The Nissan 200SX stands as one of the most beloved and enduring sports cars in automotive history, capturing enthusiasts across multiple generations with its perfect blend of performance, reliability, and affordability.

From its introduction in the late 1970s through various iterations spanning decades, the 200SX has earned a reputation as a driver’s car that delivers genuine excitement without breaking the bank.

Whether you own a classic S10, the turbocharged S12, the legendary S13, the refined S14, or the final S15 generation, understanding how to maintain your 200SX properly is crucial for preserving its performance characteristics and extending its lifespan.

These iconic vehicles have become increasingly valuable as modern classics, making proper maintenance not just about reliability, but also about preserving automotive heritage and investment value.

The 200SX’s popularity stems from its excellent weight distribution, responsive handling, and robust engineering that allows for both daily driving and spirited weekend adventures.

However, like any performance vehicle, particularly those that have aged gracefully over the years, the 200SX requires specific attention to certain systems and components to maintain its legendary reliability and driving dynamics. Many 200SX owners discover that these cars respond exceptionally well to preventive maintenance and proper care.

The SR20DET and CA18DET turbocharged engines, along with the naturally aspirated variants, are fundamentally solid powerplants that can deliver hundreds of thousands of miles of service when treated with respect and maintained according to best practices.

Similarly, the chassis, suspension components, and drivetrain systems benefit tremendously from regular attention and quality replacement parts. The key to keeping any 200SX running strong lies in understanding its unique characteristics, common wear points, and the maintenance practices that have been proven effective by decades of owner experience.

From engine management and cooling system optimization to suspension care and electrical system maintenance, each aspect of the vehicle requires specific knowledge and attention to detail.

This comprehensive guide presents ten essential tricks that have been tested and refined by 200SX enthusiasts, professional mechanics, and racing teams worldwide.

These strategies extend beyond basic maintenance schedules to address the specific needs and vulnerabilities of the 200SX platform, enabling you to maximize performance, reliability, and longevity while minimizing unexpected repairs and downtime.

1. Master the Art of Proper Engine Oil Management

Engine oil management represents perhaps the most critical aspect of 200SX maintenance, particularly for turbocharged models where oil serves the dual purpose of lubricating engine components and cooling the turbocharger’s rotating assembly.

The high-revving nature of SR20DET and CA18DET engines, combined with their relatively tight tolerances, makes oil quality and change intervals absolutely paramount for long-term reliability.

Understanding the selection of oil viscosity is crucial for optimal performance. Most 200SX engines perform best with 5W-30 or 0W-30 synthetic oils in moderate climates, though owners in extremely hot regions may benefit from 5W-40 viscosity.

The key lies in balancing adequate flow at startup with sufficient protection at operating temperature. Synthetic oils offer superior thermal stability and resistance to breakdown under the high temperatures generated by turbochargers, making them virtually mandatory for turbocharged 200SX models.

Oil change intervals should be significantly shorter than manufacturer recommendations, especially for modified or hard-driven vehicles. While Nissan may have specified 6,000-mile intervals, experienced 200SX owners typically change oil every 3,000 miles or less, with some track-focused builds requiring changes after every few events.

This frequent maintenance prevents oil degradation that can lead to bearing damage, turbo failure, and timing chain stretch. Monitoring oil consumption patterns provides valuable insight into engine health.

A healthy SR20 or CA18 engine should consume minimal oil between changes, though slight consumption under hard driving is normal. Sudden increases in oil consumption often indicate worn valve seals, piston rings, or turbo seals, allowing early intervention before catastrophic failure occurs.

Pre-turbo cool-down procedures extend turbocharger life significantly. After hard driving, allow the engine to idle for several minutes before shutdown, permitting oil and coolant circulation to remove heat from the turbo’s center section.

Some owners install turbo timer systems that automatically maintain idle for predetermined periods, though manual cool-down periods are equally effective with proper discipline.

