The GMC Sierra Z71 stands as one of the most capable off-road pickup trucks on the market, engineered with rugged terrain in mind. Its Z71 package transforms an already reliable workhorse into a trail-conquering machine, featuring specialized suspension components, skid plates, aggressive all-terrain tires, and enhanced drivetrain components designed to handle the most challenging outdoor adventures.

However, maintaining peak off-road performance requires more than just factory equipment; it demands consistent care, strategic upgrades, and proactive maintenance practices that go far beyond standard vehicle maintenance schedules.

Whether you’re going through the Rocky Mountain trails, traversing muddy forest paths, tackling sandy desert terrain, or conquering steep inclines with loose surfaces, your Sierra Z71’s longevity and reliability depend entirely on how well you maintain and protect its critical systems.

The harsh conditions encountered during off-road adventures, from extreme temperature fluctuations and corrosive mud to abrasive sand and impact-heavy rock crawling, can quickly degrade even the most robust components without proper attention and preventive care.

Off-road driving subjects your truck to stresses that normal highway and city driving never approach. Low-speed, high-torque situations generate excessive heat in drivetrain components, while dust, debris, and moisture infiltrate systems designed for controlled road environments.

Impact forces from rocks and obstacles can damage protective components, while extended periods of operation at unusual angles can affect fluid circulation and component lubrication in ways that standard maintenance schedules don’t address.

Smart truck owners understand that trail-readiness isn’t just about having the right equipment; it’s about implementing a comprehensive maintenance philosophy that addresses every aspect of off-road performance.

This includes understanding how off-road conditions affect component wear patterns, recognizing early warning signs of system stress, and taking proactive measures to protect and enhance your truck’s capabilities before problems develop into costly repairs or dangerous trail-side failures.

This comprehensive guide presents ten essential strategies that will keep your GMC Sierra Z71 performing at its peak for years to come. From fundamental maintenance practices and fluid service intervals to strategic upgrades and protective measures, these recommendations will help you maximize your investment while ensuring your truck remains ready for whatever adventure lies ahead, whether it’s a weekend camping trip or an extended backcountry expedition.

1. Regular Differential Service and Protection

The differential system serves as the heart of your Sierra Z71’s off-road capability, transferring power from the engine to the wheels while allowing them to rotate at different speeds during turns and uneven terrain navigation.

This complex mechanical system faces tremendous stress during off-road adventures, making regular service absolutely critical for long-term reliability and performance.

Understanding differential maintenance requirements and implementing protective measures can prevent costly failures that leave you stranded miles from civilization.

Factory differential fluid typically requires replacement every 50,000 miles under normal driving conditions, but off-road enthusiasts should consider drastically more frequent intervals potentially every 25,000 to 30,000 miles or immediately after particularly challenging trail sessions involving water crossings or extreme dust exposure.

The intense heat generated during low-speed, high-torque situations common in rock crawling and steep climbing breaks down differential fluid more rapidly than highway driving. This thermal stress causes additive depletion and viscosity breakdown that compromises the fluid’s ability to protect gear teeth and bearing surfaces.

Water crossings present unique challenges to differential longevity. Even minor water infiltration can contaminate gear oil, creating a milky appearance that indicates water emulsification.

This contaminated fluid loses its lubricating properties while promoting corrosion of internal components. After any water crossing deeper than the differential housing, immediate fluid inspection and potential replacement becomes necessary to prevent catastrophic gear damage.

When servicing your differential, always use GM-approved gear oil with the correct viscosity rating and limited-slip additive requirements for your specific model year and differential type.

Many Z71 owners upgrade to full synthetic differential fluid, which offers superior heat resistance, extended service intervals, and better protection across temperature extremes.

Synthetic fluids maintain their protective properties in conditions ranging from sub-zero winter temperatures to the extreme heat generated during prolonged rock crawling sessions.

Beyond fluid changes, comprehensive differential protection involves installing heavy-duty skid plates engineered specifically for your Sierra’s chassis configuration.

The differential housing sits relatively low and forward on the chassis, making it vulnerable to rock strikes and impact damage that can crack housings or damage gear teeth through shock loading.

