The Jeep Wagoneer represents a bold return to the three-row luxury SUV segment, attempting to recapture the glory of the original Wagoneer nameplate while competing against established rivals like the Chevrolet Tahoe, Ford Expedition, and Cadillac Escalade.

However, despite its impressive size, luxurious appointments, and capable Hurricane engines, the modern Wagoneer has been plagued by reliability issues that have tarnished its reputation and frustrated owners who expected premium quality to match the premium price tag.

Since its reintroduction in 2022, the Wagoneer has faced numerous challenges that stem from both design oversights and owner maintenance mistakes.

These issues have become so prevalent that many owners have reported multiple dealer visits within months of purchase, with some even pursuing lemon law claims.

The problems range from relatively minor electrical glitches to major powertrain failures that can leave owners stranded and facing thousands of dollars in repair costs.

Understanding these reliability killers is crucial for both current and prospective Wagoneer owners. Many of these issues could be prevented or mitigated through proper maintenance practices, awareness of common failure points, and proactive care.

The vehicle’s sophisticated technology, while impressive when working correctly, introduces complexity that requires more diligent attention than simpler, more traditional SUVs.

The reliability problems facing the Wagoneer are particularly concerning given the vehicle’s price point, which often exceeds $80,000 for well-equipped models and can reach over $100,000 for the Grand Wagoneer variants.

Customers investing this much in a vehicle rightfully expect years of trouble-free operation, not frequent trips to the service department and extended periods of downtime while repairs are completed.

This comprehensive analysis examines the nine most critical mistakes and oversights that destroy Wagoneer reliability, providing owners and potential buyers with the knowledge needed to protect their investment and enjoy the vehicle as intended.

1. Ignoring Electrical System Maintenance and Software Updates

The most devastating mistake Wagoneer owners make is neglecting the vehicle’s complex electrical system and failing to keep software current. The 2024 Jeep Wagoneer has been plagued by electrical issues, with one owner reporting six trips to the dealer in three months for the same electrical problems that remain unfixed.

This pattern represents a fundamental misunderstanding of how modern vehicles operate and the critical importance of proactive electrical system care.

The Wagoneer’s electrical architecture is incredibly sophisticated, featuring multiple computer modules, advanced infotainment systems, and numerous sensors that control everything from engine management to climate control.

Owners report frequent no-start conditions, with some experiencing four no-start events in six months, requiring multiple auxiliary and main battery replacements along with software updates. These failures often cascade, creating a domino effect where one electrical fault triggers others throughout the vehicle’s network.

Battery maintenance represents the foundation of electrical system health, yet many owners treat their Wagoneer’s battery like a traditional vehicle’s simple starter battery.

The Wagoneer uses both a main battery and auxiliary batteries to power its extensive electrical systems. When these batteries begin to fail, they don’t just prevent starting they create voltage fluctuations that confuse sensitive electronic modules and can cause permanent damage to expensive control units.

Software updates are equally critical but frequently overlooked. Dealerships often need to check for all available software updates and perform them to resolve electrical issues, yet many owners never inquire about updates until problems arise.

These software patches often address known bugs, improve system integration, and enhance the reliability of various electrical components. Failing to maintain current software is like using outdated operating systems on a computer; vulnerabilities and compatibility issues compound over time.

The interconnected nature of the Wagoneer’s electrical systems means that neglecting maintenance in one area affects others. For example, a failing auxiliary battery might cause the infotainment system to glitch, which then affects the backup camera functionality, leading to safety recalls and additional complications.

Regular electrical system inspections, prompt software updates, and proactive battery maintenance are essential for preventing these costly cascade failures. Prevention requires establishing a relationship with a knowledgeable service department that understands the Wagoneer’s electrical complexity.

Owners should request battery testing at every service interval, inquire about available software updates, and address any electrical anomalies immediately rather than hoping they’ll resolve themselves. The cost of preventive electrical maintenance is minimal compared to the expense and frustration of major electrical failures.