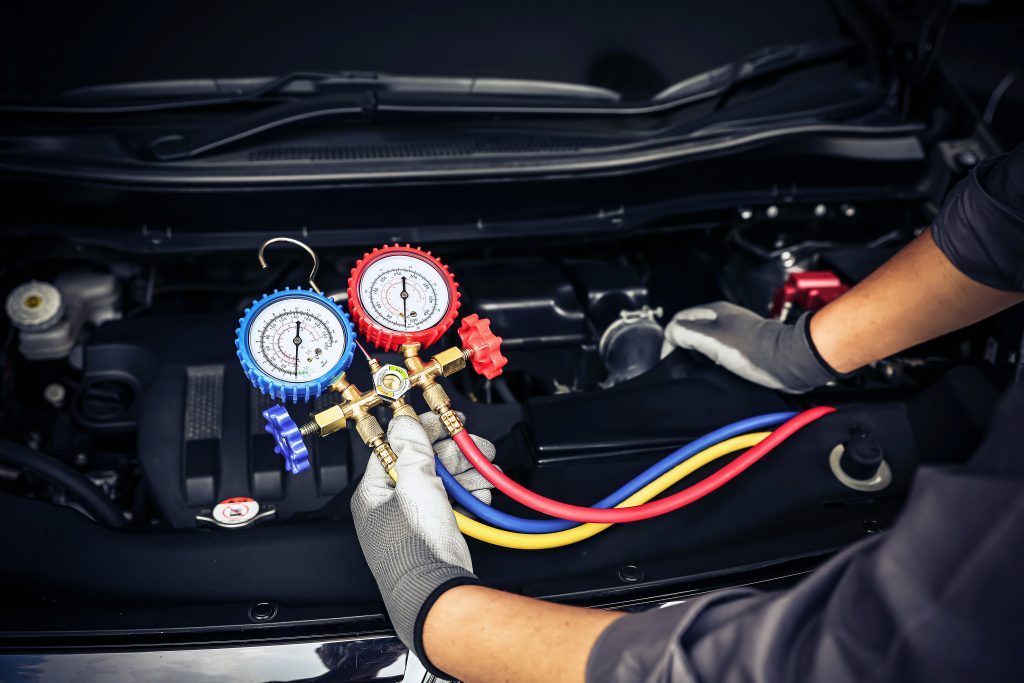

2. Optimize Your Cooling System for Maximum Efficiency

The cooling system in a 200SX requires meticulous attention, particularly in turbocharged models where heat management directly impacts performance and reliability.

Factory cooling systems were often marginal even when new, and decades of age combined with potential modifications make cooling system optimization essential for preventing overheating and subsequent engine damage.

Radiator selection forms the foundation of effective cooling system management. While factory radiators may suffice for stock, gently driven vehicles, most 200SX owners benefit from upgrading to aluminum aftermarket radiators with increased core thickness and improved fin density.

Brands like Koyo, Mishimoto, and ISR offer direct-fit replacements that provide significantly better heat dissipation than original equipment. When selecting radiators, prioritize core thickness and construction quality over flashy appearance, as function trumps form in cooling applications.

Thermostat operation directly affects cooling system efficiency and engine warm-up characteristics. Most 200SX engines utilize 180°F thermostats, though some owners experiment with 160°F units for maximum cooling.

However, excessively low thermostat temperatures can prevent the engine from reaching optimal operating temperature, potentially causing increased wear and reduced fuel economy.

Ensure thermostat replacement includes new gaskets and proper bleeding procedures to eliminate air pockets that cause localized hot spots. Water pump maintenance often gets overlooked until failure occurs, typically resulting in catastrophic overheating.

Replace water pumps preemptively during timing belt service, as the labor overlap makes economic sense. Signs of impending water pump failure include coolant weeping from the pump housing, bearing noise, or excessive play in the pump pulley.

Quality replacement pumps from Gates, Aisin, or OEM suppliers provide superior longevity compared to economy alternatives. System pressure testing reveals leaks before they cause overheating incidents.

Annual pressure testing identifies failing hoses, gaskets, and seals that might otherwise fail during high-temperature operation. Pay particular attention to heater core connections, lower radiator hose conditions, and water pump sealing, as these represent common failure points in aging 200SX cooling systems.

