The Chevrolet Nova, produced from 1962 to 1979 and again from 1985 to 1988, remains one of America’s most beloved compact cars. Whether you own a muscle car-era SS model from the late 1960s or a more practical daily driver from the 1970s, the Nova’s simple engineering and robust construction make it an excellent candidate for long-term ownership.

However, like any classic vehicle, certain components require attention to ensure reliable operation and longevity. The Nova’s appeal lies in its straightforward design philosophy.

Built on General Motors’ X-body platform, these cars feature conventional rear-wheel-drive layouts with easily accessible components. The engine bay provides ample working room, and most mechanical systems follow tried-and-true designs that any competent mechanic can service.

This accessibility makes the Nova particularly attractive to enthusiasts who prefer to maintain their own vehicles. Despite this mechanical simplicity, age-related issues inevitably arise.

Rubber components deteriorate, metal parts corrode, and wear items reach the end of their service life. The key to maintaining a road-ready Nova lies in addressing these predictable problem areas before they leave you stranded. Preventive maintenance and strategic upgrades can transform an aging Nova into a reliable daily driver or weekend cruiser.

The following ten fixes represent the most critical maintenance areas for Nova owners. These aren’t exotic modifications requiring specialized tools or extensive fabrication work.

Instead, they focus on practical improvements that address common failure points while preserving the car’s original character. From engine bay essentials to suspension components, each fix contributes to reliability and driving enjoyment.

1. Carburetor Rebuild and Tuning

The carburetor serves as the heart of your Nova’s fuel delivery system, and its condition directly impacts engine performance, fuel economy, and reliability.

Most Novas left the factory with either Rochester or Carter carburetors, depending on the engine option. Over decades of use, internal components wear out, gaskets harden, and calibration drifts from factory specifications.

A comprehensive carburetor rebuild involves complete disassembly, cleaning, and replacement of all wear items. Start by removing the carburetor and carefully documenting its configuration with photographs before disassembly.

Internal passages accumulate varnish and debris that restrict fuel flow and affect mixture quality. Professional carburetor cleaning services use ultrasonic baths and specialized solvents to remove deposits that ordinary cleaning cannot address.

Replace all gaskets, O-rings, needle valves, accelerator pump diaphragms, and other soft components regardless of their apparent condition. These parts deteriorate with age, even if they appear serviceable.

Pay particular attention to the float level setting, as an incorrect float position affects fuel delivery throughout the operating range. The float should be adjusted to the manufacturer’s specifications using a proper gauge.

Proper tuning requires attention to both idle and main metering circuits. Set the idle mixture screws for the highest idle speed, then adjust the idle speed screw to achieve the specified RPM.

Main jet selection depends on your engine’s modifications and operating altitude. Stock applications typically perform best with original jet sizes, but modified engines may require different calibration.

Consider upgrading to an electric fuel pump if your Nova still uses a mechanical pump. Electric pumps provide consistent fuel pressure and eliminate the common failure point of mechanical pump diaphragms. Install a fuel pressure regulator to maintain proper pressure, typically 4-6 PSI for most carburetor applications.

Modern ethanol-blended fuels can damage older carburetor components, particularly rubber parts. Use ethanol-compatible rebuild kits and consider adding a fuel stabilizer to prevent phase separation and corrosion. Regular operation helps prevent fuel degradation, but cars stored for extended periods require fuel system preparation to avoid carburetor damage.

2. Cooling System Overhaul

The cooling system protects your Nova’s engine from overheating damage while ensuring optimal operating temperature for performance and emissions.

Age-related deterioration affects every cooling system component, from the radiator core to rubber hoses and gaskets. A comprehensive cooling system overhaul addresses these wear items systematically.

Begin with radiator inspection and service. Remove the radiator and have it professionally cleaned and pressure tested. Many Nova radiators suffer from internal corrosion and external damage that restricts cooling capacity.

Re-coring or replacement may be necessary if cleaning cannot restore adequate flow. Consider upgrading to a higher-capacity radiator if your Nova sees hard use or operates in hot climates.

Replace all cooling system hoses, including the often-overlooked heater hoses and smaller bypass hoses. Original rubber compounds become brittle and prone to sudden failure.

Modern silicone hoses offer superior heat resistance and longevity, though they cost more than conventional rubber replacements. Ensure proper hose routing and support to prevent stress-related failures.