2. Overlooking Cooling System Problems and Engine Overheating

Engine overheating represents one of the most serious reliability threats facing Wagoneer owners, yet many dismiss early warning signs until catastrophic damage occurs.

Owners report sudden overheating in traffic situations, with one describing how their SUV couldn’t exceed 1 mph due to thermostat failure and transmission slipping, with coolant pressure building so high it blew the cap off the reservoir.

This type of failure can destroy the engine, transmission, and numerous other components in a matter of minutes. The Wagoneer’s Hurricane engines generate substantial heat, especially when towing or operating in demanding conditions.

The cooling system must work flawlessly to manage these thermal loads, but several design and maintenance issues create vulnerability points. Low coolant levels from evaporation or leaks, cooling system leaks from damaged hoses, compromised radiators, or failing water pumps all contribute to overheating problems.

These issues often develop gradually, giving owners opportunities to intervene before major damage occurs. Some owners experience heating system failures affecting both rear and front heaters, with dealerships identifying bad heating modules that require recall repairs, while rapid coolant temperature fluctuations trigger overheating warnings.

These heating system problems aren’t just comfort issues, they’re symptoms of broader cooling system dysfunction that can progress to engine damage if ignored.

The sophistication of the Wagoneer’s thermal management system creates additional complexity. The vehicle uses multiple temperature sensors, electric cooling fans, and computer-controlled thermostats to maintain optimal operating temperatures.

When any component in this system fails, the engine management computer may not respond appropriately, leading to overheating conditions that develop faster than traditional mechanical systems.

Owners report sudden onset of low oil pressure warnings combined with overheating symptoms, indicating that cooling system failures often coincide with lubrication system problems.

The cooling system should be professionally serviced according to the manufacturer’s schedule, with particular attention to coolant replacement and thermostat function.

Any signs of overheating should result in immediate shutdown and professional diagnosis rather than continued operation, hoping the problem will resolve itself.

3. Neglecting Transmission Maintenance and Overheating Prevention

Transmission failure represents one of the most expensive and devastating reliability problems affecting Wagoneer owners, yet proper transmission care remains widely misunderstood and neglected.

Customers report major transmission failures among the most serious issues affecting their ownership experience, while owners describe situations where their Wagoneer revs high without increasing speed, with clear signs that the transmission isn’t shifting gears properly.