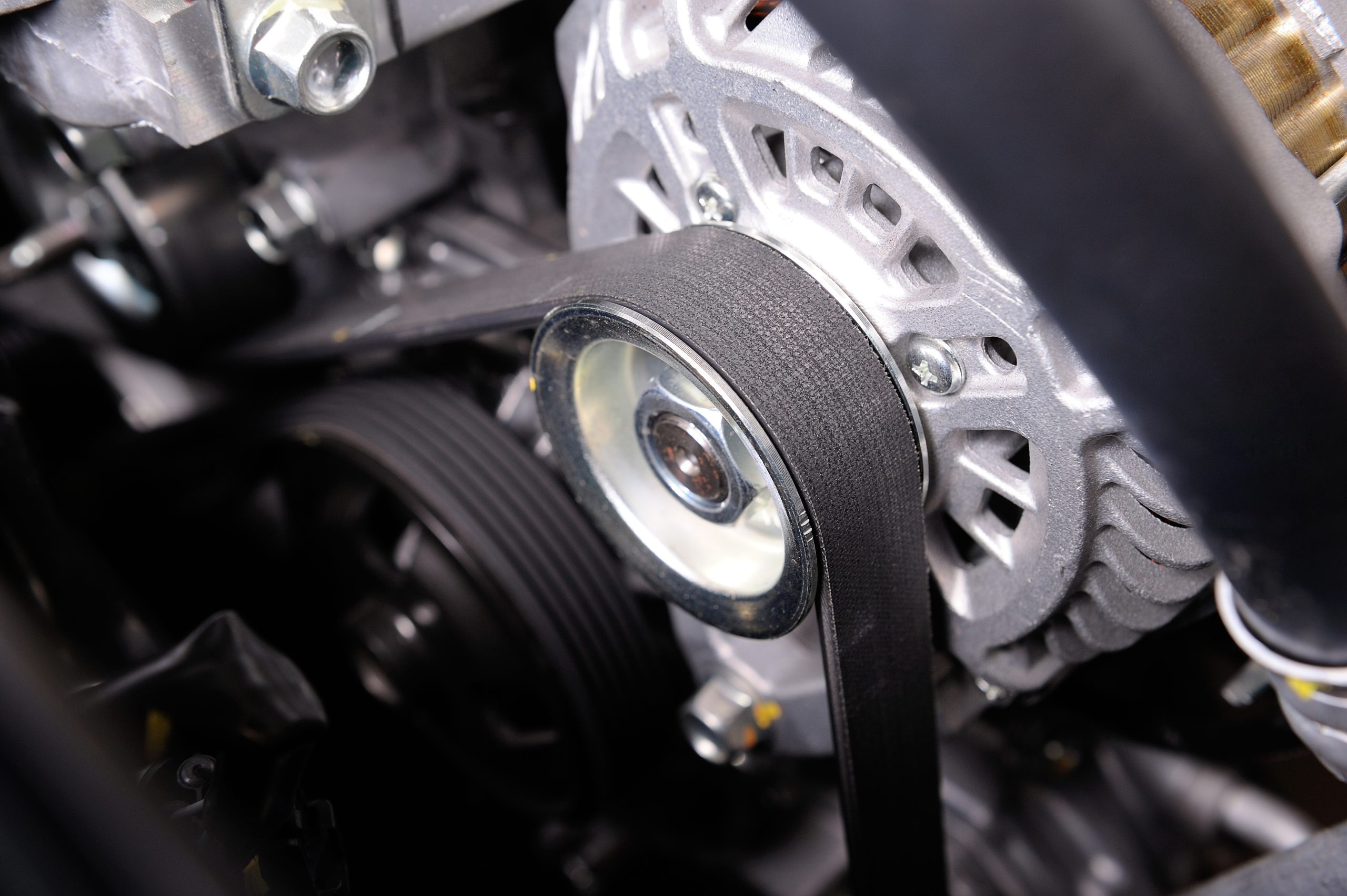

3. Maintain Timing Belt and Chain Systems Religiously

Timing system maintenance represents one of the most critical aspects of 200SX ownership, as failure typically results in catastrophic engine damage due to interference engine designs.

Whether your 200SX utilizes a timing belt or chain system depends on the specific engine variant, but both require diligent maintenance to prevent costly failures that can destroy pistons, valves, and cylinder heads.

Timing belt intervals must be strictly observed, with most SR20 and CA18 engines requiring replacement every 60,000 miles or five years, whichever comes first.

However, many experienced owners replace belts more frequently, particularly in high-performance applications where increased stress and temperature cycles accelerate belt degradation.

Age-related deterioration can cause belt failure even with low mileage, making time-based replacement intervals equally important as mileage considerations.

