The Ford Contour, produced from 1995 to 2000, represented Ford’s ambitious attempt to bring European engineering sensibilities to the American compact car market.

Based on the Ford Mondeo platform, the Contour offered a sophisticated driving experience with its refined suspension, responsive handling, and well-appointed interior.

Despite its many strengths, including a comfortable ride quality and competitive fuel economy, the Contour’s reliability record tells a more complex story.

Like many vehicles of its era, the Ford Contour possessed certain vulnerabilities that, when combined with poor maintenance practices or aggressive driving habits, could lead to premature failure of critical components.

Understanding these weak points is crucial for current owners who want to maximize their vehicle’s lifespan and potential buyers considering a used Contour purchase.

The automotive world mid to late 1990s was characterized by rapid technological advancement and intense competition. Manufacturers were pushing boundaries with new materials, more complex electronic systems, and tighter engineering tolerances.

While these innovations often resulted in improved performance and efficiency, they also sometimes created new failure modes that weren’t fully understood until vehicles had accumulated significant real-world mileage.

The Contour’s European heritage brought sophisticated engineering solutions, but it also introduced complexity that some American service technicians weren’t initially familiar with.

This knowledge gap, combined with the vehicle’s specific maintenance requirements and inherent design characteristics, created a perfect storm for premature failures when owners didn’t follow proper care protocols.

This comprehensive guide examines eight critical mistakes that can significantly shorten a Ford Contour’s operational life. From engine management oversights to transmission abuse, cooling system neglect to electrical system mishandling, we’ll explore how seemingly minor oversights can cascade into major mechanical failures.

Each section provides detailed explanations of the underlying mechanisms, warning signs to watch for, and preventive measures that can help you avoid these costly pitfalls.

Whether you’re a current Contour owner looking to extend your vehicle’s life or a prospective buyer seeking to make an informed decision, understanding these potential failure modes will help you maintain this unique piece of Ford’s automotive history for years to come.

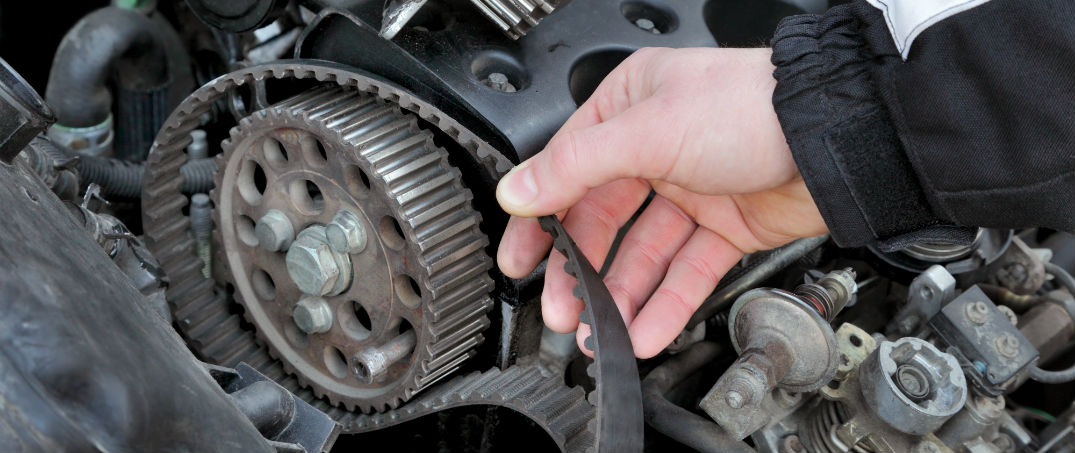

1. Ignoring the Timing Belt Service Interval

The timing belt represents one of the most critical maintenance items on Ford Contour models equipped with interference engines, particularly the 2.0L Zetec four-cylinder engine.

