Inline-6 engines hold a special place in automotive engineering due to their smooth operation, balanced design, and strong performance.

Over the decades, certain inline-6 engines have earned reputations for exceptional durability and reliability, serving enthusiasts and everyday drivers alike for hundreds of thousands of miles. However, not every inline-6 engine is created equal.

While some powertrains have stood the test of time, others have demonstrated frequent mechanical issues and failures, often leading to costly repairs and disappointment for owners.

Understanding the characteristics that set dependable inline-6 engines apart from those prone to failure can offer valuable insights for car buyers, mechanics, and enthusiasts focused on longevity and sensible maintenance.

This article will review five inline-6 engines that are celebrated for lasting forever through robust engineering and well-designed components. It will then shift focus to five inline-6 engines known for their persistent problems and reliability challenges.

Each engine will be explored in detail to explain what contributes to its reputation, why it matters, and lessons that can be drawn from their histories.

This balanced approach aims to provide a fair perspective on inline-6 engine performance and help readers make informed decisions regarding these iconic powerplants.

Also Read: 5 Sedans That Feel Solid After 15 Years vs 5 That Don’t

5 Inline-6 Engines That Last Forever

Inline-6 engines are celebrated for their inherent mechanical balance and smooth power delivery. Over many decades, several inline-6 engines have gained legendary status for their rugged durability and ability to sustain high mileage without major failures.

These engines are not just mechanical marvels but also examples of engineering choices that emphasize longevity, simplicity, and maintenance ease.

The inline-6 layout’s even firing order and balanced forces contribute to less vibration and wear, which can extend engine life when combined with solid materials and proper design.

Among all the inline-6 engines produced, a select few have consistently demonstrated exceptional reliability, making them favorites among enthusiasts, fleet operators, and daily drivers alike.

This section highlights five of these remarkable engines, detailing what makes them so resilient, how their designs contribute to their endurance, and why they continue to be trusted powerplants years after their introduction.

By understanding their construction, maintenance practices, and operational strengths, it becomes clear why these inline-6 engines are synonymous with lasting performance and engineering excellence.

1. Toyota 2JZ-GTE

One of the most famous inline-6 engines known for incredible longevity is the Toyota 2JZ-GTE. This engine has become a staple in the automotive world, especially among performance enthusiasts who prize its robust construction and tuning potential.

Originally introduced in the early 1990s, the 2JZ-GTE was built with strength and reliability as key priorities. Its cast-iron block and forged internals provide a foundation that can handle extreme power outputs well beyond stock specifications without compromising durability.

The key to the 2JZ-GTE’s lasting appeal lies in its design simplicity combined with high-quality components. It features a smooth-running inline-6 configuration that reduces vibration and wear on moving parts, helping it endure high mileage.

Toyota engineered this engine to perform consistently under varied driving conditions, contributing to its reputation for reliability even in harsh environments. Regular maintenance, such as timely oil changes and proper cooling system care, further enhances its lifespan.

Beyond its factory-built toughness, the 2JZ-GTE is widely celebrated for its ability to withstand extensive modifications while maintaining mechanical integrity.

Many owners have documented running over 300,000 miles on these engines, proving their long-term viability.

This level of durability, along with strong aftermarket support, is precisely why the 2JZ-GTE is often considered one of the best inline-6 engines that last forever. It serves as a benchmark for engineering excellence in the performance and reliability arenas.

2. BMW M30

Another noteworthy inline-6 engine renowned for its enduring reliability is the BMW M30 series. The M30 engine was produced from the late 1960s through the early 1990s, serving as the backbone powerplant for many BMW models during that era.

This engine’s longevity is owed to its robust cast-iron block and simple yet effective design. With a focus on smoothness and durability, the M30 balanced performance with the capacity to endure the rigors of daily use over many years.

The M30’s design prioritized ease of repair and maintenance, contributing significantly to its lasting reputation. It employed reliable fuel injection systems and well-engineered cooling and lubrication systems that reduced common wear issues.

