In the modern automotive world, the relationship between mechanical durability and electronic reliability has become increasingly complex.

While some vehicles are engineered with robust mechanical components that can run for hundreds of thousands of miles, their electronic systems often become the weak link that forces owners into costly repairs or premature retirement of otherwise capable machines.

Conversely, other vehicles suffer from fundamental design flaws or manufacturing shortcuts that cause critical electronic systems to fail well before the engine or transmission shows any signs of wear.

The dichotomy between mechanical and electronic longevity reflects broader changes in automotive manufacturing philosophy.

Traditional automakers who built their reputations on mechanical reliability sometimes struggle to adapt to the digital age, while others have embraced electronic complexity without ensuring adequate long-term durability. This electronic evolution has created a new category of automotive reliability concerns that didn’t exist in previous decades.

Electronic failures can range from minor inconveniences like malfunctioning infotainment systems to major safety concerns involving engine management, transmission control, or advanced driver assistance systems.

The cost of repairing these electronic components often exceeds the value of older vehicles, leading to the premature scrapping of mechanically sound cars. This phenomenon has significant implications for vehicle ownership costs, environmental impact, and consumer satisfaction.

Understanding which vehicles excel in mechanical durability while struggling with electronics, versus those that suffer from widespread electronic failures, helps consumers make informed decisions about long-term ownership.

The vehicles featured in this analysis represent different approaches to engineering, manufacturing quality control, and design philosophy. Some prioritize mechanical simplicity and reliability, while others push technological boundaries without ensuring adequate testing or component quality.

By examining these contrasting examples, we can better understand the complex relationship between mechanical engineering and electronic integration in modern vehicles, ultimately helping buyers choose cars that align with their priorities for reliability, technology, and long-term value retention.

5 Cars That Outlast Their Radios

These exceptionally engineered vehicles feature robust electrical systems and high-quality electronic components that maintain perfect operation through decades of temperature extremes and vibration stress.

Their thoughtful construction includes military-specification wiring harnesses, premium capacitors, and conservative circuit designs that resist the degradation patterns typically created by heat cycling and electromagnetic interference from modern powertrains.

From dashboard displays that remain crisp and readable to audio systems delivering concert-quality sound, these remarkable cars continue operating like new without experiencing the pixel failure, button malfunctions, or complete system crashes that plague contemporary alternatives.

Strategic component selection prioritizes proven reliability over cutting-edge features, while superior thermal management protects sensitive circuits from the engine bay heat that destroys lesser systems.

Owners report original radios, climate controls, and instrument clusters functioning perfectly after 20+ years, with some electronic modules outlasting multiple engine rebuilds.

The combination of premium components, conservative engineering, and excellent build quality creates electrical systems that prove their worth through consistent functionality long after the mechanical components require major service.