Quality aftermarket skid plates manufactured from aluminum or steel distribute impact forces across a larger structural area while maintaining proper ground clearance for approach angle optimization.

Differential breather modification prevents pressure buildup during heating cycles while preventing contamination during cooling. Extended breather lines routed to higher chassis locations prevent water ingestion during deep crossings while maintaining proper pressure equalization. This simple modification can prevent expensive gear damage from water infiltration or pressure-related seal failures.

2. Suspension System Maintenance and Upgrades

Your Sierra Z71’s suspension system endures extraordinary stress during off-road adventures, absorbing impacts from rocks, roots, and uneven terrain while maintaining vehicle control, passenger comfort, and component protection.

The factory Z71 package includes Rancho monotube shocks, enhanced springs, and other performance-oriented components, but proper maintenance schedules and strategic upgrades ensure optimal performance throughout your truck’s lifespan while preventing costly repairs from component failure.

Shock absorber inspection should occur every 12,000 to 15,000 miles with particular attention to oil leaks, mounting hardware integrity, and damping performance characteristics.

Off-road driving accelerates shock wear exponentially due to increased compression and rebound cycles, higher impact forces from obstacles, and exposure to mud, sand, debris, and temperature extremes that stress seals and internal components.

Visual signs of worn shocks include oil residue on shock bodies, excessive bouncing after hitting bumps, nose diving during braking, vehicle wandering during highway driving, or uneven tire wear patterns that indicate poor wheel control.

When replacement becomes necessary, consider upgrading to adjustable or remote reservoir shocks designed specifically for serious off-road applications.

These advanced shock absorbers offer tunable damping characteristics through external adjusters, allowing you to optimize compression and rebound settings for different terrain types, load conditions, or driving preferences.

Remote reservoir shocks feature separate oil chambers connected by high-pressure hoses, providing superior heat dissipation during extended off-road sessions while preventing shock fade that compromises handling and control.

Suspension bushings throughout the system require regular inspection and proactive replacement schedules. The constant flexing, loading, and impact forces during off-road driving deteriorate rubber bushings significantly faster than normal road use, leading to looseness, noise, and imprecise suspension geometry.

Upgraded polyurethane bushings offer dramatically increased durability and more precise suspension geometry control through reduced deflection, though they may transmit slightly more road noise and vibration to the cabin.

Control arm bushings, sway bar links, leaf spring bushings, and shock mounting bushings all contribute to suspension precision and should be evaluated as a complete system when wear becomes apparent.

Springs and other load-bearing components deserve special attention, particularly if you frequently carry heavy camping gear, recovery equipment, or tow trailers to trail destinations.

Progressive rate springs provide increasing resistance as compression increases, maintaining ride quality during normal driving while preventing bottoming during extreme compression events.

Even minor lift modifications can affect control arm angles, shock mounting positions, and driveshaft operating angles in ways that accelerate wear or create handling problems. Professional alignment and geometry verification ensure that modifications enhance rather than compromise your truck’s off-road capabilities.

