The Dodge Stealth, produced from 1990 to 1996, remains one of the most sports cars of the 1990s. Built as a joint venture between Chrysler and Mitsubishi, sharing its DNA with the legendary Mitsubishi 3000GT, the Stealth represented cutting-edge automotive technology for its era.

With its aggressive wedge-shaped design, available all-wheel drive, and twin-turbocharged variants pushing out serious horsepower, the Stealth was positioned as America’s answer to Japanese supercars.

However, beneath its stunning exterior and impressive performance capabilities lies a complex machine that demands meticulous attention to detail.

The Dodge Stealth had one major issue: All of the technology was finicky and expensive to fix. This complexity, while contributing to its advanced nature, has become the Achilles’ heel for many enthusiasts who underestimate the maintenance requirements these vehicles demand.

The Stealth’s sophisticated systems from its advanced four-wheel steering to its complex turbocharging setup require owners to be proactive rather than reactive when it comes to maintenance.

Unlike simpler sports cars of the era, the Stealth incorporates multiple interconnected systems that can cascade into catastrophic failures if minor issues are ignored. What might start as a small coolant leak can quickly evolve into a destroyed engine, or a seemingly minor electrical glitch can render the entire vehicle inoperable.

Understanding these critical maintenance points isn’t just about preventing inconvenience; it’s about protecting what has become a valuable piece of automotive history.

Clean, well-maintained Stealths are becoming increasingly rare and valuable, making proper care not just a matter of reliability but also financial preservation.

The difference between a Stealth that provides years of thrilling driving and one that becomes an expensive garage ornament often comes down to addressing these nine critical oversights before they become catastrophic failures.

Each oversight represents a ticking time bomb that, left unchecked, can result in repair bills that exceed the vehicle’s value and potentially render it beyond economical repair.

1. Ignoring Cooling System Maintenance

The cooling system represents perhaps the most critical aspect of Stealth ownership, particularly for turbocharged models where the consequences of overheating can be catastrophic within minutes.

These cars are pretty old now, have been through multiple owners in most cases, and coolant often doesn’t get replaced as often as it should. The Stealth’s complex cooling system serves multiple functions beyond just engine temperature regulation it cools the turbochargers, oil coolers, and various other heat-sensitive components throughout the vehicle.

The radiator itself is a sophisticated piece of engineering with multiple cooling circuits, but age and neglect have made failures increasingly common. The radiator has a bunch of small rectangular or oval shaped tubes that run from top to bottom.

Over time, these tubes become clogged with debris, scale buildup from old coolant, and corrosion particles that restrict flow and dramatically reduce cooling efficiency. When combined with the additional heat load from twin turbochargers, even minor restrictions can lead to rapid overheating.

The water pump, often overlooked until catastrophic failure, serves as the heart of the entire cooling system. Stealth water pumps are known for developing internal leaks that aren’t immediately visible externally but cause air pockets within the system.

These air pockets create hot spots that can cause localized overheating, leading to warped cylinder heads, blown head gaskets, or complete engine seizure. The sophisticated nature of the 6G72 engine, with its aluminum construction and tight tolerances, makes it particularly susceptible to heat damage compared to iron-block engines.

Thermostat failures represent another common yet deadly oversight. The Stealth uses a sophisticated thermostat system that maintains precise temperature control for optimal performance.

When thermostats fail in the closed position, they can cause rapid overheating that destroys engines in minutes of driving. When they fail open, the engine never reaches proper operating temperature, leading to increased wear, poor fuel economy, and potential carbon buildup that can cause long-term damage.

The cooling system’s complexity extends beyond basic components to include multiple temperature sensors, cooling fans with their own control modules, and intricate hose routing that serves different circuits.

Neglecting routine coolant changes allows corrosion and scale buildup that gradually reduces system efficiency until a hot day or spirited driving session pushes the system beyond its compromised capacity.

Regular coolant system maintenance, including complete flushes every two years, radiator inspection and cleaning, water pump replacement at recommended intervals, and thermostat testing, represents the single most important factor in Stealth longevity and the most expensive to ignore.

2. Neglecting Turbocharger Cooling and Oil Changes

The twin-turbocharged Stealth models represent the pinnacle of the platform’s performance, but their sophisticated forced-induction systems demand religious maintenance schedules that many owners underestimate.