When replacing timing belts, simultaneous replacement of all related components represents sound maintenance practice. Water pumps, tensioners, idler pulleys, and seals should be replaced together, as their similar service lives and overlapping labor requirements make piecemeal replacement economically inefficient.

Quality component selection proves crucial, with Gates, Aisin, and OEM parts providing superior reliability compared to economy alternatives that may fail prematurely.

Timing chain systems, while generally more durable than belts, require different maintenance approaches. Chain stretch occurs gradually over time, eventually affecting valve timing and potentially causing chain jump or failure.

Regular inspection of chain tension and timing marks helps identify developing problems before catastrophic failure. Listen for chain rattle during startup, particularly when cold, as this often indicates excessive stretch or tensioner wear.

Professional installation versus DIY timing system work depends on individual skill levels and available tools. While timing belt replacement is within the capabilities of experienced home mechanics, the consequences of errors make professional installation worthwhile for many owners.

Timing chain work often requires more specialized tools and knowledge, making professional service advisable unless you possess significant mechanical experience and proper equipment.

4. Perfect Your Fuel System Maintenance Strategy

Fuel system maintenance in the 200SX requires understanding both the mechanical components and the electronic fuel injection systems that evolved significantly throughout the model’s production run.

Proper fuel system care ensures optimal performance, prevents costly injector damage, and maintains the precise air-fuel ratios necessary for both power production and engine longevity, particularly in turbocharged applications where fuel quality directly impacts detonation resistance.

Fuel filter replacement represents the most fundamental aspect of fuel system maintenance, yet it’s often neglected until flow restrictions cause performance problems.

Most 200SX models utilize both a main fuel filter and a pre-filter in the tank, with replacement intervals typically ranging from 15,000 to 30,000 miles depending on fuel quality and driving conditions.

Clogged filters reduce fuel pressure, causing lean conditions that can damage engines, particularly under boost, where adequate fuel flow becomes critical for detonation prevention.

Fuel pump maintenance becomes increasingly important as vehicles age, with pump failure often preceded by gradually declining performance that’s easily mistaken for other issues.

Monitor fuel pressure regularly using a mechanical gauge, ensuring pressure meets specifications at idle, cruise, and wide-open throttle conditions.

Most SR20DET engines require approximately 36 PSI of base fuel pressure, though specific requirements vary by year and boost level. Fuel pressure that falls below specification under load indicates pump degradation or system restriction.

Injector cleaning and maintenance directly affect engine performance, fuel economy, and emissions output. Over time, fuel injectors accumulate deposits that alter spray patterns and flow rates, potentially causing individual cylinder fuel distribution problems.

Professional injector cleaning services can restore proper operation in most cases, though severely contaminated or damaged injectors require replacement. Consider upgrading to larger injectors if power modifications exceed the capacity of stock units, ensuring proper tuning accompanies any injector changes.

Fuel system pressure testing reveals developing problems before they cause performance issues or component damage. Annual testing should include static pressure, pressure under load, and fuel pressure regulator operation.

Pay particular attention to vacuum line condition and routing, as vacuum leaks can cause fuel pressure regulation problems that affect performance and fuel economy.

Document baseline pressure readings for future comparison, particularly important in modified vehicles where fuel system capacity may approach limits.

Also Read: 5 Heated Seat Systems That Last Beyond 100K Miles vs. 5 That Fail Mid-Winter

5. Suspension and Steering Component Care

Suspension maintenance in the 200SX directly impacts both handling performance and component longevity, with the multilink rear suspension design being particularly sensitive to worn bushings and components.

The 200SX’s reputation for excellent handling depends entirely on maintaining tight tolerances throughout the suspension system, making regular inspection and replacement of wear items essential for preserving the driving experience that makes these cars special.

Bushing inspection and replacement represent perhaps the most critical aspect of 200SX suspension maintenance. The multilink rear suspension utilizes numerous bushings that control wheel movement and alignment, with worn bushings causing dramatic changes in handling characteristics and tire wear patterns.

Inspect bushings regularly for cracking, deformation, or separation from their mounting points. Polyurethane bushings offer increased longevity and more precise handling than rubber alternatives, though they may transmit more noise and vibration to the chassis.

