The Dodge Charger Daytona stands as one of automotive history’s most legendary muscle cars, representing the perfect fusion of raw American power and cutting-edge aerodynamic technology.

Born from NASCAR’s competitive fires in 1969, this iconic machine was engineered to dominate both the racetrack and the street with its distinctive nose cone, towering rear wing, and thunderous high-performance engines.

Whether you own an original numbers-matching classic or one of the modern electric iterations, the Daytona demands respect, expertise, and unwavering attention to detail.

These extraordinary vehicles are not ordinary cars that can survive with basic maintenance routines. The Daytona’s specialized engineering, from its aerodynamic body modifications to its high-output powertrains, creates unique maintenance requirements that many owners tragically underestimate.

The consequences of this underestimation can be financially devastating and mechanically catastrophic. Unfortunately, countless Daytona owners have watched their prized investments transform from road-going legends into expensive garage ornaments due to preventable oversights.

These seemingly minor neglects cascade into major mechanical failures that can cost tens of thousands of dollars while destroying irreplaceable original components. More alarmingly, some of these oversights create dangerous situations that can result in sudden mechanical failures during high-speed operation.

The seven critical oversights detailed in this guide represent the most common paths to Daytona destruction. Each oversight might appear minor initially, but the high-performance nature of these machines amplifies small problems into catastrophic failures with frightening speed.

Understanding these failure points isn’t just about protecting your investment it’s about preserving an automotive icon while ensuring the safety and reliability that allows you to experience the full glory of Daytona ownership without the fear of sudden, expensive breakdowns that plague uninformed owners.

1. Neglecting the High-Performance Cooling System

The Dodge Charger Daytona’s cooling system represents one of the most critical yet commonly overlooked aspects of ownership. Unlike standard vehicles, the Daytona’s high-output engines generate tremendous amounts of heat that push cooling systems to their absolute limits, making proper maintenance not just recommended but absolutely essential for survival.

The original Daytona models featured specially designed cooling packages that included larger radiators, heavy-duty water pumps, and strategically placed ducting to manage the extreme heat generated by their legendary 426 Hemi and 440 Six Pack engines.

These systems were engineered with minimal safety margins, meaning even small deviations from optimal operating conditions can trigger cascading failures that destroy engines worth more than most people’s cars.

Modern electric Daytona variants face different but equally critical cooling challenges. The high-performance battery packs and electric motors generate substantial heat during aggressive driving, requiring sophisticated thermal management systems that maintain precise temperature ranges.

Unlike traditional engines that can tolerate brief overheating episodes, electric powertrains can suffer permanent damage from thermal events lasting mere minutes.

The most devastating oversight involves ignoring coolant system maintenance intervals. Original Daytona cooling systems require coolant changes every two years regardless of mileage, using specific formulations that prevent corrosion in the aluminum components.

Many owners assume modern “lifetime” coolants apply to these vintage systems, leading to internal corrosion that blocks passages and destroys water pumps, thermostats, and even engine blocks.

Radiator maintenance presents another critical failure point. The Daytona’s aerodynamic nose design, while revolutionary for its time, creates unique airflow patterns that can trap debris in cooling fins.

Regular professional cleaning and inspection prevents the gradual restriction that forces engines to run increasingly hot until catastrophic failure occurs. Many owners only discover cooling problems after permanent damage has occurred.

Water pump failures represent perhaps the most dangerous cooling system oversight. High-performance applications stress water pumps beyond normal limits, and failure symptoms can be subtle until complete breakdown occurs.

The Daytona’s cramped engine bay makes water pump access extremely difficult, often requiring significant disassembly that dramatically increases repair costs when emergency replacement becomes necessary.

Temperature monitoring systems require constant attention in Daytona applications. Factory gauges often provide insufficient warning of developing problems, making aftermarket monitoring equipment essential for serious owners.

Many catastrophic cooling failures could be prevented with early intervention triggered by proper temperature monitoring and immediate response to unusual readings.

2. Ignoring Transmission and Drivetrain Stress Points

The Dodge Charger Daytona’s transmission and drivetrain components face extraordinary stresses that differentiate maintenance requirements from ordinary vehicles, yet many owners treat these systems with standard care protocols that virtually guarantee expensive failures.

