The V8 engine represents the pinnacle of automotive engineering prowess, delivering the perfect symphony of power, performance, and mechanical sophistication that has raised enthusiasts for decades.

However, not all V8 engines are created equal, particularly when it comes to oil consumption and long-term reliability. Understanding the difference between engines that can run for hundreds of thousands of miles with minimal maintenance and those that seem to devour oil like a hungry beast is crucial for any automotive enthusiast, potential buyer, or current owner.

Oil consumption in V8 engines varies dramatically based on design philosophy, manufacturing quality, engineering tolerances, and the specific challenges each engine family has faced throughout its production run.

Some engines have achieved legendary status for their ability to accumulate massive mileage while maintaining tight tolerances and minimal oil consumption, often running for 200,000, 300,000, or even 500,000 miles with nothing more than regular maintenance.

These engineering marvels typically feature robust piston ring designs, quality valve stem seals, precise manufacturing tolerances, and time-tested architectures that have been refined over multiple generations.

This comprehensive analysis examines ten significant V8 engines, split evenly between those renowned for exceptional longevity and minimal oil consumption, and those infamous for their voracious appetite for motor oil.

By understanding the specific characteristics, design elements, and real-world performance of these engines, readers can make informed decisions about purchases, maintenance strategies, and realistic expectations for ownership costs and reliability.

5 Engines That Run a Lifetime

These exceptionally engineered powerplants feature robust cast-iron construction and time-tested piston ring designs that maintain proper oil sealing and consistent compression through hundreds of thousands of miles of demanding service cycles.

Their thoughtful engineering includes oversized oil galleries and precision-machined cylinder bores that resist the wear patterns and seal degradation typically associated with high-mileage operation and thermal cycling stress.

From extreme operating temperatures that challenge gasket materials to the constant friction of highway cruising, these remarkable engines continue running smoothly without developing the oil consumption or blow-by issues found in less durable designs.

Owners report decades of trouble-free operation with these legendary powerplants a testament to old-school engineering philosophy that proves its worth through consistent oil levels and maintained compression readings throughout extended ownership periods, often reaching 400,000 miles without major internal work.