Water pump replacement should be part of any comprehensive cooling system service. Original pumps develop internal wear that reduces flow capacity and can fail catastrophically.

Choose a high-quality replacement pump with a proper impeller design for your application. Some aftermarket pumps offer improved flow characteristics over original equipment.

Thermostat replacement seems routine, but it significantly impacts cooling system function. Use a thermostat rated at 180-195 degrees Fahrenheit for most applications.

Ensure the thermostat opens fully and consider upgrading to a high-flow design. Proper installation requires using a gasket or sealant as specified and ensuring correct orientation.

Address cooling fan operation for cars equipped with electric fans or consider adding electric fans to improve cooling efficiency. Electric fans provide better airflow control and reduce parasitic engine load compared to mechanical fans. Install appropriate temperature switches and relays for reliable operation.

Flush the cooling system thoroughly and refill with the proper coolant mixture. Use distilled water and high-quality antifreeze in a 50/50 mixture for most climates. Add a cooling system conditioner to help prevent corrosion and scale formation. Proper bleeding procedures ensure no air pockets remain in the system.

3. Brake System Restoration

Brake system safety makes this repair category absolutely critical for road-ready operation. Nova brake systems evolved throughout production, with early cars using drum brakes all around and later models adopting front disc brakes.

Regardless of configuration, age affects every brake component and requires systematic attention for safe operation. Master cylinder replacement or rebuilding represents the starting point for brake system restoration.

Internal seals deteriorate over time, causing brake pedal fade and potential complete failure. Modern brake fluids are more corrosive to rubber components than original formulations, accelerating seal degradation.

Choose a master cylinder designed for your brake system configuration and ensure proper bore size for adequate pedal feel. Brake line replacement addresses a common failure point in older vehicles. Steel brake lines corrode from the inside out, particularly in areas exposed to road salt.

Replace all hard lines with proper brake line tubing, using the correct fittings and flare types. Consider upgrading to stainless steel braided lines for improved pedal feel and longevity, though they require more careful routing to prevent chafing.

Front brake service depends on whether your Nova has drum or disc brakes. Drum brake systems require wheel cylinder replacement or rebuilding, brake shoe replacement, and hardware renewal.

Disc brake systems need caliper service, rotor resurfacing or replacement, and pad renewal. Both systems benefit from upgraded friction materials that provide better stopping power and fade resistance.

Rear brake service typically involves drum brake components on most Novas. Replace wheel cylinders, brake shoes, and all hardware, including springs and adjusters.

Properly adjusted rear brakes are essential for balanced braking and parking brake function. Clean and lubricate backing plates to prevent binding and ensure smooth operation.

Power brake booster service applies to cars so equipped. Vacuum boosters develop internal leaks that affect the assist function and can cause hard pedal operation.

Rebuilding or replacement requires attention to vacuum line routing and check valve function. Ensure adequate vacuum supply from the engine for proper operation.

Brake fluid selection and system bleeding complete the restoration process. Use DOT 3 or DOT 4 brake fluid as specified and ensure complete system bleeding to remove air and old fluid. Proper bleeding sequence and technique prevent air entrapment that can cause a spongy pedal feel or brake failure.