The combination of massive torque output, aggressive driving characteristics, and specialized component configurations creates a perfect storm for drivetrain destruction when proper maintenance protocols are ignored.

Original Daytona models typically featured heavy-duty transmissions like the A833 4-speed manual or TorqueFlite automatic, both specifically calibrated for high-performance applications.

These transmissions require specialized fluids, shorter service intervals, and unique adjustment procedures that many modern shops don’t understand.

Using incorrect fluids or following standard service intervals can destroy these expensive, often irreplaceable components within surprisingly short timeframes.

The manual transmission oversight that kills most Daytonas involves clutch system neglect. High-performance clutches require specific adjustment procedures and premium fluid specifications that differ dramatically from standard applications.

Many owners attempt to extend clutch life through partial engagement techniques that actually accelerate wear and can cause sudden catastrophic failure during high-stress situations. Professional clutch adjustment and premium fluid changes every 15,000 miles can prevent most manual transmission failures.

Automatic transmission oversights prove equally devastating but often more subtle in their development. TorqueFlite transmissions in Daytona applications require transmission fluid changes every 25,000 miles using specific formulations, not the “lifetime” fluids often recommended for modern vehicles.

The high heat and stress of performance driving breaks down fluid molecular structure much faster than normal conditions, leading to valve body damage, clutch pack failure, and complete transmission destruction.

Differential maintenance represents another critical oversight area. The Daytona’s high torque output places enormous stress on rear differential components, particularly the limited-slip mechanisms found in most performance variants.

These systems require specialized lubricants changed at specific intervals, along with proper break-in procedures after any service work. Ignoring differential maintenance leads to catastrophic failures that can destroy not only the differential but also damage transmission and driveshaft components.

Driveshaft balancing and universal joint maintenance demand attention levels that many owners underestimate. High-performance applications create vibration frequencies that can rapidly destroy universal joints and upset carefully calibrated driveshaft balance.

Regular inspection and preemptive replacement of universal joints prevent failures that can damage transmission tailshafts, differential pinion seals, and even floorpan components when catastrophic separation occurs.

The most expensive oversight involves ignoring early warning signs of drivetrain stress. Unusual noises, vibrations, or shifting characteristics often indicate developing problems that can be corrected with relatively minor interventions.

However, continuing to drive with these symptoms typically transforms manageable repairs into complete component replacements costing tens of thousands of dollars.

3. Improper Fuel System Management

Fuel system management in the Dodge Charger Daytona requires specialized knowledge and attention that extends far beyond simply keeping the tank full, yet this critical aspect of ownership is consistently misunderstood and neglected by owners who assume standard fuel practices apply to these high-performance machines.

The unique fuel delivery requirements, specialized components, and performance-oriented calibrations create multiple failure points that can destroy engines, fuel systems, and even pose serious safety hazards when proper protocols aren’t followed.

The original Daytona’s carburetor systems represent particularly vulnerable components that require expertise increasingly rare in modern automotive service.

High-performance carburetors like the Carter AFB or Holley configurations used in Daytona applications demand precise adjustment procedures, specialized fuel pressure requirements, and regular maintenance that differs dramatically from standard applications.

Many owners attempt to have these systems serviced by shops lacking specific carburetor expertise, resulting in poor performance, engine damage, and even dangerous fire hazards from improper fuel delivery.

Fuel quality considerations become critical in vintage Daytona applications due to modern gasoline formulations that differ significantly from the fuels these engines were designed to consume.

Contemporary pump gasoline contains ethanol concentrations and detergent packages that can damage rubber fuel system components, corrode metal fuel lines, and cause carburetor problems that didn’t exist when these vehicles were new. Premium non-ethanol fuels or appropriate fuel additives become essential for preventing system degradation.

Modern electric Daytona variants face entirely different but equally critical fuel system challenges related to electrical charging infrastructure and battery management.

The high-performance battery systems require specific charging protocols, thermal management during charging cycles, and sophisticated battery management system monitoring that many owners don’t fully understand. Improper charging practices can permanently damage battery cells worth tens of thousands of dollars while creating potential fire hazards.

