The Honda Accord Coupe represents one of the most reliable and enduring vehicles in automotive history, combining sporty styling with Honda’s legendary engineering excellence and reputation for longevity.

With proper care, these vehicles routinely surpass 200,000 miles while maintaining excellent performance and reliability. However, beneath this reputation for durability lies a sophisticated machine that requires specific care habits to reach its full potential lifespan.

Many Accord Coupe owners, influenced by the vehicle’s reputation for reliability, develop destructive habits that gradually undermine their car’s longevity.

These seemingly innocent behaviors often appear harmless initially, creating a false sense of security while causing progressive damage that eventually leads to premature failure of critical components.

The tragedy lies in how preventable these failures are, yet how commonly they occur among owners who assume their Honda will run forever regardless of treatment.

The financial impact extends beyond repair costs, affecting resale value and ownership satisfaction. More importantly, these habits can compromise safety and leave owners stranded unexpectedly.

Understanding these destructive patterns and replacing them with positive maintenance habits can ensure your Accord Coupe delivers the exceptional longevity Honda engineered into these remarkable vehicles. The difference between a Honda that lasts 100,000 miles and one that exceeds 300,000 miles often comes down to these critical ownership habits.

1. Ignoring the CVT Transmission Maintenance Schedule

One of the most devastating habits that prematurely kills Honda Accord Coupes involves completely ignoring or drastically extending Continuously Variable Transmission (CVT) maintenance intervals, leading to catastrophic transmission failures that can cost more than the vehicle’s remaining value.

Many owners mistakenly believe that CVT transmissions are maintenance-free or follow outdated advice suggesting transmission fluid never needs changing, creating a perfect storm for expensive component destruction that could have been easily prevented through proper maintenance habits.

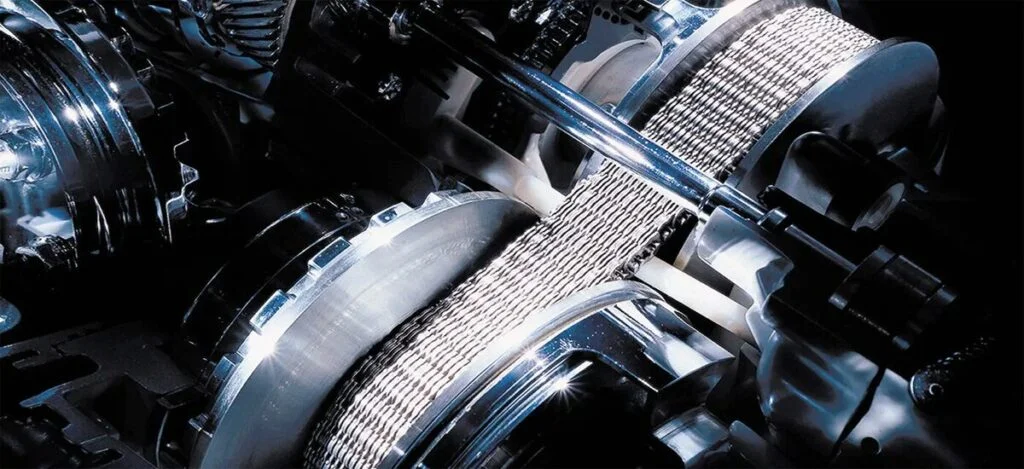

Modern CVT transmissions represent sophisticated pieces of engineering that rely on specialized fluid formulations to function properly. This fluid serves multiple critical functions: lubricating moving components, providing hydraulic pressure for operation, cooling internal parts, and maintaining the precise friction characteristics necessary for the steel belt and pulley system to transfer power efficiently.

Unlike traditional automatic transmissions that can sometimes survive neglect, CVT systems are extremely sensitive to fluid condition and will fail rapidly when maintenance is ignored.

The specialized CVT fluid contains friction modifiers, anti-wear additives, and viscosity improvers that gradually break down under the extreme pressures and temperatures generated during normal operation.

As this fluid degrades, it loses its ability to maintain proper friction between the steel belt and pulleys, leading to slipping, excessive heat generation, and rapid component wear.

Contaminated fluid also becomes abrasive, wearing away precision surfaces and generating metallic particles that further accelerate the destruction process.

