The Jeep Liberty Renegade stands as one of the most capable and beloved compact SUVs ever produced by the American automotive giant. With its rugged design, impressive off-road capabilities, and distinctive styling, the Liberty Renegade has captured the hearts of adventure enthusiasts and daily commuters alike.

However, despite its robust engineering and reputation for durability, even this reliable workhorse can fall victim to premature failure when subjected to poor maintenance habits and neglectful ownership practices.

Understanding the critical factors that can significantly shorten your Liberty Renegade’s lifespan is essential for any owner who wants to maximize their investment and enjoy years of trouble-free driving.

These seemingly innocent habits and oversights can gradually accumulate into major mechanical failures, costly repairs, and ultimately, an early trip to the junkyard. What makes this particularly frustrating is that most of these issues are entirely preventable with proper knowledge and consistent maintenance practices.

The Liberty Renegade, produced from 2002 to 2012, features a sophisticated combination of systems that work together to deliver its renowned performance and reliability.

From its robust 3.7-liter V6 engine to its advanced four-wheel-drive system, every component requires specific care and attention to function optimally. When owners develop bad habits or ignore crucial maintenance schedules, they create a domino effect that can compromise multiple systems simultaneously.

The following eight habits represent the most common and damaging practices that can kill your Liberty Renegade years before its time, along with practical solutions to protect your vehicle and ensure it serves you faithfully for many miles to come.

1. Ignoring Regular Oil Changes and Using Wrong Oil Types

Oil serves as the lifeblood of your Liberty Renegade’s 3.7-liter V6 engine, and neglecting proper oil maintenance represents one of the most devastating habits that can kill your vehicle prematurely.

The engine oil performs multiple critical functions beyond simple lubrication, including heat dissipation, contaminant removal, and component protection. When owners skip oil changes or extend intervals beyond manufacturer recommendations, they create conditions that lead to catastrophic engine failure.

The Liberty Renegade’s engine operates under demanding conditions, generating significant heat and pressure that gradually breaks down oil molecules over time.

Fresh oil maintains its viscosity and protective properties, creating a thin barrier between moving metal components that prevents direct contact and friction.

As oil ages, it becomes contaminated with combustion byproducts, metal particles, and environmental debris, losing its effectiveness and potentially becoming abrasive rather than protective.

Using the wrong oil type compounds these problems exponentially. The Liberty Renegade requires specific viscosity ratings and additive packages designed for its engine’s tolerances and operating characteristics.

Many owners make the mistake of choosing oil based solely on price or availability, ignoring manufacturer specifications. Conventional oil may seem adequate, but synthetic or synthetic blend oils often provide superior protection under the extreme conditions your Liberty Renegade encounters during off-road adventures or heavy towing.

Temperature extremes particularly highlight the importance of proper oil selection. In cold weather, incorrect oil viscosity can prevent proper circulation during startup, leaving critical components unprotected during those crucial first moments of operation.

Conversely, in hot conditions or during heavy-duty use, inadequate oil can thin excessively, failing to maintain proper pressure and protection when your engine needs it most.

The timing chain system in Liberty Renegade engines is particularly vulnerable to oil-related issues. Insufficient or degraded oil can cause timing chain stretch, leading to improper valve timing and potential engine damage.

This problem often develops gradually, with symptoms including rough idling, reduced power, and unusual engine noises. By the time these symptoms become apparent, significant damage may have already occurred, requiring expensive repairs or complete engine replacement.

Oil filter neglect represents another dimension of this destructive habit. Many owners focus solely on oil changes while ignoring filter replacement, not realizing that a clogged filter forces oil to bypass filtration entirely.

This contaminated oil circulates through the engine, carrying abrasive particles that accelerate wear on bearings, pistons, and other precision components. Quality oil and filter selection represents a worthwhile investment in your Liberty Renegade’s longevity.

While premium products cost more initially, they provide superior protection and often allow longer service intervals, potentially reducing maintenance costs. Regular oil level checks between changes can identify leaks or consumption issues before they become critical, allowing for timely repairs that prevent major damage.

2. Neglecting Transmission Maintenance and Fluid Changes

Transmission neglect ranks among the most expensive mistakes Liberty Renegade owners can make, yet it remains surprisingly common due to misconceptions about automatic transmission maintenance requirements.