Fuel pump failures represent one of the most common and dangerous oversights in Daytona ownership. High-performance engines require consistent fuel pressure and volume that standard replacement pumps cannot provide.

Many owners install incorrect pumps or ignore fuel pressure testing, leading to lean running conditions that can destroy pistons, valves, and cylinder heads through detonation and overheating. Professional fuel pressure testing and appropriate high-performance pump selection prevent most fuel delivery related engine failures.

Fuel line and fitting maintenance demands attention that many owners overlook until catastrophic failure occurs. The Daytona’s high-performance applications create fuel pressure and temperature conditions that stress lines, fittings, and connections beyond normal limits.

Regular inspection for leaks, proper line routing to prevent chafing, and preemptive replacement of aging rubber components prevent dangerous fuel leaks that can cause fires or explosions.

The most dangerous fuel system oversight involves ignoring vapor management and ventilation requirements. High-performance fuel systems generate significant fuel vapors that must be properly vented to prevent dangerous accumulations.

Many owners modify or eliminate vapor recovery systems without understanding the safety implications, creating conditions that can lead to explosions or fires during refueling or maintenance procedures.

4. Electrical System Complications and Failures

The Dodge Charger Daytona’s electrical system represents a complex network of high-performance components, specialized circuits, and precision-calibrated systems that require expert understanding and meticulous maintenance to prevent failures that can disable the vehicle, damage expensive components, or create serious safety hazards.

Many owners underestimate the sophistication of these electrical systems and apply standard automotive electrical practices that are inadequate for the Daytona’s unique requirements and performance-oriented configurations.

Original Daytona electrical systems featured heavy-duty components designed to handle the increased electrical loads from high-performance ignition systems, cooling fans, and auxiliary equipment.

However, these systems were engineered with 1960s technology and require maintenance practices that differ significantly from modern vehicles.

The points-based ignition systems, mechanical voltage regulators, and specialized wiring harnesses demand expertise that has become increasingly rare as these vehicles age and original components become harder to source.

Ignition system maintenance represents perhaps the most critical electrical oversight in vintage Daytona ownership. High-performance engines require precise ignition timing and consistent spark delivery that deteriorates rapidly without proper maintenance.

Points-based systems need adjustment every 10,000 miles, while electronic ignition conversions require different maintenance protocols that many owners don’t understand. Ignition timing that drifts from specifications can cause engine knock, overheating, and catastrophic internal damage within surprisingly short periods.

Modern electric Daytona variants present entirely different electrical challenges centered around high-voltage battery systems, sophisticated motor controllers, and complex thermal management systems.

These vehicles contain electrical systems operating at voltages that can be lethal, requiring specialized safety procedures and diagnostic equipment that most owners and even many shops don’t possess. Attempting DIY repairs on these systems can result in electrocution, expensive component damage, or complete vehicle loss.

Charging system problems plague both vintage and modern Daytona variants but manifest differently in each application. Original vehicles require properly functioning alternators and voltage regulators calibrated for high-performance electrical loads, while modern electric versions need sophisticated onboard charging systems and external charging infrastructure compatibility.

Both applications can suffer expensive damage from charging system failures that are often preventable with proper maintenance and monitoring.

Wiring harness degradation represents a particularly insidious problem in Daytona ownership that often goes undetected until major failures occur.

The high-performance environment creates temperature and vibration conditions that accelerate wire insulation breakdown, connection corrosion, and terminal degradation.

Many electrical problems that appear to be component failures actually result from wiring harness issues that require systematic diagnosis and often complete harness replacement to permanently resolve.

Grounding system maintenance demands attention that many owners overlook despite its critical importance to electrical system function.

High-performance applications require multiple grounding points and low-resistance connections that can deteriorate from corrosion, loosening, or mechanical stress.

Poor grounding causes numerous intermittent problems that are difficult to diagnose and can mask other developing electrical issues until they become critical failures requiring expensive emergency repairs.