This seemingly simple rubber belt with reinforcing cords performs the vital function of synchronizing the rotation of the crankshaft and camshaft, ensuring that the engine’s valves open and close at precisely the right moments during each combustion cycle. When this synchronization fails due to timing belt failure, the consequences can be catastrophic and financially devastating.

Ford’s recommended timing belt replacement interval for the Contour varies depending on the specific engine and model year, but generally falls between 60,000 to 100,000 miles.

However, these recommendations assume normal driving conditions and proper maintenance of related components. Real-world conditions often accelerate timing belt deterioration through exposure to extreme temperatures, oil contamination, coolant leaks, and the natural aging process that affects all rubber components.

The interference engine design used in many Contour models means that the pistons and valves occupy the same space within the cylinders, but at different times during the engine cycle.

The timing belt ensures this choreographed dance continues smoothly. When the belt breaks, stretches excessively, or jumps timing due to worn tensioner components, the carefully orchestrated timing relationship collapses.

Pistons moving upward can collide with valves that should be closed, resulting in bent valves, damaged pistons, cylinder head damage, and potentially even crankshaft problems.

Warning signs of timing belt deterioration include unusual noises from the front of the engine, particularly during startup or acceleration. A worn timing belt may produce squealing, chirping, or rattling sounds as it struggles to maintain proper tension and alignment.

Visual inspection through the timing belt covers may reveal cracking, fraying, missing teeth, or oil contamination on the belt surface. However, many timing belt failures occur without obvious warning signs, which is why preventive replacement based on mileage and time intervals is so crucial.

The complexity of timing belt replacement on the Ford Contour cannot be overstated. The procedure typically requires the removal of multiple engine accessories, motor mounts, and covers to access the timing belt assembly.

Professional technicians must carefully align timing marks on the crankshaft and camshaft before installing the new belt, and proper tensioning requires specialized tools and expertise.

The water pump, being driven by the timing belt and often requiring similar labor for access, is frequently replaced simultaneously to maximize efficiency and prevent future failures.

Preventive timing belt service should include replacement of related components such as the timing belt tensioner, idler pulleys, and water pump.

These components often wear at similar rates, and their failure can cause timing belt problems or leave you stranded shortly after expensive timing belt service.

The investment in comprehensive timing belt service, while substantial, pales in comparison to the cost of engine rebuild or replacement that follows timing belt failure in an interference engine.

2. Neglecting Regular Oil Changes and Using Wrong Oil Specifications

Engine oil serves as the lifeblood of your Ford Contour’s powerplant, performing multiple critical functions that directly impact engine longevity and performance. Beyond basic lubrication, modern engine oils provide cooling, cleaning, sealing, and protection against corrosion and wear.

The Ford Contour’s engines, particularly the higher-performance variants, demand specific oil viscosities and quality levels to maintain optimal operation.

Neglecting regular oil changes or using inappropriate oil specifications can trigger a cascade of mechanical problems that quickly escalate into catastrophic engine failure.

The Ford Contour’s engines were designed during an era of rapidly evolving oil technology and increasingly stringent emissions requirements. These factors necessitated tighter manufacturing tolerances, more sophisticated valve train designs, and higher operating temperatures than previous generations of Ford engines.

The 2.5L Duratec V6 engine, in particular, features aluminum construction and variable valve timing components that are extremely sensitive to oil quality and contamination levels.

Oil change intervals for the Ford Contour typically range from 5,000 to 7,500 miles under normal driving conditions, but severe service conditions can significantly accelerate oil degradation.

Stop-and-go traffic, short trip driving, extreme temperatures, dusty conditions, and aggressive driving all qualify as severe service and may require more frequent oil changes.

Many Contour owners mistakenly assume that modern synthetic oils allow for extended change intervals without considering their specific driving patterns and environmental conditions.

Using the wrong oil viscosity can cause immediate and long-term problems. Oils that are too thick may not circulate properly during cold starts, leading to inadequate lubrication of critical components during the most vulnerable period of engine operation.