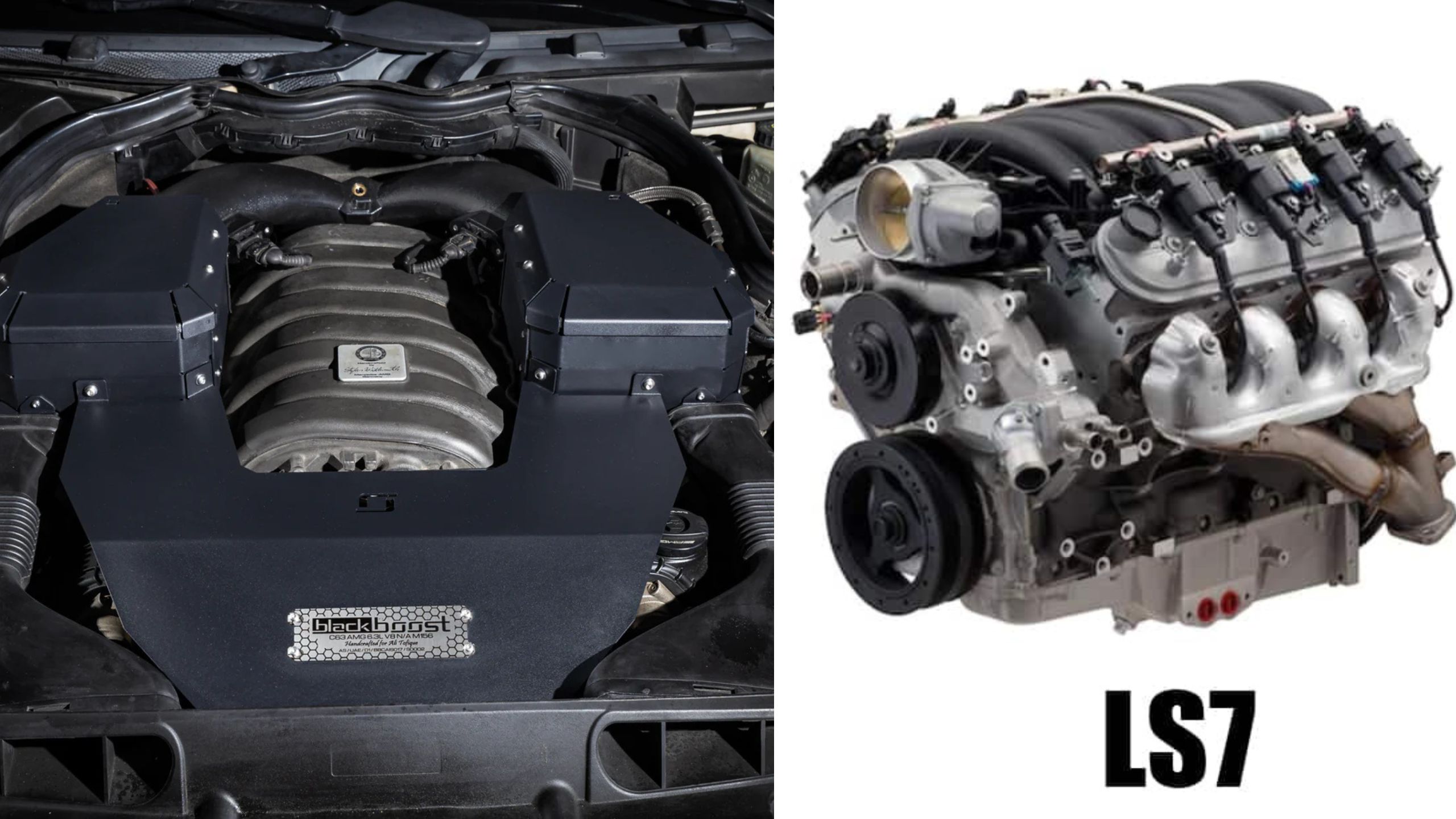

1. Chevrolet LS Series (LS1, LS2, LS3, LS6, LS7)

The Chevrolet LS series engines represent perhaps the most successful V8 architecture of the modern era, earning widespread acclaim for their exceptional reliability, minimal oil consumption, and impressive longevity.

Introduced in 1997 with the LS1, this engine family revolutionized American V8 design by incorporating aluminum construction, advanced port-fuel injection, and sophisticated engine management systems while maintaining the simplicity and durability that made pushrod V8s legendary.

The LS series’ remarkable oil consumption characteristics stem from several key design elements. The engines feature exceptionally well-designed piston ring packages with proper ring tension and gap specifications that maintain effective cylinder sealing throughout the engine’s lifespan.

The bore surfaces utilize a plateau honing process that creates optimal ring sealing while minimizing friction and wear. Additionally, the valve stem seals are manufactured from high-quality materials and designed with precise tolerances that prevent oil migration into the combustion chambers.

One of the most significant advantages of the LS architecture is its advanced PCV (Positive Crankcase Ventilation) system design. Unlike many competing engines that suffer from inadequate crankcase ventilation leading to pressure buildup and oil consumption, the LS series incorporates a sophisticated vacuum-operated PCV system that effectively manages crankcase pressures while preventing oil from being drawn into the intake system.

This design consideration alone contributes significantly to the engine’s minimal oil consumption characteristics. The LS series has also proven remarkably tolerant of varying maintenance intervals and oil quality, though proper maintenance certainly extends their already impressive lifespan.

Even under adverse conditions, these engines rarely develop the catastrophic oil consumption issues that plague many other V8 designs. This reliability has made the LS series extremely popular not only in GM vehicles but also as swap candidates for enthusiasts seeking dependable high-performance powerplants.

2. Toyota 1UZ-FE and 3UZ-FE

Toyota’s 1UZ-FE and its successor, the 3UZ-FE, represent the pinnacle of Japanese V8 engineering excellence, demonstrating that exceptional build quality and meticulous attention to detail can create engines that operate for hundreds of thousands of miles with minimal oil consumption.

These engines, primarily found in Lexus LS400, LS430, and various other luxury applications, have achieved legendary status among automotive enthusiasts for their whisper-quiet operation, silk-smooth power delivery, and remarkable longevity.

The foundation of these engines’ exceptional oil consumption characteristics lies in Toyota’s obsessive approach to manufacturing precision and quality control.

Every component is manufactured to extraordinarily tight tolerances using advanced metallurgy and precision machining techniques that were considered state-of-the-art during their respective development periods.

The cylinder bores feature a specialized honing pattern that promotes optimal ring sealing while minimizing friction, and the piston ring packages are designed with precise tension characteristics that maintain effective sealing throughout the engine’s operational lifespan.

One of the most remarkable aspects of the UZ engine family is their valve train design and manufacturing quality. The cylinder heads feature precision-machined valve guides and high-quality valve stem seals that prevent oil migration into the combustion chambers even after hundreds of thousands of miles of operation.