Turbochargers operate at extreme temperatures and rotational speeds, with turbine wheels spinning at over 100,000 RPM while exposed to exhaust gases exceeding 1,800°F. This extreme operating environment makes them exceptionally vulnerable to oil-related failures that can occur with surprising speed.

Oil quality and change intervals become critical factors in turbocharger longevity. Unlike naturally aspirated engines that might tolerate extended oil change intervals, turbocharged Stealths require frequent oil changes with high-quality synthetic oil.

The oil serves multiple critical functions: lubricating the turbocharger’s precision bearings, carrying away heat from the turbo’s center section, and maintaining proper clearances in the bearing housing.

When oil breaks down from heat and contamination, it loses its ability to protect these precision components, leading to bearing failure that destroys the turbocharger.

The cooling aspect of turbocharger maintenance involves both oil and water cooling circuits. Make sure the coolant return line isn’t plugged, if plugged it will force coolant into the housings.

Blocked coolant return lines create pressure buildup that forces coolant into areas where it doesn’t belong, potentially mixing with oil or leaking into the exhaust system. This contamination can cause rapid turbocharger failure and expensive secondary damage to the engine’s lubrication system.

Heat soak represents another critical issue that many Stealth owners overlook. Keeping the parts cool that need to be cool helps out, like air intake temps and having a cooling system that can recover easier.

After spirited driving, the turbochargers retain tremendous heat that continues to affect oil temperatures even after the engine shuts down. Without proper cool-down procedures, this residual heat can cook the oil within the turbocharger housing, creating carbon deposits and sludge that block oil passages and destroy bearings.

Proper turbocharger maintenance requires understanding the interconnected nature of all these systems. Oil change intervals should never exceed 3,000 miles with conventional oil or 5,000 miles with high-quality synthetics.

Cool-down periods after hard driving, intercooler cleaning and inspection, coolant system maintenance specific to turbocharger cooling circuits, and immediate attention to any signs of oil leaks or unusual noises from the turbocharger area all represent essential maintenance practices that separate long-lived turbocharged Stealths from expensive failures.

3. Overlooking Electrical System Degradation

The Dodge Stealth’s advanced electrical system, revolutionary for its time, has become a source of significant problems as these vehicles age. The complexity of the electrical system, with its multiple control modules, sophisticated sensors, and extensive wiring harnesses, creates numerous potential failure points that can leave owners stranded or facing expensive diagnostic challenges.

Mitsubishi used subpar capacitors in the control boards. These capacitors will start leaking, damaging the circuit. Capacitor failures in control modules represent one of the most insidious electrical problems affecting Stealths.

These electrolytic capacitors, used in power supply circuits throughout various control modules, gradually lose their ability to filter electrical noise and maintain stable voltage levels.

As they age, they often leak electrolyte onto circuit boards, causing corrosion that spreads to other components. This degradation typically manifests as intermittent electrical gremlins random warning lights, inconsistent gauge readings, or systems that work sporadically making diagnosis extremely challenging and expensive.

The main wiring harness represents another critical vulnerability in the Stealth’s electrical system. Stealth often faces fuel pump failures and ignition problems after wiring harness damage or repairs.

The harness routing in these vehicles exposes critical wires to heat, vibration, and potential damage from engine movement. Over time, wire insulation becomes brittle and cracks, creating intermittent connections or short circuits that can affect multiple systems simultaneously.

What appears to be a fuel pump failure might actually be a damaged wire in the harness, leading to misdiagnosis and unnecessary component replacement.

Preventive electrical maintenance requires systematic attention to connections, regular testing of charging system output, proactive replacement of aging control modules before complete failure, protection of wiring harnesses from heat and abrasion damage, and maintaining clean, tight battery and ground connections throughout the vehicle.