Conversely, oils that are too thin may not provide adequate protection under high-temperature, high-stress conditions, allowing metal-to-metal contact and accelerated wear. The Ford Contour’s variable valve timing systems and hydraulic valve adjusters are particularly sensitive to oil viscosity variations.

Oil contamination presents another serious threat to engine longevity. Fuel dilution, coolant contamination, metal particles from normal wear, and combustion byproducts all accumulate in the oil over time.

Extended oil change intervals allow these contaminants to reach concentrations that overwhelm the oil’s cleaning and protective capabilities. Sludge formation, particularly problematic in Ford’s engines of this era, can block oil passages, starve components of lubrication, and cause catastrophic bearing failures.

The oil filter plays a crucial role in maintaining oil cleanliness, but its capacity is finite. Overextended oil change intervals can lead to filter bypass, where contaminated oil bypasses the clogged filter and circulates through the engine without filtration.

High-quality oil filters designed specifically for the Ford Contour’s applications should always be used, as generic filters may not provide adequate filtration or may fail prematurely under the engine’s operating conditions.

Regular oil analysis can provide valuable insights into engine condition and oil performance. By monitoring wear metals, contamination levels, and oil condition through laboratory analysis, owners can optimize change intervals and identify potential problems before they become catastrophic failures.

This proactive approach is particularly valuable for high-mileage Contours where early detection of bearing wear, cylinder wear, or cooling system problems can prevent expensive repairs.

3. Overheating Due to Cooling System Neglect

The cooling system in a Ford Contour represents a sophisticated network of components working in harmony to maintain optimal engine operating temperatures.

This system faces unique challenges due to the Contour’s compact engine bay packaging, aluminum engine components, and the heat-generating demands of modern emission control systems.

Cooling system neglect can quickly transform a reliable daily driver into an expensive paperweight, as overheating events cause cumulative damage that often proves economically fatal for older vehicles.

Ford Contour cooling systems utilize a pressurized design with an aluminum radiator, electric cooling fans, a thermostat-controlled circulation system, and various sensors to monitor and regulate temperature.

The system’s aluminum radiator cores, while lightweight and efficient, are more susceptible to corrosion and electrolytic damage than traditional copper-brass designs. This vulnerability becomes particularly pronounced when owners neglect coolant maintenance or mix incompatible coolant types.

Coolant degradation represents one of the most insidious threats to cooling system integrity. Over time, coolant loses its corrosion inhibitors, becomes acidic, and develops conductive properties that accelerate galvanic corrosion between dissimilar metals in the engine.

The Ford Contour’s aluminum engine blocks and cylinder heads are particularly vulnerable to this type of corrosion, which can create coolant leaks, combustion chamber contamination, and expensive internal engine damage.

The thermostat, often overlooked during routine maintenance, plays a critical role in engine warm-up characteristics and cooling efficiency.

A stuck-closed thermostat can cause rapid overheating and immediate engine damage, while a stuck-open thermostat prevents proper engine warm-up, reducing efficiency and increasing emissions.

Original equipment thermostats are calibrated for specific opening temperatures that optimize the Ford Contour’s performance characteristics, and aftermarket substitutes may not provide equivalent protection.

Water pump failure represents another common cooling system vulnerability in Ford Contours. The water pump’s impeller, seals, and bearings experience constant stress from coolant circulation, temperature cycling, and chemical exposure.

Early warning signs of water pump problems include coolant leaks from the weep hole, unusual noises during engine operation, and gradual temperature increases under load conditions. Unfortunately, water pump failures often occur without warning, leaving drivers stranded with potentially severe engine damage.

Radiator cap functionality, though simple in concept, proves critical for cooling system operation. The cap maintains system pressure, which raises the coolant’s boiling point and improves heat transfer efficiency.