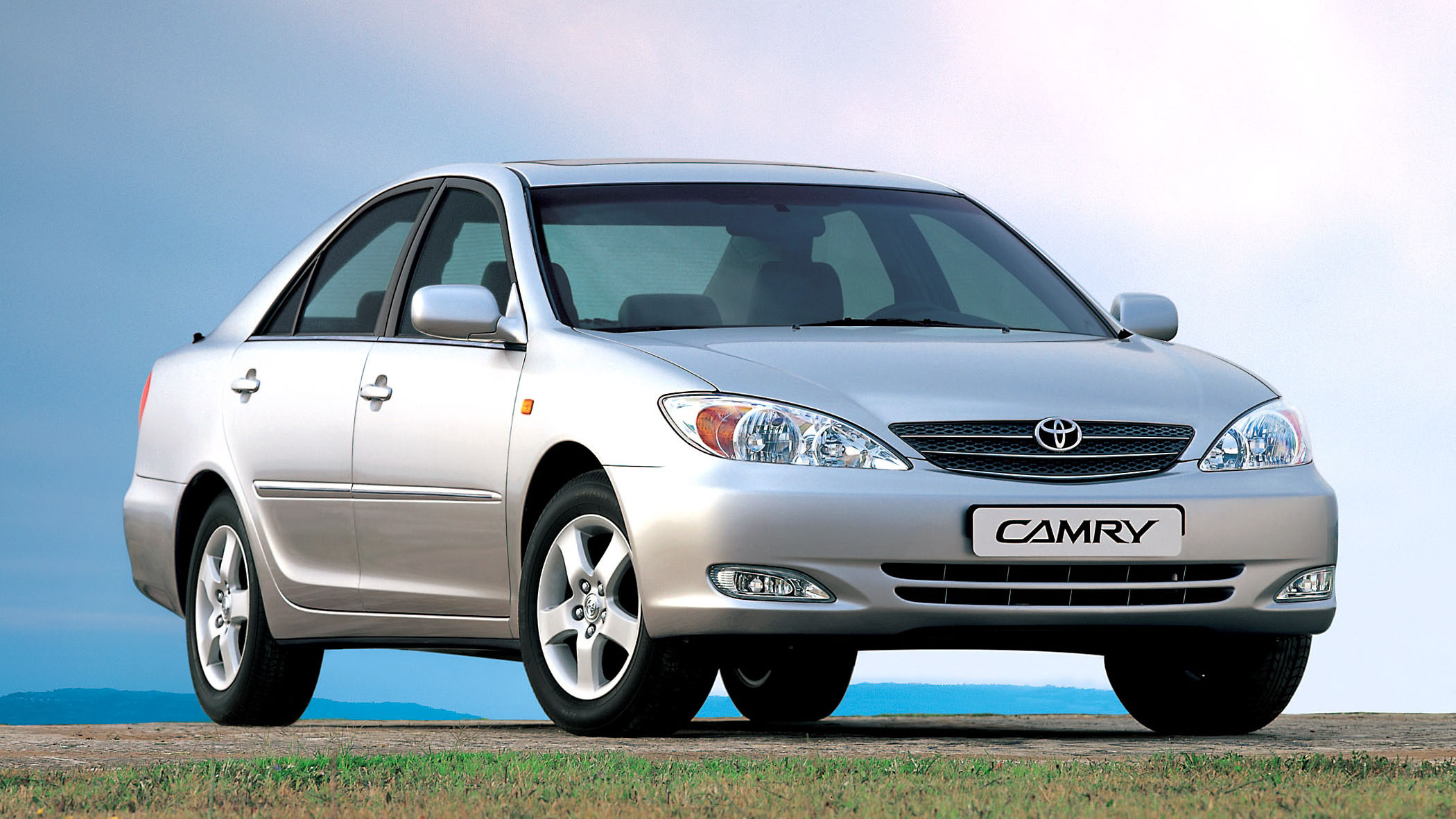

1. Toyota Camry (2002-2006)

The fifth-generation Toyota Camry represents one of the finest examples of mechanical durability overshadowing electronic reliability in modern automotive history.

Built during Toyota’s peak reputation for bulletproof engineering, these Camrys feature some of the most reliable powertrains ever produced, yet their electronic systems tell a different story entirely.

At the heart of this Camry’s legendary reliability lies the 2.4-liter 2AZ-FE four-cylinder engine and the optional 3.0-liter 1MZ-FE V6. Both engines are known for their exceptional longevity, with many examples exceeding 300,000 miles with basic maintenance.

The four-cylinder engine features a robust iron block construction with aluminum heads, while the V6 utilizes Toyota’s proven dual overhead cam design.

These powertrains are supported by equally durable transmissions, including a five-speed manual and a four-speed automatic that rarely require major service before 200,000 miles.

The mechanical components extend this reliability throughout the vehicle. The suspension system, while not particularly sophisticated, uses time-tested MacPherson struts and a multi-link rear setup that maintains functionality well beyond 200,000 miles.

