Engines are built to handle heat, but not all of them respond the same way once temperatures rise beyond normal levels.

Overheating can occur for many reasons such as a failing radiator, a coolant leak, or even a demanding environment like stop-and-go traffic under intense summer sun.

When it happens, some engines warp, seize, or suffer expensive internal damage, while others manage to keep running even after being pushed to their limits.

This difference often comes down to design strength, materials used, and the manufacturer’s focus on durability.

Drivers who live in hot climates or frequently tow heavy loads understand the importance of owning a vehicle with an engine that does not easily give up when stressed.

An overheating event may still cause wear, but certain engines are known for lasting well past the crisis without catastrophic failure.

Mechanics and long-time owners often share stories of specific motors that withstood coolant loss, fan belt breaks, or clogged radiators yet kept working long enough to reach safety or even continue reliable service afterward.

The engines that stand out in this regard tend to have heavy-duty construction, straightforward designs, and proven reliability records. They have been fitted in vehicles ranging from work trucks and SUVs to everyday sedans.

Understanding which engines have earned reputations for surviving overheating gives drivers peace of mind and helps buyers choose wisely when reliability is a top priority.

What follows is a closer look at nine engines recognized for holding up under high temperatures, with a breakdown of the qualities that allow them to keep running even when conditions are far from ideal.

Also Read: 9 Small Engines That Punch Above Their Weight

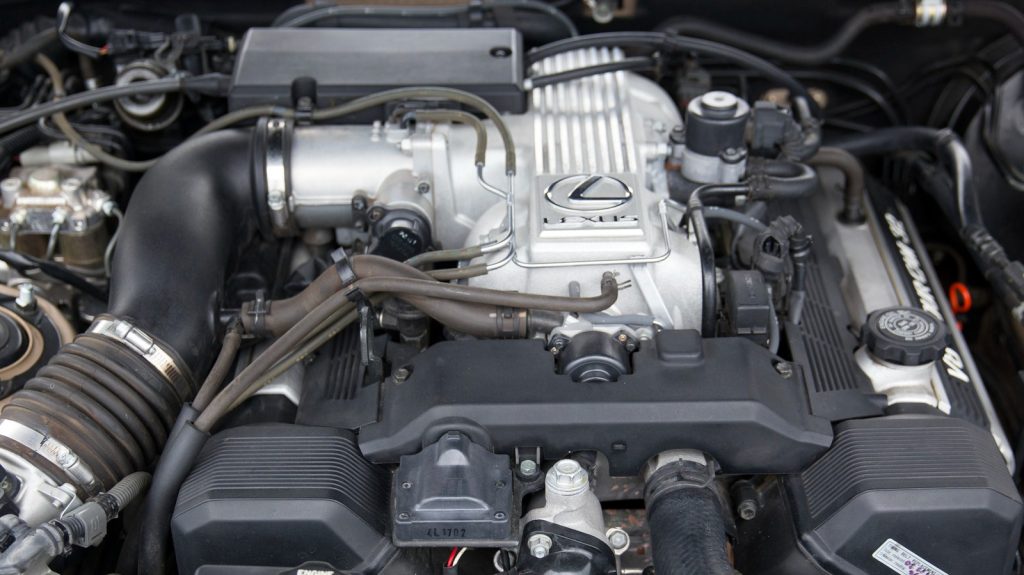

1. Toyota 2UZ-FE V8

Toyota’s 2UZ-FE V8, part of the company’s long-running UZ engine family, is legendary for its durability. Found in vehicles like the Land Cruiser, Sequoia, and Tundra, this 4.7-liter motor was built with toughness in mind.

Its iron block, paired with aluminum heads, creates a strong foundation that can handle high thermal stress without the common issues of warping or cracking.

The use of thick internal components adds weight but also gives the engine strength under harsh conditions, including overheating events that would damage lighter, less robust designs.

One of the key reasons the 2UZ-FE endures overheating better than many other engines is its conservative engineering. Toyota did not push the motor for high horsepower or cutting-edge performance.

Instead, the focus was on steady torque delivery and long-term reliability. This conservative approach reduces the strain on critical parts when coolant temperatures rise.

Owners have shared accounts of losing coolant during long desert drives or while towing heavy trailers, only to find that the engine kept running well enough to get home or to a repair shop.

Maintenance also plays a role. Regular oil changes and timely replacement of hoses and belts certainly help, but even when maintenance has been less than perfect, the 2UZ-FE often refuses to fail outright.