Honda’s recommended CVT maintenance intervals typically call for fluid changes every 25,000 to 30,000 miles under normal conditions, with more frequent service required for severe operating conditions like frequent stop-and-go traffic, mountain driving, trailer towing, or extreme temperatures.

However, many owners extend these intervals to 50,000 miles or more, often following advice from quick-lube shops unfamiliar with CVT requirements or attempting to save money on what they perceive as unnecessary maintenance.

Smart Accord Coupe owners also monitor their CVT fluid condition regularly, checking for color changes, burning odors, or unusual consistency that might indicate developing problems.

Fresh CVT fluid should be clear or light amber in color with no burnt smell or metallic particles. Any deviation from normal appearance or odor indicates the need for immediate service, regardless of mileage intervals.

2. Neglecting Engine Oil Quality and Change Intervals

The second most destructive habit that kills Honda Accord Coupes prematurely involves treating engine oil maintenance as optional or using inappropriate lubricants, leading to catastrophic engine damage that transforms reliable transportation into expensive scrap metal.

Despite Honda’s reputation for building virtually indestructible engines, these powerplants still require proper lubrication to survive, and modern engine designs are actually more sensitive to oil neglect than their predecessors due to tighter tolerances and more sophisticated components.

Contemporary Honda engines, whether equipped with naturally aspirated or turbocharged powerplants, operate under demanding conditions that generate tremendous heat, pressure, and mechanical stress.

Variable valve timing systems, direct injection components, and turbocharging elements all require oil that maintains its protective properties under extreme operating conditions.

When owners compromise on oil quality or extend change intervals beyond reasonable limits, they’re gambling with engine components that can cost $8,000 to $15,000 to rebuild or replace.

The false economy of using conventional oil when synthetic is recommended, or selecting bargain-brand lubricants to save a few dollars, often proves incredibly expensive when engines suffer premature wear or catastrophic failure.

Modern engines require oil that can maintain consistent viscosity across wide temperature ranges, resist thermal breakdown under high-heat conditions, and provide superior protection for precision-machined surfaces operating under extreme pressures.

Extended oil change intervals represent another common mistake that destroys engines gradually but relentlessly. While Honda’s maintenance schedules may suggest intervals up to 7,500 or 10,000 miles, these recommendations assume ideal operating conditions that rarely exist in real-world driving.

Stop-and-go traffic, short trips that don’t allow engines to reach full operating temperature, dusty conditions, extreme temperatures, and spirited driving all constitute severe service that requires more frequent oil changes.

The degradation process begins immediately after fresh oil is installed, but accelerates rapidly under severe conditions. Combustion byproducts contaminate the oil, fuel dilution reduces its lubricating properties, moisture accumulation promotes corrosion, and heat cycling breaks down additives designed to protect engine components.

By the time oil appears dark or develops unusual odors, significant damage may have already occurred to internal engine parts. The investment in quality oil and frequent changes represents one of the best insurance policies available for protecting expensive engine components.

Spending $50 to $80 every 5,000 miles for premium oil changes is insignificant compared to the $10,000 to $20,000 cost of engine rebuilds or replacements that result from oil neglect.

3. Ignoring Timing Belt/Chain Maintenance

The third deadly habit that destroys Honda Accord Coupes involves ignoring timing belt or timing chain maintenance, leading to catastrophic engine damage that can total otherwise excellent vehicles.

Many owners remain completely unaware of their engine’s timing system requirements or assume these components will provide warning before failing, creating dangerous situations where interference engines can suffer destruction without any advance notice.

Understanding whether your Accord Coupe has a timing belt or timing chain is absolutely critical, as maintenance requirements differ dramatically between these systems.

Timing belts require regular replacement at specific intervals regardless of appearance or symptoms, while timing chains typically last longer but still require maintenance of associated components like tensioners, guides, and oil pumps that ensure proper operation.

Timing belt engines represent the highest risk category, as these rubber components deteriorate over time regardless of mileage and will eventually fail without warning.

When timing belts break on interference engines, pistons continue moving while valves stop, causing pistons to strike open valves and resulting in bent valves, damaged pistons, and sometimes cracked cylinder heads. The repair costs for interference engine timing belt failures typically range from $3,000 to $8,000, often exceeding the vehicle’s remaining value.

Honda’s timing belt replacement intervals typically range from 60,000 to 105,000 miles, depending on the specific engine, but these intervals assume normal operating conditions.