Brake systems are straightforward and reliable, steering components rarely fail, and even the air conditioning compressors typically outlast the vehicle’s useful life. This mechanical robustness has made these Camrys popular choices for taxi services and fleet applications worldwide.

The longevity disparity highlights Toyota’s focus during this era on proven mechanical engineering while possibly underestimating the importance of electronic component quality.

Parts availability remains excellent for mechanical components, while electronic modules often require expensive dealer replacement or aftermarket alternatives of questionable quality.

This dichotomy makes the 2002-2006 Camry a perfect example of how mechanical excellence can’t compensate for electronic shortcomings in modern vehicle satisfaction.

2. Honda Accord (1998-2002)

The sixth-generation Honda Accord exemplifies Honda’s engineering philosophy during the late 1990s and early 2000s, when mechanical reliability was paramount but electronic sophistication was still developing.

This generation of Accord was built upon Honda’s reputation for durable, efficient powertrains while incorporating increasingly complex electronic systems that would prove to be less reliable than their mechanical counterparts.

The mechanical foundation of these Accords centers around Honda’s legendary F-series and J-series engines. The 2.3-liter F23A1 four-cylinder and 3.0-liter J30A1 V6 engines represent some of Honda’s most dependable powertrains.

The four-cylinder engine features Honda’s VTEC variable valve timing system, providing both efficiency and performance while maintaining exceptional reliability.

Regular oil changes and basic maintenance typically result in engine life exceeding 250,000 miles. The V6 engine, while more complex, shares this longevity when properly maintained.

Supporting these engines are equally robust transmissions, including Honda’s five-speed manual and four-speed automatic. The manual transmission is virtually bulletproof, requiring only occasional clutch replacement and gear oil changes.

The automatic transmission, while not immune to failure, generally provides reliable service when fluid changes are performed regularly. These drivetrains are complemented by durable suspension components that maintain their integrity well beyond 200,000 miles.

The body structure and mechanical systems demonstrate Honda’s commitment to long-term durability. Door hinges, hood and trunk mechanisms, and even basic mechanical components like the parking brake system are engineered for extended service life.

The exhaust system, while not stainless steel, typically provides good longevity, and replacement components are readily available and reasonably priced.

The contrast between mechanical and electronic reliability in these Accords creates a unique ownership experience. Many examples continue to provide reliable transportation well beyond 200,000 miles despite having non-functional radios, climate control problems, or failed power accessories.

This situation has created a robust aftermarket for replacement electronic components, though the quality and longevity of these alternatives vary significantly.

3. Ford Crown Victoria (2003-2011)

The Ford Crown Victoria represents the end of an era in American automotive manufacturing, combining traditional body-on-frame construction with increasingly sophisticated electronic systems.

As Ford’s last rear-wheel-drive, V8-powered full-size sedan, the Crown Victoria was engineered for durability and serviceability, particularly for police and taxi service. However, its electronic systems often proved less durable than the robust mechanical components that made these vehicles legendary for their longevity.

The mechanical foundation of the Crown Victoria centers around Ford’s 4.6-liter modular V8 engine, specifically the 2V (two-valve) variant known for its exceptional reliability and ease of maintenance.

This engine features an iron block with aluminum heads, an overhead cam design, and relatively simple electronic fuel injection. With regular maintenance, these engines routinely exceed 200,000 miles, with many police and taxi examples surpassing 300,000 miles.

The engine’s design prioritizes durability over performance, using conservative tuning and robust internal components. Supporting this reliable powertrain is Ford’s 4R70W four-speed automatic transmission, a development of the long-running AOD family.

While not as refined as contemporary transmissions from other manufacturers, the 4R70W provides dependable service when properly maintained.

The transmission benefits from simple hydraulic control systems and readily available replacement parts. Regular fluid changes typically ensure transmission life that matches the engine’s longevity.

The Crown Victoria’s body-on-frame construction contributes significantly to its mechanical durability. The separate chassis provides exceptional rigidity and allows for easy repair of collision damage.