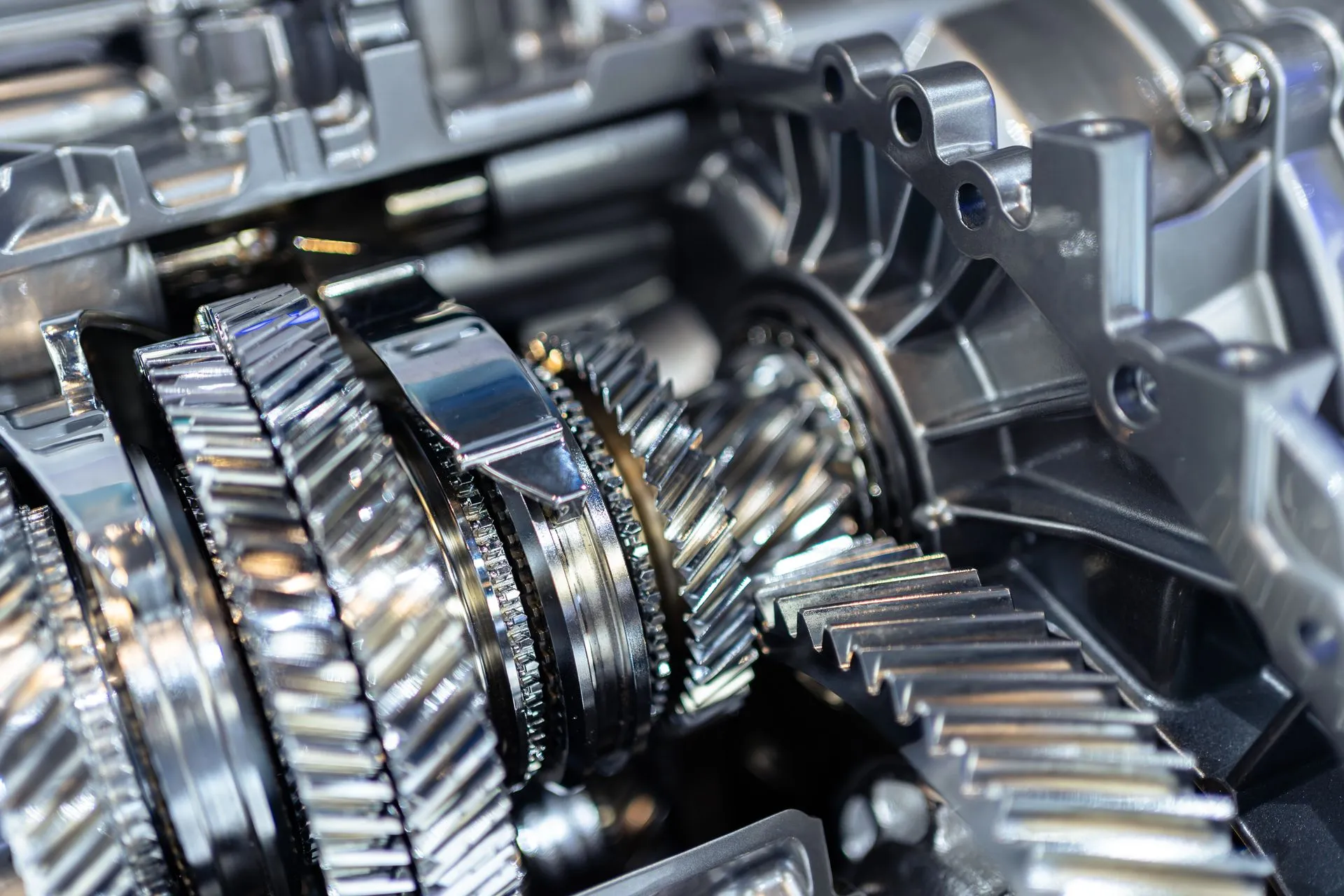

These failures often occur with little warning and can leave owners stranded far from home. The Wagoneer’s eight-speed automatic transmission is a sophisticated unit that relies on precise hydraulic pressures, clean fluid, and proper operating temperatures to function correctly.

Low fluid levels, faulty cooling systems, heavy towing, and extreme driving conditions can cause transmission overheating, and driving with an overheated transmission can cause severe damage, leading to costly repairs or replacement. Many owners don’t realize that transmission problems often stem from cooling system issues rather than internal transmission defects.

Transmission fluid serves multiple critical functions beyond simple lubrication. It provides hydraulic pressure for shifting, cools internal components, and cleans debris from moving parts.

When fluid levels drop or fluid quality degrades, all these functions suffer simultaneously. Unlike engine oil, transmission fluid changes are often scheduled at extended intervals, leading many owners to forget about this critical maintenance entirely.

The connection between engine overheating and transmission problems creates a dangerous situation where cooling system neglect destroys both major powertrain components.

When engine cooling systems fail, transmission cooling suffers because many vehicles use the engine’s cooling system to cool transmission fluid. This shared cooling arrangement means that engine overheating problems quickly become transmission overheating problems, multiplying repair costs exponentially.

Towing and heavy loading significantly increase transmission stress, yet many owners don’t adjust their maintenance schedules accordingly. The Wagoneer’s substantial towing capacity encourages owners to use it for hauling boats, trailers, and heavy loads without considering the additional transmission strain.

Prevention requires understanding that transmission maintenance extends far beyond occasional fluid changes. Owners should monitor fluid levels and condition regularly, ensure proper cooling system function, avoid overloading the vehicle, and address any shifting abnormalities immediately.

Professional transmission service should include fluid changes, filter replacements, and electronic system diagnostics to catch problems before they cause major damage.