Owners who followed regular maintenance schedules often saw these engines surpass 200,000 miles with minimal repairs. Furthermore, the M30 featured a straightforward valve train and mechanical components well-known for their resilience, minimizing the likelihood of catastrophic failures.

BMW’s inline-6 architecture allowed the M30 engine to run with minimal vibration, reducing mechanical stress and wear on bearings and seals. This smooth operation helped the engine maintain internal integrity for extended periods.

Its long life and dependable performance made it a favorite among enthusiasts who wanted a blend of refined power and lasting reliability from their BMW vehicles. The M30’s track record firmly establishes its place among the inline-6 engines that truly last forever.

3. Cummins 6BT

The Cummins 6BT inline-6 turbo diesel engine is celebrated for its incredible durability and robust construction, making it a favorite in heavy-duty applications.

Primarily found in trucks, industrial machinery, and agricultural equipment, the 6BT has earned a reputation as an engine that can literally run for hundreds of thousands of miles with minimal downtime.

The strength of the Cummins 6BT comes from its simple yet rugged design, combining a sturdy cast-iron block with a well-proven indirect injection fuel system.

Unlike many gasoline engines, the 6BT’s diesel architecture prioritizes torque and longevity over outright speed, contributing to less wear and tear under heavy loads.

Its mechanical fuel injection system, though older technology, is designed to be service-friendly and reliable in tough environments. This mechanical simplicity translates to fewer electronic components that can fail, which is part of why the 6BT endures.

Owners and fleet operators praise the 6BT for its ease of maintenance, availability of parts, and ability to handle continual heavy use without significant mechanical issues. Regular oil changes and cooling system upkeep keep this engine running reliably.

The 6BT’s proven endurance also stems from engineering choices that withstand thermal and mechanical stresses, ensuring engines can be rebuilt several times without loss of integrity. The Cummins 6BT is a textbook example of an inline-6 designed for longevity and heavy-duty reliability, echoing in numerous applications worldwide.

