The Hyundai Accent has earned its reputation as one of the most reliable and affordable vehicles in the compact car segment. This Korean-manufactured automobile offers exceptional fuel economy, comfortable seating, and dependable performance that appeals to budget-conscious drivers across America.

However, like any mechanical device, the Accent’s engine requires proper care and maintenance to function at its optimal level throughout its lifespan. Many Accent owners unknowingly engage in practices that can severely damage their vehicle’s powerplant. These destructive habits often develop gradually and may seem harmless at first glance.

Unfortunately, what appears to be minor negligence can lead to catastrophic engine failure, expensive repairs, and premature vehicle replacement. Understanding these damaging behaviors is essential for anyone who wants to maximize their Accent’s longevity and performance.

Engine destruction rarely happens overnight. Instead, it typically results from a combination of poor maintenance practices, driving habits, and environmental factors that accumulate over months or years.

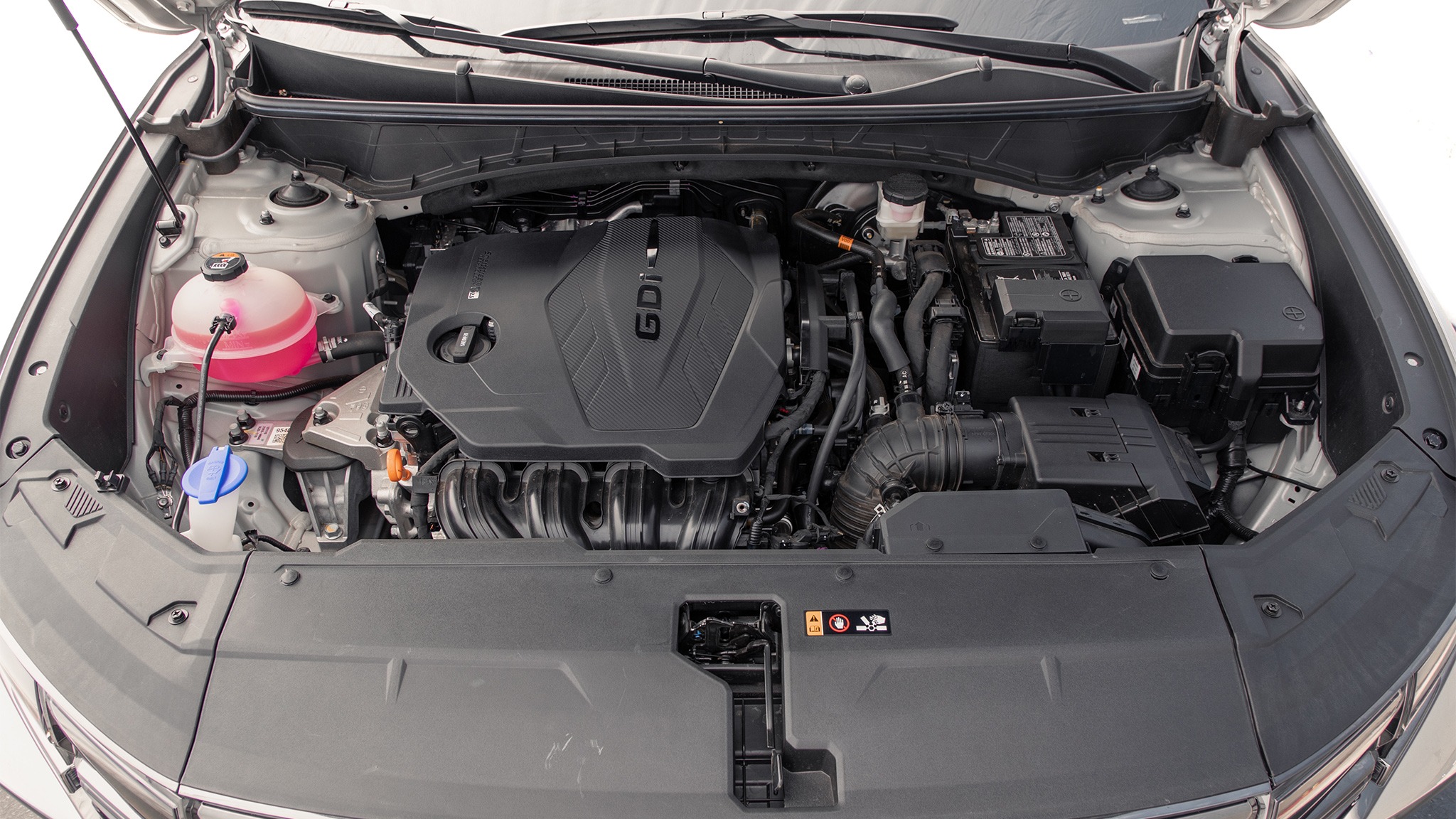

The Accent’s 1.6-liter four-cylinder engine, while robust and well-engineered, remains vulnerable to certain types of abuse and neglect. When owners fail to recognize warning signs or continue harmful practices, they risk transforming their reliable transportation into an expensive mechanical disaster.

Prevention remains far more cost-effective than repair when it comes to engine maintenance. A new Accent engine can cost anywhere from $3,000 to $5,000, not including labor charges for installation. This expense often exceeds the vehicle’s actual market value, making engine replacement financially impractical for most owners.

By identifying and eliminating destructive habits early, Accent owners can avoid these substantial costs while enjoying years of trouble-free driving. The following eight habits represent the most common ways that well-meaning owners inadvertently destroy their Accent’s engine, along with practical solutions for avoiding these costly mistakes.

1. When You Ignore Regular Oil Changes and Use Incorrect Oil Types

Oil serves as the lifeblood of your Hyundai Accent’s engine, providing essential lubrication, cooling, and cleaning functions that keep internal components operating smoothly. When owners neglect regular oil changes or use inappropriate oil types, they create conditions that can rapidly destroy even the most well-built engine.

The Accent’s manufacturer recommends oil changes every 7,500 miles under normal driving conditions, but many owners push this interval far beyond reasonable limits.