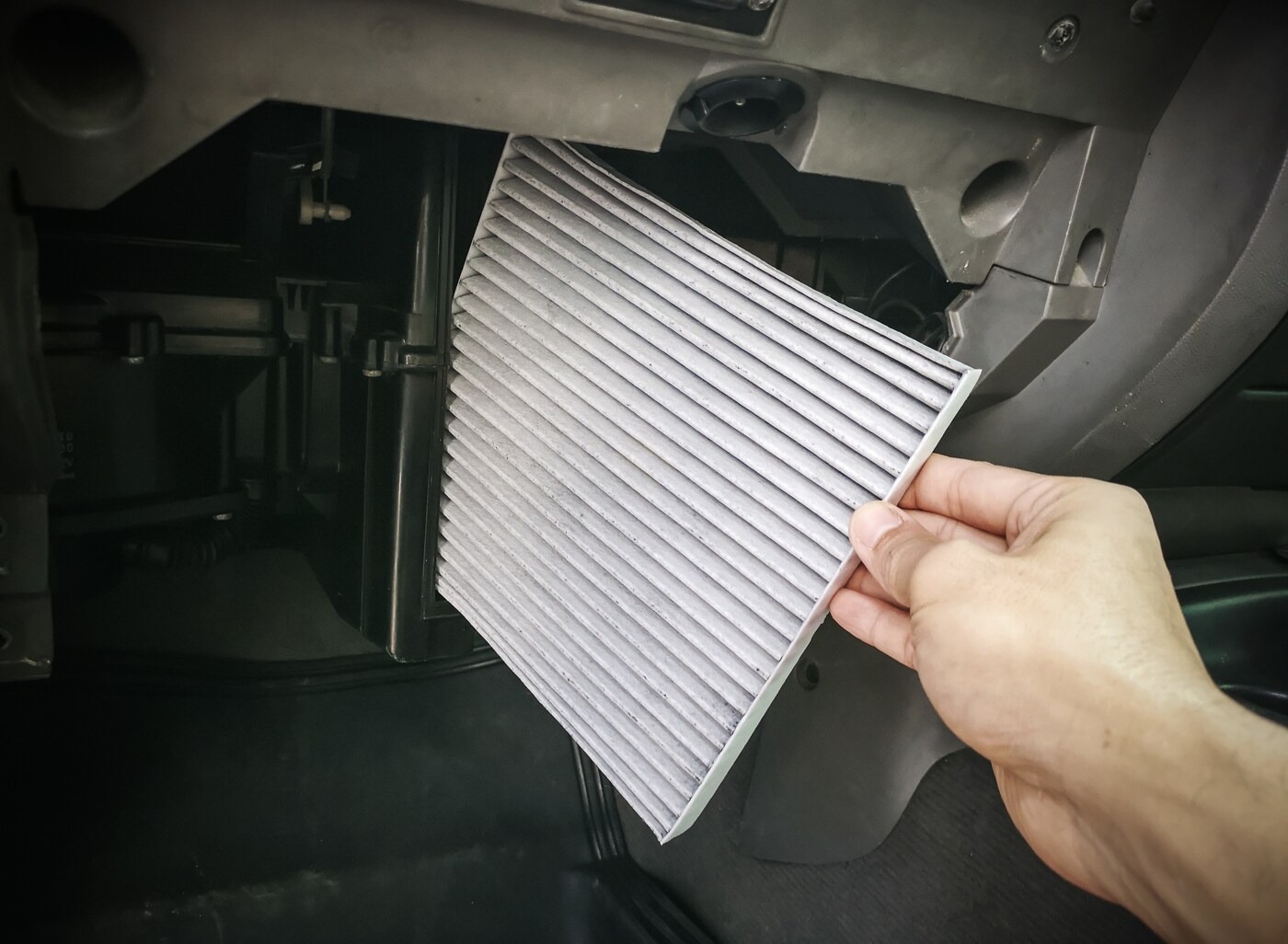

3. Engine Air Filtration and Intake Protection

The engine air filtration system protects your Sierra Z71’s powerplant from the dust, dirt, sand, and debris that characterize off-road environments.

A compromised air filter can allow microscopic and larger contaminants into the engine’s combustion chambers, causing accelerated wear on pistons, rings, cylinders, and valves that leads to reduced performance, increased oil consumption, and potentially catastrophic engine damage over time.

Understanding filtration requirements and implementing protective measures ensures your engine maintains peak performance throughout its service life.

Standard paper air filters require replacement every 12,000 to 15,000 miles under normal highway driving conditions, but off-road driving may necessitate replacement intervals as short as 3,000 to 6,000 miles, depending on environmental conditions and driving intensity.

Dusty desert trails, muddy forest paths with dry approach roads, and sandy environments all introduce different types of contaminants that can quickly overwhelm a dirty filter, causing reduced airflow that robs power and fuel economy while potentially allowing harmful particles to bypass filtration entirely.

Visual filter inspection becomes a critical skill for off-road enthusiasts. A filter showing significant dirt accumulation, torn or damaged pleats, or oil contamination requires immediate replacement regardless of mileage intervals.