Also Read: 10 Tricks That Keep a GMC Envoy Reliable for 300,000 Miles

5. Suspension and Handling Component Deterioration

The Dodge Charger Daytona’s suspension and handling systems were engineered to manage extraordinary performance capabilities while maintaining acceptable ride quality, creating a delicate balance of components that require specialized maintenance and understanding to preserve their intended function.

These systems face stresses that far exceed normal automotive applications, yet many owners treat them with standard maintenance practices that virtually guarantee premature failure and dangerous handling characteristics.

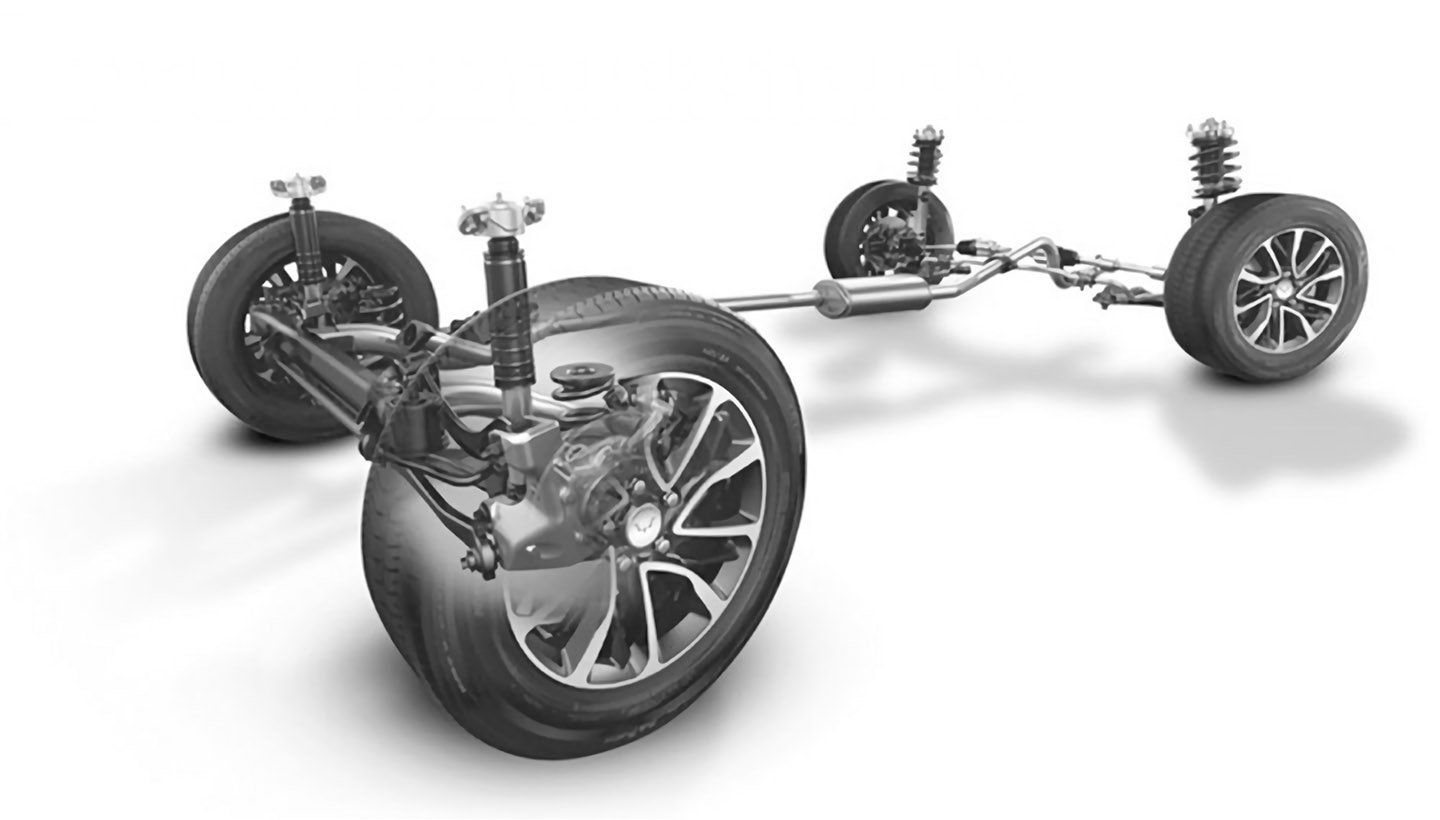

Original Daytona suspension systems featured heavy-duty components including torsion bar front suspension, leaf spring rear setups, and performance-calibrated shock absorbers that were specifically tuned for high-speed stability and aggressive handling.