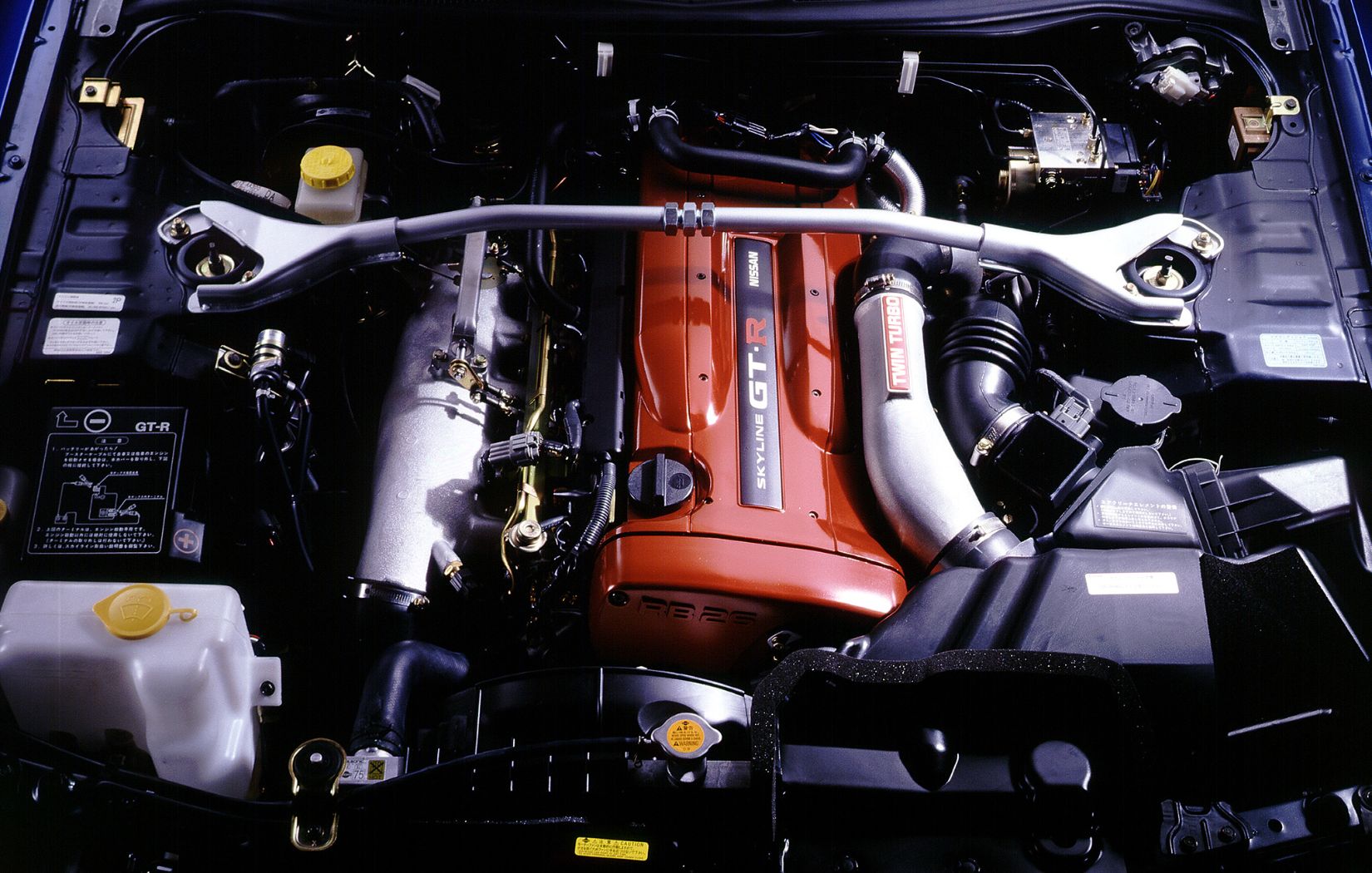

4. Nissan RB26DETT

The Nissan RB26DETT is an inline-6 engine that has garnered iconic status, particularly among enthusiasts who value both performance and longevity.

Introduced in the late 1980s and famously used in the Nissan Skyline GT-R, the RB26DETT was designed with a strong focus on durability despite its high-performance intent. Its robust iron block and aluminum head construction created a balance between strength and weight savings.

One factor contributing to the RB26DETT’s lasting reputation is its engineering for high-revving, turbocharged applications without sacrificing reliability.

The engine includes a well-designed cooling system and forged internals that help it endure thermal stresses common in performance engines. Additionally, Nissan carefully engineered the valvetrain and made provisions for routine maintenance that reduce wear and extend the engine’s operational life.

Owners have reported RB26DETT engines lasting well over 200,000 miles, particularly when proper care is taken, including regular oil changes and using high-quality fuel and lubricants.

The engine’s ability to maintain durability even when tuned for more power shows its inherent strength.

This durability combined with its high-revving inline-6 nature makes the RB26DETT a glowing example of an inline-6 engine that lasts indefinitely with appropriate care and respect to its design limitations. It remains a benchmark for reliability in performance applications.

5. Mercedes-Benz M104

Another inline-6 engine distinguished by its impressive longevity is the Mercedes-Benz M104 series. Produced in the late 1980s through the late 1990s, the M104 engine was engineered with a particular emphasis on precision, durability, and smooth operation.

Its aluminum block and heads, coupled with a sturdy design, allowed it to deliver refined power across various Mercedes-Benz sedans and coupes reliably.

The M104’s reputation for lasting forever is anchored in its robust mechanical components, including well-built pistons, camshafts, and valvetrain systems designed for longevity.

Mercedes-Benz engineers emphasized quality materials, which when combined with meticulous maintenance, translated to engines that routinely surpass 200,000 miles without major issues.

The engine’s straightforward design allowed for relatively easy maintenance and repairs, an important factor in extending its life.

