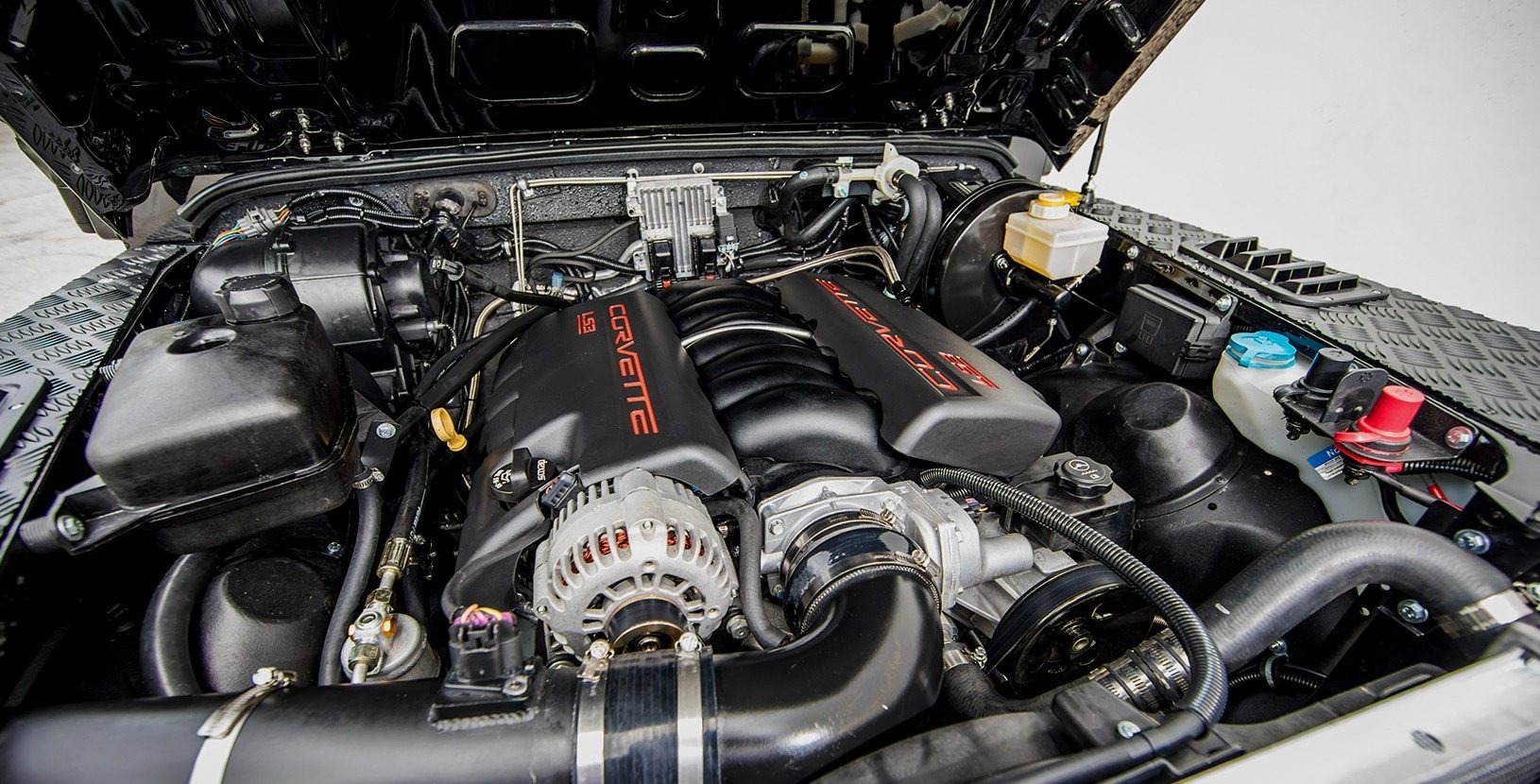

3. Chevrolet LS3

General Motors’ LS3 V8 engine represents the evolution of American automotive engineering, combining traditional V8 architecture with modern technology and manufacturing precision. This naturally aspirated engine delivers impressive performance while maintaining the simplicity and reliability that made previous generations of small-block Chevrolet engines famous.

