The GMC Sierra Pro stands as one of America’s most dependable work trucks, engineered to handle demanding tasks while delivering exceptional performance and reliability.

However, like any sophisticated piece of machinery, your Sierra Pro requires strategic maintenance and proactive care to achieve its maximum lifespan potential.

With proper attention to key systems and components, these robust trucks can easily surpass 200,000 miles while maintaining their legendary durability and performance standards.

Understanding the critical maintenance points of your GMC Sierra Pro isn’t just about preventing costly breakdowns, it’s about maximizing your investment and ensuring your truck remains a reliable partner for years to come.

Whether you’re using your Sierra Pro for heavy-duty hauling, daily commuting, or recreational adventures, implementing smart maintenance strategies will significantly extend its operational life while preserving its resale value.

The modern GMC Sierra Pro incorporates advanced engineering and technology that, when properly maintained, creates a synergistic effect where each system supports the others in optimal performance.

From the robust powertrain to the sophisticated suspension system, every component plays a crucial role in the truck’s longevity. Neglecting any single aspect can create a domino effect that compromises other systems and accelerates wear.

This comprehensive guide focuses on ten essential maintenance strategies that address the most critical aspects of Sierra Pro ownership. These aren’t just routine maintenance items they’re strategic interventions that target the areas most likely to cause expensive problems if neglected.

Each fix has been carefully selected based on common failure points, manufacturer recommendations, and field experience from mechanics and owners who have successfully maintained their trucks for hundreds of thousands of miles.

By implementing these smart fixes consistently and proactively, you’ll not only extend your truck’s lifespan but also improve its performance, fuel efficiency, and reliability.

The investment in proper maintenance pays dividends in reduced repair costs, improved safety, and the peace of mind that comes with driving a well-maintained vehicle.

1. Regular Engine Oil and Filter Changes with Quality Products

The foundation of long-term engine health in your GMC Sierra Pro begins with maintaining a strict oil change schedule using high-quality lubricants and filters.

Your truck’s engine operates under demanding conditions, whether you’re towing heavy loads, driving in extreme temperatures, or going through stop and go traffic.

These conditions place tremendous stress on engine oil, breaking down its protective properties and reducing its ability to lubricate critical components effectively.

Modern GMC Sierra Pro engines are equipped with sophisticated variable valve timing systems, direct fuel injection, and turbocharging technology that demands superior lubrication.

Using manufacturer-specified oil viscosity and quality ratings isn’t just a recommendation; it’s essential for maintaining proper hydraulic pressure in these advanced systems.

The wrong oil can cause timing chain issues, turbocharger failures, and premature wear in high-precision components that cost thousands to repair.

Quality matters significantly when selecting oil and filters. Premium synthetic oils offer superior thermal stability, better flow characteristics in extreme temperatures, and enhanced detergent packages that keep internal components cleaner.

These oils maintain their protective properties longer than conventional oils, providing consistent lubrication even under severe operating conditions. The molecular structure of synthetic oils resists breakdown, ensuring your engine receives optimal protection throughout the entire service interval.

The oil filter plays an equally critical role in engine longevity. A high-quality filter doesn’t just remove particles it maintains consistent oil flow while capturing contaminants as small as 25 microns.

Cheap filters often bypass contaminants when they become loaded, allowing harmful particles to circulate through your engine. Investing in OEM or premium aftermarket filters ensures maximum filtration efficiency and proper bypass valve operation.

Establishing the right change interval requires understanding your specific operating conditions. While manufacturers often specify extended intervals for “normal” driving, most Sierra Pro trucks operate under “severe” conditions that require more frequent changes.

Frequent short trips, dusty environments, trailer towing, and extreme temperatures all accelerate oil degradation. Many experienced mechanics recommend changing oil every 5,000 miles regardless of the manufacturer’s extended interval recommendations. The investment in quality oil and filters pays substantial dividends in engine longevity.

Engines maintained with premium lubricants and filters regularly exceed 300,000 miles with minimal internal wear, while those maintained with bargain products often require major repairs before reaching 150,000 miles. The cost difference between premium and economy products is minimal compared to the potential repair costs of premature engine failure.