Toyota designed this engine for markets where tough conditions and limited repair options are common, which explains its reputation across Africa, the Middle East, and rural parts of North America.

While no engine is truly immune to overheating damage, the 2UZ-FE consistently ranks as one of the most dependable V8s ever built. Its ability to survive temperature spikes has earned it respect from both mechanics and owners, making it a motor that proves its worth when conditions are at their worst.

2. Chevrolet 350 Small Block

The Chevrolet 350 small block has been a cornerstone of American automotive culture for decades, and its ability to withstand punishment is a major reason behind its popularity.

Introduced in the late 1960s and used across cars, trucks, and performance applications, the 5.7-liter V8 became known not only for its power but also for its resilience in challenging conditions. Overheating events that could cripple other motors often leave the Chevy 350 bruised but still running.

One of the biggest advantages of the 350 lies in its simplicity. The design uses pushrod valve operation, cast-iron construction, and relatively loose tolerances compared to more modern engines.

While this means the 350 may not be as fuel efficient or refined, it also allows it to tolerate abuse. The iron block resists cracking under heat, and the straightforward design helps prevent catastrophic failures when temperatures climb.

Owners and mechanics have long told stories of these engines continuing to run after coolant leaks, failed water pumps, or clogged radiators.

Even when overheated to the point of smoking, many 350s manage to cool down and carry on with only minor issues such as a blown head gasket or warped valve cover. Compared to more fragile engines, the 350’s survival rate is impressive.

The aftermarket support also contributes to its reputation. Parts are widely available and inexpensive, making it easy to repair damage if overheating does leave its mark.

This has cemented the 350 as a favorite among hot rodders, off-roaders, and work truck owners who value an engine that can take abuse and still live to fight another day.

Although modern technology has moved on, the Chevy 350 remains a benchmark for toughness. Its ability to keep running when things get hot reinforces why it became one of the most produced and respected V8s in automotive history.

3. Ford 300 Inline-Six

The Ford 300 cubic-inch inline-six is one of the most respected truck engines ever built. Produced from the 1960s through the 1990s, this 4.9-liter workhorse earned its reputation in F-Series pickups, vans, and industrial equipment.

It was never the most powerful engine, but its durability made it legendary. Among its many strengths, the ability to withstand overheating stands out.

One reason the 300 survives temperature stress so well is its straightforward design. With its long-stroke inline-six layout, cast-iron block, and simple valve train, the engine lacks the fragile components that can fail in more complex motors.

The heavy iron construction absorbs and dissipates heat slowly, which reduces the chance of sudden damage when coolant temperatures rise. Even if the cooling system fails, the engine often manages to limp along until repairs can be made.

Truck owners often share stories of these engines surviving overheats caused by broken fan belts or clogged radiators while hauling heavy loads.

Instead of seizing, the 300 usually develops manageable issues such as a blown gasket or cracked manifold, problems that can be repaired without scrapping the entire motor. This resilience is one of the reasons fleets and farms relied on the 300 for so long.

Its reputation for endurance also comes from its use in industrial settings. Generators, forklifts, and other equipment powered by the 300 frequently operated in harsh conditions without proper cooling. Even in those environments, the engine proved it could tolerate overheating and keep going.

While it may lack the glamour of a V8, the Ford 300 inline-six holds a special place in automotive history. Its ability to endure extreme heat makes it one of the most reliable choices for drivers who need a motor that keeps working when conditions go wrong.

4. Jeep 4.0 Inline-Six

The Jeep 4.0 inline-six is one of the most beloved engines among off-road enthusiasts, known for its ability to keep running even in the harshest conditions.

Produced from 1986 until 2006, this 4.0-liter motor powered Cherokees, Wranglers, and Grand Cherokees, becoming a symbol of Jeep toughness. Its survival record during overheating events is one of the main reasons it remains so respected.

The design is rooted in simplicity. With a cast-iron block and cast-iron head, the 4.0 has the strength to handle temperature fluctuations.

While iron heads are heavier, they resist warping when heat levels rise, which is critical during overheating. The engine also uses a straightforward pushrod design, avoiding the complex timing systems that can fail under stress.

Off-road drivers often push their vehicles in low-speed, high-heat situations where cooling systems struggle. Stories are common of Jeep 4.0 engines running without coolant for extended periods during trail rides, only to restart after cooling down with minimal damage.

Even when problems occur, such as a cracked head, the bottom end of the engine usually survives, allowing for repairs rather than total replacement.