The LS3’s aluminum construction provides excellent strength-to-weight ratios, while the sophisticated port fuel injection system ensures optimal fuel delivery under all operating conditions.

The engine’s reliability stems from its proven architecture and conservative engineering approach. GM utilized decades of V8 development experience to create an engine with robust bottom-end components, efficient cooling systems, and durable valve train designs.

The LS3 features advanced materials throughout, including lightweight pistons, forged connecting rods, and precision-manufactured cylinder heads that contribute to both performance and longevity. The coil-on-plug ignition system eliminates traditional distributor problems while providing precise spark timing control.

Cooling system design in the LS3 receives particular attention from GM engineers, who understand that proper thermal management is crucial for long-term reliability. The engine features efficient coolant flow patterns, adequate radiator capacity, and sophisticated engine management systems that monitor temperatures continuously.

These design elements work together to prevent overheating conditions that could damage internal components or cause premature wear. The LS3’s maintenance schedule remains refreshingly simple despite its advanced technology.

Regular oil changes, periodic coolant system service, and attention to air filtration keep these engines running trouble-free for hundreds of thousands of miles. The sophisticated engine management system monitors all critical parameters and can adapt to changing conditions, ensuring optimal performance while protecting internal components from damage.

Aftermarket support for the LS3 is extensive, with countless companies producing performance upgrades, replacement parts, and maintenance supplies. This robust support network means owners can easily find qualified technicians and affordable parts when service becomes necessary. The engine’s popularity in both OEM applications and aftermarket swaps has created a wealth of knowledge and expertise that benefits all owners.

4. Ford 5.0 Coyote

Ford’s 5.0-liter Coyote V8 engine represents the successful modernization of the classic American muscle car engines, delivering impressive performance while maintaining exceptional reliability standards.

This naturally aspirated engine features advanced technologies like dual overhead cams, variable valve timing, and sophisticated engine management systems that optimize performance across the entire rev range. The aluminum construction keeps weight reasonable while providing excellent heat dissipation characteristics that contribute to the engine’s durability.

The Coyote’s reliability foundation begins with its robust bottom-end construction, featuring forged steel crankshafts, powder-forged connecting rods, and high-strength pistons designed to withstand high-performance applications.

Ford engineers incorporated lessons learned from decades of V8 development to create an engine with exceptional strength margins and conservative stress levels during normal operation. The sophisticated valve train design includes roller followers and hydraulic lash adjusters that minimize maintenance requirements while ensuring precise valve control.

Cooling system engineering in the Coyote reflects Ford’s commitment to reliability, with efficient coolant flow patterns and adequate heat rejection capacity for all operating conditions. The engine features multiple temperature sensors that allow the sophisticated engine management system to monitor thermal conditions continuously and adjust operation accordingly.

This proactive approach prevents overheating conditions that could damage internal components or cause premature wear. The Coyote’s direct injection fuel system provides exceptional fuel atomization and precise control over mixture preparation, contributing to both performance and efficiency.

This advanced technology requires minimal maintenance while providing reliable operation throughout the engine’s service life. The sophisticated ignition system features individual coil packs for each cylinder, eliminating traditional distributor problems while ensuring optimal spark timing under all conditions.

Maintenance requirements for the Coyote remain reasonable despite its advanced technology, with regular oil changes, periodic coolant system service, and attention to air filtration keeping these engines running flawlessly.

The engine’s sophisticated diagnostic capabilities make troubleshooting simple when issues do arise, while the extensive service network ensures qualified technicians and genuine parts are readily available when needed.