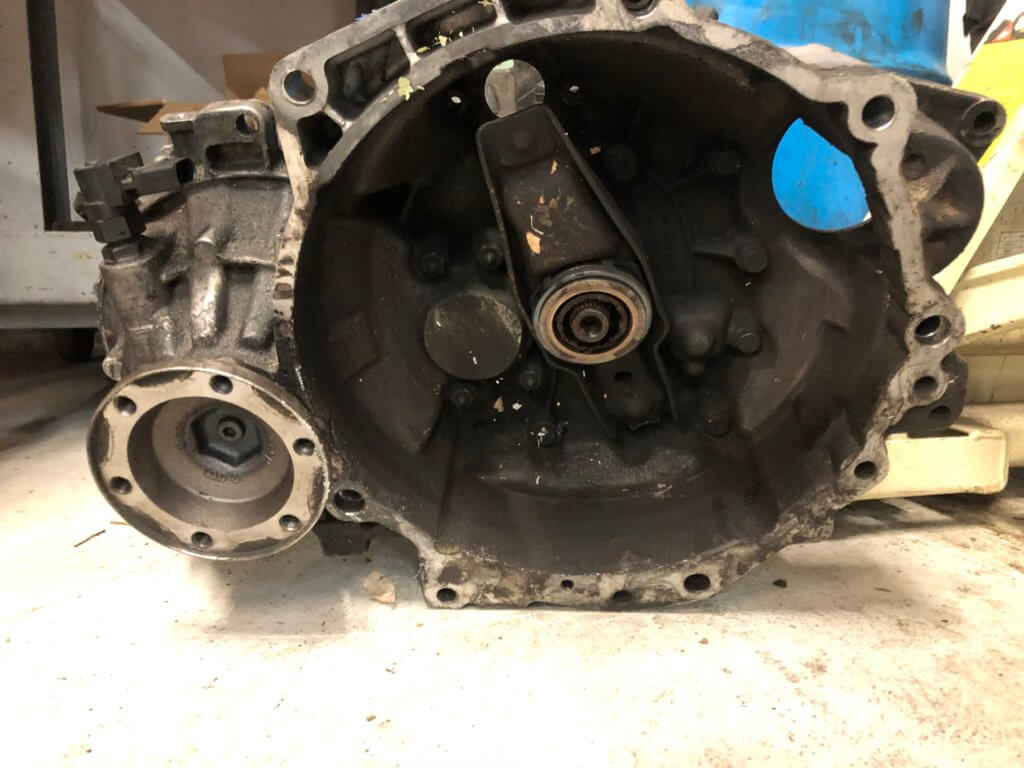

2. Transmission Fluid and Filter Maintenance

Your GMC Sierra Pro’s transmission represents one of the most complex and expensive components in your truck, making proper fluid maintenance absolutely critical for long-term reliability.

Modern automatic transmissions operate with incredibly tight tolerances and sophisticated hydraulic control systems that depend on clean, properly conditioned transmission fluid to function correctly. Neglecting transmission maintenance often results in complete transmission failure, requiring rebuilds costing $3,000 to $5,000 or more.

Transmission fluid serves multiple critical functions beyond simple lubrication. It acts as a hydraulic medium for shift operation, provides cooling for internal components, conditions seals and gaskets, and carries away contaminants generated during normal operation.

As transmission fluid ages, it loses these essential properties, becoming acidic and forming varnish deposits that interfere with proper valve operation and heat dissipation.

The modern GMC Sierra Pro transmission generates significant heat during operation, especially when towing or operating under heavy loads. Heat is the primary enemy of transmission fluid, accelerating oxidation and causing the fluid to lose its protective properties.

Fluid temperatures above 200 degrees Fahrenheit dramatically reduce fluid life, with each additional 20-degree increase cutting fluid life in half. This makes regular fluid changes essential for trucks operating under demanding conditions.

Unlike engine oil, transmission fluid doesn’t get contaminated by combustion byproducts, but it does accumulate metal particles from normal clutch and gear wear. These particles act as abrasives, accelerating wear throughout the transmission.

The transmission filter captures these contaminants, but as it becomes loaded, flow restriction increases and filtration efficiency decreases. Regular filter replacement ensures optimal flow and contamination control.

Proper transmission service involves more than just draining and refilling the pan. A complete fluid exchange removes old fluid from the torque converter, cooler lines, and valve body passages that aren’t accessible through simple pan drainage.

This process typically requires 12-14 quarts of new fluid compared to the 4-6 quarts replaced during a simple drain and fill. While more expensive initially, complete fluid exchanges provide superior protection and longer service intervals.