The valve train components, including camshafts, followers, and timing chain systems, are manufactured to such exacting standards that they rarely require replacement even at extremely high mileages.

The UZ engines’ exceptional reliability extends beyond just oil consumption to mechanical durability. Components such as timing chains, water pumps, and accessory drives routinely exceed 200,000 miles without replacement, and the engines’ sophisticated engine management systems adapt to minor wear patterns to maintain optimal performance throughout their lifespan.

This holistic approach to engine design and manufacturing quality has established Toyota’s UZ engines as benchmarks for V8 reliability and longevity in the automotive industry.

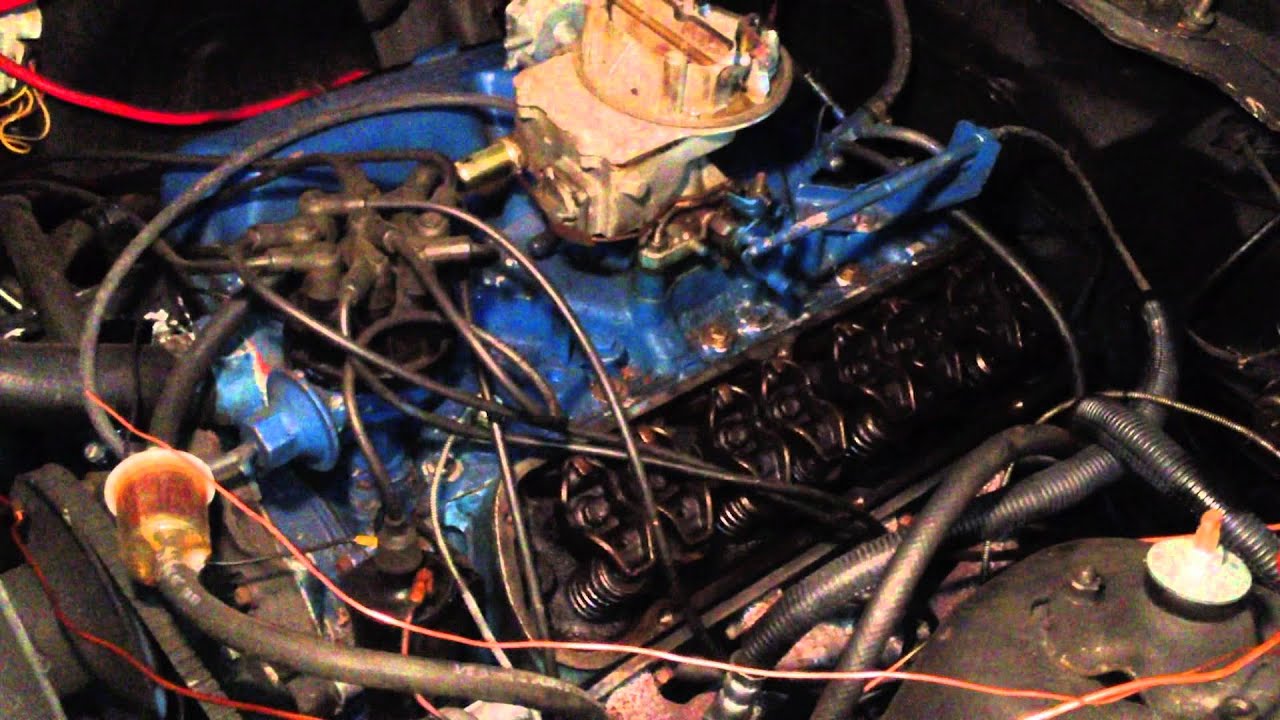

3. Ford 302/5.0L Windsor

The Ford 302 cubic inch (5.0L) Windsor V8 engine stands as one of the most enduring and reliable powerplants in automotive history, with a production run spanning over three decades and applications ranging from everyday transportation to high-performance vehicles.

This pushrod V8, first introduced in 1968 and continuously refined through 1995, earned an exceptional reputation for longevity and minimal oil consumption when properly maintained, making it a favorite among enthusiasts and fleet operators alike.

The Windsor 302’s exceptional oil consumption characteristics result from its time-tested design philosophy and robust construction methods. The engine features a cast-iron block with siamesed cylinders that provide excellent structural integrity and heat dissipation characteristics.

The cylinder bores are manufactured with traditional cast-iron construction that, while not as advanced as modern coatings, provides excellent durability and ring sealing characteristics when properly broken in and maintained.