4. Improper Battery Management and Charging System Neglect

Battery and charging system problems plague Wagoneer owners more than any other reliability issue, yet most owners treat these components like traditional vehicle electrical systems rather than the sophisticated power management networks they actually represent.

Multiple owners report requiring three auxiliary batteries and two main battery replacements within short ownership periods, indicating systemic problems with power management that go far beyond normal battery wear.

The Wagoneer uses a dual-battery system with both a main starting battery and auxiliary batteries that power the extensive electronic systems when the engine isn’t running.

This integration requirement means that battery replacement isn’t simply a matter of swapping old units for new ones the vehicle’s computer systems must be reprogrammed to recognize and work with replacement batteries properly.

Many reliability problems stem from owners’ failure to understand how modern battery systems work. Unlike traditional vehicles where batteries either work or don’t, sophisticated battery management systems can limp along with degraded batteries for extended periods while causing intermittent problems throughout the electrical system.

These problems often manifest as seemingly unrelated issues like infotainment glitches, camera malfunctions, or accessory failures that owners don’t initially connect to battery problems.

The Wagoneer’s extensive idle-time electrical loads accelerate battery degradation compared to simpler vehicles. Features like remote start, security systems, and connectivity modules draw power continuously, even when the vehicle sits unused for extended periods.

Owners who don’t drive regularly or take primarily short trips may not provide sufficient charging time to maintain battery health, leading to premature failure and cascading electrical problems.

Owners should have batteries tested at least twice yearly, ensure proper connections and terminal cleanliness, and consider battery tender use during extended storage periods.

Any signs of electrical system irregularities should prompt immediate battery and charging system diagnostics rather than waiting for complete failure.

Also Read: 8 Driving Habits That Kill a Honda Accord Coupe Too Early

5. Inadequate Regular Maintenance Scheduling and Service Intervals

The complexity of modern Wagoneers demands far more rigorous maintenance schedules than many owners realize, yet inadequate maintenance remains one of the primary reliability killers affecting these vehicles.

Owners purchasing vehicles exceeding $100,000 expect premium service levels but report frustration with inadequate customer support and service quality that fails to meet their expectations. This service gap often stems from both dealership limitations and owner misunderstandings about maintenance requirements.

Modern vehicles integrate numerous systems that require coordinated maintenance approaches rather than traditional isolated component servicing.

The Wagoneer’s Hurricane engines, sophisticated transmissions, complex electrical systems, and advanced emissions controls all interact in ways that require comprehensive maintenance strategies. When owners focus on basic oil changes while neglecting other systems, reliability suffers across multiple areas simultaneously.

Software maintenance represents a critical but frequently overlooked aspect of modern vehicle care. The Wagoneer’s numerous computer modules receive periodic updates that address known issues, improve performance, and enhance integration between systems.

Software problems in systems like rearview camera modules can cause safety compliance failures that require dealer updates to resolve. Owners who don’t regularly inquire about software updates miss opportunities to prevent known problems.

Service interval compliance becomes particularly critical for vehicles operating in severe conditions, which include most real-world driving scenarios.

Stop-and-go traffic, extreme temperatures, dusty conditions, and towing all qualify as severe service conditions that require more frequent maintenance than standard recommendations.

Many owners follow normal service intervals despite operating primarily under severe conditions, leading to premature wear and reliability problems. The interconnected nature of modern vehicle systems means that neglecting maintenance in one area affects others.

For example, failing to replace air filters on schedule can affect engine performance, which stresses the transmission, which increases heat generation, which affects cooling system performance, creating a cascade of problems that eventually manifest as major component failures.

Owners should establish relationships with service providers who understand the vehicle’s requirements, maintain detailed service records, and consider accelerated maintenance schedules if their driving conditions qualify as severe service. The cost of preventive maintenance is minimal compared to major component replacement costs when maintenance neglect causes failures.