Suspension components, including the independent front suspension and solid rear axle, are overbuilt for typical passenger car duty. This robust construction made the Crown Victoria ideal for demanding applications like police pursuit and taxi service, where durability and repairability are paramount.

Brake systems exemplify the vehicle’s mechanical reliability, featuring large rotors and calipers that provide consistent performance and long service life.

The power steering system uses a traditional hydraulic setup that rarely requires attention beyond fluid changes. Even comfort features like the air conditioning system are designed for durability, with robust compressors and easily serviceable components.

However, the electronic systems tell a different story, often failing well before the mechanical components show significant wear. The factory audio system, particularly in later model years with CD and eventually MP3 capability, suffers from frequent failures.

Head unit displays fade or fail, CD mechanisms jam, and amplifiers develop problems that affect sound quality. The premium audio systems available in higher trim levels are particularly susceptible to component failures.

Despite these electronic shortcomings, the Crown Victoria’s mechanical reliability ensures continued operation long after electronic conveniences have failed. This reliability made these vehicles popular in the used car market, where buyers prioritize mechanical dependability over electronic sophistication.

4. Chevrolet Tahoe (2000-2006)

The GMT800 generation Chevrolet Tahoe represents General Motors’ commitment to traditional truck-based SUV construction, featuring robust mechanical components designed for towing and heavy-duty use.

Built on a proven truck platform with time-tested drivetrains, these Tahoes demonstrate exceptional mechanical longevity that often far exceeds the reliability of their increasingly complex electronic systems.

This generation marked a transition period for GM, as they incorporated more sophisticated electronics while maintaining their focus on mechanical durability.

The mechanical foundation of these Tahoes centers around GM’s legendary small-block V8 engines, specifically the 4.8-liter LR4 and 5.3-liter LM7 variants of the Gen III LS family.

These engines represent a significant advancement over previous GM powertrains, featuring aluminum heads, electronic fuel injection, and more sophisticated engine management.

Despite their electronic complexity, the fundamental mechanical design is exceptionally robust. The iron block construction, forged steel crankshafts, and conservative tuning contribute to engine longevity that routinely exceeds 200,000 miles with proper maintenance.

Supporting these reliable engines is GM’s 4L60E four-speed automatic transmission, a development of the long-running 700R4 family. While the 4L60E has electronic controls, its mechanical components are well-proven and generally reliable when properly maintained.

The transmission benefits from widespread parts availability and extensive aftermarket support, making repairs economical compared to more complex contemporary designs.

The truck-based platform contributes significantly to mechanical durability. The separate body-on-frame construction provides exceptional rigidity and allows for easy repair of damage.

The independent front suspension uses robust components sized for truck duty, while the solid rear axle is virtually bulletproof under normal passenger vehicle use.

This construction philosophy prioritizes durability and repairability over refinement, making these Tahoes popular for commercial and recreational towing applications.

Mechanical systems throughout the vehicle demonstrate GM’s traditional strengths. The power steering system uses a reliable hydraulic setup with a robust pump and steering gear.

Brake systems feature large rotors and calipers appropriate for the vehicle’s size and weight, providing consistent performance and reasonable service life. Even the air conditioning system benefits from truck-grade components that typically provide years of reliable service.

However, the electronic systems present significant challenges that often frustrate owners of otherwise reliable vehicles. The factory audio system, particularly the premium Bose setup available in higher trim levels, suffers from frequent component failures.

CD players jam or refuse to operate, radio displays fade or malfunction, and amplifiers develop problems that affect sound quality throughout the system. The integration of audio controls with climate and information systems means that radio failures can impact other vehicle functions.

Climate control electronics represent a major reliability concern. The electronic automatic climate control system frequently develops problems with temperature regulation, fan operation, and mode selection.

Actuator motors that control air distribution fail regularly, creating situations where heating or air conditioning cannot be properly directed. The rear climate control systems, when equipped, add additional complexity and failure points.