Strut and shock absorber condition affects both handling and ride quality, with replacement typically necessary every 60,000 to 80,000 miles depending on driving conditions and component quality.

Bilstein, KYB, and Tokico offer excellent replacement options that often provide superior performance compared to original equipment. When replacing struts, always replace strut mounts simultaneously, as worn mounts cause noise, vibration, and reduced handling precision.

Ball joint inspection requires regular attention, particularly in high-mileage vehicles where joint wear can cause dangerous handling characteristics and tire wear.

Check ball joints for excessive play by attempting to move the wheel while it’s supported off the ground. Replace ball joints in pairs to maintain consistent handling characteristics, and always perform alignment after ball joint replacement to ensure proper toe and camber settings.

Sway bar and end link condition affects body roll characteristics and handling balance. Inspect sway bar bushings for wear and end links for looseness or damage.

Worn sway bar components typically produce clunking noises over bumps and can affect handling predictability. Quality replacement bushings from Energy Suspension or Whiteline provide improved durability compared to stock rubber components, with some owners preferring the more precise feel of polyurethane alternatives despite their increased noise transmission.

6. Electrical System Health and Diagnostics

The electrical system in the 200SX evolved significantly throughout its production run, from relatively simple early systems to complex engine management and safety systems in later models.

Maintaining electrical system health requires understanding both basic electrical principles and the specific characteristics of Nissan’s systems, with particular attention to aging wiring, connectors, and ground connections that commonly cause intermittent problems.

Battery and charging system maintenance forms the foundation of electrical system reliability. The alternator should maintain approximately 13.5 to 14.5 volts at idle with all accessories operating, with voltage remaining stable under varying load conditions.

Test the charging system output regularly, particularly in vehicles with aftermarket electrical accessories that may overload the charging system. Replace the battery proactively every four to five years, as weak batteries can cause numerous electrical problems and may damage alternators through overwork.

Ground connection integrity represents a commonly overlooked aspect of electrical system maintenance that can cause numerous seemingly unrelated problems.

Clean and inspect all major ground points annually, including engine-to-chassis grounds, battery grounds, and body panel grounds. Poor ground connections can cause everything from instrument cluster problems to engine management issues, often creating intermittent problems that are difficult to diagnose.

Apply dielectric grease to ground connections to prevent corrosion and ensure long-term reliability. Wiring harness inspection becomes increasingly important as vehicles age, with particular attention to areas subject to heat, vibration, or moisture exposure.

Engine bay harnesses near exhaust components are particularly susceptible to damage, as are harnesses routed near suspension mounting points where movement can cause fatigue failures. Inspect for cracked or hardened insulation, and address any damage immediately to prevent more extensive problems.

Aftermarket electrical accessory installation requires careful planning to prevent system overload and ensure reliable operation. Calculate total electrical load before adding accessories, ensuring the charging system can maintain adequate voltage under all operating conditions.

Use proper gauge wiring for current requirements and install appropriate fusing to protect both accessories and vehicle wiring. Route new wiring away from heat sources and move components, securing it properly to prevent chafing or damage.