6. Ignoring Early Warning Signs and Diagnostic Alerts

One of the most costly mistakes Wagoneer owners make is dismissing or ignoring early warning signs and diagnostic alerts, allowing minor issues to escalate into major failures that could have been prevented with prompt attention.

Owners report situations where vehicles suddenly won’t shift past fourth gear, followed by low oil pressure warnings and engine overheat warnings, indicating that multiple systems failed in sequence after earlier warning signs were likely present but ignored.

Modern vehicles like the Wagoneer are equipped with sophisticated diagnostic systems designed to alert owners to developing problems before they cause major damage.

These systems monitor everything from fluid levels and temperatures to emission control function and electrical system performance. When these systems generate warnings, they’re indicating that intervention is needed to prevent more serious problems from developing.

Many owners develop warning light fatigue, becoming accustomed to minor alerts and assuming they represent normal vehicle behavior rather than indicators of developing problems.

This attitude proves particularly dangerous with complex vehicles like the Wagoneer, where seemingly minor issues often indicate broader system problems that can cascade quickly into major failures.

The interconnected nature of modern vehicle systems means that problems rarely remain isolated. Owners report progression from service engine lights to oil pressure warnings to overheating and complete loss of drivability, demonstrating how initial warning signs evolve into multiple system failures when ignored. Early intervention during the initial warning phase could have prevented the entire cascade of problems.

Diagnostic trouble codes provide specific information about detected problems, yet many owners never have these codes read and interpreted by qualified technicians.

These codes often identify specific sensors, circuits, or systems experiencing problems, providing roadmaps for targeted repairs that prevent broader failures. Ignoring or clearing codes without addressing underlying problems allows conditions to worsen until major damage occurs.

Intermittent problems require particular attention because they often indicate developing failures that haven’t yet progressed to permanent conditions.

Owners should maintain relationships with service providers capable of proper diagnostic procedures and avoid the temptation to ignore intermittent problems or clear warning lights without addressing root causes. The cost of early intervention is minimal compared to the major repairs required when minor problems escalate into system failures.

7. Poor Driving Habits and Operational Misunderstanding

Driving habits significantly impact Wagoneer reliability, yet many owners operate these sophisticated vehicles without understanding how their behavior affects long-term durability and performance.

Poor driving practices can accelerate wear, stress critical systems, and create operating conditions that overwhelm the vehicle’s design parameters, leading to premature failures and reliability problems.

The Wagoneer’s substantial size and weight require different driving techniques than smaller vehicles, yet many owners apply habits developed with lighter, less complex vehicles.

Heavy towing combined with extreme driving conditions can cause transmission overheating that leads to severe damage. Proper towing requires understanding weight limits, trailer setup, and the additional maintenance needed when regularly pulling heavy loads.

Engine management during cold starts significantly affects longevity, yet many owners don’t allow proper warm-up periods before demanding full performance.

Modern engines use sophisticated thermal management strategies that require specific temperature ranges for optimal operation. Demanding immediate full power from cold engines stresses internal components and can affect long-term reliability.

Stop-and-go driving creates particularly challenging operating conditions for the Wagoneer’s systems. The constant starting and stopping prevent engines and transmissions from reaching optimal operating temperatures while creating thermal cycling that stresses components.

These conditions also prevent charging systems from fully recharging batteries, contributing to the electrical problems that plague many owners. Fuel quality and selection impact engine performance and longevity more than many owners realize.

The Hurricane engines are designed for specific fuel octane ratings, and using lower-grade fuels can cause detonation that damages internal engine components over time. Additionally, poor-quality fuel can contain contaminants that affect fuel system components and emission controls.

Understanding the vehicle’s various driving modes and when to use them can significantly impact reliability. The Wagoneer offers multiple driving modes designed for specific conditions, and using inappropriate modes can stress systems unnecessarily.

Owners should read and understand their owner’s manual, avoid operating extremes, and consider how their driving habits might affect long-term reliability.

Professional driving instruction specific to large SUVs can help owners develop techniques that preserve vehicle longevity while maintaining safety and performance.