Part of the 4.0’s reputation also comes from its versatility. It served in countless Jeep models for two decades, which means millions of units were built and tested in real-world conditions. This long production run created a deep pool of owner experiences, many of which highlight how well the motor tolerates overheating.

Although it has been retired, the Jeep 4.0 inline-six remains a favorite among enthusiasts for its reliability and simplicity. Its ability to keep working even when the cooling system fails ensures its place as one of the most trusted engines in history.

5. Mercedes-Benz OM617 Diesel

The Mercedes-Benz OM617 is a 3.0-liter five-cylinder diesel engine that has earned worldwide recognition for its toughness. Produced from the mid-1970s through the 1980s, it powered models like the 240D, 300D, and 300SD.

Known for clocking half a million miles with ease, the OM617 is equally respected for its ability to withstand overheating without catastrophic failure.

Diesel engines generally run at higher compression and produce more heat than gasoline motors, but the OM617’s cast-iron block and head make it especially resistant to warping and cracking.

This solid construction is one of the main reasons it handles overheating so well. The engine’s slow-revving nature also reduces internal stress during hot conditions, giving it more tolerance than higher-strung designs.

Owners often report situations where these engines continued to run even after radiator or hose failures. Some recount long-distance drives with little coolant left, where the engine still managed to carry them to their destination.

While overheating can cause damage such as blown gaskets or injector issues, the OM617 frequently remains repairable instead of being completely destroyed.

Another factor in its durability is the engineering philosophy of Mercedes at the time. The OM617 was designed for longevity above all else, with an emphasis on overbuilt parts and conservative performance tuning. This makes it heavy and less efficient compared to modern diesels, but nearly indestructible when abused.

The OM617’s track record in taxis, especially in Africa and the Middle East, further proves its resilience. These cars often faced poor maintenance and extreme heat, yet the engines kept going. For those who value a motor that can survive tough conditions, the OM617 remains a benchmark of reliability.

6. Honda K-Series

Honda’s K-Series four-cylinder engines, introduced in the early 2000s, are celebrated for performance and efficiency, but they also earn high marks for reliability.

Found in Civics, Accords, CR-Vs, and performance models like the Civic Type R, the K-Series has proven it can handle overheating better than many modern engines.

The aluminum block and head might suggest fragility, but Honda engineered the K-Series with precision. It uses strong materials, balanced internals, and advanced cooling passages that allow it to shed heat efficiently under normal conditions.

When overheating does occur, the engine often tolerates it without immediate catastrophic damage. Many owners report driving short distances with failing cooling systems and still avoiding permanent failure.

One of the reasons the K-Series survives overheating is its advanced design. Features like roller rockers, variable valve timing, and stiff cylinder walls contribute to strength and durability.

Even in performance versions, Honda built in a safety margin to handle aggressive driving and high heat levels. This margin helps when unexpected overheating happens.

Enthusiasts have tested these engines in racing and tuning scenarios where cooling systems are pushed to their limits.

While repeated overheating will eventually cause head gasket failure or warping, the K-Series often continues to run long enough to reach safety or complete an event. Compared to other aluminum engines, this resilience stands out.

The K-Series also benefits from Honda’s track record of engineering reliable four-cylinders. It has become one of the most swapped and modified engines worldwide, partly because owners trust its strength under pressure. Even when neglected, it often outlives the cars it powers.

For drivers seeking a modern engine that balances efficiency with resilience, the Honda K-Series proves that careful engineering can produce a motor capable of surviving conditions that would sideline lesser designs.

7. Cummins 6BT 5.9 Diesel

The Cummins 6BT, better known as the 5.9-liter twelve-valve diesel, has a reputation that borders on legendary.

Used in Dodge Ram pickups from 1989 through the late 1990s, this engine became the heart of a movement that put heavy-duty diesel trucks on the map for everyday drivers. Its ability to handle abuse, including overheating, is one of the reasons it maintains such a strong following.

The 6BT was originally designed for commercial and industrial applications, so it came with an iron block, iron head, and overbuilt internal components. This construction allows it to tolerate high combustion pressures and extreme heat.

When cooling systems fail, the heavy materials help prevent warping or cracking, giving the engine a chance to keep running long enough for the driver to address the issue.

Truck owners have countless stories of the 6BT surviving broken radiators, leaking hoses, or clogged cooling systems. In many cases, these engines were pushed to redline temperatures while towing heavy loads, yet they continued to function afterward.