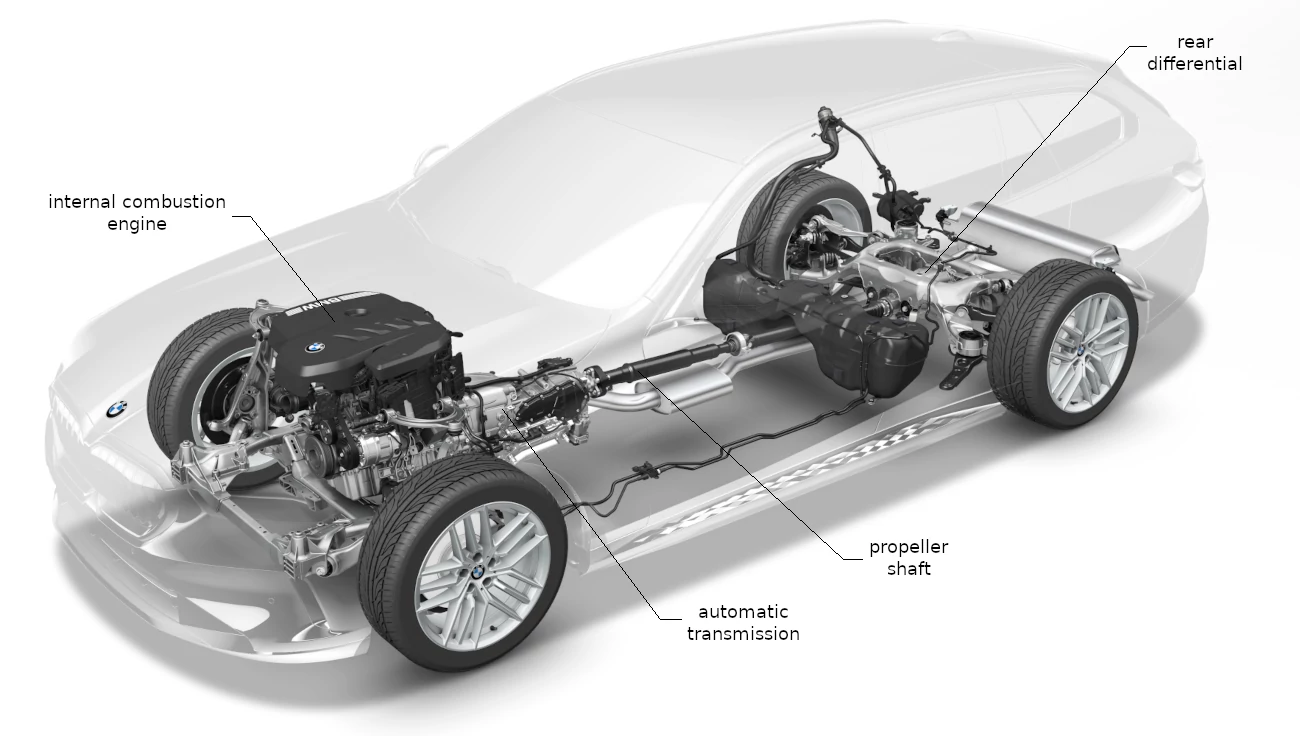

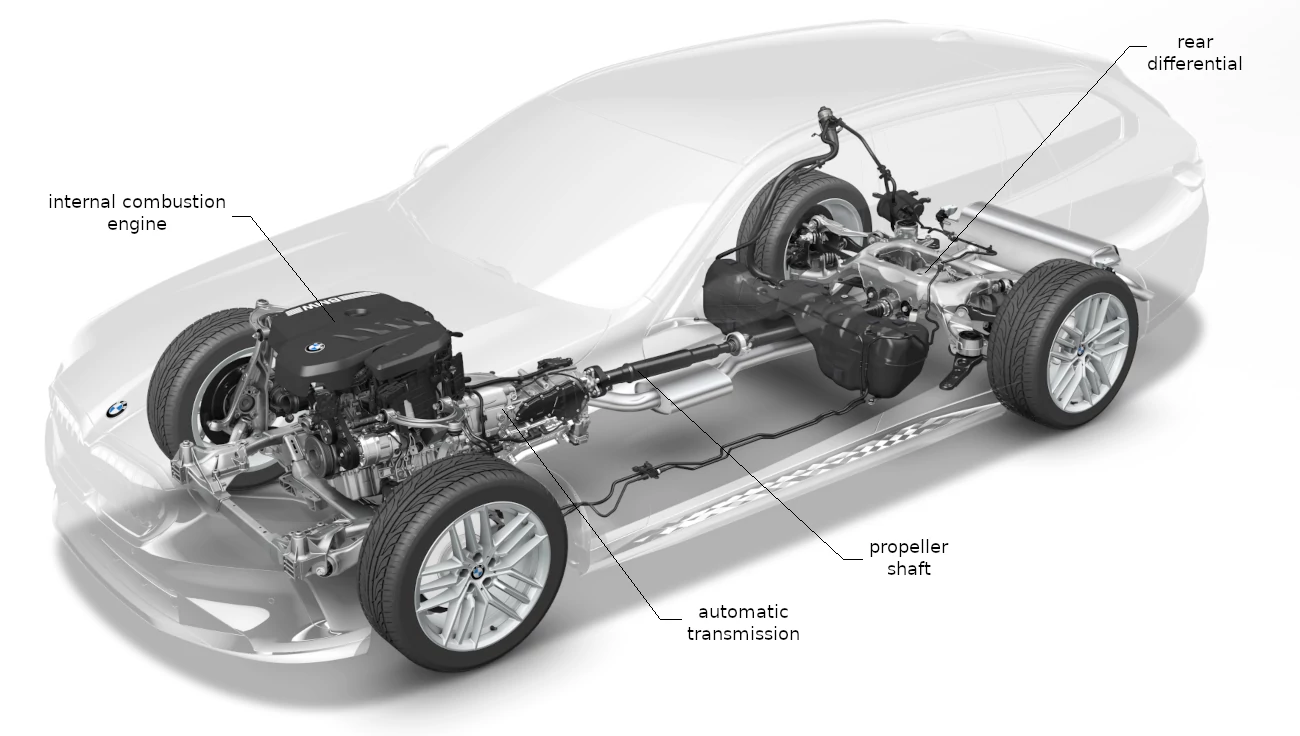

7. Transmission and Drivetrain Optimization

Transmission maintenance in the 200SX varies significantly between manual and automatic variants, with manual transmissions generally requiring less frequent service but benefiting greatly from proper fluid selection and change intervals.

The robust nature of most 200SX transmissions means they can provide hundreds of thousands of miles of service when maintained properly, though certain wear items and service procedures are critical for longevity.

Manual transmission fluid selection directly impacts shift quality, synchronizer life, and transmission longevity. Most 200SX manual transmissions perform best with 75W-90 synthetic gear oil, though some owners prefer slightly lighter viscosities for improved cold-weather shifting.

Avoid using automatic transmission fluid in manual transmissions unless specifically recommended by Nissan, as ATF may not provide adequate protection for synchronizers and bearings under high-load conditions.

Clutch system maintenance involves more than just clutch disc replacement, encompassing hydraulic system service, flywheel condition, and release bearing replacement.

Clutch hydraulic fluid should be flushed every two years or whenever the system is opened for service, using DOT 3 brake fluid or the manufacturer’s specified fluid.

Bleed the system thoroughly to remove all air bubbles, which can cause a spongy pedal feel and incomplete clutch release that damages synchronizers and clutch components. Differential maintenance often gets overlooked but significantly impacts drivetrain longevity and performance.

Limited-slip differentials require special fluid additives to prevent chatter and ensure proper operation, while conventional differentials benefit from regular gear oil changes using high-quality synthetic lubricants.

Inspect differential fluid regularly for contamination or unusual odors that might indicate bearing or gear problems, addressing any issues promptly to prevent catastrophic failure.