Severe conditions, including extreme temperatures, dusty environments, frequent short trips, and aggressive driving, can accelerate belt deterioration, making more frequent inspection and earlier replacement advisable for protecting expensive engine components.

Many owners make the fatal mistake of attempting to extend timing belt life by inspecting belts visually and assuming they’re acceptable if they appear intact.

However, timing belts can maintain a normal appearance while suffering internal deterioration that makes them vulnerable to sudden failure. The reinforcement cords inside timing belts can weaken gradually, and rubber compounds can lose flexibility and strength long before visible cracking appears on belt surfaces.

Timing chain engines, while generally more durable than timing belt systems, still require proper maintenance to prevent premature failure and expensive damage.

Chain stretch over time affects valve timing precision, while tensioner failures can allow chains to jump timing or become loose enough to damage engine components.

Oil maintenance becomes critical for timing chain longevity, as these systems rely on engine oil for lubrication and hydraulic tensioner operation. The investment in proper timing system maintenance represents essential insurance for protecting valuable engine components.

Spending $800 to $1,500 for planned timing belt replacement is insignificant compared to the $5,000 to $10,000 cost of repairing interference engine damage caused by belt failure, while proper timing chain maintenance prevents equally expensive problems.

4. Neglecting Cooling System Maintenance

The fourth destructive habit that prematurely kills Honda Accord Coupes involves systematic neglect of cooling system maintenance, leading to overheating damage that can destroy engines in minutes while leaving owners stranded with repair bills that exceed vehicle values.

Many owners assume cooling systems are maintenance-free or follow extended service intervals that allow coolant to deteriorate and cooling components to fail, creating conditions perfect for catastrophic overheating that could have been prevented through proper maintenance habits.

Modern Honda engines operate at precisely controlled temperatures that optimize performance, emissions, and fuel economy while maintaining durability margins.

When cooling systems fail to maintain these critical temperatures, engine damage occurs rapidly and extensively, affecting expensive components, including cylinder heads, head gaskets, engine blocks, and internal engine parts that can cost thousands of dollars to repair or replace.

Coolant represents far more than colored water, containing sophisticated chemical packages designed to prevent corrosion, lubricate water pump seals, maintain optimal heat transfer characteristics, and protect cooling system components from damage.

Fresh coolant includes corrosion inhibitors that protect aluminum and steel components, anti-foaming agents that ensure proper circulation, and pH buffers that prevent acidic conditions from developing inside cooling systems.

However, these protective additives gradually deplete over time and mileage, losing their effectiveness and allowing cooling systems to deteriorate from within.

Old coolant becomes corrosive rather than protective, attacking radiator cores, water pump impellers, thermostat housings, and engine passages while generating debris that restricts coolant flow and reduces cooling efficiency.

This deterioration process accelerates when cooling systems are neglected, creating cascading failures that can destroy multiple components simultaneously.

Honda’s coolant replacement intervals typically range from 30,000 to 100,000 miles, depending on coolant type and operating conditions, but many owners extend these intervals significantly or ignore coolant maintenance entirely until problems develop.

Severe operating conditions, including extreme temperatures, frequent towing, stop-and-go driving, and dusty environments, accelerate coolant degradation and require more frequent service than normal conditions.

Prevention requires comprehensive cooling system maintenance, including regular coolant replacement using Honda-approved formulations, periodic radiator cleaning and inspection, thermostat replacement at recommended intervals, water pump monitoring for leaks or unusual noises, and cooling system pressure testing to identify developing problems before they become critical.

Smart owners also monitor cooling system performance regularly, watching temperature gauge readings and addressing any unusual symptoms immediately rather than hoping problems will resolve themselves.

Also Read: 5 Toyota Tacoma Model Years That Last and 5 You Should Avoid

5. Poor Fuel System Maintenance Habits

The fifth habit that kills Honda Accord Coupes prematurely involves poor fuel system maintenance, leading to fuel injector damage, fuel pump failures, and carbon buildup that degrades performance while shortening engine life.

Many owners assume modern fuel systems are maintenance-free or follow misguided advice about fuel additives and quality, creating conditions that damage expensive fuel system components and reduce engine longevity significantly.

Modern Honda engines utilize sophisticated direct injection systems that operate under extreme pressures and temperatures while maintaining precise fuel delivery control for optimal performance and emissions compliance.