The complex hydraulic systems within your Liberty Renegade’s transmission depend entirely on clean, properly functioning fluid to operate reliably. When owners ignore transmission maintenance or follow outdated “lifetime fluid” myths, they set the stage for catastrophic failure that can cost thousands of dollars to repair.

Modern automatic transmissions represent marvels of engineering complexity, featuring intricate networks of hydraulic circuits, electronic controls, and precision mechanical components.

The transmission fluid serves multiple critical functions simultaneously, acting as a hydraulic medium, lubricant, coolant, and cleaning agent. Over time, this fluid degrades due to heat, contamination, and chemical breakdown, losing its ability to protect and operate the transmission effectively.

Heat represents the transmission’s greatest enemy, and degraded fluid compounds this problem significantly. Fresh transmission fluid maintains specific viscosity characteristics that enable proper hydraulic pressure and smooth operation.

As fluid ages, it oxidizes and thickens, creating flow restrictions that force the transmission to work harder and generate even more heat. This creates a destructive cycle where increased heat accelerates fluid degradation, leading to progressively worse performance and eventual failure.

The torque converter, a key component in automatic transmissions, is particularly vulnerable to fluid-related problems. This device uses transmission fluid to transfer power from the engine to the transmission through hydraulic coupling.

Contaminated or degraded fluid can cause torque converter shudder, lock-up clutch failure, or complete converter breakdown. These problems often manifest as vibration during acceleration, delayed engagement, or transmission overheating.

Electronic transmission controls in modern Liberty Renegades rely on precise hydraulic pressures to function correctly. Degraded fluid affects pressure regulation, leading to harsh shifts, slipping, or erratic behavior.

The transmission’s computer may compensate for these issues initially, but eventually, the system becomes unable to maintain proper operation, resulting in limp mode activation or complete transmission shutdown.

Contamination represents another critical factor in transmission longevity. Over time, normal wear creates metal particles that circulate with the fluid, acting as abrasives that accelerate component wear.

Proper transmission maintenance involves more than simple fluid changes. The filter, pan gasket, and other serviceable components require attention during maintenance intervals.

Some transmissions also feature external filters or coolers that need periodic service. Following manufacturer recommendations and using specified fluid types ensures optimal performance and longevity.

3. Skipping Coolant System Maintenance

The cooling system in your Liberty Renegade represents a critical network of components working together to maintain optimal engine operating temperatures, and neglecting this system can lead to catastrophic engine damage that kills your vehicle prematurely.

Despite its importance, coolant system maintenance often gets overlooked by owners who focus primarily on oil changes while ignoring the complex requirements of modern cooling systems. This oversight can result in overheating, head gasket failure, cracked engine blocks, and complete engine destruction.

Modern Liberty Renegade engines operate at precisely controlled temperatures to maximize efficiency and minimize emissions. The cooling system maintains this delicate balance through a sophisticated combination of coolant circulation, heat transfer, and pressure regulation.

When any component fails or the coolant becomes degraded, the entire system’s effectiveness diminishes, potentially leading to engine temperatures that exceed safe operating limits.

Coolant serves multiple functions beyond simple heat absorption and transfer. Modern formulations include corrosion inhibitors, lubricants for water pump seals, and additives that prevent scale formation and electrolysis.

Over time, these additives become depleted, and the coolant’s pH changes, creating conditions that promote corrosion throughout the cooling system. This internal corrosion can clog passages, damage components, and create leaks that lead to sudden coolant loss and overheating.

The radiator represents the cooling system’s primary heat exchanger, and its effectiveness depends on both internal cleanliness and external airflow.

Contaminated coolant can create deposits that reduce heat transfer efficiency, while external debris accumulation blocks airflow through the radiator fins.

Many Liberty Renegade owners neglect radiator cleaning, allowing leaves, insects, and dirt to accumulate until cooling capacity becomes severely compromised.

Water pump failure represents one of the most serious consequences of coolant neglect. This critical component circulates coolant throughout the engine, and its internal seals and bearings depend on proper coolant lubrication and corrosion protection.

Head gasket failure represents one of the most expensive consequences of cooling system neglect. When engines overheat repeatedly or severely, the cylinder head can warp, compromising the head gasket seal.