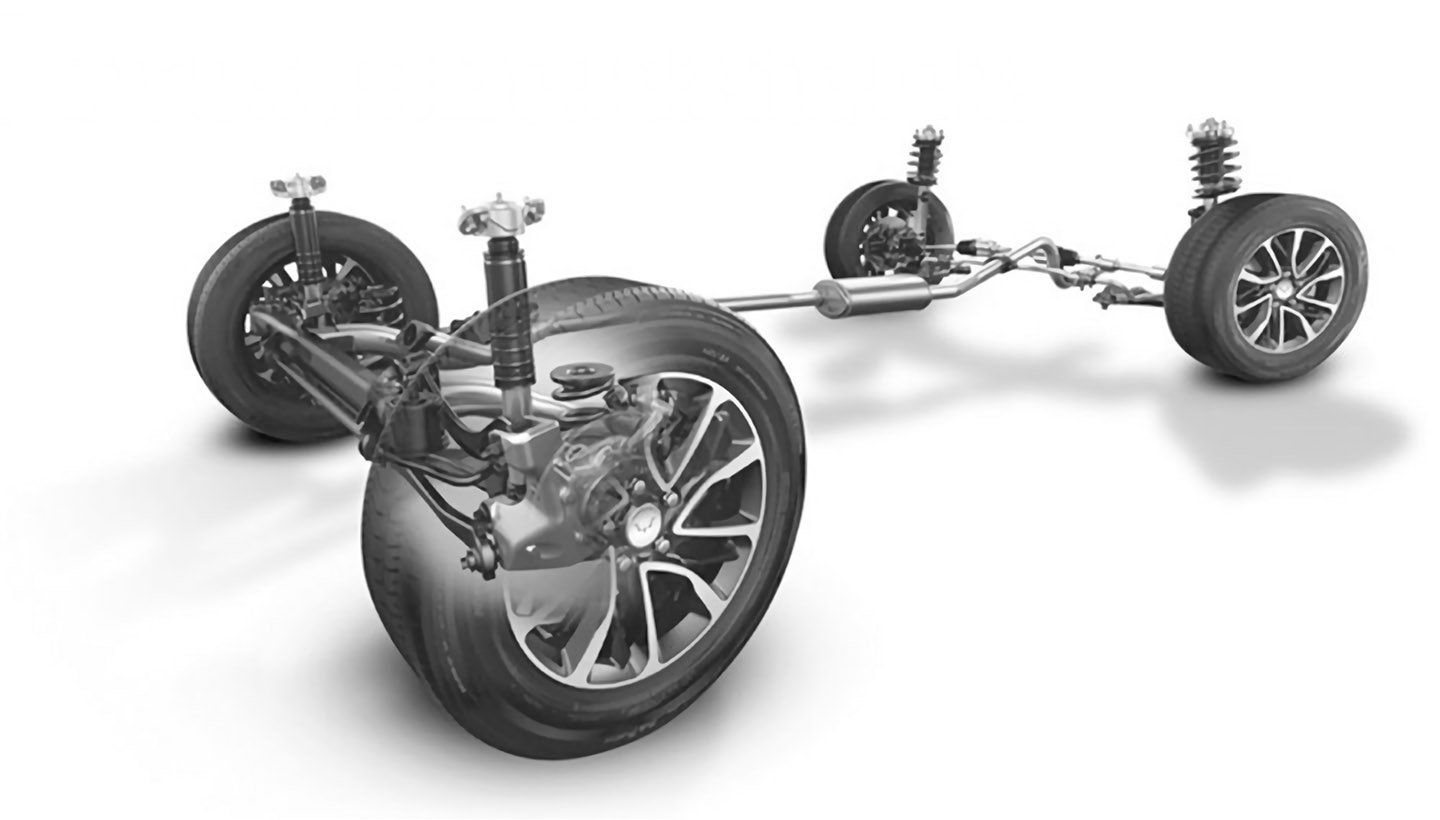

4. Suspension Component Replacement

Suspension components directly affect ride quality, handling, and tire wear patterns. Nova suspension systems use conventional designs with replaceable wear items that require periodic attention.

Front suspension uses upper and lower control arms with ball joints, while rear suspension employs leaf springs with shock absorbers. Front suspension service begins with ball joint inspection and replacement.

Both upper and lower ball joints wear over time, developing play that affects steering precision and tire wear. Use proper ball joint separators during removal to prevent damage to control arms.

Quality replacement ball joints last longer and provide better performance than economy alternatives. Control arm bushing replacement addresses another common wear point.

Rubber bushings deteriorate and allow excessive control arm movement that affects alignment and handling. Polyurethane bushings offer improved durability and performance but may transmit more road noise than rubber alternatives. Proper installation requires attention to bushing orientation and torque specifications.

Shock absorber replacement significantly impacts ride quality and handling. Original shock absorbers lose their damping ability over time, causing poor ride control and handling degradation.

Choose shock absorbers appropriate for your driving style and vehicle use. Performance-oriented drivers may prefer gas-charged shocks with firmer valving, while comfort-oriented owners might choose conventional hydraulic shocks.

Leaf spring service applies to rear suspension maintenance. Springs sag over time and may develop broken leaves that affect ride height and handling.

Re-arching services can restore original spring rates and ride height. Replace spring bushings and shackles during spring service, as these wear items affect spring operation and alignment.

Steering linkage components require regular inspection and replacement. Tie rod ends, idler arms, and center links develop wear that creates steering looseness and tire wear.