Transmission cooler maintenance often gets overlooked but plays a crucial role in fluid longevity. External coolers can become restricted with debris, reducing cooling efficiency and increasing operating temperatures.

Regular inspection and cleaning of cooler fins, along with checking cooler line connections for leaks, prevents overheating conditions that dramatically reduce transmission life.

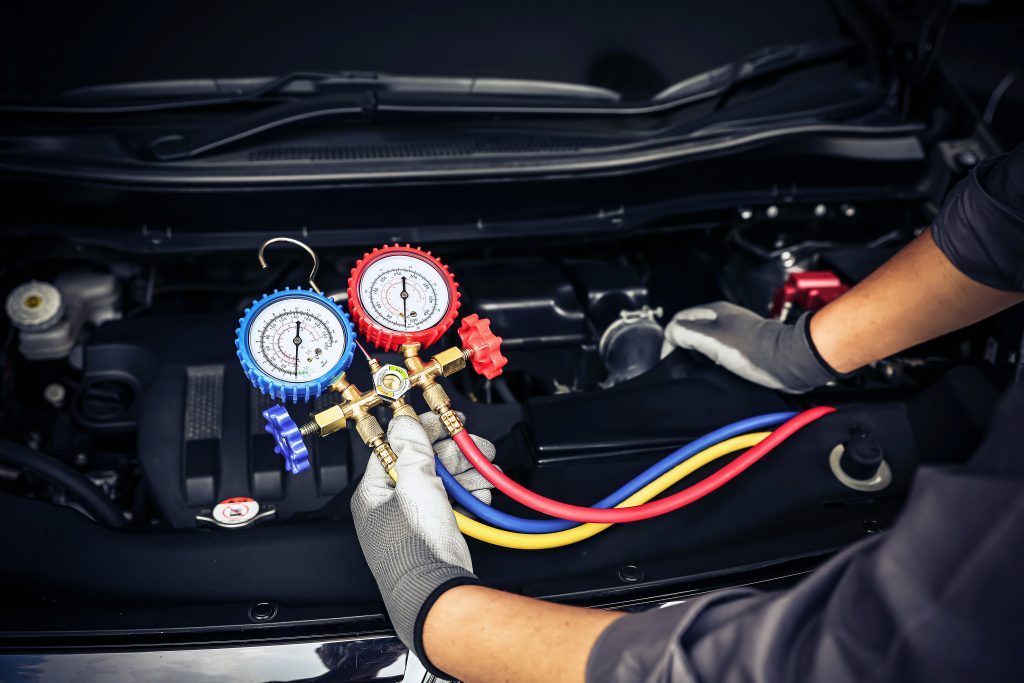

3. Cooling System Comprehensive Care

The cooling system in your GMC Sierra Pro serves as the thermal management center for your entire powertrain, making its proper maintenance essential for preventing costly engine damage and ensuring optimal performance.

Modern engines operate at higher temperatures and tighter tolerances than ever before, placing increased demands on cooling system components. A failure in any part of this system can result in catastrophic engine damage within minutes, making proactive maintenance absolutely critical.

Your Sierra Pro’s cooling system consists of multiple interconnected components, including the radiator, water pump, thermostat, hoses, belts, and electronic cooling fans.

Each component must function properly to maintain optimal engine temperature under varying load and environmental conditions. The system’s complexity means that failure of any single component can compromise the entire system’s effectiveness, potentially leading to overheating and severe engine damage.

Coolant serves multiple functions beyond temperature regulation. Modern extended-life coolants contain corrosion inhibitors that protect aluminum and steel components from galvanic corrosion, scale formation, and cavitation damage.

These inhibitors deplete over time, allowing corrosion to attack expensive components like the radiator, water pump, and cylinder head. Regular coolant replacement maintains these protective properties and prevents costly component failures.

The radiator cap plays a crucial role in system operation that’s often underestimated. This simple component maintains proper system pressure, allowing coolant to operate at higher temperatures without boiling.

A weak or defective radiator cap reduces system pressure, lowering the boiling point and causing coolant loss through overflow. Regular pressure testing of the radiator cap ensures proper system pressure and prevents coolant loss that can lead to overheating.