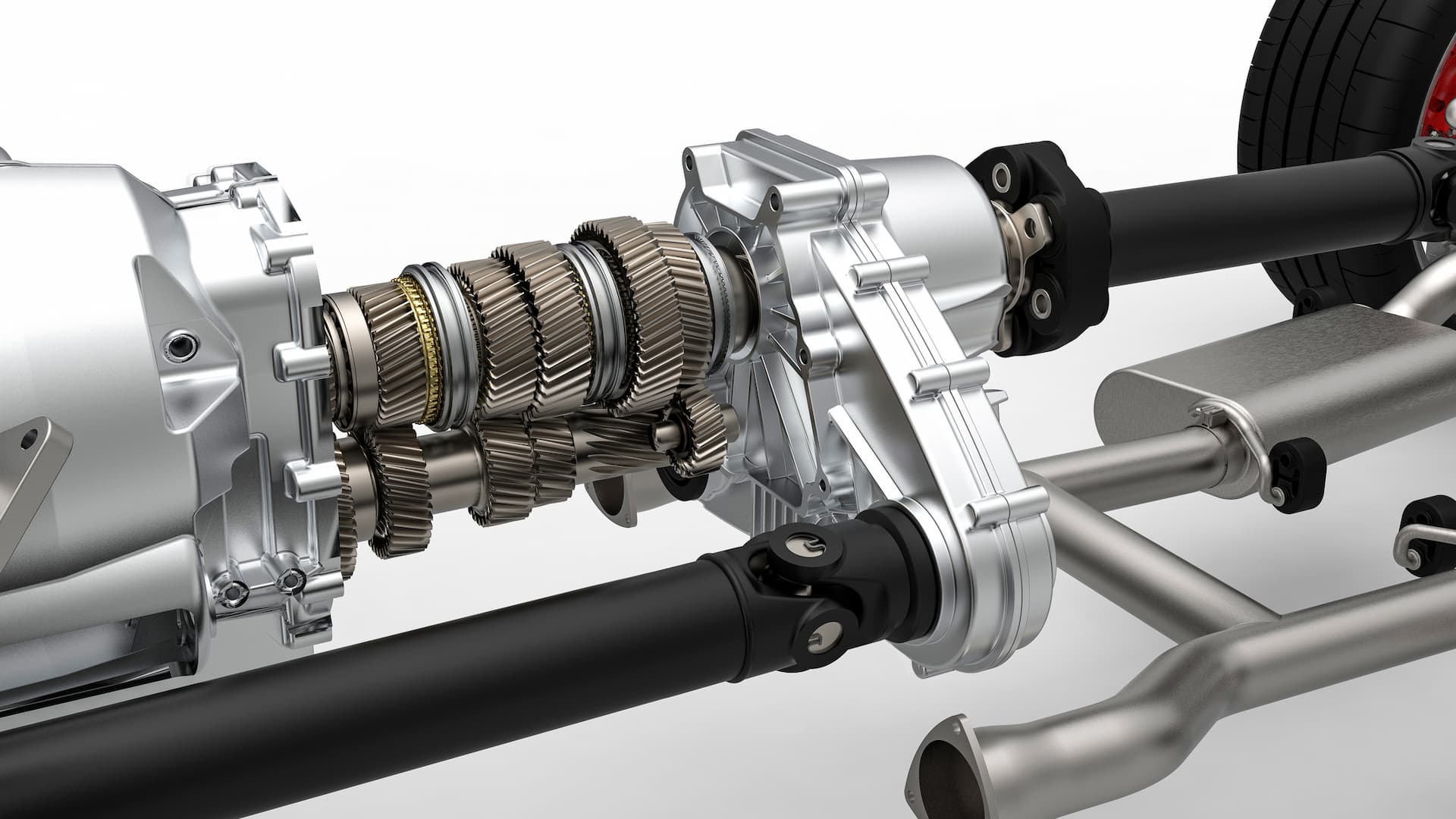

4. Transfer Case and Drivetrain Neglect

The all-wheel-drive system in the Dodge Stealth represents one of its most sophisticated mechanical features, but this complexity comes with maintenance requirements that many owners either overlook or underestimate.

The transfer case may develop a leak from the output seal. Transfer case seal failures, while seemingly minor, can quickly lead to complete drivetrain destruction if not addressed promptly.

The transfer case operates as the heart of the AWD system, distributing power between front and rear axles while managing torque split based on traction conditions.

This sophisticated mechanical system operates under extreme stress, particularly during aggressive driving or when traction conditions vary dramatically between wheels.

The transfer case oil serves multiple critical functions: lubricating the complex gear sets, cooling internal components, and maintaining proper hydraulic pressure for the torque split mechanism.

When transfer case seals fail, the immediate concern is oil loss, but the secondary effects prove far more destructive. Low oil levels cause increased friction and heat generation within the transfer case, leading to accelerated wear of expensive internal components.

The tight tolerances required for proper torque distribution become compromised as components wear, resulting in binding, grinding noises, and eventual complete failure of the AWD system.