Dirty oil loses its ability to lubricate moving parts effectively, leading to increased friction between pistons, cylinders, crankshaft bearings, and other critical components. This friction generates excessive heat, which breaks down the oil even further and creates a destructive cycle.

As oil degrades, it becomes thick and sludgy, clogging oil passages and preventing proper circulation throughout the engine. When oil cannot reach vital components, metal-on-metal contact occurs, causing permanent damage that often requires complete engine replacement.

Using the wrong oil viscosity can be equally damaging to your Accent’s engine. The owner’s manual specifies either 5W-20 or 5W-30 oil for most Accent models, depending on the specific year and engine configuration.

Thicker oils may not flow properly during cold starts, while thinner oils may not provide adequate protection at high temperatures. Some owners mistakenly believe that thicker oil provides better protection, but this assumption can lead to poor circulation and inadequate lubrication during startup periods when most engine wear occurs.

Many Accent owners also fall into the trap of using cheap, low-quality oil to save money on maintenance costs. While budget oils may meet basic specifications, they often lack the advanced additives found in higher-quality products.

These additives help prevent sludge formation, reduce oxidation, and maintain viscosity under extreme conditions. Investing in quality oil and changing it regularly represents one of the most cost-effective ways to protect your Accent’s engine and avoid expensive repairs down the road.

The oil filter plays an equally important role in maintaining engine health, yet many owners overlook this component during maintenance. A quality oil filter removes contaminants and debris from circulating oil, preventing these particles from causing abrasive wear on engine internals.

Cheap filters may have poor filtration media or inadequate bypass valves, allowing dirty oil to circulate when the filter becomes clogged. This contaminated oil can cause rapid engine wear and premature component failure.

2. Driving With Low Coolant Levels or Ignoring Cooling System Maintenance

The cooling system plays a crucial role in maintaining proper engine temperature and preventing catastrophic overheating damage. Many Accent owners underestimate the importance of coolant maintenance, leading to system failures that can destroy their engine within minutes. Low coolant levels, contaminated coolant, or cooling system leaks create conditions that allow engine temperatures to rise beyond safe operating limits.

