The Jeep Wrangler Sahara represents the perfect balance between rugged capability and everyday comfort, making it one of the most sought-after variants in the Wrangler lineup.

With its distinctive styling, premium interior features, and legendary off-road prowess, the Sahara has captured the hearts of adventure enthusiasts and daily drivers alike.

However, beneath its robust exterior lies a complex machine that requires proper care and attention to reach its full potential lifespan. Many Sahara owners, caught up in the excitement of their new vehicle’s capabilities, inadvertently make critical mistakes that can significantly shorten their Jeep’s life.

These errors range from neglecting essential maintenance procedures to pushing the vehicle beyond its designed limits without proper preparation.

What makes these mistakes particularly devastating is that they often appear harmless at first, creating a false sense of security until major damage has already occurred.

The financial impact of these mistakes can be staggering, with some owners facing repair bills that exceed the vehicle’s remaining value. More importantly, these issues can compromise safety, leaving drivers stranded in remote locations or facing dangerous mechanical failures during critical moments.

Understanding and avoiding these common pitfalls is essential for any Sahara owner who wants to enjoy their vehicle for years to come while maintaining its reliability and resale value.

1. Neglecting Regular Oil Changes and Using Wrong Oil Types

One of the most catastrophic mistakes Jeep Wrangler Sahara owners make is treating oil changes as optional or using inappropriate oil types for their specific engine configuration.

The Sahara’s engine, whether it’s the 3.6L Pentastar V6 or the available turbocharged four-cylinder, operates under demanding conditions that require premium lubrication to function properly.

These engines generate significant heat and stress, particularly during off-road adventures or heavy towing situations, making quality oil absolutely critical for longevity.

The consequences of using conventional oil when synthetic is recommended, or worse, using the wrong viscosity grade, can be immediate and severe.

Modern Jeep engines are designed with tighter tolerances and more sophisticated components than their predecessors, requiring oil that can maintain its protective properties under extreme temperatures and pressures.

When owners skimp on oil quality or extend change intervals beyond manufacturer recommendations, they’re essentially gambling with their engine’s life expectancy.

Extended oil change intervals represent another deadly mistake that many Sahara owners make, often influenced by quick-lube shops or outdated information.

While some vehicles can safely go 7,500 to 10,000 miles between changes, the Wrangler’s demanding operating conditions typically require more frequent service.

Dusty off-road environments, frequent short trips that don’t allow the engine to reach full operating temperature, and stop-and-go traffic all contribute to oil degradation that occurs much faster than in normal driving conditions.

The symptoms of oil-related damage often appear gradually, starting with increased engine noise, reduced fuel economy, and rough idle conditions. By the time these warning signs become obvious, significant internal damage may have already occurred.

Worn camshafts, damaged valve trains, and scored cylinder walls are common results of inadequate lubrication, often requiring complete engine rebuilds or replacements that can cost more than the vehicle is worth. Prevention through proper oil maintenance is infinitely more cost-effective than dealing with the devastating consequences of neglect.

2. Ignoring Cooling System Maintenance in Extreme Conditions

The cooling system in a Jeep Wrangler Sahara faces unique challenges that many owners underestimate, leading to premature engine failure and costly repairs.

Unlike typical passenger vehicles that spend most of their time on smooth highways with consistent airflow, the Sahara often operates in demanding conditions that put extreme stress on cooling components.

Rock crawling at low speeds, sitting in traffic with oversized tires and lifted suspensions, and going through the sandy or muddy terrain all reduce cooling efficiency while simultaneously increasing heat generation.

Many Sahara owners make the critical mistake of assuming that their cooling system will automatically handle these extreme conditions without additional attention or modifications.

The factory cooling system is designed for normal driving conditions with adequate safety margins, but it can quickly become overwhelmed when faced with the demands of serious off-road use.

This is particularly problematic for owners who install aftermarket accessories like winches, auxiliary lighting, or larger tires without considering the additional heat load these modifications create.

Neglecting coolant maintenance represents another fatal error that can destroy an engine in a single overheating event. Old coolant loses its ability to prevent corrosion, leading to internal damage that restricts coolant flow and reduces heat transfer efficiency.

Radiator cores become plugged with debris and corrosion, water pumps fail due to contaminated coolant, and thermostats stick in closed positions, all contributing to overheating scenarios that can warp cylinder heads or crack engine blocks.

The warning signs of cooling system problems are often ignored until catastrophic failure occurs. Rising temperature gauges, coolant loss, white exhaust smoke, and unusual engine noises all indicate serious cooling system issues that require immediate attention.

Unfortunately, many Sahara owners continue driving when these symptoms appear, often in remote locations where professional help isn’t readily available.