This allows coolant to enter combustion chambers or mix with engine oil, creating a cascade of problems that often require complete engine rebuild or replacement.

Proper coolant selection is crucial for Liberty Renegade longevity. Using the correct coolant type and mixture ratio ensures optimal protection and performance. Different coolant chemistries are not compatible, and mixing types can create precipitates that clog the system. Following manufacturer specifications for coolant type and change intervals provides the best protection for your investment.

4. Poor Air Filter Maintenance and Intake System Neglect

The air intake system of your Liberty Renegade serves as the lungs of your engine, and neglecting this critical system can gradually strangle your vehicle’s performance while accelerating engine wear that ultimately leads to premature failure.

Many owners underestimate the importance of clean air filtration, viewing air filter replacement as an optional maintenance item rather than a critical component in engine longevity.

This misconception can result in reduced power, increased fuel consumption, and accelerated engine wear that significantly shortens your Liberty Renegade’s operational life.

Your Liberty Renegade’s engine requires approximately 12,000 gallons of air for every gallon of fuel burned, making air quality absolutely crucial for proper combustion and engine protection.

The air filter serves as the primary defense against environmental contaminants, including dust, pollen, insects, and other debris that can damage internal engine components.

When this filter becomes clogged or damaged, it restricts airflow while allowing contaminants to enter the engine, creating a double-edged problem that affects both performance and longevity.

Restricted airflow from a clogged air filter forces the engine to work harder to draw the air needed for combustion. This increased effort manifests as reduced power output, decreased fuel economy, and altered air-fuel ratios that can affect combustion quality.

The engine management system attempts to compensate for these changes, but eventually reaches the limits of its adjustment capabilities, leading to rough idle, hesitation, and other performance issues that indicate potential internal damage.

Contaminated air entering the engine through a compromised filter creates abrasive conditions that accelerate wear on pistons, rings, cylinders, and other precision components.

These microscopic particles act like sandpaper within the engine, gradually wearing away protective surfaces and tolerances that took precision manufacturing to achieve.

Over time, this wear accumulates into decreased compression, increased oil consumption, and eventually complete engine failure requiring expensive rebuild or replacement.

The Mass Airflow (MAF) sensor, a critical component in modern fuel injection systems, is particularly vulnerable to contamination from neglected air filters.

This sensor measures incoming airflow to determine proper fuel delivery, and contamination can cause erratic readings that lead to incorrect fuel mixtures. Cleaning or replacing a contaminated MAF sensor can be expensive, but the long-term effects of incorrect fuel delivery on engine components can be catastrophic.

Off-road driving, popular among Liberty Renegade owners, exposes the air intake system to particularly harsh conditions. Dust, sand, and debris are more prevalent in these environments, requiring more frequent air filter inspection and replacement.

Many owners fail to adjust their maintenance schedules for severe driving conditions, allowing filters to become severely clogged before replacement.

The intake system extends beyond the air filter to include ducting, throttle body, and intake manifold components that also require periodic attention. Debris that bypasses compromised filters can accumulate in these areas, restricting airflow and affecting engine performance.

Proper installation is crucial for air filter effectiveness. Incorrectly seated filters create bypass routes that allow unfiltered air to enter the engine. Ensuring proper filter orientation and sealing prevents contamination while maintaining optimal airflow.

Using genuine or high-quality replacement filters ensures proper fit and filtration characteristics designed for your Liberty Renegade’s specific requirements.

Also Read: 8 Moves That Ruin a Ford Contour Too Soon

5. Ignoring Brake System Maintenance

Brake system neglect in your Liberty Renegade represents not only a serious safety hazard but also a costly oversight that can lead to cascading mechanical failures throughout your vehicle’s systems.

The brake system operates under extreme conditions, generating tremendous heat and pressure while requiring precise hydraulic operation to function effectively.

When owners ignore brake maintenance schedules or dismiss early warning signs, they create conditions that can result in complete brake failure, damaged suspension components, and even transmission problems that can kill your Liberty Renegade prematurely.

The hydraulic nature of modern brake systems means that contaminated brake fluid can cause widespread component damage throughout the entire system. Brake fluid is hygroscopic, meaning it absorbs moisture from the atmosphere over time.

This absorbed moisture lowers the fluid’s boiling point, creating the potential for brake fade or complete failure under heavy braking conditions. Additionally, moisture promotes corrosion within brake lines, calipers, and other components, leading to leaks and reduced braking effectiveness.