When coolant levels drop below the minimum line, air pockets form within the cooling system, creating hot spots that can warp cylinder heads, crack engine blocks, or damage head gaskets. The Accent’s aluminum engine components are particularly susceptible to heat damage, as aluminum expands and contracts more than cast iron when subjected to temperature changes.

Once warping occurs, the engine may never seal properly again, leading to persistent coolant leaks, oil contamination, and poor performance. Contaminated coolant poses another serious threat to engine longevity. Old coolant becomes acidic after a while, corroding metal components and rubber seals throughout the cooling system.

This corrosion can cause radiator leaks, water pump failure, and thermostat malfunction. Additionally, contaminated coolant may not transfer heat effectively, allowing engine temperatures to climb even when adequate coolant is present in the system.

Many owners ignore early warning signs of cooling system problems, such as white exhaust smoke, sweet smells from the engine bay, or temperature gauge readings that climb higher than normal.

These symptoms often indicate head gasket failure or other serious cooling system issues that require immediate attention. Continuing to drive an overheating Accent can cause complete engine seizure within a matter of miles, transforming a relatively minor repair into a total loss situation.

The radiator cap and coolant reservoir also require regular inspection and maintenance. A faulty radiator cap may not maintain proper system pressure, allowing coolant to boil at lower temperatures and reducing cooling efficiency.

The coolant reservoir should be inspected for cracks, leaks, and proper fluid levels. Many owners only check coolant when the engine is hot, but accurate level readings can only be obtained when the engine is completely cool.

Regular coolant system flushes help remove accumulated debris, scale, and corrosion products that can interfere with proper heat transfer. Most manufacturers recommend coolant replacement every 60,000 to 100,000 miles, depending on the specific coolant type used.

Using the correct coolant specification is essential, as different coolant types may not be compatible and can cause chemical reactions that damage system components.

Also Read: 12 Fixes That Extend a Hyundai Sonata’s Engine Life

3. Neglecting Air Filter Replacement and Intake System Cleaning

The air filtration system protects your Accent’s engine from dust, dirt, and debris that can cause severe internal damage. A clean air filter ensures proper airflow into the engine while preventing contaminants from reaching sensitive components. When owners neglect air filter maintenance, they expose their engine to particles that act like sandpaper on cylinder walls, pistons, and valve seats.

Clogged air filters restrict airflow into the engine, creating a lean fuel mixture that burns hotter than normal. This increased combustion temperature can damage pistons, valves, and cylinder heads after a while. Additionally, restricted airflow forces the engine to work harder to draw in adequate air, reducing fuel economy and performance while increasing wear on internal components.

Some owners attempt to clean disposable paper filters instead of replacing them, but this practice rarely restores proper filtration and may actually make the problem worse. Dirty air can also contaminate the Mass Air Flow sensor, which measures incoming air and helps the engine management system determine proper fuel delivery.

When this sensor becomes dirty or fails, the engine may run too rich or too lean, causing poor performance, increased emissions, and potential internal damage. Cleaning or replacing a contaminated MAF sensor requires special procedures and cleaning solutions that many owners are not familiar with.

The intake system includes various components beyond the air filter, such as the throttle body, intake manifold, and PCV system. These components can accumulate carbon deposits and oil residue over time, restricting airflow and affecting engine performance.

Regular cleaning of these components helps maintain proper air delivery and prevents the buildup of deposits that can interfere with normal engine operation. Neglecting intake system maintenance can lead to reduced power output, poor fuel economy, and increased emissions that may cause your Accent to fail mandatory inspections.

The PCV (Positive Crankcase Ventilation) system removes harmful vapors from the engine crankcase and recirculates them through the intake system for combustion. When PCV components fail or become clogged, pressure can build up in the crankcase, forcing oil past seals and gaskets.

This oil contamination can foul the intake system and damage engine components. Regular PCV system inspection and maintenance help prevent these problems and maintain proper engine ventilation. Cabin air filters, while not directly related to engine performance, can affect the health of your vehicle’s ventilation system.

Clogged cabin filters force the HVAC system to work harder, potentially affecting electrical system performance and reducing vehicle efficiency. Replacing cabin air filters according to manufacturer recommendations helps maintain proper airflow and prevents contamination of the vehicle’s interior air supply.