Desert environments present particularly challenging conditions where fine dust particles can completely clog filter media in a single day of aggressive trail riding, while muddy conditions can saturate filters with moisture that compromises filtration effectiveness and promotes bacterial growth.

Many Z71 owners upgrade to high-flow, washable air filters constructed from cotton-gauze or advanced synthetic materials that offer superior filtration efficiency while maintaining optimal airflow to the engine.

Quality reusable filters can be cleaned and re-oiled multiple times using specialized cleaning kits, providing long-term cost savings while ensuring consistent protection and performance.

These filters typically flow significantly more air than paper alternatives while maintaining or exceeding OEM filtration efficiency ratings, supporting engine performance in demanding off-road situations where maximum power output becomes critical.

Intake system sealing deserves attention to prevent unfiltered air from bypassing the filtration system entirely. Loose clamps, damaged intake boots, or improperly sealed filter housings can allow contaminated air to enter the engine regardless of filter condition, making regular inspection of all intake system connections essential for maintaining protection.

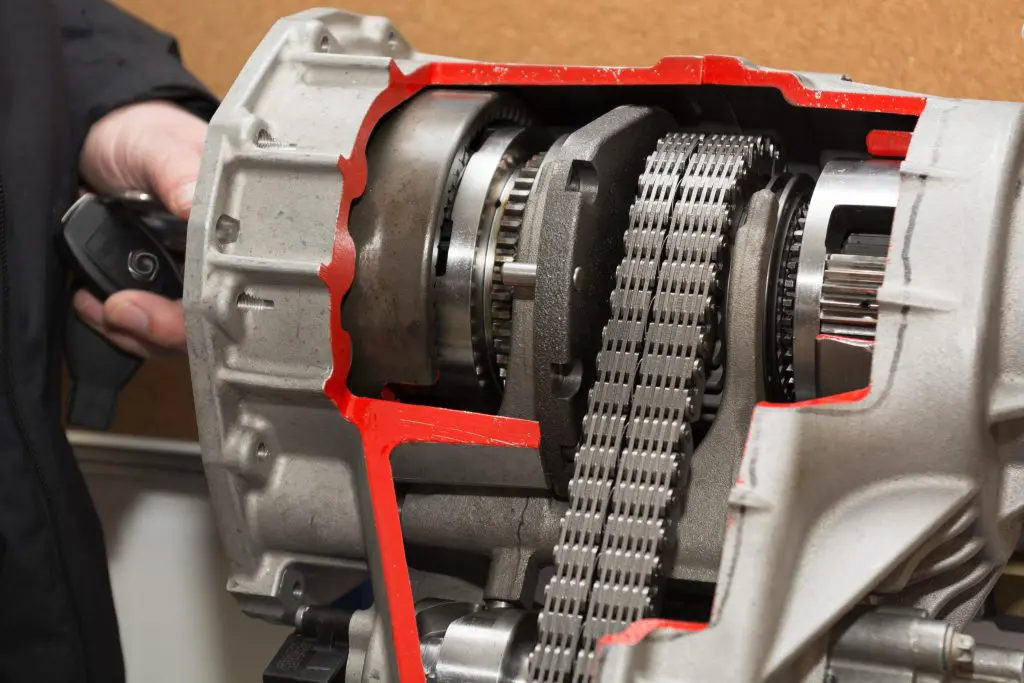

4. Transmission and Transfer Case Service

The transmission and transfer case work together as an integrated system to deliver power effectively across varying terrain conditions, making their proper maintenance crucial for reliable off-road performance and long-term durability.

These components operate under extreme stress during trail driving, particularly during low-speed climbs, technical descents, and situations requiring precise throttle control and gear selection, where heat generation and component loading far exceed normal highway driving conditions.

Automatic transmission fluid degrades more rapidly during off-road use due to dramatically increased heat generation from torque converter operation, extended periods in lower gears, and stop-and-go trail conditions that prevent adequate cooling.