A failing radiator cap can allow coolant to boil at lower temperatures, create air pockets in the cooling system, and lead to overheating despite adequate coolant levels. Regular pressure testing of the radiator cap should be part of routine cooling system maintenance.

Electric cooling fan operation becomes crucial during low-speed driving, air conditioning operation, and stop-and-go traffic conditions. The Ford Contour’s cooling fans are controlled by temperature sensors and the engine management system, creating multiple potential failure points.

Fan motor failures, relay problems, temperature sensor malfunctions, and wiring issues can all prevent proper fan operation, leading to overheating in traffic conditions where the vehicle previously performed flawlessly.

Preventive cooling system maintenance should include regular coolant replacement using the correct specification fluid, pressure testing to identify leaks before they become critical, thermostat replacement at appropriate intervals, and inspection of all system components, including hoses, clamps, and connections. The relatively modest cost of preventive maintenance pales in comparison to engine replacement costs following severe overheating damage.

4. Automatic Transmission Abuse and Poor Maintenance

The automatic transmission in Ford Contour vehicles represents a sophisticated piece of engineering that enables smooth, efficient power delivery from the engine to the wheels.

However, this complexity also creates numerous opportunities for premature failure when owners engage in abusive driving practices or neglect proper maintenance procedures.

Understanding how transmission abuse accelerates wear and failure modes is crucial for maximizing the operational life of these often-expensive-to-replace components.

Ford Contours were equipped with various automatic transmission designs depending on model year and engine combination, including the CD4E and other electronically controlled units.

These transmissions feature multiple planetary gear sets, hydraulic control systems, electronic solenoids, and sophisticated computer controls that optimize shift timing and quality based on driving conditions and driver inputs.

This complexity provides excellent drivability when properly maintained, but creates multiple failure points when subjected to abuse or neglect. Transmission fluid serves multiple critical functions beyond simple lubrication.

It acts as a hydraulic medium for clutch and band operation, provides cooling for internal components, and contains detergents and dispersants that keep the transmission clean.

Ford specifies particular transmission fluid types for Contour applications, and using incorrect fluids can cause immediate problems with shift quality, component swelling or shrinkage, and accelerated wear of friction materials.

Heat represents the greatest enemy of automatic transmission longevity. Normal operation generates significant heat through fluid shear, clutch engagement, and torque converter operation.

Aggressive driving practices such as frequent full-throttle acceleration, racing, trailer towing without proper cooling, and prolonged high-speed operation can push transmission temperatures beyond safe limits.

Sustained operation above optimal temperature ranges causes fluid breakdown, seal deterioration, and component warping that quickly progresses to complete transmission failure.

Regular transmission service should include fluid and filter changes at appropriate intervals, typically every 30,000 to 60,000 miles depending on driving conditions.

This service removes accumulated contaminants, replaces worn-out additives, and allows inspection of the transmission’s internal condition through examination of the old fluid and filter.

Bands, clutches, and other wear items gradually accumulate metal particles and friction material debris that can accelerate wear of other components if not removed through regular service.

Also Read: 10 Tricks That Keep a GMC Envoy Reliable for 300,000 Miles

5. Ignoring Warning Signs of Fuel System Problems

The fuel system in a Ford Contour represents a precisely calibrated network of components designed to deliver clean, pressurized fuel to the engine’s injection system while maintaining emissions compliance and optimal performance.

Modern fuel injection systems operate at high pressures with extremely tight tolerances, making them vulnerable to contamination, component wear, and system degradation that can quickly progress from minor drivability issues to complete engine failure if warning signs are ignored.

Fuel quality plays a fundamental role in system longevity and performance. Today’s reformulated gasoline contains various additives, alcohol blends, and detergents that can interact with fuel system components in unexpected ways.

Water contamination, particularly problematic with ethanol-blended fuels, can cause corrosion in fuel lines, filters, and injection components while supporting microbial growth that clogs filters and creates acidic byproducts.