4. Using Poor Quality Fuel and Ignoring Fuel System Maintenance

Fuel quality has a direct impact on engine performance, longevity, and reliability. Many Accent owners choose the cheapest available gasoline without considering the potential consequences of using low-quality fuel.

Poor-quality gasoline may contain excessive amounts of water, dirt, or other contaminants that can damage fuel system components and affect combustion quality. Additionally, some discount fuel stations may not maintain their storage tanks properly, allowing contamination to occur before the fuel reaches your vehicle.

The Accent’s fuel injection system relies on precise fuel delivery to maintain proper engine operation. Contaminated fuel can clog fuel injectors, reducing their ability to spray fuel evenly into the combustion chambers.

When injectors become partially blocked, some cylinders may receive inadequate fuel while others receive too much, creating an imbalanced condition that can damage pistons, valves, and other internal components. Cleaning fuel injectors requires specialized equipment and procedures that most owners cannot perform themselves.

Water contamination in fuel poses a particularly serious threat to engine integrity. Water does not burn like gasoline and can cause engine misfires, rough idle, and poor acceleration. In extreme cases, water in the fuel system can cause hydrolock, a condition where water enters the combustion chambers and prevents the pistons from moving properly.

Hydrolock can bend connecting rods, crack pistons, or cause other catastrophic internal damage that requires complete engine replacement. The fuel pump, fuel filter, and fuel lines also require periodic maintenance to ensure proper system operation. Old fuel filters can become clogged with debris, restricting fuel flow and causing the fuel pump to work harder than necessary.

This increased workload can lead to premature fuel pump failure, leaving you stranded and facing expensive towing and repair bills. Replacing the fuel filter according to the manufacturer’s recommendations helps prevent these problems and maintains consistent fuel delivery to the engine.

Ethanol content in modern gasoline can also affect fuel system components after some time. Ethanol attracts moisture from the atmosphere and can corrode certain metals and rubber components in older fuel systems.

While the Accent’s fuel system is designed to handle ethanol blends up to E10 (10% ethanol), higher concentrations can cause problems with fuel system seals, gaskets, and other components. Using fuel from reputable stations and adding fuel system cleaners periodically can help prevent ethanol-related problems.

Carbon deposits can accumulate on intake valves, combustion chambers, and fuel injectors after some time, reducing engine performance and efficiency. These deposits form from the incomplete combustion of fuel and oil vapors that enter the combustion chambers through the PCV system. Regular use of quality fuel additives and periodic professional cleaning services can help remove these deposits and restore optimal engine performance.

5. Ignoring Warning Signs and Dashboard Indicators

Modern Hyundai Accents include sophisticated monitoring systems that track engine performance and alert drivers to potential problems before they become catastrophic failures. Unfortunately, many owners ignore these warning systems or postpone necessary repairs until minor issues become major expenses. The check engine light, oil pressure warning, temperature gauge, and other indicators provide valuable information about engine condition and should never be ignored.

The check engine light can illuminate for dozens of different reasons, ranging from loose gas caps to serious internal engine problems. When this light appears, the engine management system has detected a fault condition that could affect performance, emissions, or reliability.

Continuing to drive with an illuminated check engine light may cause additional damage and can result in more expensive repairs than addressing the original problem promptly. Many auto parts stores offer free diagnostic scanning services that can help identify the specific issue triggering the warning light.

Oil pressure warnings represent one of the most serious dashboard indicators in any vehicle. Low oil pressure can indicate inadequate oil levels, oil pump failure, or worn engine bearings that require immediate attention.

Driving an Accent with low oil pressure can cause complete engine seizure within minutes, transforming a potentially minor repair into a total loss situation. When oil pressure warnings appear, the safest course of action is to stop driving immediately and have the vehicle towed to a qualified repair facility.

Temperature warnings indicate that the engine is running hotter than normal, which can quickly lead to catastrophic overheating damage. Many owners mistakenly believe they can continue driving as long as the temperature gauge has not reached the red zone, but this assumption can prove costly.