Despite these electronic challenges, the Tahoe’s mechanical reliability ensures that many examples continue providing reliable transportation long after various electronic systems have failed.

This durability has made these vehicles popular in the used market, where buyers often accept electronic shortcomings in exchange for proven mechanical reliability and excellent towing capability.

Also Read: 8 Habits That Ruin a Jeep Liberty Renegade Too Soon

5. Nissan Altima (2002-2006)

The third-generation Nissan Altima marked a significant evolution in Nissan’s midsize sedan offerings, introducing more sophisticated powertrains and electronic systems while maintaining the mechanical reliability that had established the model’s reputation.

This generation represents an interesting case study in automotive engineering priorities, where Nissan’s focus on mechanical durability and performance created vehicles that could easily outlast their increasingly complex electronic components.

The mechanical foundation of these Altimas centers around Nissan’s QR25DE 2.5-liter four-cylinder and VQ35DE 3.5-liter V6 engines, both representing significant advances in Nissan’s powertrain technology.

The QR25DE features an aluminum block and head construction with dual overhead cams and variable valve timing, providing an excellent balance of performance and efficiency. Despite its complexity, this engine demonstrates exceptional reliability when properly maintained, with many examples exceeding 200,000 miles.

The VQ35DE V6, part of Nissan’s award-winning VQ family, provides impressive performance while maintaining the mechanical durability that made Nissan engines legendary. Supporting these engines are well-engineered transmissions that contribute to the vehicle’s mechanical reliability.

The six-speed manual transmission, when equipped, provides precise shifting and excellent durability with minimal maintenance requirements. The continuously variable transmission (CVT) and five-speed automatic options, while more complex, generally provide reliable service when fluid changes are performed regularly.

These drivetrains benefit from Nissan’s conservative tuning philosophy, prioritizing longevity over maximum performance.Despite these electronic shortcomings, the fundamental mechanical reliability of these Altimas means that many continue providing dependable transportation long after various electronic conveniences have failed.

This durability, combined with reasonable parts costs for mechanical components, has made these vehicles popular choices in the used car market, where buyers prioritize reliability over electronic sophistication.

5 Cars With Failing Electronics

These problematic vehicles suffer from fundamental cost-cutting in their electrical systems, featuring bargain-basement components and inadequate testing that create perfect conditions for premature electronic failure.

Their penny-pinching construction shows in thin wiring prone to corrosion, cheap capacitors that fail from normal heat exposure, and complex control modules with insufficient protection from electromagnetic interference.

Poor circuit board design allows moisture infiltration that destroys sensitive components, while inadequate voltage regulation causes cascade failures that take down multiple systems simultaneously.

The combination of overly complex electronics and insufficient quality control creates vehicles where perfectly running engines are rendered useless by failed computers, dead displays, or malfunctioning safety systems.

These cars represent the unfortunate consequences of prioritizing flashy electronic features over reliability, creating vehicles that become expensive diagnostic puzzles rather than dependable transportation, often requiring specialized equipment and dealer-only parts that make repairs prohibitively expensive.

1. BMW 7 Series (2001-2008)

The E65/E66 generation BMW 7 Series represents one of the most ambitious attempts at electronic integration in automotive history, and unfortunately, one of the most problematic.

This flagship sedan was designed to showcase BMW’s technological prowess, incorporating an unprecedented number of electronic systems and innovations.

However, the complexity and premature failure of these systems have made this generation of 7 Series synonymous with expensive electronic repairs and frustrated ownership experiences.

BMW’s engineers packed the E65/E66 with revolutionary technology for its time, including the controversial iDrive system, electronic everything from seat adjustments to trunk operation, and a network of interconnected control modules that managed nearly every vehicle function.

The philosophy behind this approach was to create a seamless, luxurious experience where electronics would enhance every aspect of vehicle operation. Unfortunately, the execution fell far short of the ambitious goals, creating a vehicle where electronic failures could disable multiple systems simultaneously.