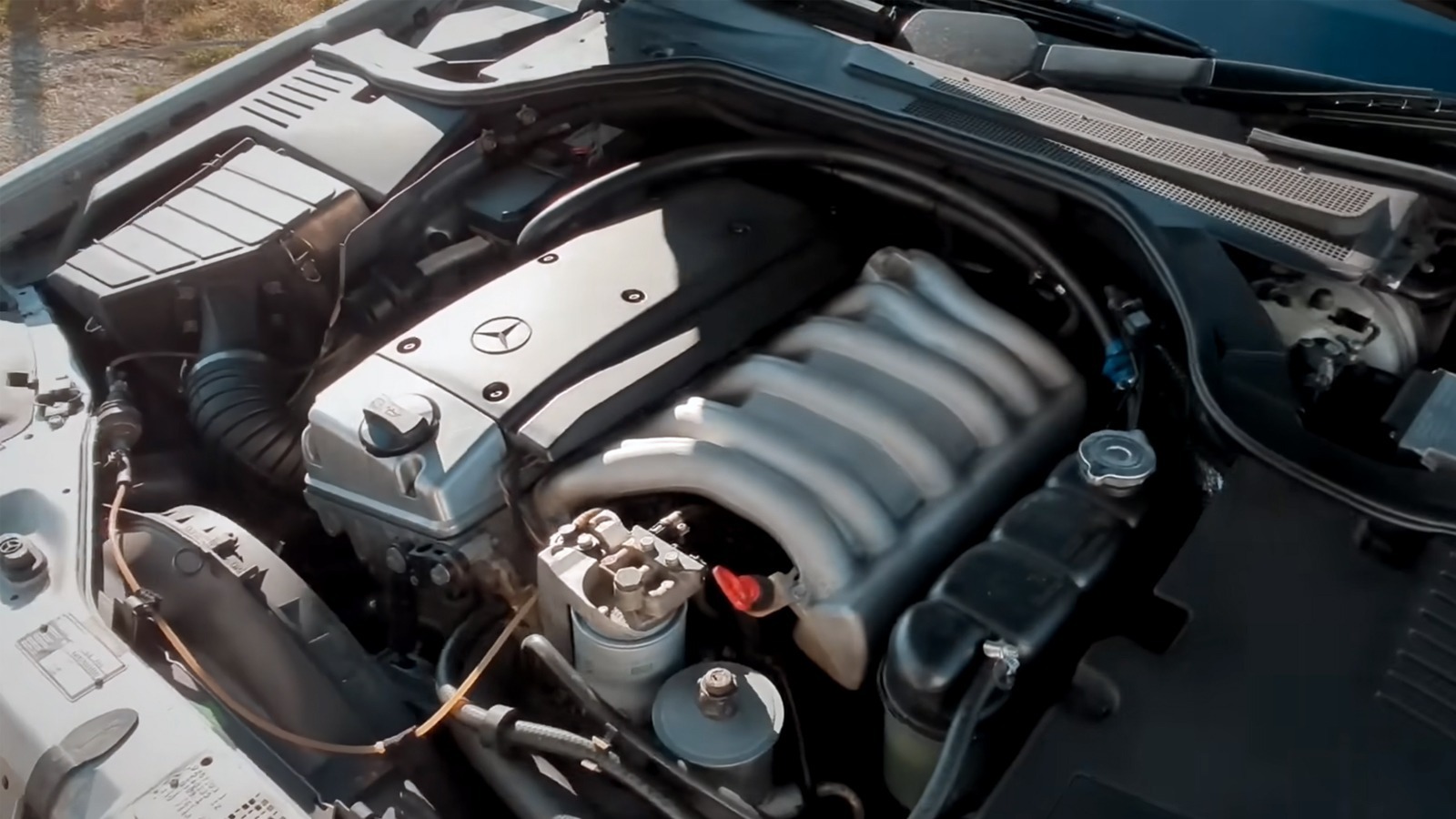

5. Mercedes-Benz OM606

The Mercedes-Benz OM606 diesel engine stands as a testament to German engineering excellence, combining exceptional fuel economy with legendary reliability that has made these engines highly sought after by enthusiasts worldwide.