Engine damage can occur well before the gauge reaches maximum readings, particularly in aluminum engines like those found in most Accent models. When temperature warnings appear, immediate action is required to prevent expensive engine damage.

Battery and charging system warnings can also affect engine operation indirectly. When the charging system fails, the battery may not provide adequate power to operate fuel injectors, ignition coils, and engine management systems properly.

This can lead to poor performance, misfiring, and potential engine damage from incomplete combustion. Regular battery and alternator testing helps prevent charging system failures that could affect engine operation.

Unusual noises from the engine bay can indicate developing problems before dashboard warnings appear. Knocking sounds may indicate bearing wear, valve problems, or carbon knock from using low-octane fuel.

Squealing noises often indicate belt problems that could lead to charging system or cooling system failures. Grinding sounds may suggest timing chain problems or other internal engine issues that require immediate professional attention.

6. Poor Driving Habits That Stress the Engine

Driving style has a serious impact on engine longevity and reliability. Many Accent owners develop habits that place unnecessary stress on their engine, accelerating wear and increasing the likelihood of premature failure.

Aggressive acceleration, excessive idling, short-trip driving, and other poor practices can reduce engine life by thousands of miles while increasing maintenance costs and repair frequency. Rapid acceleration from stops places tremendous stress on engine components, particularly when the engine is cold or has not reached optimal operating temperature.

Cold engines require richer fuel mixtures and produce less power than fully warmed engines, making aggressive acceleration particularly harmful during startup periods. The additional stress can accelerate wear on pistons, cylinders, connecting rods, and crankshaft bearings while reducing fuel economy and increasing emissions production.

Excessive idling represents another common driving habit that can damage your Accent’s engine as time goes on. Extended idling prevents the engine from reaching optimal operating temperature, leading to incomplete fuel combustion and carbon buildup on internal components.

Additionally, idling does not provide adequate oil circulation to all engine parts, allowing some components to operate with marginal lubrication. Many owners idle their vehicles to warm up the cabin during cold weather, but modern engines require only a few minutes of gentle driving to reach operating temperature.

Short trip driving poses unique challenges for engine longevity because the engine never reaches full operating temperature during brief journeys. Cold engines produce more wear particles, consume more fuel, and generate higher emissions than properly warmed power plants.

Frequent short trips also prevent the exhaust system from reaching temperatures hot enough to burn off accumulated moisture, leading to internal corrosion and premature component failure. When possible, combining multiple errands into single trips helps reduce the impact of short-trip driving on engine life.

High-speed driving can also stress engine components beyond their design limits. Extended highway driving at maximum speeds increases engine temperatures, oil consumption, and component wear rates.

While modern engines are designed to handle highway speeds safely, prolonged high-speed operation can accelerate wear on bearings, seals, and other internal components. Maintaining reasonable speeds and taking periodic breaks during long trips helps reduce engine stress and extends component life.

Racing the engine during warm-up periods represents another harmful practice that many owners unknowingly engage in. Cold oil is thick and may not circulate properly throughout the engine, leaving some components temporarily unprotected.

Racing a cold engine can cause immediate damage to bearings, cylinders, and other internal parts. Allowing the engine to warm up gradually at idle speeds or through gentle driving provides the best protection during startup periods.

7. Neglecting Timing Belt or Timing Chain Maintenance

The timing system ensures that engine valves open and close at precisely the right moments during the combustion cycle. Most Hyundai Accent models use either a timing belt or a timing chain to synchronize valve operation with piston movement.

When owners neglect timing system maintenance, they risk catastrophic engine damage that can cost thousands of dollars to repair or may require complete engine replacement. Timing belts are rubber components that stretch and deteriorate as time goes on, eventually breaking if not replaced according to the manufacturer’s specifications.

When a timing belt breaks on an interference engine like those found in many Accent models, the pistons can collide with open valves, causing bent valves, damaged pistons, and other expensive internal damage. The recommended replacement interval for timing belts typically ranges from 60,000 to 100,000 miles, depending on the specific engine and model year.

Timing chains are metal components that typically last longer than rubber timing belts but still require periodic inspection and maintenance. Chain stretch, worn tensioners, and faulty guides can cause timing chains to jump teeth on their sprockets, leading to incorrect valve timing and potential internal engine damage.