Replace worn components as sets to maintain proper geometry and steering response. Lubricate all grease fittings regularly to extend component life. Wheel alignment completes suspension service and ensures proper tire wear patterns.

Alignment specifications may differ from original settings if suspension modifications have been made. Professional alignment services can accommodate modified suspensions and recommend appropriate settings for your driving requirements.

Also Read: 5 Turbo V6s With No Issues vs. 5 Known for Valve Problems

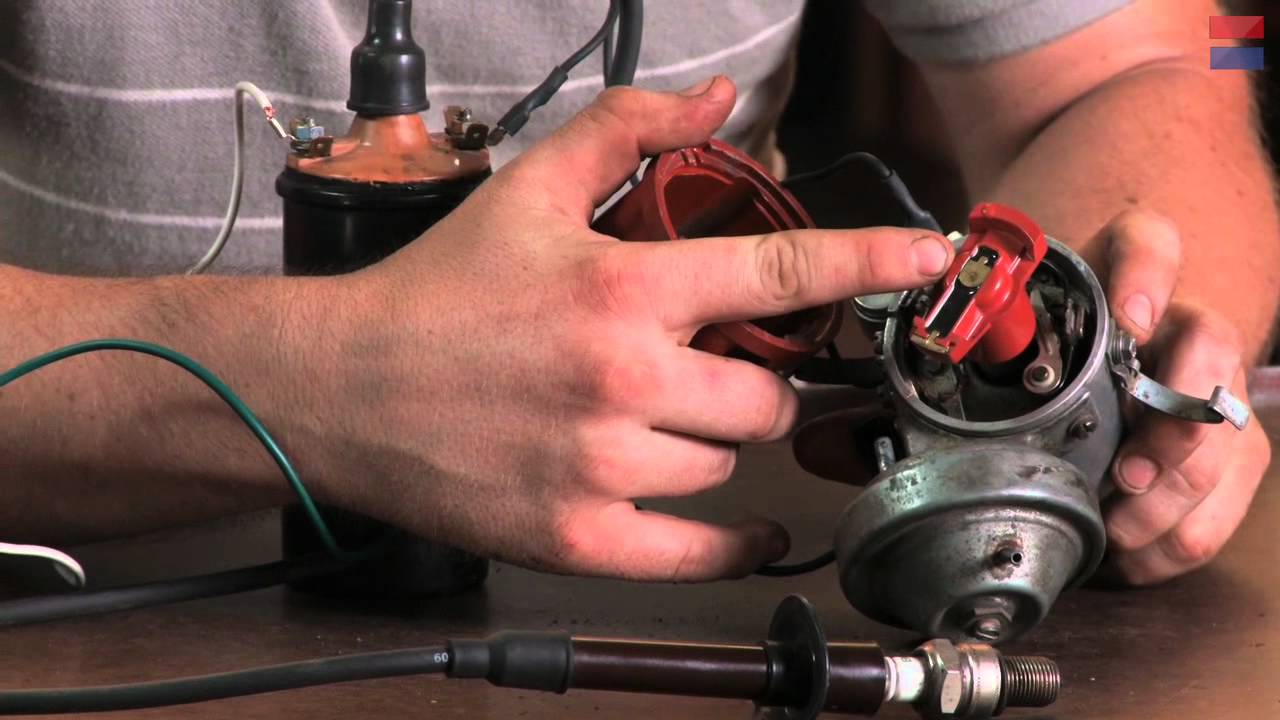

5. Ignition System Upgrade

The ignition system provides the spark that ignites the air-fuel mixture in each cylinder. Nova ignition systems evolved from mechanical points-based systems to electronic ignition, but both benefit from modern upgrades that improve reliability and performance.

A comprehensive ignition system upgrade addresses every component from the distributor to the spark plugs. Distributor service or replacement forms the foundation of ignition system improvement.

Points-based distributors require regular adjustment and component replacement, while electronic distributors offer improved reliability and timing accuracy.

Converting from points to electronic ignition eliminates routine points adjustment and provides more consistent spark timing throughout the RPM range.

Ignition coil upgrade provides stronger spark energy and improved high-RPM performance. High-performance coils produce higher secondary voltage and maintain spark strength at raised engine speeds.

Choose a coil compatible with your ignition system and ensure proper primary resistance for reliable operation. Some aftermarket coils require ballast resistor modifications.