This inline-six turbocharged diesel engine features robust construction, conservative tuning, and meticulous attention to detail that results in service lives measured in hundreds of thousands of miles. The cast-iron construction provides exceptional durability, while the sophisticated fuel injection system delivers precise control over combustion processes.

Engineering excellence permeates every aspect of the OM606’s design, from its robust bottom-end construction to its efficient turbocharging system. Mercedes engineers utilized forged steel crankshafts, heavy-duty connecting rods, and reinforced engine blocks capable of withstanding the high compression ratios and combustion pressures inherent in diesel operation.

The sophisticated timing chain system ensures precise valve timing throughout the engine’s service life while eliminating the maintenance requirements associated with timing belt designs. The OM606’s fuel injection system represents the pinnacle of pre-common rail diesel technology, featuring mechanical Bosch pumps that provide exceptional reliability and serviceability.

This proven technology delivers precise fuel metering without the electronic complication that can cause problems in modern diesel engines. The robust construction of these injection components means they often outlast the rest of the vehicle with proper maintenance and quality fuel.

Cooling system design in the OM606 reflects Mercedes’ understanding of diesel engine thermal management requirements. The engine features adequate coolant capacity, efficient heat rejection, and sophisticated temperature monitoring systems that prevent overheating conditions. The oil cooling system receives particular attention, with dedicated oil coolers ensuring proper lubrication temperatures even during extended high-load operation.

Maintenance requirements for the OM606 are straightforward and cost-effective, making these engines excellent choices for high-mileage applications. Regular oil changes using appropriate diesel-specific lubricants, periodic fuel filter replacement, and attention to the cooling system keep these engines running indefinitely.

The mechanical simplicity of the injection system means most service procedures can be performed by competent technicians without specialized electronic diagnostic equipment.

5 Engines That Shake Apart

1. Ford 6.0 PowerStroke

The Ford 6.0-liter PowerStroke V8 diesel engine earned an unfortunate reputation as one of the most problematic engines in modern automotive history. Common problems associated with these engines include coolant and oil leaks, overheating issues, turbocharger failure, timing chain issues, bad injectors, coils, oil pumps, and cam phasers.

This turbocharged diesel engine powered Ford’s Super Duty trucks from 2003 to 2007, but its reliability issues became legendary among diesel enthusiasts and commercial users alike. The 6.0 PowerStroke’s problems stem from several fundamental design flaws that compound each other under real-world operating conditions.

The engine features an inadequate cooling system that struggles to maintain proper temperatures during heavy-duty applications, leading to head gasket failures and cylinder head warping. The EGR (Exhaust Gas Recirculation) system creates additional heat and introduces contaminants into the intake system, exacerbating cooling problems and causing carbon buildup that reduces performance and increases wear.

Oil cooler failures represent another major weakness in the 6.0 PowerStroke design. The oil cooler is positioned in the valley between cylinder banks, where it experiences extreme temperatures and pressure cycling.

When these coolers fail, they contaminate the cooling system with oil and vice versa, creating cascading failures that can destroy the entire engine. The replacement procedure requires extensive disassembly, making repairs expensive and time-consuming.

Fuel injection system problems plague the 6.0 PowerStroke throughout its service life, with high-pressure oil pumps, injectors, and related components failing prematurely. The engine uses a HEUI (Hydraulically-actuated Electronically-controlled Unit Injector) system that relies on high-pressure oil to operate the fuel injectors.

When components in this system fail, the engine loses power and may not run at all. Repair costs can easily reach thousands of dollars for injection system problems. The turbocharger system adds another layer of potential problems to the 6.0 PowerStroke package.

The variable geometry turbocharger is prone to sticking, carbon buildup, and actuator failures that reduce performance and can cause complete turbo failure. The hard emissions equipment required for these engines creates additional failure points and maintenance requirements that many owners find overwhelming. These cumulative problems have made the 6.0 PowerStroke synonymous with reliability issues in the diesel community.