Preventive cooling system maintenance pays substantial dividends in reliability and component longevity. Engines maintained with proper cooling system care regularly exceed 300,000 miles without major cooling-related repairs, while neglected systems often experience catastrophic failures before reaching 150,000 miles.

The relatively low cost of preventive maintenance compared to engine rebuild costs makes cooling system care one of the most cost-effective investments in vehicle longevity.

4. Differential and Transfer Case Service

The differential and transfer case in your GMC Sierra Pro represent critical drivetrain components that enable proper power distribution and handling characteristics while enduring extreme loads and operating conditions.

These components operate in harsh environments with high pressures, temperatures, and contamination exposure, making regular service essential for maintaining their longevity and preventing costly failures that can leave you stranded.

Your Sierra Pro’s rear differential handles the enormous torque multiplication that occurs during acceleration and load hauling. The ring and pinion gears operate under tremendous pressure, while the differential carrier allows wheels to rotate at different speeds during cornering.

These components depend on proper lubrication for protection against wear and heat generation. As differential fluid ages, it loses its protective properties and accumulates metal particles from normal gear wear.

Transfer case operation in four-wheel-drive Sierra Pro models involves complex gear trains, clutch packs, and chain drives that distribute power between front and rear axles. These components operate under varying loads and speeds, creating unique lubrication challenges.

The transfer case experiences extreme pressure changes during engagement and disengagement of four-wheel drive, placing additional stress on seals and internal components.

Differential fluid serves multiple functions, including lubrication, cooling, and seal conditioning. Modern gear oils incorporate extreme pressure additives that form protective films under high load conditions, preventing metal-to-metal contact between gear teeth.

Limited-slip differentials require special additives that allow proper clutch operation while maintaining gear protection. Using incorrect fluid types can cause clutch chatter, gear wear, and premature component failure.

Proper filling procedures ensure optimal performance and component protection. Overfilling can cause seal failure and fluid loss, while underfilling results in inadequate lubrication and accelerated wear. Using the correct fill level and appropriate fluid specifications maintains proper operating characteristics and component longevity.

Also Read: 5 Steering Racks That Stay Tight vs 5 That Loosen Quickly

5. Brake System Maintenance and Upgrades

Your GMC Sierra Pro’s braking system represents the most critical safety component of your truck, requiring meticulous maintenance to ensure reliable stopping power while preventing costly repairs and potential accidents.

Modern brake systems incorporate sophisticated technologies, including anti-lock braking (ABS), electronic stability control, and advanced friction materials that demand proper care to maintain optimal performance throughout their service life.

Brake fluid serves as the hydraulic medium that transfers pedal force to the brake calipers and wheel cylinders. This fluid operates under extreme pressures and temperatures, making its condition critical for safe operation. Brake fluid is hygroscopic, meaning it absorbs moisture from the atmosphere over time.

This moisture contamination lowers the fluid’s boiling point, potentially causing brake fade during heavy use and promoting internal corrosion of expensive brake components.

The brake pad and rotor interface generates tremendous heat during normal operation, with temperatures often exceeding 600 degrees Fahrenheit during heavy braking.

This heat stress causes brake pads to wear and release gases that can contaminate brake fluid and cause glazing of friction surfaces. Regular inspection and replacement of brake pads before they reach minimum thickness prevents rotor damage and maintains optimal stopping performance.

Brake rotors require attention beyond simple pad replacement. Heat cycling causes rotors to develop thickness variations and surface imperfections that reduce braking effectiveness and cause pedal pulsation.

Regular rotor measurement and resurfacing when necessary maintains smooth operation and prevents premature pad wear. Severely worn rotors require replacement to restore proper heat dissipation and braking performance.

Proper break-in procedures for new brake components ensure optimal performance and longevity. New brake pads require gradual heat cycling to properly seat against rotor surfaces and develop optimal friction characteristics.

Following manufacturer-recommended break-in procedures prevents glazing and ensures maximum stopping power throughout the component’s service life.

6. Air Filter and Intake System Optimization

The air intake system of your GMC Sierra Pro plays a fundamental role in engine performance, fuel efficiency, and longevity by ensuring your engine receives the clean, properly measured air supply it needs for optimal combustion.

Modern engines are precisely calibrated to operate with specific air-fuel ratios, making the condition and performance of intake components critical for maintaining factory performance levels and preventing expensive engine damage caused by contamination or improper air metering.