This leads to complete engine failure that could have been prevented with proper cooling system maintenance and attention to warning signs. Regular coolant flushes, radiator cleaning, and cooling system inspections are essential preventive measures that can save thousands of dollars in repair costs.

3. Improper Tire and Wheel Modifications Without Supporting Upgrades

The allure of larger, more aggressive tires is one of the first modifications most Jeep Wrangler Sahara owners consider, but this seemingly simple upgrade can trigger a cascade of mechanical problems when not properly executed.

Many owners make the mistake of installing significantly larger tires without addressing the supporting systems that must accommodate the increased size, weight, and performance demands.

This oversight leads to premature wear of critical drivetrain components and can result in expensive failures that far exceed the cost of doing the modification correctly from the beginning.

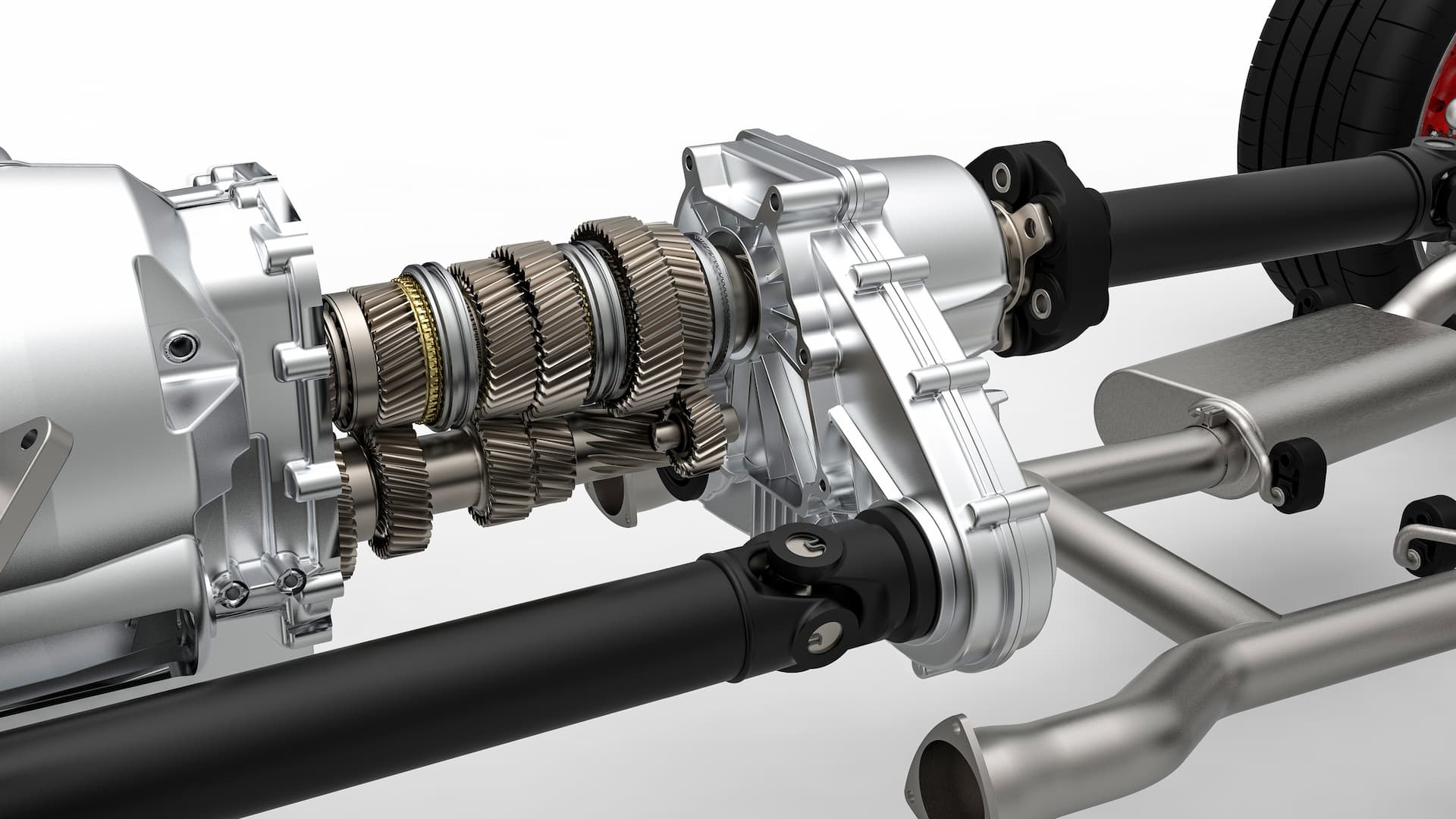

Oversized tires dramatically increase the load on the axles, transmission, and transfer case, particularly during off-road situations where traction demands are high.