These systems require clean fuel and properly functioning components to operate reliably, and contamination or component failures can cause extensive damage that requires expensive repairs or complete system replacement.

Fuel quality represents a critical factor that many owners ignore or misunderstand, assuming all gasoline meets minimum standards for their vehicles.

However, fuel quality varies significantly between suppliers, seasonal formulations, storage conditions, and regional specifications. Low-quality fuel can contain contaminants, excessive ethanol concentrations, or inadequate additive packages that damage fuel system components while reducing engine performance and longevity.

Ethanol content in modern gasoline presents particular challenges for Honda fuel systems, as ethanol attracts moisture that can cause corrosion in fuel lines, tanks, and injectors while promoting microbial growth that clogs filters and damages components.

Higher ethanol concentrations than recommended can damage seals, gaskets, and plastic components while affecting fuel delivery characteristics and engine performance.

Water contamination in fuel tanks creates multiple problems, including corrosion, microbial growth, fuel system component damage, and engine performance issues that can cause expensive repairs.

Water enters fuel systems through condensation in partially filled tanks, contaminated fuel supplies, and damaged fuel caps or tank seals. Once present, water promotes corrosion throughout the fuel system while creating conditions for bacteria and algae growth that generate acids and sludge.

Fuel filter neglect represents another common mistake that damages expensive fuel system components while reducing engine performance. Fuel filters protect fuel injectors and other precision components from contaminants, but become less effective as they accumulate debris and restrictions.

Clogged fuel filters reduce fuel flow, causing lean running conditions that can damage engines while placing additional stress on fuel pumps that must work harder to maintain proper pressure.

Fuel injector contamination and carbon buildup affect direct injection engines particularly severely, as these systems operate at much higher pressures than traditional port injection systems.

Carbon deposits accumulate on injector tips, intake valves, and combustion chambers, reducing fuel flow accuracy, affecting mixture distribution, and creating hot spots that can cause engine knock and damage.

Smart owners also avoid ethanol concentrations higher than recommended, use fuel stabilizers when vehicles will be stored for extended periods, keep fuel tanks relatively full to minimize condensation, and replace fuel caps when seals deteriorate to prevent contamination entry.

Regular fuel system service by qualified technicians can identify developing problems before they cause expensive damage while ensuring optimal engine performance and longevity.

6. Ignoring Brake System Maintenance

The sixth deadly habit that kills Honda Accord Coupes prematurely involves systematic neglect of brake system maintenance, creating safety hazards while causing expensive damage to brake components that could have been prevented through proper maintenance habits.

Many owners assume brake systems only require attention when obvious problems develop, ignoring the gradual deterioration processes that can lead to sudden brake failures and expensive repairs that far exceed preventive maintenance costs.

Brake systems represent critical safety equipment that requires regular maintenance to function properly and reliably. Unlike other vehicle systems, where failures may cause inconvenience or expense, brake system failures can result in accidents that cause injuries, fatalities, and extensive property damage.

Maintaining brake systems in peak condition is essential for safety while protecting valuable brake components from premature wear and damage.

Brake fluid represents one of the most neglected maintenance items in brake systems, yet fluid condition directly affects brake performance, component longevity, and safety.

Fresh brake fluid contains corrosion inhibitors that protect brake lines, calipers, and master cylinders from internal damage while maintaining consistent viscosity and boiling point characteristics essential for proper brake operation.

However, brake fluid is hygroscopic, meaning it absorbs moisture from the atmosphere over time, regardless of whether the brake system is opened for service.

This absorbed moisture reduces brake fluid’s boiling point, making it susceptible to vapor formation during heavy braking that can cause complete brake failure.

Contaminated brake fluid also becomes corrosive, attacking brake system components and causing internal damage that leads to leaks, reduced performance, and expensive repairs.

Most Honda brake systems require brake fluid replacement every 24,000 to 36,000 miles or every two to three years, regardless of fluid appearance or brake system performance.

Many owners ignore these intervals or extend them significantly, allowing brake fluid to deteriorate and damage expensive brake components while compromising safety and reliability.

Brake pad and rotor maintenance requires careful attention to wear patterns, thickness measurements, and replacement intervals to prevent damage and maintain optimal braking performance.

Brake pads contain wear indicators designed to alert drivers when replacement becomes necessary, but many owners ignore these warnings and continue driving until the pad material is completely worn away.