Spark plug wire replacement addresses a common source of ignition problems. Original plug wires deteriorate internally and can cause misfiring, rough idle, and performance loss.

High-quality replacement wires use better insulation and conductors that resist moisture and heat damage. Proper routing and support prevent premature wire failure from engine heat and vibration.

Spark plug selection affects engine performance and longevity. Choose plugs with the correct heat range for your engine and driving conditions. Colder plugs resist pre-ignition in high-performance applications, while hotter plugs improve idle quality in mild engines.

Gap plugs according to ignition system requirements, typically wider gaps for electronic ignition systems. Timing adjustment optimizes engine performance and prevents damage from incorrect timing.

Use a timing light to set initial timing according to specifications, then verify total advance with a timing light that reads advance. Mechanical and vacuum advance systems require individual adjustment for optimal performance across the operating range. Consider upgrading to a complete aftermarket ignition system for maximum performance and reliability.

These systems often include improved distributors, coils, and control modules designed to work together. While more expensive than component upgrades, complete systems provide optimized performance and simplified installation.

6. Transmission and Driveline Service

Transmission and driveline components transfer engine power to the wheels and require regular service to maintain smooth operation and prevent costly failures.

Nova transmissions include three-speed and four-speed manual transmissions, plus various automatic transmission options. Each requires specific service procedures and fluid types.

Manual transmission service involves fluid changes, clutch adjustment, and linkage maintenance. Transmission fluid breaks down over time and should be changed regularly using the specified gear oil grade.

Clutch hydraulic systems on later Novas require brake fluid changes and system bleeding. Mechanical clutch linkages need periodic lubrication and adjustment for proper engagement.

Automatic transmission service requires more frequent attention due to complex hydraulic controls and heat generation. Change transmission fluid and filter according to manufacturer recommendations, typically every 30,000-50,000 miles.

Use only the specified automatic transmission fluid type, as different fluids have incompatible additive packages. Service includes pan removal, filter replacement, and adjustment of bands and linkages.

Driveshaft service addresses universal joints and center support bearings where applicable. Universal joints develop wear that causes vibration and can fail catastrophically.

Replace U-joints in pairs and ensure proper phasing during installation. Driveshaft balance is critical for smooth operation, so avoid disturbing balance weights during service.

Rear axle service includes differential fluid changes and axle bearing inspection. Differential fluid should be changed periodically, especially if the car sees hard use or towing duty.

Limited-slip differentials require special fluid additives for proper operation. Axle bearings may require replacement if they develop noise or play.

Transmission cooling system maintenance applies to automatic transmissions, which generate significant heat during operation. Ensure transmission cooler lines are in good condition and consider adding an auxiliary transmission cooler for severe-duty applications.

Proper cooling extends transmission life significantly and prevents costly overheating damage. Regular inspection of transmission and driveline mounts prevents excessive vibration and component damage.

Worn mounts allow excessive movement that can damage other components and create objectionable noise and vibration. Replace worn mounts with quality replacements designed for your specific application.

7. Electrical System Modernization

Nova electrical systems reflect 1960s and 1970s technology that, while functional, can benefit from selective modernization for improved reliability and performance.

Age affects wiring insulation, connections, and components throughout the electrical system. A systematic approach to electrical system improvement enhances reliability without compromising originality.

Battery and charging system service provides the foundation for electrical system reliability. Modern batteries offer improved performance and longer life than original equipment.

Choose a battery with adequate cold-cranking amperage for your climate and engine requirements. Clean and protect battery terminals with dielectric grease to prevent corrosion.

Alternator upgrade or rebuilding ensures adequate charging capacity for modern electrical loads. Original generators or early alternators may lack sufficient output for additional accessories or modern ignition systems.

High-output alternators provide improved charging at idle speeds and support additional electrical accessories. Ensure proper belt tension and pulley alignment during installation.

Wiring harness inspection identifies potential failure points before they cause problems. Look for cracked or brittle insulation, corroded connections, and improper modifications.

Replace damaged sections with proper gauge wire and quality connections. Consider upgrading to modern wire with better insulation materials for improved longevity.

Lighting system improvements enhance both safety and appearance. Sealed beam headlights can be upgraded to modern halogen or LED units that provide better illumination and lower power consumption.

Ensure all exterior lights function properly and consider upgrading to LED bulbs for improved reliability and reduced electrical load. Fuse box and relay upgrades provide better circuit protection and switching capacity.