The piston ring packages used in most 302 applications feature conservative gap specifications and appropriate ring tension that maintains effective cylinder sealing throughout the engine’s operational lifespan.

One of the most significant advantages of the 302 Windsor is its simple yet effective valvetrain design. The overhead valve configuration with hydraulic lifters provides reliable operation with minimal maintenance requirements, and the valve stem seals, while not as advanced as modern designs, prove remarkably durable when quality components are used.

The cylinder heads, whether the earlier cast-iron versions or later aluminum designs, feature robust valve guide construction that maintains proper clearances even at high mileages.

Real-world evidence of the 302 Windsor’s exceptional longevity is abundant, with numerous documented cases of engines exceeding 300,000 miles while maintaining reasonable oil consumption levels.

Many enthusiasts report 302 engines that consume less than a quart of oil between 3,000-mile service intervals even at high mileages, provided they receive regular maintenance and are not subjected to severe abuse.

The engine’s robust bottom end, featuring a forged steel crankshaft in most applications, provides the durability necessary for high-mileage operation without developing the bearing wear that often leads to increased oil consumption in other engines.

4. Chrysler 360 LA Small Block

The Chrysler 360 cubic inch LA (Light A-series) small block V8 represents one of Mopar’s most successful and durable engine designs, earning a well-deserved reputation for exceptional longevity and minimal oil consumption when properly maintained.

Produced from 1971 through 2003 in various configurations, this engine served as the backbone of Chrysler’s truck and performance vehicle lineup, demonstrating remarkable consistency in build quality and operational characteristics throughout its extensive production run.

The 360 LA’s exceptional oil consumption characteristics stem from its robust design philosophy and proven construction methods. The engine features a cast-iron block with thick cylinder walls and generous bearing surfaces that provide excellent structural integrity and heat dissipation.

The cylinder bores utilize traditional cast-iron construction with a crosshatch honing pattern that promotes proper ring sealing and oil control. The piston ring packages, particularly in later applications, feature well-designed oil control rings with proper tension characteristics that maintain effective cylinder sealing throughout the engine’s operational lifespan.

One of the most significant advantages of the 360 LA is its simple yet effective valvetrain design. The overhead valve configuration with hydraulic lifters provides reliable operation with minimal maintenance requirements, and the cylinder heads feature robust construction with adequate port volumes for the engine’s displacement.

The valve stem seals, while not as advanced as modern elastomeric designs, prove remarkably durable when quality components are installed and proper clearances are maintained.

The rocker arm assemblies and pushrod systems are designed with conservative load factors that ensure long-term durability even under demanding operating conditions.

Real-world examples of 360 LA durability are numerous, particularly among truck and van applications where these engines routinely accumulated high mileages under demanding operating conditions.

Many 360-powered vehicles report engines exceeding 250,000 miles while maintaining oil consumption levels below one quart per 3,000-mile service interval.

The engine’s reputation for reliability made it popular among fleet operators who valued predictable maintenance costs and minimal downtime, further demonstrating its practical durability and low operating costs over extended service periods.

Also Read: 12 Durable Cars That Refuse to Die Even After 300k Miles

5. General Motors 6.0L Vortec (LQ4, LQ9)

The General Motors 6.0L Vortec engine family, represented primarily by the LQ4 and LQ9 variants, stands as a testament to the successful evolution of traditional pushrod V8 architecture into the modern era.

These iron-block engines, produced from 1999 through 2019 in various applications, have earned exceptional reputations for durability, minimal oil consumption, and remarkable longevity in both light-duty and heavy-duty service applications ranging from pickup trucks to commercial vehicles.

The 6.0L Vortec’s exceptional oil consumption characteristics result from a combination of proven design elements and modern manufacturing techniques.

The cast-iron block construction provides excellent dimensional stability and heat dissipation characteristics, while the cylinder bores feature plateau honing processes that create optimal surface finishes for ring sealing.

The piston assemblies incorporate well-designed ring packages with appropriate tension characteristics and gap specifications that maintain effective cylinder sealing throughout hundreds of thousands of miles of operation.

One of the most significant advantages of the 6.0L Vortec family is their sophisticated combustion chamber and valvetrain design. The cylinder heads feature efficient port designs that promote good airflow while maintaining adequate cooling around critical areas.

The valve stem seals utilize modern elastomeric materials and precision manufacturing techniques that prevent oil migration into the combustion chambers even after extended high-mileage operation.