Your truck’s air filtration system must handle enormous volumes of air while removing harmful contaminants that can cause accelerated engine wear.

A typical engine consumes over 10,000 gallons of air for every gallon of fuel burned, meaning even small concentrations of contaminants can cause significant damage over time.

Dust, pollen, insects, and other airborne particles can cause premature wear of cylinder walls, piston rings, and valve guides if allowed to enter the combustion chamber.

The air filter element represents the first line of defense against contamination, but its effectiveness depends on proper maintenance and timely replacement.

As filters collect contaminants, they become more efficient at capturing particles but also create increased flow restriction. This restriction forces the engine to work harder to draw in the air it needs, reducing performance and fuel economy while potentially causing rich running conditions that can damage expensive emissions control components.

Mass airflow sensors and throttle bodies in modern Sierra Pro engines require pristine operating conditions to maintain accurate air measurement and throttle control.

Contaminated or restricted air filters can cause these components to malfunction, resulting in poor performance, increased emissions, and potential damage to the engine or emissions control systems.

Regular filter replacement prevents these problems and maintains optimal sensor operation. The investment in quality air filtration and intake system maintenance pays significant dividends in engine longevity and performance.

Engines maintained with proper air filtration regularly exceed 300,000 miles with minimal internal wear, while those subjected to contaminated air often require major repairs before reaching 200,000 miles.

The relatively low cost of quality air filters compared to potential engine repair costs makes this one of the most cost-effective maintenance investments possible.

7. Suspension Component Care and Replacement

Your GMC Sierra Pro’s suspension system endures constant stress from road impacts, load variations, and environmental exposure, making regular maintenance and timely component replacement essential for maintaining ride quality, handling characteristics, and preventing accelerated tire wear.

The suspension system affects virtually every aspect of vehicle operation, from comfort and safety to tire life and vehicle longevity. Modern truck suspension systems incorporate sophisticated technologies, including variable damping shocks, electronic load leveling, and advanced bushings that require specific maintenance procedures.

These components work together to control vehicle motion, maintain tire contact with the road surface, and isolate the chassis from road irregularities. When suspension components wear or fail, the effects cascade throughout the entire vehicle, causing accelerated wear of other components and compromising safety.

Shock absorbers and struts represent the primary wear items in any suspension system, gradually losing their damping effectiveness as internal seals wear and fluid leaks occur.

This deterioration happens slowly, making it difficult to notice until the components are severely compromised. Worn shocks allow excessive vehicle motion during braking, acceleration, and cornering, reducing tire contact with the road and compromising both safety and tire life.

Suspension bushings provide flexible connections between suspension components while controlling unwanted movement and vibration. These rubber and polyurethane components are constantly flexing and are exposed to road chemicals, temperature extremes, and ozone, which cause deterioration over time.

Worn bushings allow excessive play in suspension components, causing handling problems, tire wear, and noise issues. Ball joints and tie rod ends form the critical connections that allow suspension movement while maintaining proper wheel alignment.

These components incorporate protective boots that seal out contaminants while retaining lubricating grease. Boot failure allows water and dirt to contaminate the joint, causing rapid wear and potential failure. Regular inspection and boot replacement prevent premature joint failure and the safety hazards associated with suspension failure.

Load-carrying springs, whether coil or leaf type, can develop fatigue and sagging over time, particularly in trucks used for heavy hauling. Sagging springs affect ride height, handling characteristics, and load capacity while potentially causing contact with other components.

Spring replacement or supplemental support systems can restore proper vehicle stance and handling characteristics. Performance suspension upgrades can significantly improve handling and load capacity for trucks used in demanding applications.

Heavy-duty shocks, upgraded springs, and performance bushings provide better control and durability than stock components. These upgrades are particularly beneficial for trucks used for towing, off-road operation, or performance applications.

8. Fuel System Cleaning and Filter Replacement

The fuel system in your GMC Sierra Pro delivers precisely metered fuel to sophisticated injection systems operating at extremely high pressures, making cleanliness and proper filtration absolutely critical for optimal performance and component longevity.

Modern direct injection systems operate at pressures exceeding 2,000 PSI, with injector tolerances measured in microns. Even microscopic contaminants can cause expensive component failures and performance problems.

Fuel quality varies significantly depending on source, age, and storage conditions. Gasoline and diesel fuels can become contaminated with water, sediment, microbial growth, and chemical degradation products that interfere with proper combustion and damage fuel system components.