The Ford Contour’s fuel system components were designed during the transition period to higher ethanol content fuels, making them potentially vulnerable to alcohol-related degradation.

The fuel pump, typically mounted in the fuel tank, operates under challenging conditions including temperature extremes, contamination exposure, and continuous duty cycles. Electric fuel pumps generate significant heat during operation and rely on fuel flow for cooling.

Operating with low fuel levels forces the pump to work harder and reduces its cooling, accelerating wear and increasing failure probability. Fuel pump problems often manifest as intermittent symptoms that gradually worsen, including hard starting, stumbling during acceleration, and complete stalling.

Fuel filter obstruction represents another common but often overlooked problem. The fuel filter protects sensitive injection components from contamination but has a finite capacity.

Gradual filter restriction can cause fuel starvation symptoms that mimic more expensive problems like fuel pump failure or injection system malfunctions. Symptoms typically appear first during high-demand situations like highway acceleration or climbing hills, where fuel flow requirements exceed the restricted filter’s capacity.

Preventive fuel system maintenance should include regular fuel filter replacement, use of quality fuels with appropriate detergent packages, and periodic fuel system cleaning to remove deposits and contamination.

Fuel additives can provide some benefit, but they should be used judiciously and according to manufacturer recommendations. Professional fuel system diagnosis requires specialized pressure testing equipment and scan tools capable of monitoring fuel system parameters in real-time.