While factory service intervals may recommend transmission service every 100,000 miles for normal driving, serious off-road enthusiasts should consider fluid changes every 40,000 to 50,000 miles or sooner if the truck frequently operates in severe conditions such as heavy trailer towing, extreme temperature environments, or prolonged low-speed technical terrain navigation.

Heat represents the primary enemy of transmission longevity, breaking down fluid additives that protect internal components while causing seal deterioration and component expansion that affects precise hydraulic control.

Transmission fluid temperature monitoring through aftermarket gauges helps identify potential problems before damage occurs, with sustained temperatures above 200°F indicating the need for cooling system upgrades or driving technique modifications to prevent costly internal damage.

Service intervals should be shortened immediately following severe use episodes such as extended rock crawling sessions, deep sand driving, or any situation where transmission temperatures exceeded normal ranges.

Fluid analysis services can provide detailed information about component wear, contamination levels, and remaining fluid life, helping optimize service intervals while identifying potential problems before they become expensive failures.

Also Read: 10 Fixes That Keep a Chevy Nova Road-Ready for Life

5. Brake System Optimization and Protection

Your Sierra Z71’s brake system faces unique and extreme challenges during off-road adventures, from steep descents that generate intense heat to mud, sand, and debris infiltration that can compromise component function and safety.

Maintaining optimal brake performance requires attention to both standard maintenance intervals and off-road-specific considerations that ensure reliable stopping power in all conditions while preventing dangerous fade or failure during critical situations.

Brake fluid replacement becomes significantly more critical for off-road vehicles due to dramatically increased heat generation during steep descents, technical terrain navigation, and repeated heavy braking situations that can boil contaminated or degraded fluid.

Standard brake fluid should be replaced every two years or 24,000 miles under normal conditions, but trucks that frequently tackle mountainous terrain, extended trail systems, or participate in competitive off-road events may benefit from annual fluid changes to maintain peak performance and safety margins.

DOT 4 brake fluid offers substantially higher wet and dry boiling points compared to DOT 3 alternatives, reducing the risk of brake fade during prolonged descents or repeated heavy braking situations common in technical off-road driving.

Some enthusiasts upgrade to DOT 5.1 synthetic brake fluid, which provides even higher temperature resistance while maintaining compatibility with existing brake system components and ABS operation. However, never mix different brake fluid types, as this can cause component damage and brake system failure.

Master cylinder and brake booster function should be verified regularly through pedal feel evaluation and visual inspection, as these components work significantly harder during off-road driving situations requiring frequent, sustained, or maximum braking applications that can reveal marginal performance before complete failure occurs.

6. Tire Selection, Maintenance, and Rotation Strategy

Tires represent the most critical interface between your Sierra Z71 and the terrain you’re conquering, making proper selection, maintenance, and rotation practices essential for optimal off-road performance, safety, and longevity.

The factory all-terrain tires provide excellent capability for most situations, but understanding tire technology, maintenance requirements, and performance optimization techniques maximizes both capability and value while preventing dangerous failures in remote locations.

All-terrain tires offer the optimal balance of on-road comfort, highway performance, and off-road capability for most Z71 owners who split time between daily driving and weekend adventures.

These tires feature aggressive tread patterns with large, widely-spaced lugs designed to provide traction in mud, sand, loose rock, and other challenging surfaces while maintaining acceptable road manners, noise levels, and fuel economy for daily transportation use.

However, tire selection should match your specific off-road priorities and usage patterns rather than following generic recommendations. Mud-terrain tires excel in soft, loose conditions like deep mud, sand, and loose soil but sacrifice on-road comfort, fuel economy, and highway performance through increased rolling resistance and road noise.

These tires feature extremely aggressive tread patterns with large void areas and specialized compound formulations designed for maximum traction in challenging conditions.

Conversely, hybrid all-terrain designs attempt to bridge the gap between categories, offering improved off-road capability compared to standard all-terrains while maintaining better on-road characteristics than dedicated mud-terrains.