This engine also benefits from Mercedes’ attention to cooling and lubrication, with systems optimized to prevent overheating and reduce internal wear.

The inline-6 smoothness minimizes vibration, reducing stress on parts and contributing further to its endurance. Drivers who maintained their M104 engines carefully often found them reliable through many years and miles, showing that well-designed inline-6 engines from premium manufacturers can indeed last forever with the right care.

The M104’s lasting legacy is a testament to quality engineering meeting rigorous standards and customer expectations.

5 Inline-6 Engines That Constantly Fail

Not every inline-6 engine enjoys a reputation for longevity and reliability. Despite the inherent balance and smoothness of the inline-6 design, some engines in this category have struggled with persistent mechanical and electronic issues that have led to frequent breakdowns and costly repairs.

These engines often suffer from design flaws, material weaknesses, or manufacturing oversights that result in problems such as overheating, premature wear, or failures of critical components like timing systems, cooling parts, or electronic sensors.

Such challenges can frustrate owners and mechanics alike, requiring substantial maintenance efforts to keep these engines running reliably.

Examining these less reliable inline-6 engines sheds light on the difficulties that can arise even within a seemingly promising engine layout.

By analyzing the root causes of their failures, it becomes evident how important it is to consider not just the engine configuration but also the quality of engineering, materials, and support systems.

This section focuses on five notable inline-6 engines that have been reported to suffer from chronic reliability problems, explaining why they struggle and the lessons that can be drawn from their histories.

Understanding these issues helps inform better maintenance, smarter purchasing decisions, and improvement opportunities within the inline-6 engine family.

1. Rover M57

The Rover M57 inline-6 diesel engine is an example of an engine that has frequently been criticized for its shortcomings in reliability and durability.

Introduced in the early 2000s in various Rover and MG models, the M57 struggled to gain a reputation for dependability despite its promising technical basics.

One of the main issues with the M57 was its complex engineering and electronics, which often resulted in frequent sensor failures and erratic engine management systems.

Owners regularly reported problems with rough running, stalling, and poor fuel economy, all indicative of deeper issues with the engine’s fuel injection and control modules.

The M57 also suffered from cooling system inefficiencies leading to overheating, which caused premature wear on critical engine components such as the head gasket and cylinder liners.

Another challenge was the M57’s sensitivity to maintenance neglect. Even small lapses in oil changes or coolant upkeep could accelerate failures, reducing the engine’s service life substantially.

Parts availability and cost were also sources of frustration for owners attempting repairs. While the M57 inline-6 diesel had potential in theory, its practical application revealed numerous engineering and manufacturing weaknesses, leading to a reputation for constant failure and high repair costs.

This engine underscores how intricate design paired with maintenance sensitivities can negatively impact the reliability of an otherwise promising inline-6.

2. Ford Barra

The Ford Barra inline-6 engine, despite being a technically advanced and powerful powerplant, has been known to exhibit reliability issues in certain versions and applications.

Introduced primarily in the Australian market, the Barra engine featured modern technology such as variable cam timing and electronic fuel injection but experienced issues that eroded confidence in some owners.

A primary source of failure in the Barra engines stemmed from the timing chain and its associated components. Premature wear or failure of the timing chain tensioner and guides led to catastrophic engine damage for many users.

This was exacerbated by the engine’s high-revving nature and the stresses placed on these components without adequate reinforcement or improved materials in earlier models. Additionally, some Barra variants suffered from oil pump failures and problems with the valvetrain, leading to costly repairs.

Cooling system weaknesses, including thermostat and water pump failures, contributed to overheating risks that further shortened engine life if not addressed promptly. The electronic systems controlling fuel delivery and ignition also occasionally caused performance inconsistencies and breakdowns.

While the Barra inline-6 had potential as a smooth and powerful engine, these recurring issues created a reputation for instability and reliability concerns.

Owner experiences revealed that without vigilant maintenance and sometimes costly interventions, the Barra could be a challenging inline-6 to keep on the road long term. This highlights how gaps in timing and cooling system robustness can undo an engine’s otherwise promising design.