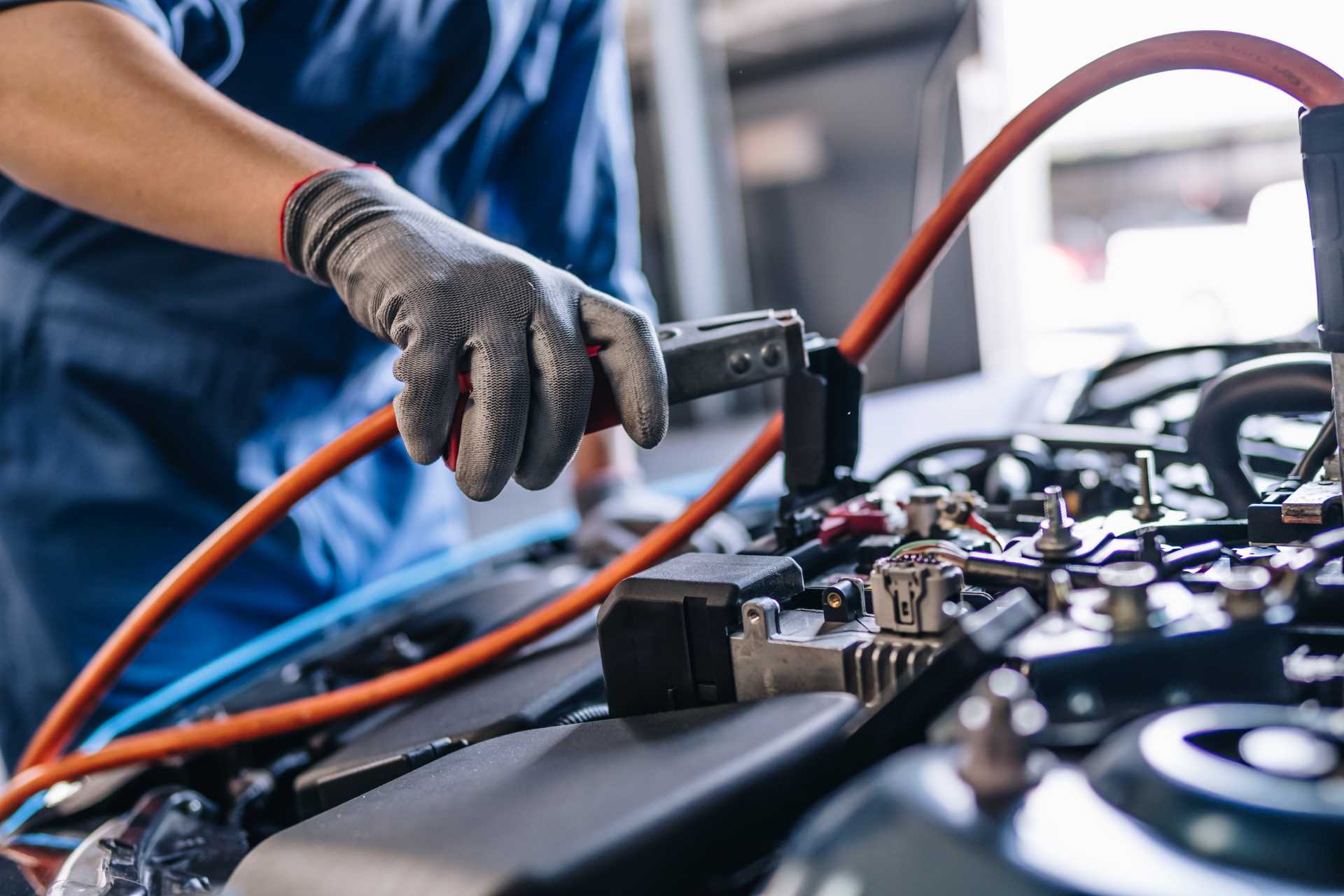

6. Electrical System Abuse and Aftermarket Installation Errors

The electrical system in a Ford Contour represents a complex network of circuits, control modules, sensors, and actuators that coordinate engine management, transmission operation, safety systems, and comfort features.

This system’s complexity increased significantly during the Contour’s production years as manufacturers integrated more sophisticated electronics to meet emissions requirements and consumer expectations.

Unfortunately, this complexity also created numerous opportunities for expensive failures when owners engage in improper modification practices or neglect basic electrical system maintenance.

Modern automotive electrical systems operate on precise voltage and current specifications, with many components sensitive to variations in power quality.

The Ford Contour’s charging system, consisting of the alternator, voltage regulator, and battery, must maintain consistent voltage output across varying engine speeds and electrical loads.

Aftermarket electrical accessories that exceed the system’s capacity or create electrical noise can disrupt sensitive electronic components and cause seemingly unrelated problems throughout the vehicle.

Improper aftermarket installations represent one of the most common causes of electrical system problems in Ford Contours. Aftermarket stereo systems, alarm systems, remote starters, and performance modifications often require connections to existing vehicle wiring.

When these installations are performed incorrectly, they can create voltage drops, current overloads, electromagnetic interference, and ground loops that affect multiple vehicle systems. Professional installation techniques, including proper wire sizing, fusing, and routin,g are essential for maintaining system integrity.

Ground connection quality proves critical for reliable electrical system operation. The Ford Contour uses multiple ground points throughout the chassis and engine bay to complete electrical circuits.

Corrosion, looseness, or poor connections at these ground points can cause intermittent electrical problems that are difficult to diagnose and may affect multiple systems simultaneously. Regular inspection and maintenance of ground connections should be part of routine electrical system service.

Engine management system electrical problems can cause symptoms ranging from minor performance issues to complete engine shutdown. The Ford Contour’s engine control module communicates with numerous sensors and actuators through dedicated wiring networks.

Electrical problems in these circuits can cause error codes, reduced performance, increased emissions, and potential engine damage if critical sensors fail. Professional diagnosis requires specialized scan tools and electrical testing equipment to properly isolate and repair these problems.

7. Suspension Component Wear Through Aggressive Driving

The suspension system in a Ford Contour was designed to provide a balance between ride comfort and handling precision that appealed to drivers seeking a more engaging driving experience than typical American compact cars of the era.

This sophisticated suspension design, borrowed from Ford’s European operations, featured advanced geometry and tuning that delivered excellent road manners when properly maintained.