Tire pressure management proves crucial for off-road success, component longevity, and safety. Lower pressures dramatically increase the contact patch area for improved traction on soft surfaces, provide better rock crawling performance by allowing tires to conform to obstacles and maintain contact over irregular surfaces, and improve ride comfort over rough terrain by allowing sidewall flexing to absorb impacts.

However, reduced pressure generates significantly more heat during highway driving due to increased sidewall flexing and can cause premature wear patterns, tire damage, or dangerous blowouts if not managed properly.

Many serious off-roaders invest in onboard air compressor systems and comprehensive tire pressure monitoring to optimize pressure for specific conditions while ensuring safe highway pressures for return trips.

Portable compressor systems allow real-time pressure adjustments for changing terrain conditions, while tire pressure monitoring systems provide continuous feedback about pressure changes that could indicate leaks, damage, or unsafe conditions developing during trail operation.

Regular rotation prevents uneven wear patterns that compromise both on-road and off-road performance while maximizing tire life and maintaining consistent traction characteristics across all wheel positions.

Off-road driving often creates unusual wear patterns due to varied traction demands, different loading conditions between front and rear axles, and surface conditions that wear specific tread areas preferentially.

A five-tire rotation pattern that includes the spare tire ensures even wear across all tires while providing a fresh, full-tread tire for emergencies or maximum traction when needed.

Tire inspection becomes more critical for off-road vehicles due to increased exposure to puncture hazards and impact damage. Sharp rocks, thorns, and debris can cause slow leaks or sudden failures that strand you on remote trails.

Regular pressure checks, visual inspections for embedded objects, and tread depth monitoring help prevent trail-side tire problems. Many off-road enthusiasts carry tire repair kits, portable compressors, and tire pressure gauges as standard trail equipment to address minor issues before they become major problems.

7. Cooling System Enhancement and Protection

The cooling system maintains optimal engine operating temperatures despite the extreme demands of off-road driving, where low-speed operation, steep climbs, and stop-and-go trail conditions can quickly overwhelm inadequate cooling capacity.

Proper cooling system maintenance and strategic upgrades ensure reliable performance while preventing costly engine damage from overheating.

Radiator and cooling system flushing should occur more frequently for off-road vehicles due to increased contamination from dust, mud, and debris.

While manufacturer recommendations typically suggest coolant replacement every 100,000 miles or five years, trucks that regularly go through dusty or muddy conditions benefit from more frequent service, potentially every 50,000 to 60,000 miles.

Contaminated coolant loses its ability to transfer heat effectively while potentially causing corrosion and component damage throughout the cooling system.

The radiator itself requires regular cleaning to maintain optimal heat transfer. Off-road driving often results in mud, leaves, and debris accumulating between the radiator fins, reducing airflow and cooling efficiency.

External cleaning with low-pressure water and soft brushes helps remove accumulated debris without damaging delicate fins. Some enthusiasts install radiator screens or guards that prevent larger debris from reaching the radiator while still allowing adequate airflow for cooling.

The cooling system’s secondary components also deserve attention, particularly the thermostat, water pump, and hoses that can fail catastrophically if not properly maintained.

High-temperature thermostats designed for performance applications open at optimal temperatures while providing more precise temperature control.

Upgraded water pumps with improved impeller designs or higher flow rates support enhanced cooling capacity, while silicone radiator hoses resist heat and aging better than standard rubber alternatives.

8. Electrical System Protection and Reliability Modifications

Off-road environments present unique challenges to electrical systems through exposure to water, mud, vibration, and physical impact that can compromise connections and components.

Protecting and upgrading your Sierra Z71’s electrical systems ensures reliable operation of critical functions like lighting, ignition, and fuel delivery while supporting additional accessories that enhance off-road capability.

Battery selection and mounting become critical considerations for off-road vehicles that may experience extreme tilting, vibration, and environmental exposure.

Deep-cycle batteries designed for marine or RV applications often provide better performance in off-road situations where prolonged accessory operation without engine running may be necessary.

AGM (Absorbed Glass Mat) batteries resist vibration damage and provide more consistent performance across temperature ranges while offering maintenance-free operation ideal for trail use.

Electrical connections throughout the vehicle require protection from moisture and corrosion that can cause intermittent failures or complete system breakdown.