When brake pads wear completely, metal backing plates contact brake rotors directly, causing extensive damage that requires rotor replacement or resurfacing in addition to pad replacement.

This damage significantly increases repair costs while creating temporary safety hazards until repairs are completed. Severely worn brake pads can also damage calipers and other brake components, further increasing repair expenses.

Brake rotor maintenance involves regular inspection for wear, warping, cracking, and surface damage that affects braking performance and safety.

Rotors operate under extreme temperatures and pressures that can cause warping, cracking, or excessive wear that creates vibrations, reduced stopping power, and unsafe braking characteristics. Warped rotors create pedal pulsation that affects driver control while indicating potentially dangerous brake system problems.

Brake caliper maintenance often gets overlooked until problems become severe enough to cause brake failures or expensive damage. Brake calipers contain pistons, seals, and moving components that require proper lubrication and clean brake fluid to function correctly.

Contaminated brake fluid attacks caliper seals and pistons, causing leaks, sticking, and uneven brake pad wear that reduces braking effectiveness while increasing component replacement costs.

Regular brake system inspection by qualified technicians can identify developing problems before they become dangerous or expensive, while ensuring optimal braking performance and safety for all driving conditions.

7. Neglecting Suspension and Steering Maintenance

The seventh habit that prematurely destroys Honda Accord Coupes involves systematic neglect of suspension and steering system maintenance, leading to dangerous handling characteristics, accelerated tire wear, and expensive component failures that could have been prevented through proper maintenance attention.

Many owners assume these systems are maintenance-free or ignore gradual deterioration that affects safety, comfort, and vehicle control while causing cascading damage to related components.

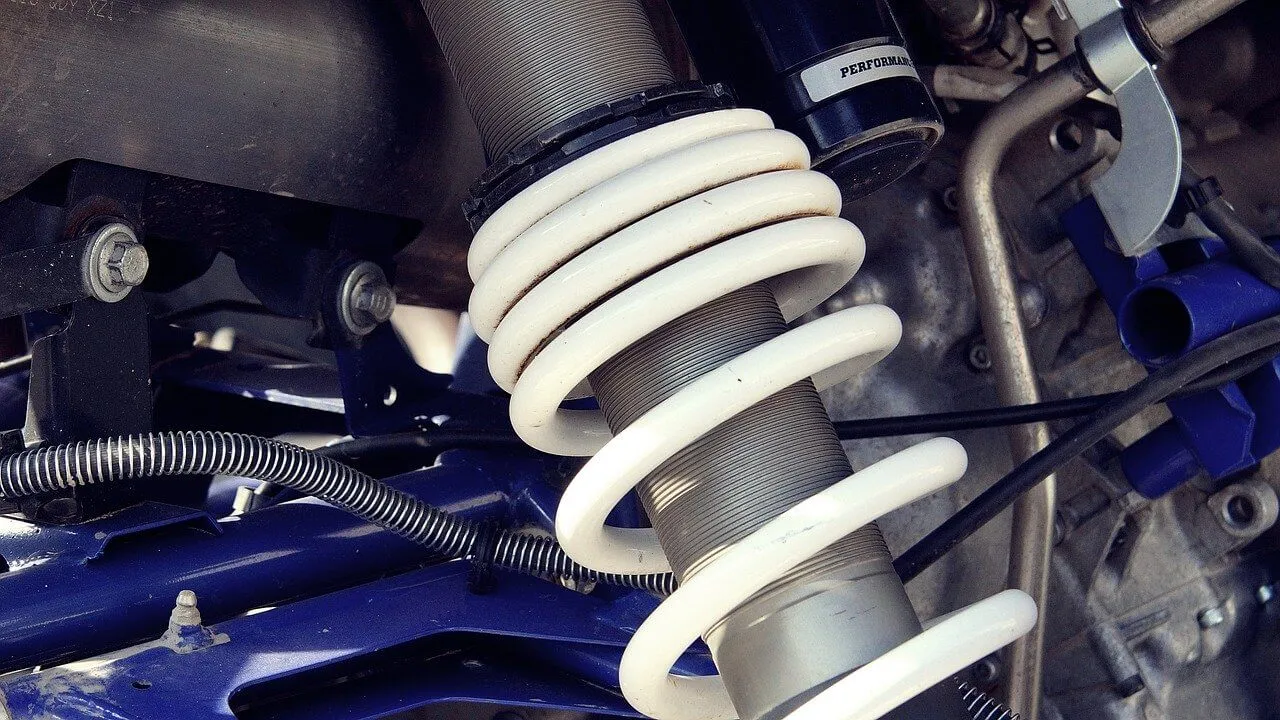

Suspension systems endure constant stress from road irregularities, weight transfer during acceleration and braking, and cornering forces that gradually wear components and reduce their effectiveness.