The center differential, a particularly sophisticated component within the transfer case, relies on precise oil viscosity and cleanliness for proper operation.

Contaminated or degraded oil affects the center differential’s ability to manage torque distribution, potentially causing one axle to receive excessive power while the other becomes ineffective.

This imbalance creates dangerous handling characteristics and accelerates wear on tires, axles, and other drivetrain components. The sophistication of the Stealth’s AWD system means that component failures rarely occur in isolation.

A failing transfer case can damage the transmission, worn CV joints can affect differential operation, and contaminated fluids can accelerate wear throughout the entire drivetrain.

Regular fluid changes, seal inspection and replacement, CV joint boot maintenance, and immediate attention to any drivetrain noises or vibrations represent essential maintenance practices that prevent catastrophic drivetrain failures that can exceed the vehicle’s value to repair.

Also Read: 5 Toyota Tacoma Model Years That Last and 5 You Should Avoid

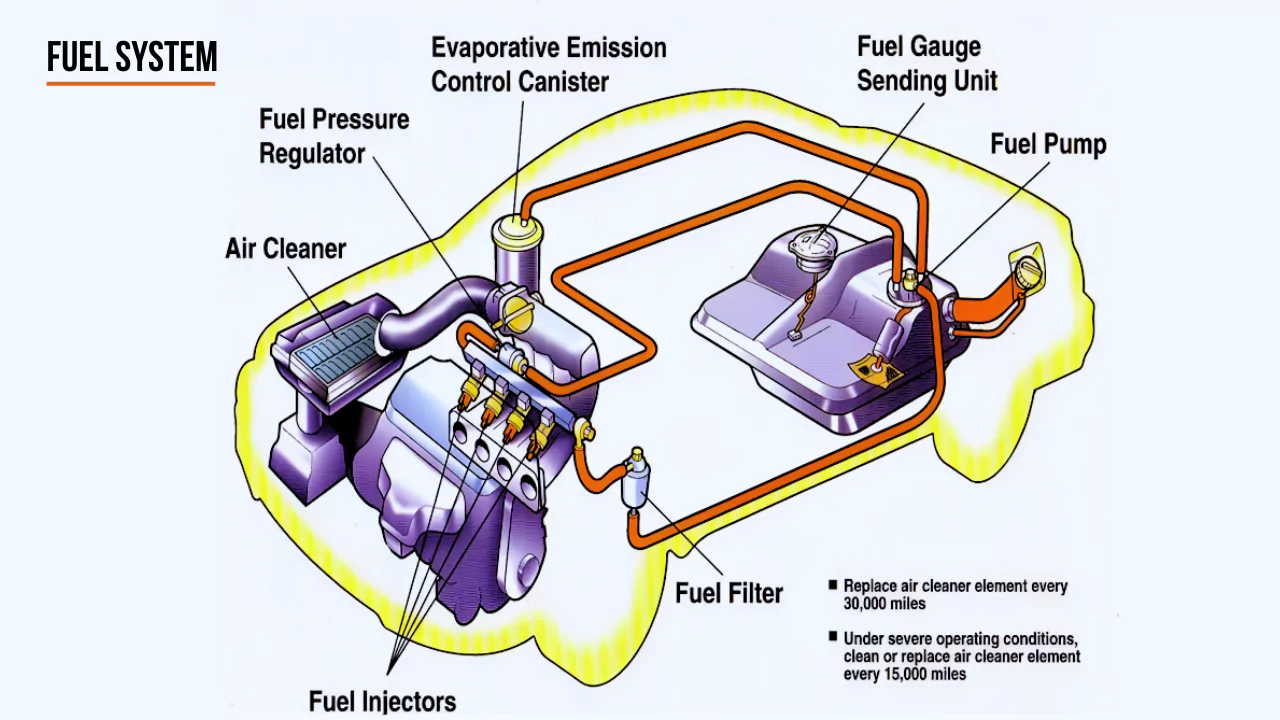

5. Fuel System Component Failures

The Dodge Stealth’s fuel system, designed to support both naturally aspirated and high-performance turbocharged applications, incorporates sophisticated components that are prone to age-related failures with potentially catastrophic consequences.

The complexity of this system, particularly in turbocharged models requiring higher fuel pressures and volumes, creates multiple failure points that can leave owners stranded or cause expensive secondary damage to other systems.