The valvetrain components, including hydraulic roller lifters, pushrods, and rocker arms, are designed with conservative load factors that ensure reliable operation with minimal maintenance requirements.

Real-world evidence of 6.0L Vortec durability is extensive, with numerous documented cases of engines in commercial truck applications exceeding 400,000 miles while maintaining oil consumption levels below one quart per 7,500-mile service interval.

These engines have proven particularly popular among fleet operators who value predictable maintenance costs and minimal downtime. The engine’s robust design has also made it a favorite among enthusiasts for high-performance applications, where its ability to handle significant power increases while maintaining reliability has been well-documented through aftermarket modifications and racing applications.

5 Engines That Eat Oil Fast

These problematic V8 engines suffer from inadequate piston ring tension and defective cylinder bore coatings that create excessive oil consumption patterns within the first 50,000 miles, despite proper break-in procedures and quality lubricants.

Their flawed engineering includes poorly designed valve seals and insufficient crankcase ventilation systems that cannot prevent oil migration into combustion chambers, leading to constant oil additions and fouled spark plugs.

Despite manufacturer claims and initial performance, these engines develop serious consumption problems requiring quart additions between oil changes and creating expensive catalytic converter damage from oil burning.

Owners experience constant monitoring stress as these thirsty powerplants transform from smooth performers into oil-hungry nightmares a costly reality that demonstrates how modern manufacturing shortcuts can completely undermine fundamental engine durability expectations.

1. BMW N63 4.4L Twin-Turbo V8

The BMW N63 4.4L twin-turbo V8 engine represents one of the most technologically advanced yet problematic powerplants in modern automotive history.

Despite its impressive power output and sophisticated engineering, this engine has gained an unfortunate reputation for excessive oil consumption that can reach alarming levels, sometimes requiring multiple quarts of oil between service intervals.

The N63’s oil consumption issues stem from a combination of complex design elements, manufacturing challenges, and inherent flaws in critical sealing components.

The primary culprit behind the N63’s voracious oil appetite lies in its innovative but problematic cylinder head design. BMW positioned the turbochargers in the “hot V” configuration between the cylinder banks, creating extreme heat conditions that stress critical engine components beyond their design limits.

This arrangement subjects valve stem seals to temperatures far exceeding those encountered in naturally aspirated engines, causing premature deterioration of sealing materials and allowing oil to migrate into the combustion chambers.

The valve guides, manufactured from aluminum alloy, expand at different rates than the valve stems under extreme heat cycles, creating clearances that permit excessive oil passage.

The N63’s piston ring design compounds the oil consumption problem significantly. The engine utilizes low-tension piston rings designed to reduce friction and improve fuel economy, but these rings prove inadequate for maintaining proper cylinder sealing under the extreme pressures generated by the turbocharging system.

The bore coating, while advanced in concept, has proven susceptible to wear patterns that create microscopic channels allowing oil to bypass the ring package.

Additionally, the engine’s direct injection system contributes to carbon buildup on intake valves, which can affect sealing surfaces and exacerbate oil consumption issues.

Real-world N63 oil consumption experiences vary dramatically, with some owners reporting consumption rates exceeding two quarts per 1,000 miles, while others experience more moderate but still excessive consumption of one quart per 2,500 miles.

The unpredictable nature of the oil consumption makes ownership particularly frustrating, as consumption rates can increase suddenly without warning.

Many owners report that oil consumption tends to worsen as mileage accumulates, with engines showing acceptable consumption initially but developing severe problems after 60,000-80,000 miles.

The cost of addressing N63 oil consumption issues can exceed $10,000, making it one of the most expensive engine problems in modern automotive history.

2. Audi 4.2L V8 (B6/B7 S4, C5 A6/S6)

The Audi 4.2L V8 engine, found in B6/B7 S4 and C5 A6/S6 models, represents a classic example of advanced German engineering undermined by fundamental design flaws that lead to catastrophic oil consumption issues.

This naturally aspirated powerplant, while capable of impressive performance and smooth operation when functioning properly, has earned notoriety among enthusiasts for its tendency to consume oil at alarming rates, often requiring constant monitoring and frequent top-offs to prevent engine damage.

The primary source of the 4.2L V8’s oil consumption problems lies in its cylinder head design and valve stem seal configuration. Audi utilized aluminum cylinder heads with pressed-in valve guides that prove susceptible to wear and movement under thermal cycling.

The valve stem seals, while initially effective, deteriorate rapidly under the extreme temperature conditions found in the aluminum heads. The thermal expansion characteristics of the aluminum construction create situations where clearances between valve stems and guides increase beyond acceptable tolerances, allowing oil to flow past the seals into the combustion chambers.