These components require maintenance intervals and procedures that differ significantly from standard vehicles, with particular attention to proper torque specifications, component alignment, and wear pattern monitoring that can prevent catastrophic failures during high-performance driving situations.

Torsion bar suspension systems demand expertise that has become increasingly rare in modern automotive service. Proper adjustment requires understanding of suspension geometry, load distribution, and alignment relationships that many shops don’t possess.

Incorrect torsion bar adjustment can create dangerous handling characteristics, accelerate tire wear, and place destructive stresses on steering and suspension components that lead to expensive failures and potential loss of vehicle control.

Shock absorber and strut maintenance represents a critical oversight area that many owners ignore until handling becomes dangerously compromised.

High-performance applications destroy shock absorbers much faster than normal driving conditions, with performance degradation occurring gradually enough that drivers often don’t notice the deterioration until comparison with new components reveals the dramatic difference.

Worn shocks not only compromise handling but also accelerate wear on tires, springs, and other suspension components. Steering system maintenance demands attention levels that many Daytona owners underestimate due to the high stresses placed on these components during performance driving.

Power steering systems require specific fluid types and change intervals, while manual steering applications need regular lubrication and adjustment to prevent excessive wear and maintain proper feel.

Steering component failure during high-performance driving can result in complete loss of control with potentially catastrophic consequences. Wheel bearing and hub maintenance becomes critical in Daytona applications due to the combination of high speeds, aggressive braking, and performance tire loads that stress these components beyond normal limits.

Regular inspection and preemptive replacement prevent failures that can cause wheel separation, brake system damage, and complete loss of vehicle control. Many owners ignore early warning signs like noise or vibration until catastrophic failure occurs during critical driving situations.

Bushing and joint replacement represents perhaps the most overlooked aspect of Daytona suspension maintenance despite its critical importance to handling precision and component longevity.

Performance applications rapidly deteriorate rubber bushings and ball joints, creating play and misalignment that compromises handling while accelerating wear on tires and other suspension components.

Regular inspection and preemptive replacement maintain proper suspension geometry and prevent the cascading failures that result from worn bushings and joints.

6. Engine Oil and Lubrication System Neglect

Engine oil and lubrication system maintenance in the Dodge Charger Daytona requires understanding and attention that far exceeds standard automotive applications, yet this critical aspect of ownership is consistently underestimated by owners who assume standard oil change intervals and conventional lubricants provide adequate protection for these high-performance engines.

The extreme operating conditions, tight tolerances, and performance-oriented configurations create lubrication challenges that can destroy engines worth more than most vehicles when proper protocols aren’t followed.

High-performance engines like the legendary 426 Hemi and 440 Six Pack found in original Daytona applications generate internal pressures, temperatures, and mechanical stresses that push lubrication systems to their absolute limits.

These engines require premium oil formulations, shorter change intervals, and specific viscosity grades that differ significantly from modern engine recommendations.

Many owners attempt to apply contemporary oil change practices to vintage high-performance engines, leading to accelerated wear, bearing failure, and complete engine destruction.

Oil change intervals represent the most critical oversight in Daytona engine maintenance, with high-performance applications requiring changes every 3,000 miles regardless of oil type or manufacturer claims.

The extreme heat and combustion pressures break down oil molecular structure much faster than normal applications, while metal particles and combustion byproducts contaminate oil beyond acceptable levels within shorter timeframes.

Extended oil change intervals that might be acceptable in standard engines can cause catastrophic bearing failure in high-performance applications.

Oil pressure monitoring becomes essential in Daytona ownership due to the critical importance of maintaining adequate lubrication under all operating conditions.

High-performance engines operate with tighter clearances and higher RPM ranges that demand consistent oil pressure throughout the operating envelope.