Fuel pump failures represent one of the most common and problematic issues affecting Stealths as they age. The in-tank electric fuel pump operates continuously when the engine runs, submerged in gasoline that serves as both lubricant and coolant for the pump motor.

Over time, the pump’s internal components wear, electrical connections corrode, and the pump housing develops cracks that allow air infiltration.

When fuel pumps begin failing, they often exhibit intermittent symptoms the car may run perfectly for weeks, then suddenly lose power or refuse to start, making diagnosis challenging and leaving owners stranded unpredictably.

The fuel pressure regulator, a critical component in maintaining proper fuel system operation, becomes increasingly problematic as diaphragm materials age and spring tensions change. Failed pressure regulators can cause fuel pressures that are either too high or too low, both conditions creating serious engine problems.

Excessive fuel pressure can flood the engine, wash oil from cylinder walls, and damage catalytic converters with unburned fuel. Insufficient pressure causes lean running conditions that can destroy pistons and valves through detonation and overheating.

Fuel injectors in the Stealth’s sophisticated fuel injection system require precise operation to maintain proper air-fuel ratios across all operating conditions.

These precision components contain tiny orifices and electromagnetic actuators that become clogged with fuel deposits or fail electrically over time.

When injectors begin failing, they typically don’t fail completely at once instead, they develop inconsistent spray patterns or flow rates that create cylinder-to-cylinder variations in fuel delivery. This inconsistency causes rough idle, misfires under load, and potential engine damage from lean or rich conditions in individual cylinders.

Preventive fuel system maintenance requires regular fuel filter replacement to prevent contamination from reaching sensitive components, periodic fuel injector cleaning to maintain proper spray patterns and flow rates, fuel pressure testing to verify proper regulator and pump operation, inspection of fuel lines and connections for leaks or deterioration, and prompt attention to any symptoms of fuel delivery problems before they cause secondary engine damage.

6. Transmission and Clutch System Deterioration

The transmission systems in Dodge Stealths, whether manual or automatic, represent complex mechanical systems that suffer from specific age-related problems compounded by the high-performance nature of these vehicles.

The substantial torque output, particularly from turbocharged models, places extreme stress on transmission components that many owners underestimate, leading to premature failures that can cost more than the vehicle’s value to repair properly.

Manual transmission Stealths utilize a sophisticated 5-speed unit that shares components with other high-performance Mitsubishi applications, but the combination of age, wear, and often inadequate maintenance has created a perfect storm for transmission problems.

The transmission oil, often neglected because manual transmissions are perceived as maintenance-free, breaks down over time and loses its ability to lubricate and cool internal components effectively.

Degraded transmission fluid cannot provide proper protection for synchronizers, causing difficult shifting, grinding noises, and eventual synchronizer failure that requires complete transmission rebuilds.

The clutch system in manual Stealths represents a particularly problematic area due to the combination of high torque output and the hydraulic actuation system used.

The clutch hydraulic system, utilizing a master cylinder, slave cylinder, and connecting hydraulic line, becomes prone to seal failures that create inconsistent clutch operation or complete clutch failure.

When hydraulic seals fail, they often do so gradually, creating symptoms like spongy clutch pedal feel, difficulty engaging gears, or clutch slippage that worsens progressively until complete system failure occurs.

The clutch disc and pressure plate assembly face extreme stress from the engine’s torque output, particularly in turbocharged applications where torque multiplication under boost conditions can exceed the clutch’s design capacity.

Worn clutch components don’t just slip they can fail catastrophically, sending debris throughout the transmission that damages other internal components. Clutch pressure plates can crack or warp, creating uneven clamping forces that cause premature disc wear and potential flywheel damage.

Proper transmission maintenance requires regular fluid changes using manufacturer-specified fluids, hydraulic system inspection and bleeding for manual transmissions, attention to cooling system maintenance for automatic transmissions, immediate investigation of any changes in shift quality or pedal feel, and recognition that transmission problems typically worsen rapidly once symptoms appear, making early intervention critical for avoiding catastrophic failures.

7. Suspension Component Wear and Failure

The Dodge Stealth’s sophisticated suspension system, featuring independent suspension at all four corners with available electronically controlled damping, represents one of its most advanced features but also one of its most problematic areas as these vehicles age.

The combination of high-performance driving, component age, and the complexity of the electronic systems creates multiple failure points that can dramatically affect vehicle safety and handling characteristics.