Many owners assume that timing chains are maintenance-free components, but this assumption can prove costly when chains fail without warning. The water pump is often replaced simultaneously with timing belt service because both components are located in the same area of the engine and have similar service intervals.

Replacing the water pump during timing belt service helps prevent future failures that would require removing the same components again. This preventive approach saves money and reduces the risk of cooling system failures that could damage the engine after timing belt replacement.

Timing system tensioners and guides also require attention during timing belt or chain service. Worn tensioners may not maintain proper belt or chain tension, leading to premature failure or incorrect timing.

Failed guides can allow timing chains to contact other engine components, causing noise, wear, and potential failure. Replacing these components during timing system service helps ensure reliable operation and prevents premature timing system failures.

The crankshaft and camshaft seals often leak oil onto timing belts, causing premature deterioration and potential failure. These seals should be inspected during timing belt service and replaced if signs of leakage are present.

Oil-soaked timing belts may slip or stretch more than dry belts, affecting engine timing and performance. Addressing seal leaks during timing belt replacement prevents contamination of the new belt and extends service life.

Also Read: 5 Hyundai Accent Years Worth Owning vs 5 To Avoid

8. Improper Engine Break-In and Maintenance During Early Ownership

New or rebuilt engines require careful break-in procedures to ensure proper seating of internal components and long-term reliability. Many Accent owners are unaware of proper break-in procedures or choose to ignore manufacturer recommendations during the critical first few thousand miles of operation.

Improper break-in can reduce engine life, increase oil consumption, and lead to premature component failure throughout the vehicle’s service life. During the break-in period, engine components are still settling into their final positions and developing proper sealing surfaces.

Aggressive driving, high RPM operation, or extended highway cruising can prevent proper component seating and lead to increased wear rates throughout the engine’s life. The first oil change is particularly critical because break-in debris and metal particles accumulate in the oil during initial operation.

Extending the first oil change interval beyond manufacturer recommendations allows these contaminants to circulate longer than necessary. Many owners mistakenly believe that babying a new engine during break-in provides the best protection, but engines actually require some load variation to seat properly.

Constant gentle driving may not provide enough pressure for piston rings to seat against cylinder walls, leading to increased oil consumption and reduced compression throughout the engine’s life. The key is finding the right balance between avoiding abuse and providing adequate loading for proper component seating.

Quality maintenance products become even more important during the break-in period because new engines may be more sensitive to contamination and inferior lubricants. Using high-quality oil, fuel, and other fluids during break-in helps ensure optimal component seating while protecting against premature wear.

Many manufacturers void warranty coverage if owners use inappropriate fluids or extend service intervals beyond recommended limits during the break-in period, making adherence to manufacturer specifications essential for maintaining warranty protection.

The first few thousand miles also provide an opportunity to identify potential manufacturing defects or assembly problems before they cause serious damage. Unusual noises, vibrations, or performance issues during break-in may indicate problems that should be addressed under warranty coverage.

Ignoring these early warning signs can lead to more serious problems that may not be covered by warranty protection. Break-in procedures typically include avoiding sustained high speeds, varying engine loads and RPM ranges, and performing the first oil change earlier than normal service intervals.

Some manufacturers recommend specific break-in procedures that should be followed exactly to ensure optimal engine life and maintain warranty coverage. These procedures may include restrictions on towing, racing, or other high-stress activities during the initial ownership period.

Temperature cycling during break-in helps components reach their final dimensions and sealing characteristics. Extended highway driving at constant speeds may not provide adequate temperature variation for proper component seating.

City driving with frequent stops and starts often provides better conditions for break-in than extended highway cruising. Understanding these requirements helps new Accent owners protect their investment and ensure maximum engine longevity.

Regular inspections during the break-in period can help identify potential problems before they become serious issues. Checking fluid levels, listening for unusual noises, and monitoring performance characteristics help ensure that the engine is developing properly.

Any concerns should be addressed immediately with qualified technicians who can determine whether problems represent normal break-in characteristics or indicate potential warranty issues that require correction.