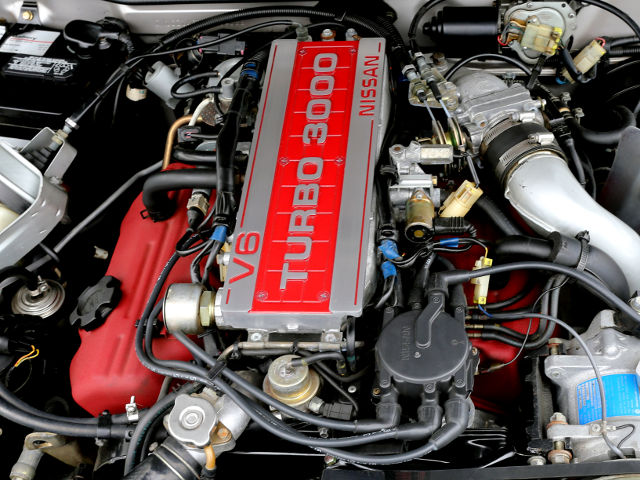

3. Nissan VG30ET

The Nissan VG30ET inline-6 engine, though praised for its performance when new, has consistently faced reliability challenges that have impacted its reputation over the years.

Introduced in the 1980s as a turbocharged option for several Nissan models, the VG30ET was ambitious in its power delivery but vulnerable to certain mechanical weaknesses.

One of the most notorious problems with the VG30ET involved the turbocharger and its related components. Turbo failure was common, caused by inadequate cooling and oil supply issues within the turbo assembly.

This often led to catastrophic engine damage if not addressed early. The engine also suffered from a less-than-robust head gasket design, with failures often triggered by overheating or detonation under boosted conditions.

Additionally, the VG30ET’s timing belt system required exacting maintenance intervals; failure to replace the belt and tensioners on schedule frequently resulted in severe engine damage from valve-to-piston contact.

The engine’s cooling system showed signs of inefficiency, heightening risks of overheating, especially in older or neglected vehicles.

While the VG30ET offered attractive power and smoothness on paper, many owners experienced disappointing reliability due to these mechanical vulnerabilities.

Its reputation for constant failure, especially related to forced induction components and cooling system weaknesses, marks it as one of the inline-6 engines that require caution and attentive maintenance to prevent costly repairs.

4. BMW N52

The BMW N52 inline-6 engine, known for its lightweight magnesium-aluminum construction and advanced technology, has faced mixed reviews regarding its long-term reliability.

Produced in the mid-2000s, the N52 featured innovations like variable valve timing and an electric water pump, enhancing performance and efficiency. However, these features also introduced reliability concerns that affected many owners.

One common failure point in the N52 engine is the electric water pump. Unlike traditional mechanical pumps, the N52’s electric pump is prone to early failure, which can cause rapid overheating if not detected promptly.

The plastic impellers inside the pump can deteriorate and break, leading to coolant circulation issues. Additionally, the engine’s thermostat is another frequent weak component that can cause cooling system malfunctions.

The N52 also experiences issues with valve cover gasket leaks, oil sludge buildup due to short drives or infrequent oil changes, and problematic fuel injectors causing misfires. The complexity of the engine’s electronics increases the potential for sensor failures and related performance problems.

While the N52’s design aimed at lightness and efficiency, some engineering choices have resulted in components that do not last as long as more traditional inline-6 engines.

Owners must be vigilant with maintenance, especially cooling and oil service, to avoid frequent failures that have earned this engine a reputation for being less robust than older designs.