Automatic transmission service requires more frequent attention than manual units, with fluid and filter changes typically recommended every 30,000 to 50,000 miles, depending on driving conditions.

Use only the specified automatic transmission fluid, as incorrect fluid can cause shifting problems, seal damage, or complete transmission failure. Some automatic transmissions benefit from external coolers in high-performance applications or severe duty service, helping extend transmission life by reducing operating temperatures.

8. Brake System Excellence and Safety

Brake system maintenance in the 200SX requires understanding both the mechanical components and the specific characteristics of each model’s braking system, from basic disc brake setups in early models to more sophisticated ABS systems in later variants.

Proper brake maintenance ensures not only stopping performance but also component longevity and vehicle safety, making it one of the most critical aspects of 200SX ownership.

Brake fluid management represents the foundation of brake system maintenance, with fluid condition directly affecting pedal feel, component longevity, and stopping performance.

Brake fluid absorbs moisture over time, reducing its boiling point and causing corrosion of internal brake system components. Replace brake fluid every two years regardless of apparent condition, using DOT 3 or DOT 4 fluid as specified by Nissan.

Performance-oriented drivers may benefit from DOT 4 or racing brake fluids with higher boiling points, particularly important during track use or aggressive driving conditions.

Brake pad selection significantly impacts both performance and component wear, with numerous options available ranging from organic compounds for quiet daily driving to semi-metallic or ceramic compounds for enhanced performance.

Monitor pad thickness regularly and replace pads before they reach minimum thickness specifications, as worn pads can damage rotors and reduce braking effectiveness. Break in new pads properly according to the manufacturer’s instructions to ensure optimal performance and longevity.