The iDrive system, BMW’s first attempt at centralized vehicle control, became the poster child for over-complicated automotive electronics. The system controlled audio, navigation, climate, communication, and vehicle settings through a single rotary controller and display screen.

While revolutionary in concept, the early iDrive systems were plagued with software bugs, slow response times, and counterintuitive operation. More problematically, iDrive failures could affect multiple vehicle systems, turning what should be simple adjustments into major repair events requiring dealer intervention and expensive module replacement.

Perhaps most frustratingly, many of these electronic failures occur in systems that worked perfectly well as mechanical or simpler electronic systems in previous generations.

The pursuit of technological advancement created vehicles that were less reliable and more expensive to maintain than their predecessors, ultimately damaging BMW’s reputation for quality and engineering excellence.

2. Audi A6 (2004-2011)

The C6 generation Audi A6 represents Audi’s ambitious push into advanced electronic systems and luxury technology, resulting in a sophisticated vehicle that unfortunately became notorious for widespread electronic failures.

This generation marked Audi’s commitment to electronic innovation, incorporating complex systems for engine management, transmission control, suspension adjustment, and infotainment.

While the mechanical components generally provided adequate reliability, the extensive electronic systems created a maintenance nightmare that often exceeded the vehicle’s value in repair costs.

Audi’s Multi Media Interface (MMI) system became the central nervous system for the C6 A6, controlling audio, navigation, climate, and vehicle settings through a complex electronic interface.

The first-generation MMI system suffered from numerous software bugs, hardware failures, and user interface problems that frustrated owners and technicians alike.

The system’s complexity meant that failures often affected multiple vehicle functions simultaneously, turning simple preference adjustments into major repair events requiring dealer intervention and expensive module programming.

The electronic transmission controls present particularly problematic issues in both the CVT and traditional automatic transmissions offered in the A6.

The multitronic CVT system, while innovative, suffered from numerous electronic control problems that could cause erratic shifting, transmission overheating, and complete transmission failure.

The control modules for these systems are expensive to replace and often require specialized programming that can only be performed by Audi dealers or facilities with advanced diagnostic equipment.

The result of all this electronic complexity is a vehicle that requires frequent and expensive maintenance from specialists familiar with Audi’s systems.

Many independent shops lack the diagnostic equipment and expertise necessary to properly service these vehicles, forcing owners to rely on expensive dealer service.

The interconnected nature of the electronic systems means that seemingly minor problems can cascade into major repair events, creating ownership experiences that are both frustrating and financially draining.

3. Mercedes-Benz S-Class (2006-2013)

The W221 generation Mercedes-Benz S-Class represented the pinnacle of automotive luxury and technology during its production run, incorporating an unprecedented array of electronic systems designed to provide the ultimate driving and passenger experience.

However, this technological tour de force became notorious for complex electronic failures that could cripple multiple vehicle systems and generate repair bills that often exceeded the vehicle’s value.

The W221 S-Class exemplifies the risks of pushing electronic boundaries without ensuring adequate long-term reliability. Mercedes-Benz engineered the W221 with the philosophy that electronics could enhance every aspect of luxury vehicle operation, from basic functions like window operation to sophisticated systems like active suspension and night vision.

The Command system served as the central hub for controlling audio, navigation, climate, communication, and vehicle settings through a complex interface that, while impressive when functioning, became a source of frustration when problems developed.

The integration of so many functions through electronic controls meant that single component failures could affect multiple vehicle systems simultaneously.

The air suspension system, standard on most S-Class models, represents one of the most problematic electronic systems in the vehicle. The Airmatic system uses electronic controls to manage air springs, shock absorber damping, and vehicle height adjustment.

While providing exceptional ride quality when functioning properly, the system is prone to air spring leaks, compressor failures, and electronic control problems. Air spring replacement is expensive and often requires multiple times during vehicle ownership.

More problematically, electronic control module failures can disable the entire suspension system, leaving the vehicle undrivable until expensive repairs are completed. Engine management electronics, while generally more reliable than comfort systems, still present significant challenges in the W221.