Water contamination is particularly problematic in diesel systems, promoting microbial growth and causing corrosion of expensive injection components.

The fuel filter serves as the final barrier against contamination reaching your engine’s injection system. As filters collect contaminants, flow restriction increases, potentially starving the engine of fuel under high-demand conditions.

Severely restricted filters can cause fuel pump damage as the pump works harder to overcome the restriction, leading to premature failure of this expensive component.

Fuel pumps in modern vehicles operate at high pressures and depend on fuel flow for cooling and lubrication. Contaminated fuel can cause accelerated wear of pump components, while restricted filters force pumps to operate under higher loads.

Electric fuel pumps are particularly susceptible to contamination damage, with replacement costs often exceeding $500 for the pump alone, not including labor and associated parts.

Direct injection systems incorporate high-pressure fuel pumps, fuel rails, and precision injectors that demand exceptional fuel cleanliness. These components operate with tolerances measured in microns, making them extremely sensitive to contamination.

A single contaminated fuel load can damage multiple injectors, resulting in repair costs exceeding $2,000 in some cases. The investment in proper fuel system maintenance pays substantial dividends in performance and reliability.

Fuel systems maintained with quality filters and regular cleaning services provide trouble-free operation for hundreds of thousands of miles, while neglected systems often experience expensive component failures before reaching 150,000 miles. The cost of preventive maintenance is minimal compared to the expense of replacing damaged injection components.

9. Electrical System and Battery Maintenance

Your GMC Sierra Pro’s electrical system has evolved into a complex network of interconnected components that control everything from basic engine operation to advanced safety and convenience features.

Modern trucks contain dozens of electronic control modules, hundreds of sensors, and miles of wiring that must function reliably to ensure proper vehicle operation. Electrical system problems can cause intermittent issues that are difficult to diagnose and expensive to repair.

The battery serves as the foundation of the entire electrical system, providing power for starting and serving as a voltage stabilizer during operation.

Modern trucks place enormous demands on their electrical systems, with power-hungry accessories and electronic control modules requiring consistent, clean electrical power. Battery degradation affects the entire electrical system, causing modules to malfunction and potentially damaging expensive electronic components.

Battery maintenance involves more than simply replacing failed units. Regular cleaning of battery terminals prevents corrosion buildup that increases electrical resistance and causes voltage drops throughout the system.

Corrosion at battery terminals can cause charging system problems, starting difficulties, and electronic module malfunctions that are often misdiagnosed as component failures rather than connection problems.

Preventive electrical system maintenance significantly improves reliability and reduces repair costs. Regular battery and charging system testing, connection cleaning, and wiring inspection identify problems before they cause expensive failures. The investment in proper electrical system maintenance pays substantial dividends in reliability and component longevity.

10. Preventive Maintenance Schedule and Record Keeping

Establishing and maintaining a comprehensive preventive maintenance schedule represents the single most important factor in maximizing your GMC Sierra Pro’s longevity and reliability.

A well-planned maintenance program addresses all critical vehicle systems before problems develop, preventing expensive repairs while ensuring optimal performance throughout your truck’s service life.

The key to successful preventive maintenance lies in understanding your specific operating conditions and adjusting service intervals accordingly. Operating conditions significantly affect maintenance requirements and service intervals.

Trucks used for frequent towing, stop and go driving, extreme temperatures, or dusty environments require more frequent service than those used primarily for highway driving.

Understanding these differences and adjusting maintenance schedules accordingly prevents premature component wear and ensures optimal protection under your specific operating conditions.

Comprehensive record keeping provides valuable insights into vehicle condition and helps identify developing patterns that indicate potential problems.

Detailed maintenance records document service intervals, component replacements, and fluid consumption patterns that can reveal emerging issues before they cause expensive failures. These records also significantly improve resale value by demonstrating proper care and maintenance to potential buyers.

The comprehensive approach to preventive maintenance integrates all these factors into a cohesive program that maximizes reliability while controlling costs.

Success requires commitment to regular service, attention to detail, and willingness to invest in proper care before problems develop. The rewards include years of reliable service, reduced repair costs, and the satisfaction that comes from maintaining a vehicle properly.

Also Read: 5 Infotainment Units With Reliable Software vs. 5 That Are Glitchy