Brake pad wear creates more than just reduced stopping power; worn pads can damage expensive components throughout the braking system. When pads wear beyond their intended limits, metal backing plates contact brake rotors directly, creating excessive heat and causing rotor warping or cracking.

This metal on metal contact can also damage calipers, as the pistons extend beyond their normal operating range to compensate for missing pad material. The Liberty Renegade’s Anti-lock Braking System (ABS) adds complexity that requires specific maintenance attention.

ABS components, including wheel speed sensors, hydraulic modulators, and control modules, can be damaged by contaminated brake fluid or excessive heat from neglected brake maintenance.

ABS repairs often cost significantly more than conventional brake work, and failure can affect vehicle stability and safety systems. Heat buildup from neglected brakes affects more than just braking components.

Excessive brake heat can damage wheel bearings, CV joints, and suspension components located near the brake assemblies. Warped rotors create vibrations that stress suspension bushings and ball joints, leading to premature wear and expensive repairs.

This cascading effect means that brake neglect can result in thousands of dollars in related repairs beyond simple brake component replacement.

Quality replacement parts are crucial for brake system longevity and performance. Cheap brake pads may save money initially, but they often wear faster and can damage rotors, leading to higher long-term costs.

Using manufacturer-specified brake fluid ensures compatibility with system seals and components, preventing premature failure and maintaining optimal performance.

6. Neglecting the Four-Wheel Drive System

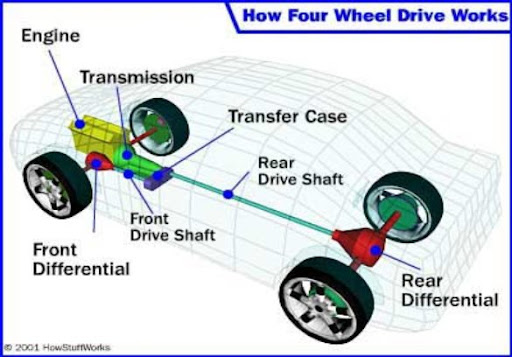

The four-wheel drive system represents one of the Liberty Renegade’s defining features, providing the capability that attracts many owners to this versatile SUV.

However, this complex mechanical system requires specific maintenance and proper operation to function reliably over the vehicle’s lifetime. Neglecting 4WD maintenance or misusing the system can lead to catastrophic failures that require thousands of dollars in repairs while potentially damaging other drivetrain components.

Understanding proper 4WD care is essential for preserving your Liberty Renegade’s capability and value. The transfer case serves as the heart of the 4WD system, distributing power between front and rear axles while providing different operating modes for various driving conditions.

This component contains its own lubrication system with specific fluid requirements that differ from engine oil or transmission fluid. Many owners incorrectly assume that transfer case fluid never requires changing, leading to contamination and component wear that can cause complete system failure.

Transfer case fluid serves multiple critical functions, including lubrication of gears and chains, heat dissipation, and protection against corrosion. Over time, this fluid degrades due to heat, contamination, and normal wear particles from internal components.

Degraded fluid can cause increased wear, overheating, and eventual failure of expensive internal components like chains, gears, and shift mechanisms.

The Liberty Renegade’s 4WD system includes front and rear differentials that also require periodic fluid changes. Differential fluid lubricates ring and pinion gears that operate under extreme pressure and heat.

Contaminated differential fluid can cause premature gear wear, bearing failure, and complete axle assembly damage. Many owners focus on engine and transmission maintenance while ignoring these equally important components.

Improper 4WD usage represents another common cause of premature system failure. Many Liberty Renegade owners engage 4WD on dry pavement or fail to disengage the system when returning to normal road conditions.

This misuse places tremendous stress on drivetrain components and can cause tire wear, driveline binding, and expensive component damage. Understanding when and how to use 4WD properly is crucial for system longevity.

Proper fluid specifications are crucial for 4WD system longevity. Using incorrect fluids can cause seal damage, increased wear, and premature failure. Different components may require different fluid types, and mixing incompatible fluids can create chemical reactions that damage seals and internal components.

7. Overlooking Electrical System Health

The electrical system in modern Liberty Renegades represents a complex network of interconnected components that control everything from basic engine operation to advanced safety and comfort features.