The electronically controlled suspension system, available on higher trim levels, utilizes sophisticated dampers with solenoid-controlled valving that adjusts damping characteristics based on driving conditions and driver preferences.

These electronic dampers contain complex internal mechanisms that regulate fluid flow through precisely calibrated orifices, and the electronic control systems that manage these adjustments.

As these components age, the electronic actuators fail, seals within the dampers deteriorate, and the control modules develop faults that prevent proper operation.

When electronic suspension components fail, they don’t simply revert to conventional operation instead, they often lock in one damping mode or develop inconsistent operation that creates dangerous handling characteristics.

A failed damper might provide normal operation during gentle driving but suddenly become overly stiff or soft during emergency maneuvers, potentially causing loss of vehicle control. The electronic control systems can also fail intermittently, creating unpredictable suspension behavior that makes the vehicle unsafe to drive.

Conventional suspension components throughout the Stealth platform suffer from age-related deterioration that affects both ride quality and safety.

Strut mounts, often overlooked during routine maintenance, develop wear that creates clunking noises, poor handling, and potential separation that can cause catastrophic loss of vehicle control.

The rubber components within strut mounts deteriorate over time, allowing excessive movement and metal-to-metal contact that accelerates wear of other suspension components.

Ball joints and control arm bushings represent critical safety components that fail gradually, often without obvious symptoms until failure becomes imminent. Worn ball joints can separate without warning, causing immediate loss of steering control and potential vehicle rollover.

Control arm bushings, when worn, allow excessive suspension movement that affects wheel alignment, tire wear, and handling predictability. These components often develop play gradually, making wear difficult to detect during casual inspection.

Proper suspension maintenance requires regular inspection of all rubber components for cracking or deterioration, testing of electronic suspension systems using appropriate diagnostic equipment, immediate attention to any changes in ride quality or handling characteristics, periodic replacement of wear items like strut mounts and bushings before complete failure, and understanding that suspension component failures can create dangerous driving conditions that require immediate repair rather than deferred maintenance.

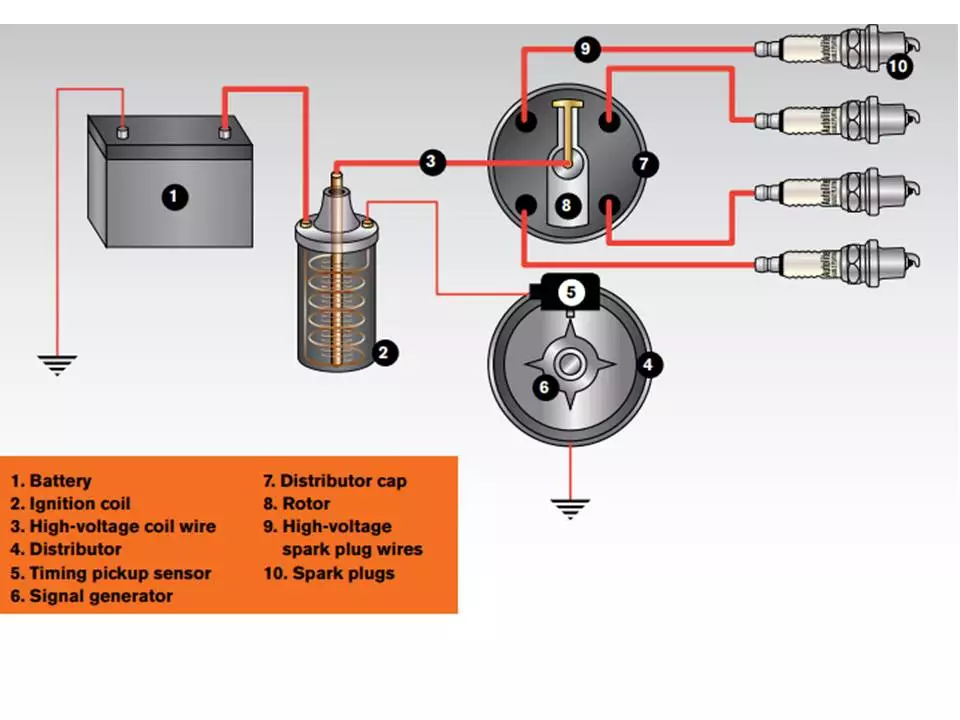

8. Ignition System Component Degradation

The Dodge Stealth’s sophisticated ignition system, utilizing distributorless ignition with individual coil packs for each cylinder, represented advanced technology for its era but has become a source of significant problems as these vehicles age.