The various engine options rely heavily on electronic controls for fuel injection, ignition timing, turbocharger management, and emissions control.

These systems are prone to sensor failures that can cause poor performance and reduced fuel economy. The electronic throttle control systems require periodic adaptation and can develop problems affecting throttle response and idle quality.

4. Jaguar XJ (2003-2009)

The X350/X358 generation Jaguar XJ represented Jaguar’s ambitious attempt to compete with German luxury sedans through advanced technology and electronic sophistication.

However, this generation became notorious for widespread electronic failures that often rendered these beautiful vehicles unreliable and expensive to maintain.

The combination of complex electronic systems and questionable component quality created a perfect storm of reliability problems that damaged Jaguar’s reputation and frustrated owners worldwide.

Jaguar’s approach to the X350 XJ emphasized electronic innovation over proven reliability, incorporating systems that were advanced for their time but inadequately tested for long-term durability.

The vehicle featured electronic controls for nearly every function, from basic operations like window controls to sophisticated systems like adaptive suspension and transmission management.

This electronic complexity was layered onto a platform that retained some traditional Jaguar engineering approaches, creating integration challenges that manifested as reliability problems.

The electronic transmission controls in the XJ, particularly in models equipped with the ZF six-speed automatic, present major reliability challenges.

The transmission control modules are prone to failure, causing erratic shifting, harsh engagement, and complete transmission malfunction. These failures often occur without warning and can leave drivers stranded.

The complexity of the electronic controls means that transmission problems often require complete module replacement and reprogramming rather than simple repairs, creating expensive maintenance events that can exceed the vehicle’s value.

Lighting systems demonstrate additional electronic complexity problems. Xenon headlight systems require expensive ballasts that fail regularly and are costly to replace.

The adaptive lighting systems use complex electronic controls that frequently malfunction, affecting headlight aiming and operation. Interior lighting systems controlled through electronic modules can develop problems that affect multiple lighting circuits simultaneously.

5. Land Rover Range Rover (2002-2012)

The L322 generation Range Rover represents Land Rover’s most ambitious attempt at creating a luxury SUV that combines traditional off-road capability with sophisticated electronic systems.

Unfortunately, this generation became synonymous with electronic reliability problems that often left these expensive vehicles stranded and generated repair bills that frequently exceeded the vehicle’s value.

The L322’s electronic problems were so widespread and severe that they significantly damaged Land Rover’s reputation and created a generation of vehicles that depreciated rapidly due to reliability concerns.

Land Rover’s approach to the L322 emphasized electronic sophistication over proven reliability, incorporating advanced systems for engine management, transmission control, suspension adjustment, and terrain management.

The Electronic Air Suspension (EAS) system became the most notorious example of Land Rover’s electronic problems. While providing excellent ride quality and off-road capability when functioning properly, the EAS system is prone to air spring leaks, compressor failures, and electronic control problems that can leave the vehicle completely immobilized.

The EAS system’s complexity creates cascading failure scenarios where individual component problems affect the entire suspension system. Air springs frequently develop leaks that cause the vehicle to sag or become unlevel.

The air compressor, which runs almost constantly to compensate for leaks, often fails from overuse. More problematically, the electronic control modules that manage the system frequently malfunction, causing erratic height adjustment, inability to raise or lower the vehicle, or a complete system shutdown that leaves the Range Rover sitting on its bump stops.

The result of all these electronic problems is a vehicle that, despite its impressive capabilities and luxury features, requires constant and expensive maintenance from specialists familiar with Land Rover’s complex systems.

Many independent repair shops lack the diagnostic equipment and expertise necessary to properly service these vehicles, forcing owners to rely on expensive dealer service.

The interconnected nature of the electronic systems means that minor problems often escalate into major repair events, creating ownership experiences that are both frustrating and financially devastating.

Also Read: 5 Cars That Keep Their Value vs 5 That Become Worthless Fast