The factory gearing ratios that worked perfectly with stock tires become inadequate when larger rubber is installed, forcing the engine to work harder and operate outside its optimal power band.

This results in increased fuel consumption, reduced performance, and accelerated wear on clutches, synchronizers, and differential components that weren’t designed to handle the additional stress.

The suspension system also suffers when larger tires are installed without proper supporting modifications. Increased unsprung weight affects handling, braking performance, and component longevity, while altered geometry can cause premature wear of ball joints, tie rod ends, and steering components.

Many owners compound these problems by installing wheel spacers or wheels with incorrect offset, further stressing suspension components and potentially creating dangerous handling characteristics that can lead to accidents.

Braking system inadequacy represents another serious consequence of improper tire and wheel modifications. Larger, heavier tires require more force to stop, and the increased rotational mass makes it more difficult for the factory brake system to provide adequate stopping power.

This is particularly dangerous during off-road descents or emergency braking situations where brake fade can occur rapidly. Heat buildup in undersized brake components can lead to brake failure, rotor warping, and premature wear of pads and other friction materials.

Smart Sahara owners invest in comprehensive modification packages that address gearing, suspension, and braking upgrades alongside tire changes, ensuring that all systems work together harmoniously while maintaining safety and reliability.

4. Skipping Differential and Transfer Case Service

The differential and transfer case represent the heart of the Jeep Wrangler Sahara’s legendary four-wheel-drive capability, yet these critical components are among the most neglected by owners who don’t understand their importance or maintenance requirements.

These complex mechanical systems operate under extreme conditions, especially during off-road adventures where they must handle varying traction conditions, temperature extremes, and heavy loads that would overwhelm lesser vehicles.

Failure to properly maintain these components often results in catastrophic failures that can leave owners stranded and facing repair bills that rival the cost of a new vehicle.

Many Sahara owners make the mistake of assuming that differential and transfer case fluids never need changing, or they follow maintenance intervals designed for normal highway driving rather than the severe conditions their vehicle actually experiences.

Off-road driving, frequent four-wheel-drive engagement, and towing all constitute severe service conditions that require more frequent fluid changes and inspections. The specialized lubricants used in these systems break down over time, losing their ability to protect gears and bearings from wear and corrosion.

Water contamination represents a particularly serious threat to differential and transfer case longevity, especially for owners who enjoy water crossings or drive in wet conditions.

Many Sahara owners don’t realize that these components can breathe moisture-laden air through their vent systems, leading to condensation inside the housings.

This moisture mixes with the lubricants, creating a corrosive environment that rapidly destroys internal components. Regular fluid changes and proper breather maintenance are essential for preventing this type of damage, yet many owners never check these items until failure occurs.

The symptoms of differential and transfer case problems often develop gradually, making them easy to ignore until major damage occurs. Unusual noises during turns, vibrations during four-wheel-drive operation, and difficulty shifting between drive modes all indicate developing problems that require immediate attention.

Unfortunately, many owners continue driving when these symptoms appear, often attributing them to normal Jeep characteristics rather than recognizing them as warning signs of impending failure.

The cost of rebuilding or replacing these components can easily exceed ten thousand dollars, making preventive maintenance an incredibly wise investment that pays for itself many times over.

Also Read: 5 Heated Seat Systems That Last Beyond 100K Miles vs. 5 That Fail Mid-Winter

5. Overloading and Improper Weight Distribution

The Jeep Wrangler Sahara’s rugged appearance and capable suspension system often lead owners to believe they can load their vehicle with unlimited amounts of gear without consequences.

This misconception results in chronic overloading that accelerates wear on virtually every vehicle system, from the engine and transmission to the suspension and braking components.

Understanding and respecting payload limits isn’t just about legal compliance; it’s about preserving the vehicle’s longevity and maintaining safe operation under all conditions.

Exceeding the Gross Vehicle Weight Rating (GVWR) puts excessive stress on the frame, suspension components, and drivetrain, leading to premature failures that can be both dangerous and expensive.

Many Sahara owners make the mistake of calculating payload based only on obvious additions like passengers and cargo, forgetting to account for aftermarket accessories, full fuel tanks, and the cumulative weight of multiple modifications.

A fully loaded Sahara with accessories, fuel, passengers, and gear can easily exceed its designed limits, especially when configured for extended off-road adventures or camping trips.

Improper weight distribution creates additional problems beyond simple overloading, affecting the vehicle’s handling characteristics and component wear patterns.

Loading too much weight in the rear cargo area shifts the center of gravity backward, reducing front wheel traction and affecting steering response.