The high-energy ignition system, designed to reliably fire spark plugs under the extreme conditions found in high-performance and turbocharged applications, contains multiple precision components that are vulnerable to heat, vibration, and electrical stress over time.

The coil pack assemblies, mounted directly above each spark plug, operate in the harsh environment of the engine bay where they face extreme temperature cycling, vibration from engine operation, and exposure to oil vapors and moisture.

These coil packs contain sophisticated electronic circuits and high-voltage transformers that gradually degrade from thermal stress and electrical fatigue.

When coil packs begin failing, they typically don’t fail completely at once instead, they develop weak spark output that creates subtle misfires under load conditions while appearing to function normally at idle.

The challenge with degrading coil packs lies in their intermittent nature of failure. A weakening coil pack might provide adequate spark for normal driving but fail under the higher compression and cylinder pressure conditions found during acceleration or boost situations in turbocharged models.

This intermittent operation creates frustrating diagnostic challenges where the problem seems to come and go unpredictably, often leaving owners stranded when the ignition system fails completely during demanding driving conditions.

Spark plugs in the Stealth require careful selection and maintenance due to the high-performance nature of the engines and the potential for boost conditions in turbocharged models.

The correct spark plug heat range becomes critical plugs that are too cold will foul with carbon deposits during normal driving, while plugs that are too hot will cause pre-ignition and detonation that can destroy pistons and valves.

As engines age and develop wear, the optimal spark plug specification may change, requiring careful selection based on actual engine condition rather than original specifications.

Proper ignition system maintenance requires regular replacement of spark plugs using correct specifications for current engine condition, periodic testing of coil pack output and replacement before complete failure, inspection of high-voltage wiring for insulation breakdown or damage, testing of position sensors and their wiring harnesses, and monitoring of engine management system operation for signs of electronic control problems that require immediate attention.

9. Timing Belt and Engine Timing Neglect

The timing belt system in Dodge Stealth engines represents perhaps the most critical maintenance item that owners commonly overlook, with catastrophic consequences that can destroy the entire engine within seconds of failure.

The 6G72 engine used in Stealths utilizes an interference design where pistons and valves occupy the same space at different points in their cycles, relying entirely on precise timing belt operation to prevent collision between these components.

When a timing belt fails in an interference engine, the immediate result is catastrophic internal engine damage as pistons moving upward collide with valves that remain open due to camshaft timing loss.

This collision typically bends or breaks multiple valves, damages pistons, and can crack cylinder heads or block components. The repair costs from timing belt failure often exceed the vehicle’s value, effectively totaling the car from a relatively inexpensive maintenance oversight.

The timing belt system encompasses more than just the belt itself it includes tensioners, idler pulleys, water pump, and timing covers that all require maintenance as an integrated system.

Timing belt tensioners utilize spring-loaded mechanisms that maintain proper belt tension as the belt stretches slightly during operation. These tensioners can fail by becoming too loose, allowing belt slack that affects timing precision, or too tight, creating excessive stress that accelerates belt wear and increases the load on other system components.

Idler pulleys and tensioner pulleys contain bearings that are exposed to engine bay heat, contamination from oil leaks, and the constant stress of belt tension.

These bearings gradually develop play or seize completely, creating noise and vibration that can cause premature timing belt failure. When pulleys fail, they often don’t fail completely at once instead, they develop rough operation that creates belt wear patterns and stress concentrations that lead to sudden belt failure.

The sophisticated nature of the Stealth’s engine means that timing belt failure affects multiple systems simultaneously. Variable valve timing mechanisms, cam position sensors, and other timing-dependent systems can be damaged by timing belt failure, adding to repair costs and complexity.

The precision required for proper timing belt installation means that even minor errors during replacement can cause performance problems or accelerated component wear.

Timing belt maintenance must be performed on schedule regardless of mileage if time intervals are reached first, as rubber degradation occurs even in stored vehicles.

The recommended replacement interval represents the maximum safe service life, not a suggested timeframe waiting until symptoms appear virtually guarantees catastrophic engine damage.

Proper timing belt service includes replacement of all system components including tensioners, pulleys, seals, and water pump as a preventive measure that ensures reliable operation and prevents cascade failures that can destroy the engine.

Also Read: 5 Pickup Beds That Resist Dents vs. 5 That Warp Easily