Neglecting electrical system maintenance can lead to cascading failures that affect multiple vehicle systems simultaneously, creating expensive repair situations that can effectively kill your Liberty Renegade’s reliability and value.

Understanding the importance of electrical system health and implementing proper maintenance practices is crucial for preventing these costly failures.

The battery serves as the foundation of your Liberty Renegade’s electrical system, but many owners treat it as a simple maintenance-free component that requires no attention until complete failure.

Modern automotive batteries face numerous challenges, including extreme temperatures, vibration, and constant charging and discharging cycles that gradually reduce capacity and reliability. A failing battery doesn’t simply stop starting the vehicle; it can damage expensive electronic components throughout the system.

Corrosion represents another critical threat to electrical system health that many owners ignore until visible damage becomes apparent. Battery terminal corrosion creates resistance that reduces charging system efficiency and can cause voltage drops throughout the electrical system.

This corrosion can spread to nearby components, including fuse boxes, relays, and wiring harnesses, creating multiple failure points that require expensive repairs.

The alternator works in partnership with the battery to provide electrical power while the engine runs, and neglecting this component can result in sudden electrical system failure.

Many owners focus on battery replacement while ignoring alternator maintenance, not realizing that a failing alternator can damage batteries and electronic components throughout the vehicle. Regular alternator testing can identify developing problems before complete failure occurs.

Accessory installation represents another common source of electrical system problems in Liberty Renegades. Many owners install aftermarket accessories without proper electrical knowledge, creating circuits that can overload the charging system or cause interference with factory systems.

Improper installation techniques can also create voltage drops, ground loops, or other problems that affect multiple vehicle systems. Proper electrical system maintenance also includes protecting components from environmental damage through appropriate cleaning and protection products.

Dielectric grease can prevent corrosion in connections, while proper cleaning techniques can remove contaminants that cause electrical problems. These simple preventive measures can significantly extend the life of expensive electrical components.

8. Poor Tire Maintenance and Suspension Neglect

The tire and suspension system of your Liberty Renegade works together as an integrated unit, affecting virtually every aspect of vehicle operation, from safety and handling to fuel economy and component longevity.

Neglecting this critical system can lead to premature wear of expensive components throughout the vehicle while compromising safety and performance.

Poor tire maintenance and suspension neglect represent false economy that ultimately costs far more than proper preventive care while potentially creating dangerous driving conditions.

Improper tire pressure represents the most common and destructive tire maintenance oversight, yet many Liberty Renegade owners check their tire pressure infrequently or rely solely on tire pressure monitoring systems for pressure management.

Under-inflated tires generate excessive heat, which breaks down the tire compounds and can lead to sudden tire failure. This heat also increases rolling resistance, reducing fuel economy and placing additional stress on the engine and drivetrain components.

Over-inflation creates different but equally serious problems, reducing the tire’s contact patch and creating uneven wear patterns that reduce tire life and compromise traction.

Over-inflated tires also provide less impact absorption, transmitting more road shock to suspension components and potentially causing premature wear of bushings, ball joints, and shock absorbers. The ride quality degradation from over-inflated tires can also mask developing suspension problems.

Tire rotation schedules are frequently ignored by Liberty Renegade owners, leading to uneven wear patterns that require premature tire replacement and can indicate developing suspension problems.

Different wheel positions experience different loading and wear patterns, and regular rotation helps ensure even wear across all tires. Failure to rotate tires regularly can also mask alignment problems or suspension wear that would otherwise be detected early.

Wheel alignment significantly affects tire life and vehicle handling, yet many owners only consider alignment after noticing severe tire wear or handling problems.

Misalignment can be caused by road hazards, worn suspension components, or normal settling of suspension parts over time. Even slight misalignment can reduce tire life dramatically while affecting fuel economy and vehicle safety. Prevention of tire and suspension problems requires regular inspection, proper maintenance techniques, and attention to driving conditions.

Adjusting maintenance schedules for severe use conditions, using quality components, and addressing problems promptly can significantly extend component life while maintaining safety and performance. These practices represent wise investments that preserve your Liberty Renegade’s reliability and value while ensuring safe operation.

Also Read: 9 Common Mistakes That Ruin a Jeep Wagoneer’s Reliability