Rotor maintenance and replacement require attention to both thickness measurements and surface condition. Rotors should be replaced when they reach minimum thickness specifications or exhibit significant warping, cracking, or grooving.

While rotor resurfacing can address minor issues, replacement with quality aftermarket rotors often provides better value and performance. Cross-drilled or slotted rotors may offer improved cooling and wet-weather performance but can be more susceptible to cracking under severe use.

Parking brake adjustment ensures proper holding power and prevents rear brake problems caused by excessive cable tension or inadequate adjustment.

Adjust parking brake cables according to service manual specifications, ensuring proper engagement without dragging when released. Inspect parking brake cables for fraying or corrosion that can cause binding or failure, replacing cables as necessary to maintain proper operation.

9. Air Intake and Exhaust System Optimization

Air intake and exhaust system maintenance in the 200SX directly impacts engine performance, fuel economy, and emissions compliance, with proper attention to these systems enabling engines to breathe efficiently and operate at their designed parameters.

Understanding airflow principles and component interactions allows owners to maintain optimal performance while avoiding modifications that might compromise reliability or drivability.

Air filter maintenance represents the most basic yet critical aspect of intake system care, with clogged filters dramatically reducing engine performance and fuel economy.

Replace air filters according to manufacturer recommendations or more frequently in dusty conditions, using quality paper filters for optimal filtration and airflow.

High-flow aftermarket filters may offer improved performance but require careful selection to ensure adequate filtration, particularly important in turbocharged applications where contamination can damage expensive turbo components.

Intake system inspection should include all ducting, connections, and sensors that can affect engine operation. Check for loose clamps, cracked ducting, or damaged sensors that can cause vacuum leaks and affect fuel mixture calculations.

Mass airflow sensors require periodic cleaning with appropriate solvents to maintain accuracy, as contaminated sensors can cause running problems and reduced performance.

Throttle body cleaning helps maintain smooth idle and throttle response, particularly important in vehicles with high mileage or those operated in dusty conditions.

PCV system maintenance prevents oil consumption problems and maintains proper crankcase ventilation that’s essential for engine longevity. Replace PCV valves according to manufacturer recommendations and inspect all vacuum lines for cracks or damage that can cause vacuum leaks.

Clogged PCV systems can cause oil leaks, rough idle, and increased oil consumption, while excessive blowby may indicate internal engine wear requiring attention.

Exhaust system modifications require careful consideration of backpressure effects, noise levels, and emissions compliance. While performance exhaust systems can improve power output, poorly designed systems may reduce low-end torque or create excessive noise that attracts unwanted attention.

Choose exhaust modifications based on your specific performance goals and local noise regulations, ensuring any changes complement rather than compromise vehicle performance and drivability.

10. Preventive Maintenance Scheduling and Documentation

Developing and maintaining a comprehensive preventive maintenance schedule represents the culmination of all previous maintenance strategies, creating a systematic approach that ensures no critical services are overlooked while optimizing maintenance intervals based on driving conditions and vehicle usage patterns.

Proper documentation enables trend analysis, warranty claim support, and provides valuable information for future owners, making meticulous record-keeping an essential aspect of responsible 200SX ownership.

Maintenance interval establishment requires balancing manufacturer recommendations with real-world experience and driving conditions. While factory service intervals provide baseline guidelines, most experienced 200SX owners develop customized schedules that reflect their specific usage patterns, environmental conditions, and performance modifications.

Severe service conditions, including frequent short trips, dusty environments, or performance driving, typically require shortened intervals for critical services like oil changes, air filters, and brake inspections. Documentation systems should capture all maintenance activities, parts used, and observations about vehicle condition or performance changes.

Modern smartphone apps offer convenient maintenance logging capabilities, though traditional paper logbooks remain equally effective for recording service history. Include dates, mileage, parts specifications, and any unusual observations that might indicate developing problems or successful maintenance strategies.

Performance monitoring through regular testing and observation enables early problem detection and validates maintenance effectiveness. Establish baseline performance measurements for acceleration, fuel economy, and operating parameters, monitoring for changes that might indicate developing problems or successful maintenance interventions.

Document any performance modifications and their effects on reliability, maintenance requirements, and vehicle satisfaction to guide future decisions and share knowledge with the 200SX community.

Also Read: 5 Turbo V6s With No Issues vs. 5 Known for Valve Problems