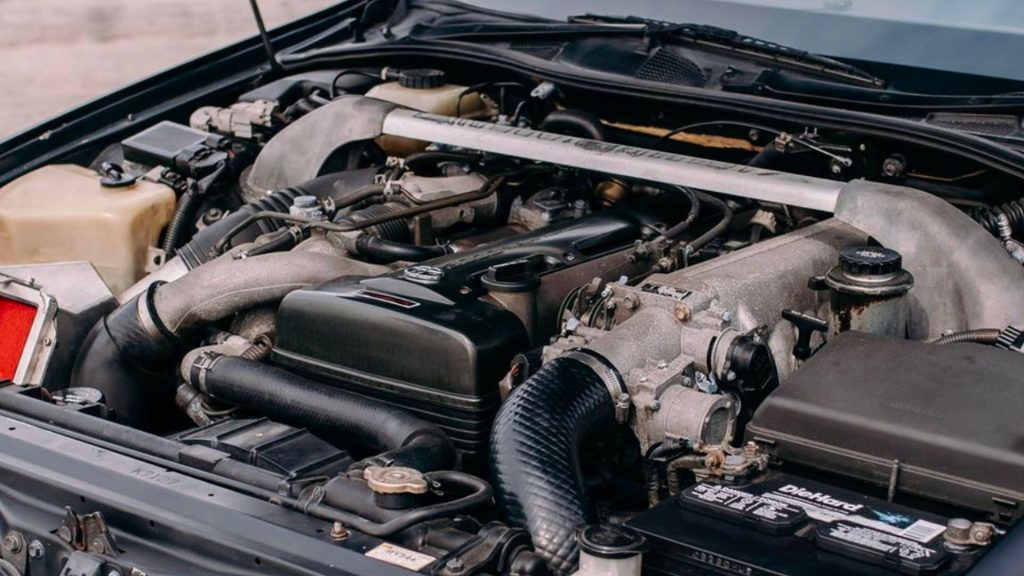

5. Jeep 4.0L Inline-6

The Jeep 4.0L inline-6 engine, while historically praised for its ruggedness, has experienced specific issues in later years that contributed to reliability concerns.

This engine powered various Jeep models from the 1980s through the early 2000s and was widely regarded for its torque and durability.

However, a closer look at its later iterations reveals a number of persistent problems that led some owners to rate it as an inline-6 with frequent troubles.

A significant source of failure was head gasket leaks. Some versions of the 4.0L engine developed problems due to the gasket design and cooling system management, which resulted in overheating and premature gasket failure. These leaks often caused coolant mixing with oil, escalating engine damage.

The engine also faced challenges with the crankshaft position sensor, which could fail and cause stalling or starting difficulties. In addition, the ignition system and fuel injection components sometimes showed vulnerability to age-related issues, affecting drivability.

Another issue involved the camshaft and lifter wear, which, when coupled with improper maintenance, led to rough running and decreased engine longevity. Despite its overall strong reputation, the Jeep 4.0L inline-6’s period-specific problems with sealing, sensors, and valve train contributed to its classification among inline-6 engines that consistently face reliability hurdles. Regular inspection and preventative maintenance were essential to mitigate these issues.

Inline-6 engines are admired for their balanced design, smooth power delivery, and strong performance characteristics. Their inherently even firing order and mechanical equilibrium contribute to less vibration and reduced mechanical stress, which can translate into longer engine life compared to other configurations. Yet, not all inline-6 engines share the same level of reliability and durability. Some have earned solid reputations for lasting hundreds of thousands of miles with minimal issues, while others struggle with chronic mechanical failures and high maintenance costs. This contrast highlights the importance of engineering decisions, material quality, maintenance practices, and design robustness in determining an engine’s longevity.

Among the inline-6 engines celebrated for exceptional durability, the Toyota 2JZ-GTE easily stands out.

Renowned for its rugged cast-iron block and forged internals, it supports very high power levels without sacrificing reliability.

Its smooth operation and consistent performance under various conditions have made it a favorite among enthusiasts worldwide, with many documented instances of these engines surpassing 300,000 miles.

Similarly, the BMW M30 engine series exemplifies longevity through its simple, effective design and strong cast-iron construction.

Its reputation for minimal vibration and mechanical wear has made it a dependable choice for decades, regularly crossing the 200,000-mile mark.