Many catastrophic engine failures could be prevented with proper oil pressure monitoring and immediate response to pressure drops that indicate developing lubrication problems.

Oil filtration systems in Daytona applications require premium filters designed for high-performance use, not standard filters that may lack adequate flow capacity or filtration efficiency.

High-performance engines generate more contamination and require higher flow rates that can overwhelm standard filters, leading to bypass valve activation that allows unfiltered oil to circulate.

Premium filters with appropriate flow ratings and superior filtration media prevent contamination-related wear and maintain oil cleanliness essential for component longevity.

Lubrication system modifications and upgrades often become necessary in Daytona applications to provide adequate protection under extreme operating conditions.

High-volume oil pumps, external oil coolers, and improved pickup systems can prevent lubrication failures that destroy stock systems under racing or aggressive driving conditions.

However, these modifications require careful engineering and professional installation to avoid creating new problems while solving existing limitations. The most expensive lubrication oversight involves ignoring early warning signs of lubrication system problems.

Oil pressure drops, unusual noises, or contamination indicators often provide advance warning of developing failures that can be corrected with relatively minor interventions.

Continuing to operate with these symptoms typically transforms manageable problems into complete engine rebuilds costing tens of thousands of dollars while destroying irreplaceable original components.

7. Aerodynamic Component and Body Integrity Issues

The Dodge Charger Daytona’s revolutionary aerodynamic design represents both its most distinctive feature and one of its most vulnerable aspects, requiring specialized maintenance and understanding that many owners lack despite the critical importance of these components to both performance and structural integrity.

The iconic nose cone, rear wing, and aerodynamic modifications create unique maintenance challenges while serving essential functions that extend far beyond mere appearance enhancement.

The distinctive Daytona nose cone represents perhaps the most critical aerodynamic component that requires constant attention and specialized maintenance.

This fiberglass component was designed to reduce drag and improve high-speed stability, but its construction and mounting methods create vulnerabilities that can lead to catastrophic failure if not properly maintained.

The nose cone’s attachment points require regular inspection for cracks, stress fractures, or loosening that could result in separation during high-speed operation, creating dangerous situations and destroying irreplaceable original components.

Structural integrity monitoring becomes essential in Daytona ownership due to the unique stresses placed on body components by aerodynamic loads and high-performance driving conditions.

The rear wing assembly, in particular, creates significant downforce that places unusual stresses on rear deck mounting points and supporting structures.

Many owners fail to inspect these critical areas regularly, leading to stress crack development that can compromise structural integrity and result in expensive bodywork or even dangerous component failure.

Paint and finish maintenance takes on heightened importance in Daytona applications due to the aerodynamic significance of surface smoothness and the collector value implications of original finishes.

The unique aerodynamic components require specialized painting techniques and materials to maintain their intended function while preserving authenticity. Many owners allow paint deterioration or use inappropriate refinishing materials that can affect aerodynamic performance while destroying collector value.

Weatherstripping and seal maintenance becomes critical in Daytona applications due to the unique body configurations and aerodynamic modifications that create different airflow patterns and pressure distributions than standard Chargers.

Deteriorated seals can allow water infiltration that damages interior components and creates rust problems in critical structural areas. The specialized weatherstripping used in Daytona applications often requires custom fabrication when replacement becomes necessary.

Panel alignment and gap specifications require precise maintenance in Daytona applications due to their aerodynamic significance and visual impact. The nose cone, hood, and other aerodynamic components must maintain specific relationships to function properly and preserve the vehicle’s distinctive appearance.

Many owners overlook gradual alignment changes that can affect both aerodynamic performance and aesthetic appeal while indicating developing structural problems.

The most serious aerodynamic oversight involves modifications or repairs that alter the original aerodynamic configuration without understanding the performance and safety implications.

The Daytona’s aerodynamic package was carefully engineered as an integrated system, and changes to any component can have unexpected effects on high-speed stability and handling characteristics.

Professional consultation becomes essential when any aerodynamic modifications or repairs are contemplated to ensure both safety and performance preservation.

Also Read: 10 Hacks That Help a Toyota Paseo Survive Another Decade