Dielectric grease applied to connections helps prevent corrosion while maintaining reliable electrical contact. Weatherproof connectors and sealed junction boxes provide additional protection for critical circuits, particularly those related to ignition, fuel, and safety systems.

Auxiliary lighting systems enhance safety and capability during early morning, late evening, or emergency trail situations. LED light bars, rock lights, and upgraded headlights provide superior illumination while drawing less current than traditional incandescent alternatives.

However, proper wiring with appropriate gauges, fuses, and switching prevents electrical fires or system overloads that could disable the vehicle in remote locations.

Winch-ready electrical systems require special consideration due to the high current demands of electric winches. Even if you don’t currently own a winch, preparing the electrical system with appropriate alternator capacity, battery configurations, and wiring infrastructure makes future installation straightforward while ensuring adequate power for current and future electrical accessories.

High-output alternators maintain battery charge during extended periods of accessory operation while supporting the additional electrical loads common in well-equipped trail vehicles.

9. Undercarriage Protection and Corrosion Prevention

The underside of your Sierra Z71 faces constant attack from rocks, debris, mud, salt, and corrosive materials encountered during off-road adventures.

Comprehensive undercarriage protection prevents damage to critical components while corrosion prevention measures ensure long-term structural integrity and component reliability.

Skid plate systems provide the first line of defense against impact damage to vulnerable components like the oil pan, transmission, transfer case, and fuel tank.

While the Z71 package includes some protective elements, comprehensive aftermarket skid plate systems offer superior coverage and impact resistance.

Quality skid plates distribute impact forces across a larger area while providing access ports for service intervals and drain plugs. Aluminum plates offer excellent strength-to-weight ratios, while steel alternatives provide maximum impact resistance for extreme rock crawling applications.

Frame and suspension component protection involves regular cleaning and application of protective coatings that prevent corrosion from salt, mud, and moisture exposure.

Undercoating applications create barriers between metal surfaces and corrosive elements, but proper surface preparation and product selection are essential for long-term effectiveness. Some coatings require annual reapplication, while others provide multi-year protection with proper initial application.

Rust prevention and treatment become ongoing processes for trucks that regularly encounter salt water, road salt, or other corrosive conditions. Early intervention with rust converters and protective coatings prevents small problems from becoming major structural issues.

Regular inspection of brake lines, fuel lines, and electrical connections helps identify corrosion problems before they cause system failures that could strand you on remote trails.

10. Preventive Maintenance Schedule and Documentation

Developing and maintaining a comprehensive preventive maintenance schedule ensures that all critical systems receive appropriate attention before problems develop into costly repairs or trail-side failures.

Documentation of all maintenance activities provides valuable information for troubleshooting problems while maintaining warranty coverage and resale value.

Creating a maintenance schedule that addresses both standard manufacturer recommendations and off-road-specific requirements helps prevent oversight of critical service intervals.

Many maintenance items require shortened intervals for off-road use, oil changes every 3,000 to 5,000 miles instead of manufacturer recommendations, air filter inspection every 3,000 miles, and differential service every 25,000 to 30,000 miles rather than standard intervals.

Seasonal maintenance schedules help prepare your truck for specific conditions like winter storage or summer trail seasons. Pre-trip and post-trip inspection routines identify potential problems before they strand you on trails while documenting any damage or wear that requires attention.

Pre-trip inspections should include tire pressure checks, fluid level verification, belt and hose inspection, and basic system functionality tests. Post-trip inspections focus on identifying any damage from trail obstacles, fluid leaks that may have developed, or component wear that needs addressing before the next adventure.

Professional service relationships with shops experienced in off-road vehicle maintenance ensure access to specialized knowledge and parts when needed.

While many maintenance tasks can be performed by enthusiastic owners, complex repairs or specialized procedures may require professional expertise.

Developing relationships with qualified shops before problems occur ensures access to knowledgeable help when critical repairs are needed to get you back on the trails quickly and safely.

Also Read: 10 Smart Steps That Extend a Nissan 240SX Past 200k