Damage such as head gasket failure can occur, but the motor rarely experiences total destruction from a single overheating event.

The simplicity of the 12-valve design also plays a role. With mechanical fuel injection and minimal electronics, there are fewer components at risk of failing when heat rises. This makes the 6BT not only resilient to overheating but also easy to repair if problems do occur.

Its reputation for toughness has made the 6BT a favorite for swaps into Jeeps, boats, and even buses. The engine’s ability to keep working when stressed sets it apart from more delicate modern diesels.

For drivers who need absolute confidence that their truck can survive tough conditions, the Cummins 6BT remains a proven choice.

8. BMW M30 Inline-Six

BMW’s M30 inline-six, produced from the 1960s through the early 1990s, is one of the brand’s most durable engines. It powered iconic models such as the 5 Series, 6 Series, and 7 Series, as well as some coupes that became classics.

While BMW engines are often associated with performance and refinement, the M30 also built a reputation for toughness, particularly its ability to endure overheating better than many of its successors.

The M30’s cast-iron block is the foundation of its strength. Paired with an aluminum head, the design balances durability with weight management. In many cases, overheating damages aluminum heads, but the M30’s overall build quality helps prevent catastrophic failure.

Owners often report engines that survived blown hoses or stuck thermostats, continuing to run after cooling issues that might destroy more fragile motors.

Part of the resilience comes from the simplicity of the engine’s mechanical systems. With single overhead camshaft design and straightforward fuel injection in later versions, the M30 lacks the fragile electronics and complex valve systems that became more common in later BMW engines. This simplicity reduces the chances of total failure when temperatures spike.

Enthusiasts note that even after serious overheating events, the M30 often remains repairable. At worst, the head may need resurfacing or gasket replacement, but the bottom end is rarely destroyed. This makes the engine cost-effective to maintain for classic BMW owners today.

The M30 became known as the “big six” because of its size and durability, and it lived up to the name. While newer BMW engines may offer more performance, few match the M30’s ability to withstand overheating. For classic car enthusiasts, it remains a benchmark of German engineering strength.

9. Toyota 22R/22RE Four-Cylinder

The Toyota 22R and its fuel-injected variant, the 22RE, are among the most respected four-cylinder truck engines ever built.

Produced from the late 1970s through the mid-1990s, these 2.4-liter engines powered Hilux pickups and 4Runners, earning reputations for reliability that few motors can match. One of their standout qualities is their ability to keep going even after overheating.

The 22R’s cast-iron block and simple design provide a solid base. While the aluminum head can suffer warping in extreme cases, the overall strength of the engine means it often survives overheating incidents with repairable damage rather than total failure.

Toyota engineered the motor with durability as a priority, understanding that many of these vehicles would be used in rugged conditions with limited access to proper maintenance.

Owners frequently tell stories of 22R engines running after coolant leaks or overheating during off-road adventures.

Even after running hot for extended periods, many of these motors restart once cooled, needing only gasket replacement or head machining. Compared to modern engines with tighter tolerances, the 22R offers far more forgiveness.

The simplicity of the design also helps. With a timing chain setup and carburetor or simple fuel injection, there are fewer delicate parts that fail under heat stress. This is why mechanics often recommend the 22R for drivers heading into remote areas, where reliability is essential.

Though no longer in production, the 22R and 22RE continue to be revered in off-road and classic Toyota communities. Their ability to survive overheating is just one aspect of their legendary toughness, ensuring they remain among the most respected four-cylinders ever built.

Engines that withstand overheating share a mix of sturdy construction, simple design, and conservative tuning.

The nine highlighted examples, from Toyota’s 2UZ-FE V8 and 22R four-cylinder to the Chevrolet 350 and Ford 300 inline-six, demonstrate how strong blocks and durable components make the difference when cooling systems fail.

The Jeep 4.0 and BMW M30 show how cast-iron strength allows engines to resist warping, while Honda’s K-Series proves that modern aluminum designs can also survive with precise engineering.

Diesel powerplants like the Mercedes OM617 and Cummins 6BT further underline the value of overbuilt parts and slow-revving durability, thriving in harsh conditions worldwide.

Together, these engines reveal why certain motors have earned reputations for toughness. They may suffer damage under extreme heat, but they rarely collapse completely, often continuing to run long enough to reach safety or remain serviceable with repairs, ensuring their place among the most dependable ever built.

Also Read: 5 Small Car Engines That Run Like Big Ones and 5 That Can’t Keep Up