However, the system’s complexity and performance orientation also made it vulnerable to accelerated wear when subjected to aggressive driving practices or poor maintenance habits.

Ford engineered the Contour’s suspension with sport-oriented characteristics, including firmer spring rates, precisely tuned damping, and sophisticated control arm geometry.

While these design choices provided responsive handling and good road feel, they also transmitted more road impacts to suspension components and created higher stress levels during aggressive driving maneuvers.

The suspension components were sized appropriately for normal driving conditions, but could be overwhelmed by consistent abuse or extreme operating conditions.

Shock absorber and strut assemblies bear the primary responsibility for controlling suspension movement and maintaining tire contact with the road surface.

The Ford Contour’s dampers were calibrated for specific performance characteristics that complement the spring rates and suspension geometry.

Worn dampers allow excessive suspension movement that can cause tire wear, handling degradation, and increased stress on other suspension components. Signs of damper wear include bouncing after hitting bumps, nose diving during braking, and excessive body roll during cornering.

Ball joints and control arm bushings represent critical wear points in the Ford Contour’s suspension system. These components allow controlled movement between suspension members while maintaining proper wheel alignment geometry.

Aggressive driving practices, including hard cornering, rapid acceleration, and abrupt braking, create increased forces that accelerate ball joint and bushing wear. Worn components can cause alignment changes, tire wear, and potentially dangerous handling characteristics, including wheel separation in extreme cases.

Tire selection and maintenance significantly impact suspension component wear and vehicle handling. The Ford Contour was designed around specific tire sizes and performance characteristics that complement the suspension tuning.

Inappropriate tire selections, incorrect air pressures, or worn tires can alter the vehicle’s handling balance and create increased stress on suspension components. Regular tire rotation, pressure monitoring, and replacement with appropriate specifications help maintain the intended suspension performance and component longevity.

8. Premature Clutch Failure in Manual Transmission Models

Manual transmission Ford Contours equipped with clutch systems require careful operation and maintenance to achieve their intended service life.

The clutch assembly represents a sophisticated friction-based coupling system that enables smooth power transfer from the engine to the transmission while allowing for gear changes and vehicle starting.

However, the clutch system’s reliance on friction materials and precise hydraulic operation makes it vulnerable to premature failure when subjected to abusive driving practices or inadequate maintenance procedures.

The clutch system in the manual transmission Ford Contours consists of several critical components, including the clutch disc, pressure plate, release bearing, and hydraulic actuation system.

Each component must function properly for smooth clutch operation, and failure of any single element can affect the entire system’s performance. The clutch disc contains friction materials similar to brake pads that gradually wear during normal operation but can be quickly destroyed by abusive driving practices.

Riding the clutch represents one of the most destructive habits that manual transmission drivers can develop. This practice involves partially engaging the clutch during normal driving, often unconsciously, which creates continuous slippage between the clutch disc and flywheel.

The resulting friction generates excessive heat that quickly degrades the clutch disc material and can cause pressure plate warping, flywheel damage, and premature release bearing failure.

Proper clutch operation requires complete engagement or disengagement with minimal time spent in the transition zone. Aggressive starting techniques can dramatically reduce clutch life in Ford Contours.

High-performance starts that involve slipping the clutch while applying significant engine power create extreme heat and wear conditions that quickly consume clutch disc material.

This practice is particularly destructive when combined with repeated attempts, as the accumulated heat can exceed the clutch system’s thermal capacity and cause permanent damage to multiple components.

The flywheel condition significantly affects clutch performance and longevity in the manual transmission Ford Contours. The flywheel provides the friction surface for clutch engagement and must maintain proper surface finish and flatness for optimal operation.

Overheated or damaged flywheels can cause clutch chatter, incomplete engagement, and rapid clutch disc wear. Professional resurfacing or replacement of damaged flywheels is essential for reliable clutch operation and maximum component life.

Also Read: 7 Mistakes That Kill a Jeep Wrangler Sahara Too Soon