2. BMW N63

The BMW N63 twin-turbocharged V8 engine represents the dark side of advanced automotive technology, combining impressive performance with a troubling list of reliability issues that have plagued owners since its introduction. With its overly complicated design, it has a lot of potential failure points.

Turbo failures, oil leaks and consumption, coolant leaks, injector, fuel pump, and timing chain failures, as well as carbon buildup, all potentially await an N63 owner. This sophisticated engine features cutting-edge technologies that, unfortunately, translate into expensive maintenance and frequent failures.

The N63’s fundamental problem lies in its overly ambitious design approach, which prioritizes performance and efficiency over long-term reliability. The engine features a hot-vee configuration with turbochargers mounted between the cylinder banks, creating extreme heat conditions that stress components beyond their design limits.

The direct injection system, while providing excellent performance, creates carbon buildup problems that require expensive cleaning procedures and can cause valve damage as time goes on. Oil consumption issues represent one of the most common and frustrating problems with the N63 engine.

Many owners report consumption rates exceeding one quart per 1,000 miles, requiring constant monitoring and frequent oil additions between service intervals. The excessive oil consumption stems from design flaws in the piston ring package and valve stem seals that allow oil to enter the combustion chambers, where it burns and creates deposits throughout the system.

Timing chain problems plague the N63 throughout its production run, with stretched chains, failed tensioners, and worn guides causing timing issues that can result in catastrophic engine damage.

The complicated timing chain system features multiple chains and tensioners that operate in the high-heat environment created by the hot-vee turbocharger arrangement. When these components fail, repair costs can easily exceed the value of older vehicles equipped with this engine.

Cooling system failures add another expensive dimension to N63 ownership, with water pumps, thermostats, and coolant hoses failing prematurely due to the extreme heat conditions. The hard cooling system routing required by the hot-vee design creates multiple potential failure points, and repairs often require extensive disassembly to access failed components. These problems have made the N63 one of the most expensive engines to maintain in the luxury car segment.

3. Chrysler 2.7L V6

The Chrysler 2.7-liter V6 engine earned its notorious reputation through a combination of poor design decisions and inadequate lubrication systems that resulted in premature engine failures across multiple vehicle platforms.

This all-aluminum engine appeared in various Chrysler, Dodge, and Plymouth vehicles during the late 1990s and early 2000s, but its tendency to develop catastrophic problems made it one of the most feared engines among used car buyers and mechanics alike.

The 2.7L V6’s most infamous problem involves oil sludge formation that clogs oil passages and starves critical engine components of lubrication. The engine’s design features narrow oil passages and inadequate oil drain-back provisions that allow oil to remain in hot areas where it cooks and forms thick sludge deposits.

These deposits eventually block oil flow to bearings, camshafts, and other critical components, resulting in complete engine failure, often well before 100,000 miles. Water pump failures represent another systematic problem with the 2.7L V6, as the pump is integrated into the timing chain housing and driven by the timing chain itself.

When the water pump fails, coolant contaminates the engine oil and causes immediate lubrication problems that can destroy the engine within miles. The water pump replacement procedure requires timing chain removal, making repairs expensive and time-consuming even when caught early.

The timing chain system adds another layer of problems to the 2.7L V6 package, with chains stretching prematurely and tensioners failing under normal operating conditions. The aluminum timing chain housing is prone to cracking, which allows coolant to leak into the oil system and causes the same lubrication contamination problems associated with water pump failures. These structural failures often require complete engine replacement rather than repair.

Heat-related problems compound all other issues with the 2.7L V6, as the all-aluminum construction and inadequate cooling system design create conditions that accelerate wear and component failures.

The engine runs hotter than many comparable designs, which speeds oil breakdown, increases thermal stress on gaskets and seals, and reduces the service life of all internal components. These thermal management problems have made the 2.7L V6 synonymous with premature engine replacement in the used car market.