8. Inadequate Environmental Protection and Storage Practices

Environmental factors and storage practices profoundly impact Wagoneer reliability, yet many owners underestimate how exposure conditions and storage choices affect their vehicle’s long-term durability.

The sophisticated electronics, complex mechanical systems, and premium materials used in these vehicles require more protection from environmental extremes than traditional vehicles.

Temperature extremes create multiple reliability challenges that compound over time. Extreme heat accelerates battery degradation, stresses cooling system components, and can cause electronic modules to malfunction or fail prematurely.

Conversely, extreme cold reduces battery capacity, thickens fluids, and can cause seals and gaskets to contract and leak. Rapid coolant temperature fluctuations result in overheating warnings, indicating that thermal cycling from environmental conditions contributes to cooling system stress.

Humidity and moisture exposure present particular challenges for the Wagoneer’s extensive electrical systems. Moisture infiltration can cause corrosion in electrical connections, leading to intermittent electrical problems that plague many owners.

Water intrusion into electronic modules can cause permanent damage requiring expensive replacements. Even seemingly minor moisture exposure can create long-term reliability problems that don’t manifest immediately.

This might include regular washing to remove salt and contaminants, using quality car covers for outdoor storage, maintaining proper indoor storage environments, and adjusting maintenance schedules based on environmental stress factors. The investment in environmental protection pays dividends in reduced repair costs and extended vehicle life.

9. Failing to Address Recalls and Technical Service Bulletins

Perhaps the most preventable reliability mistake Wagoneer owners make is failing to stay current with recalls and technical service bulletins (TSBs) that address known problems and provide solutions for common issues.

The Wagoneer has been subject to recalls for issues like rearview camera module software problems that cause safety compliance failures, and heating module problems that affect both front and rear heating systems. Ignoring these official notifications allows known problems to persist and potentially worsen into major failures.

Recalls represent mandatory repairs for safety-related defects identified by manufacturers or regulatory agencies. These repairs are provided at no cost to owners and address problems that could affect vehicle safety, emissions compliance, or other regulatory requirements.

Failing to complete recall repairs not only perpetuates known problems but can also affect warranty coverage for related issues and may create liability concerns if problems contribute to accidents or injuries.

Technical Service Bulletins provide repair procedures and part updates for known problems that don’t rise to the level of safety recalls but still affect vehicle reliability or customer satisfaction.

While TSB repairs aren’t always free, they often provide solutions for chronic problems that might otherwise require repeated repair attempts using outdated procedures or parts. Many of the electrical and overheating problems affecting Wagoneers have associated TSBs that provide updated repair procedures.

The complexity of modern vehicles means that problems often have interconnected causes requiring coordinated solutions that individual repair attempts might miss.

Recalls and TSBs provide comprehensive approaches developed through extensive investigation of failure patterns and root causes. Independent repair attempts might address symptoms without resolving underlying causes, leading to recurring problems that proper recall or TSB procedures would eliminate.

Timing plays a critical role in recall and TSB effectiveness. Some repairs become more complex or expensive if problems are allowed to persist before correction.

For example, software-related problems might cause secondary damage to hardware components if not addressed promptly, requiring additional repairs beyond the original recall or TSB scope.

Warranty implications make recall and TSB compliance particularly important for newer vehicles. Failing to complete recalls might void warranty coverage for related problems, while TSB repairs often extend warranty coverage for specific issues. Understanding these warranty interactions can save thousands of dollars in repair costs that might otherwise fall to owners.

Prevention requires staying informed about recall and TSB releases, scheduling prompt completion of required repairs, and maintaining complete records of all work performed.

Owners should regularly check manufacturer websites for updates, respond promptly to recall notifications, and discuss applicable TSBs with service providers during routine maintenance visits.

The investment in staying current with official repairs prevents many of the chronic problems that otherwise plague Wagoneer owners and preserves the vehicle’s reliability, safety, and warranty coverage.

Also Read: 7 Oversights That Ruin a Dodge Charger Daytona Quickly