Original fuse boxes may have corroded connections or inadequate circuit protection for modern electrical loads. Aftermarket fuse panels offer improved connections and additional circuits for accessories. Add relays for high-current accessories to reduce switch loading and improve reliability.

Ground system improvement addresses a common source of electrical problems in older vehicles. Add additional ground straps between the engine, transmission, and body to ensure proper grounding for all electrical components. Clean and tighten all ground connections regularly to maintain low resistance paths.

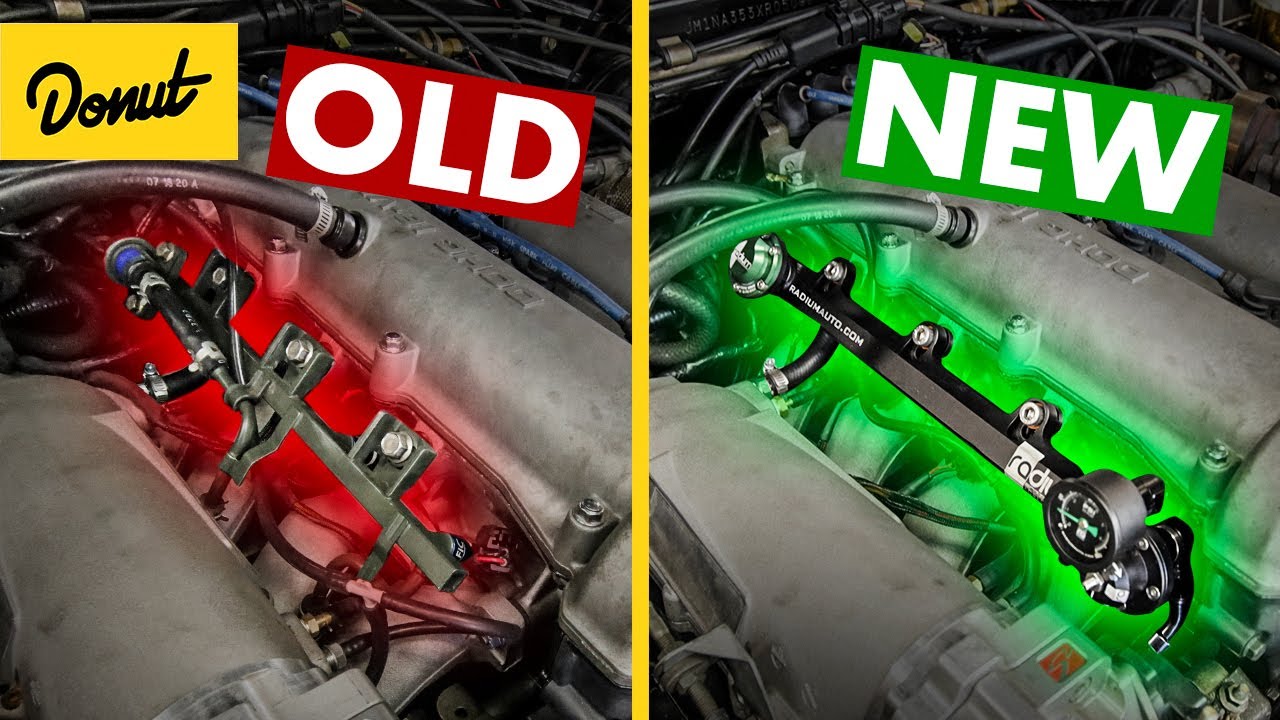

8. Fuel System Upgrade

The fuel system delivers gasoline from the tank to the carburetor and requires attention to ensure reliable fuel delivery and prevent contamination.

Nova fuel systems use relatively simple designs, but age affects every component from the tank to the carburetor inlet. Modern ethanol-blended fuels present additional challenges for older fuel system components.

Fuel tank service addresses the largest component in the fuel system and often the most problematic. Remove and inspect the tank for rust, debris, and proper vent operation.

Internal rust treatment or tank replacement may be necessary for severely corroded tanks. Consider upgrading to a stainless steel tank for ultimate corrosion resistance, though cost is significantly higher than restoration.

Fuel pump replacement or rebuilding ensures adequate fuel pressure and volume. Mechanical fuel pumps develop diaphragm problems that cause erratic fuel delivery and potential vapor lock.