4. Jaguar AJ-V8 Supercharged

The Jaguar AJ-V8 supercharged engine represents the intersection of British luxury engineering and systematic reliability problems that have frustrated owners and mechanics for decades. These engines are prone to several issues, including timing chain failure, oil and coolant leaks, gasket failures, oil consumption, supercharger problems, water pump failure, and several other smaller problems with expensive repair costs.

This sophisticated engine combines impressive performance with a troubling array of problems that make ownership expensive and unpredictable. The AJ-V8’s timing chain system has become legendary for its premature failures, with plastic chain guides disintegrating and causing timing chain slack that can result in catastrophic engine damage.

The hard timing system features multiple chains and guides that operate in high-stress conditions, and when these components fail, repair costs often exceed the value of the vehicle. The plastic construction of critical components represents a fundamental design flaw that affects virtually every example of this engine.

Supercharger problems add another expensive dimension to AJ-V8 ownership, with the Eaton supercharger unit prone to bearing failures, seal leaks, and pulley problems that reduce performance and can cause complete system failure.

The supercharger’s complicated installation makes removal and repair procedures extremely labor-intensive, while replacement parts carry premium prices typical of British luxury car components. These problems often develop without warning and can leave drivers stranded.

The cooling system design in the AJ-V8 suffers from multiple weaknesses that contribute to overheating problems and component failures. The plastic components used throughout the cooling system are prone to cracking and leaking, while the complicated routing required by the supercharger installation creates multiple potential failure points.

Water pump failures are common and expensive to repair due to the extensive disassembly required to access the pump. Electrical system problems plague the AJ-V8 throughout its production run, with sensors, wiring harnesses, and control modules failing regularly.

The sophisticated engine management system requires multiple sensors and actuators to function properly, and when these components fail, the engine may not run at all or may operate in reduced-power limp mode. Diagnosis can be challenging due to the complication of the system, while replacement parts are expensive and sometimes difficult to obtain.

Also Read: 5 Engines That Rarely Fail Smog and 5 That Always Fail Tests

5. Subaru EJ25

The Subaru EJ25 horizontally opposed four-cylinder engine has achieved infamous status among automotive enthusiasts for its systematic head gasket failures that affect the majority of vehicles equipped with this engine.

This boxer engine design powered countless Subaru models throughout the 1990s and 2000s, but its tendency to develop expensive cooling system problems has made it one of the most feared engines in the used car market. The head gasket failures typically occur between 100,000 and 150,000 miles, making them a predictable but expensive maintenance item.

The EJ25’s head gasket problems stem from fundamental design flaws in the gasket material and cylinder head bolt pattern that create uneven clamping forces and inadequate sealing under thermal cycling conditions.

Subaru used composite head gaskets in many applications that proved inadequate for the thermal stresses created by the boxer engine design. The horizontal cylinder orientation creates unique challenges for head gasket sealing, as gravity affects coolant flow patterns differently than in conventional vertical engine designs.

Oil consumption issues frequently accompany head gasket problems in the EJ25, as the failing gaskets allow oil to leak externally and enter the cooling system. This oil contamination creates additional problems throughout the cooling system, while external oil leaks can create fire hazards and environmental concerns.

The oil consumption problems often develop gradually, making them difficult to detect until serious damage has occurred. The timing belt system adds another maintenance burden to EJ25 ownership, as these engines use interference designs that require precise timing to prevent valve damage.

When timing belts fail, the pistons can contact the valves and cause expensive internal damage that often requires complete engine rebuilding. The timing belt replacement interval is relatively short, and many owners defer this maintenance due to the high labor costs involved.

Cooling system complication in the EJ25 design creates multiple potential failure points beyond the head gasket issues. The radiator, water pump, thermostat, and numerous hoses are all prone to failures that can cause overheating and exacerbate head gasket problems.

The boxer engine design makes cooling system service more difficult than conventional engines, increasing labor costs for routine maintenance procedures. These cumulative problems have made EJ25 ownership expensive and unpredictable for many Subaru enthusiasts.