This is particularly dangerous during off-road situations where precise vehicle control is essential for safety. Conversely, excessive front loading from winches, bumpers, and other accessories can overload the front axle and suspension components while reducing rear traction.

The effects of chronic overloading become apparent through various symptoms that many owners misinterpret or ignore. Sagging suspension, premature tire wear, reduced fuel economy, and overheating during climbs all indicate that the vehicle is being asked to carry more than it was designed to handle.

Transmission and differential overheating become common problems when heavy loads are combined with challenging terrain, leading to expensive failures that could have been prevented through proper load management.

Smart Sahara owners invest in accurate scales to verify their vehicle’s actual weight and distribute loads properly to maintain safe operation and component longevity.

6. Neglecting Air Filter and Intake System Maintenance

The air intake system of a Jeep Wrangler Sahara faces unique challenges that many owners underestimate, particularly those who frequently drive in dusty or dirty conditions where airborne contaminants can quickly overwhelm filtration systems.

The engine’s appetite for clean air is enormous, with modern power plants requiring thousands of gallons of filtered air for every gallon of fuel consumed. When this air isn’t properly filtered, the results can be catastrophic, leading to premature engine wear that dramatically shortens the vehicle’s lifespan.

Many Sahara owners make the critical mistake of treating air filter maintenance as optional or following replacement intervals designed for normal highway driving rather than the severe conditions their vehicle actually experiences.

Off-road driving, construction site work, and even driving on gravel roads expose the intake system to dramatically higher levels of dust and debris than typical urban or highway driving.

This contamination can overwhelm even high-quality air filters in a fraction of the time normally expected, yet many owners continue driving with severely restricted or damaged filters.

The installation of aftermarket air intake systems without proper understanding or maintenance represents another common mistake that can destroy engines quickly.

While performance air filters and cold air intake systems can provide benefits when properly maintained, they often require more frequent cleaning and replacement than factory systems.

Many owners install these modifications for their promised performance gains but fail to maintain them properly, resulting in worse filtration than the factory system provided.

Contaminated air entering the engine causes immediate and cumulative damage that becomes more severe over time. Sand, dirt, and other abrasive particles act like grinding compound inside the engine, wearing away cylinder walls, piston rings, and valve guides with devastating efficiency.

The symptoms often develop gradually, starting with reduced power and fuel economy before progressing to excessive oil consumption and engine knock.

By the time these problems become obvious, significant internal damage has usually occurred, often requiring complete engine rebuilds or replacements.

Regular air filter inspection and replacement, especially after dusty driving conditions, is one of the least expensive forms of insurance against catastrophic engine failure.

7. Inadequate Preparation for Extreme Off-Road Conditions

The final and perhaps most dangerous mistake that kills Jeep Wrangler Sahara vehicles prematurely is inadequate preparation for extreme off-road conditions, leading to mechanical failures that could have been prevented with proper planning and equipment.

Many owners are drawn to challenging trails by their vehicle’s impressive capabilities, but they fail to understand that even the most capable Jeep requires proper preparation and support systems to handle truly demanding terrain safely and reliably.

Mechanical preparation encompasses far more than simply checking fluid levels and tire pressure before heading out on an adventure. Extreme off-road conditions place unprecedented demands on every vehicle system, from cooling and lubrication to electrical and fuel delivery.

Without proper upgrades and preparations, even minor trail obstacles can result in catastrophic failures that leave owners stranded in remote locations where recovery and repair costs can be enormous.

Recovery equipment and knowledge represent critical safety factors that many Sahara owners overlook until they find themselves in desperate situations. Proper recovery gear, including winches, straps, shackles, and communication devices, can mean the difference between a minor inconvenience and a life-threatening situation.

However, having the equipment without understanding how to use it safely can be equally dangerous, as improper recovery techniques can cause serious injuries or additional vehicle damage.

The psychological aspect of extreme off-road driving is equally important but often ignored by enthusiastic owners who overestimate their abilities or underestimate the challenges they’ll face.

Poor decision-making under stress, inadequate route planning, and failure to inform others of travel plans can turn mechanical problems into survival situations.

The most prepared Sahara owners approach extreme off-roading with humility, proper training, and comprehensive support systems that ensure they can handle whatever challenges they encounter while preserving their vehicle’s longevity and their own safety.

Understanding these seven critical mistakes and taking proactive steps to avoid them can dramatically extend your Jeep Wrangler Sahara’s lifespan while ensuring many years of reliable adventure.

The cost of prevention is always far less than the cost of repair, and the peace of mind that comes with proper maintenance and preparation is invaluable for any serious Jeep enthusiast.

Also Read: 5 Turbo V6s With No Issues vs. 5 Known for Valve Problems