Electric fuel pump conversion provides more consistent fuel pressure and eliminates mechanical pump problems. Install a fuel pressure regulator with electric pump conversions to maintain proper carburetor inlet pressure.

Fuel line replacement addresses another age-related concern. Steel fuel lines corrode internally and externally, potentially causing fuel leaks or flow restrictions. Replace all hard lines with proper fuel line tubing and fittings.

Use a fuel injection hose for flexible sections, as it resists ethanol better than conventional fuel hose. Fuel filter upgrade provides better protection against contamination and water separation.

Install a high-quality fuel filter with adequate flow capacity for your engine requirements. Some filters include a water separation capability that helps protect against fuel system corrosion. Replace fuel filters regularly to maintain proper fuel flow.

The vapor return system helps prevent vapor lock in hot weather operation. Many Novas lack adequate vapor return systems, causing hot weather driveability problems.

Add a vapor return line from the fuel pump or carburetor back to the tank to prevent vapor accumulation in the fuel system. Fuel system cleaning removes deposits and contamination that affect performance and reliability.

Professional fuel system cleaning services can remove varnish and deposits that accumulate over years of operation. Regular use of fuel system cleaners helps prevent deposit formation and maintains optimal fuel system operation.

9. Engine Mount and Drivetrain Mount Renewal

Engine and transmission mounts absorb vibration and secure the drivetrain in the proper position relative to the chassis. These rubber-and-metal assemblies deteriorate over time, allowing excessive movement that creates noise, vibration, and potential component damage.

Mount renewal significantly improves driving comfort and prevents related problems. Engine mount inspection reveals wear patterns and damage that may not be immediately obvious.

Look for cracked rubber, separation between rubber and metal components, and evidence of fluid contamination that accelerates rubber deterioration. Engine mounts typically fail gradually, so symptoms develop slowly and may go unnoticed until replacement reveals the improvement.

Front engine mount replacement requires careful attention to engine support during the procedure. Use proper engine support equipment to prevent damage to oil pans, transmission cases, or other components.

Choose quality replacement mounts designed for your specific engine and transmission combination. Some aftermarket mounts offer improved durability over original equipment.

Proper installation procedures ensure maximum mount life and performance. Torque all mounting bolts to specification and ensure proper alignment between the engine and transmission. Avoid over-tightening, which can damage mount bushings or create stress concentrations that cause premature failure.

10. Body and Frame Integrity Maintenance

Structural integrity forms the foundation for all other systems and directly affects safety, handling, and longevity. Nova’s unibody construction integrates the frame and body into a single structure that can develop problems in specific areas.

Regular inspection and maintenance prevent minor issues from becoming major structural concerns. Rust prevention and treatment address the primary threat to Nova’s structural integrity.

Inspect common rust areas, including rocker panels, rear quarter panels, and trunk floors. Surface rust can be treated with conversion products and protective coatings, while structural rust requires metal replacement or professional repair.

Regular washing and waxing help prevent rust formation. Frame rail inspection focuses on areas subject to impact damage and corrosion. Look for evidence of collision damage, excessive corrosion, or modifications that may have weakened the structure. Frame straightening equipment can correct minor damage, but severe damage may require professional assessment to determine repairability.

Door and window alignment indicates body integrity and affects both appearance and weather sealing. Doors that don’t close properly or windows that bind may indicate structural movement or worn hinges and regulators.

Address alignment issues promptly to prevent accelerated wear of related components. Weather stripping replacement maintains interior comfort and prevents water damage that can cause structural corrosion.

Replace door seals, window seals, and trunk seals with quality reproductions designed for your specific year and model. Proper installation requires attention to seal positioning and adjustment for optimal fit.

Subframe connector installation strengthens unibody structures for improved handling and reduced chassis flex. These bolt-on or weld-in components tie the front and rear subframes together for increased structural rigidity.

Performance-oriented drivers particularly benefit from the improved handling and reduced body flex that subframe connectors provide. Regular inspection schedules help identify problems before they become serious.

Inspect the underside annually for rust, damage, or loose components. Pay particular attention to suspension mounting points, which are highly loaded and critical for safety. Professional inspection may be warranted if you discover significant problems or lack the expertise to properly assess structural integrity.

Also Read: 5 Turbo V6s With No Issues vs. 5 Known for Valve Problems