While Honda designs robust suspension systems capable of providing excellent service for many years, these components still require regular inspection, maintenance, and eventual replacement to maintain optimal performance and safety characteristics.

Shock absorber and strut maintenance represents a critical aspect of suspension care that many owners completely ignore until handling problems become severe enough to affect safety.

These components control suspension movement, maintain tire contact with road surfaces, and provide stable handling characteristics essential for safe vehicle operation.

Worn shock absorbers and struts allow excessive suspension movement that affects braking, steering, and cornering performance while causing accelerated tire wear and reduced vehicle stability.

The deterioration process occurs gradually over thousands of miles, making it difficult for drivers to notice changes in handling and ride quality until problems become severe.

Internal seals wear out, allowing hydraulic fluid to leak and reducing damping effectiveness, while worn components create rattling noises and allow excessive suspension movement that affects vehicle control and safety.

Strut mount and bearing failures create steering and handling problems while causing noise and vibration that affects comfort and vehicle control.

These components support strut assemblies while allowing steering movement, and wear or failure can cause clunking noises, steering binding, and alignment problems that affect tire wear and handling characteristics.

Ball joint maintenance requires regular inspection and lubrication to prevent wear and failure that can cause complete loss of vehicle control. Ball joints connect suspension components while allowing movement necessary for steering and suspension operation, and excessive wear can cause steering play, alignment problems, and catastrophic failures that result in wheel separation and loss of vehicle control.

Smart owners also practice driving habits that extend suspension and steering component life, including avoiding potholes and road hazards when possible, driving at appropriate speeds for road conditions, avoiding excessive loads that stress suspension components, and maintaining proper tire pressures that affect suspension loading and component wear.

8. Poor Battery and Electrical System Care

The eighth and final habit that kills Honda Accord Coupes prematurely involves neglecting battery and electrical system maintenance, leading to unexpected breakdowns, expensive component damage, and cascading failures throughout electrical systems that could have been prevented through proper care habits.

Many owners assume automotive electrical systems are maintenance free or ignore gradual deterioration that affects reliability, performance, and component longevity while creating conditions for sudden failures that can strand vehicles and require expensive repairs.

Modern Honda vehicles rely heavily on sophisticated electrical systems for engine management, safety systems, comfort features, and basic vehicle operation.

These systems require clean, stable electrical power to function properly, and battery or charging system problems can cause extensive damage to expensive electronic components while affecting vehicle reliability and safety.

Battery maintenance involves far more than simply replacing batteries when they fail, encompassing regular inspection, cleaning, testing, and preventive care that extends battery life while preventing electrical system damage.

Automotive batteries operate under demanding conditions, including temperature extremes, vibration, and electrical loads that gradually reduce their capacity and reliability over time.

Corrosion buildup on battery terminals and cables creates electrical resistance that reduces charging efficiency, affects electrical system performance, and can cause starting problems or charging system damage.

Many owners ignore terminal corrosion until starting problems develop, allowing electrical resistance to increase and damage expensive electrical components while reducing battery life and system reliability.

Ground connection maintenance represents a critical aspect of electrical system care that many owners and even some technicians overlook. Poor ground connections cause voltage drops that affect electrical system operation while creating conditions that can damage sensitive electronic components.

Engine ground straps, body ground connections, and component ground points all require periodic inspection and maintenance to ensure proper electrical system operation.

Parasitic drain problems gradually discharge batteries while vehicles are parked, leading to starting problems and reduced battery life that many owners attribute to battery defects rather than electrical system problems.

Modern vehicles contain numerous electronic modules that draw small amounts of current continuously, and problems with these systems can create excessive drains that prevent batteries from maintaining proper charge levels.

Regular electrical system inspection by qualified technicians can identify developing problems before they cause breakdowns or expensive damage while ensuring optimal electrical system performance and reliability for all vehicle systems and accessories.

Also Read: 5 Pickup Beds That Resist Dents vs. 5 That Warp Easily