The piston ring design in the 4.2L V8 contributes significantly to oil consumption issues, particularly as mileage accumulates. The engine utilizes relatively low-tension rings designed to reduce friction, but these rings prove inadequate for maintaining proper cylinder sealing as bore wear occurs.

The aluminum-silicon bore coating, while advanced for its time, demonstrates susceptibility to scoring and wear patterns that create paths for oil to bypass the ring package.

Additionally, the engine’s relatively long stroke design creates higher piston speeds that accelerate ring and bore wear, exacerbating consumption issues over time.

Carbon buildup represents another significant factor in the 4.2L V8’s oil consumption problems. The engine’s port injection system, combined with the PCV system design, allows oil vapors to coat intake ports and valve stems with carbon deposits.

These deposits interfere with proper valve seating and can hold intake valves slightly open, creating additional pathways for oil to enter the combustion chambers.

The carbon accumulation also affects the PCV system’s ability to properly manage crankcase pressures, leading to increased oil carryover into the intake system.

Real-world experiences with 4.2L V8 oil consumption vary widely, but problem engines typically consume between one and three quarts per 1,000 miles. Many owners report that consumption begins gradually but accelerates rapidly once problems develop.

The unpredictable nature of the oil consumption, combined with the engine’s tendency to show no external signs of oil leakage, makes monitoring oil levels critical for preventing catastrophic damage. Owners frequently report that even with constant vigilance, the rapid consumption rates can lead to dangerously low oil levels between checks.

3. Cadillac Northstar 4.6L V8

The Cadillac Northstar 4.6L V8 engine stands as one of the most technologically advanced yet fundamentally flawed powerplants in American automotive history.

Despite its impressive performance capabilities, sophisticated aluminum construction, and innovative engineering features, the Northstar has earned an infamous reputation for excessive oil consumption that often reaches catastrophic levels, requiring constant monitoring and frequent oil additions to prevent complete engine failure.

The root cause of the Northstar’s oil consumption problems lies in its revolutionary but problematic head bolt design. Instead of traditional head bolts that thread into the block, GM engineers utilized a system where bolts thread into the aluminum cylinder heads themselves.

This design, intended to reduce manufacturing costs and complexity, creates a fundamental weakness as the aluminum threads strip or pull out under the extreme clamping forces required to maintain proper head gasket sealing.

Once the head bolt threads begin to fail, combustion gases can enter the cooling system while coolant enters the combustion chambers, leading to rapid oil consumption and potential engine destruction.

The Northstar’s aluminum block construction, while advanced, contributes to oil consumption issues through thermal expansion and contraction cycles that affect sealing surfaces.

The engine utilizes cast-iron cylinder liners that expand at different rates than the surrounding aluminum block, creating opportunities for oil to bypass piston rings and enter the combustion chambers.

The piston ring design, optimized for performance rather than longevity, utilizes relatively low tension specifications that prove inadequate for maintaining proper sealing as the engine accumulates mileage and thermal cycles.

Valve stem seal deterioration represents another significant contributor to Northstar oil consumption problems. The aluminum cylinder heads subject valve stem seals to extreme temperature conditions that cause rapid deterioration of sealing materials.

The valve guides, integrated into the aluminum casting, wear at different rates than the valve stems, creating clearances that allow oil to flow past deteriorated seals. The sophisticated variable valve timing system adds complexity to the valve train that creates additional potential failure points for oil sealing.

Real-world Northstar oil consumption experiences are consistently problematic, with many owners reporting consumption rates between two and five quarts per 1,000 miles once problems develop.

The engine’s tendency to consume oil internally rather than leak externally makes monitoring oil levels critical, as low oil conditions can develop rapidly without visible warning signs.

Many Northstar engines require oil level checks every few hundred miles to prevent damage, and consumption rates often increase dramatically as mileage accumulates beyond 100,000 miles.

4. Jaguar AJ-V8 4.0L and 4.2L

The Jaguar AJ-V8 engine family, encompassing both 4.0L and 4.2L variants, represents British automotive engineering at its most ambitious and problematic.

While these engines deliver impressive performance and the sophisticated character expected from Jaguar powerplants, they have developed notorious reputations for excessive oil consumption that can transform ownership from pleasure to constant anxiety about engine oil levels and potential catastrophic failure.

The fundamental design philosophy behind the AJ-V8 emphasized performance and refinement over long-term durability, resulting in engineering compromises that contribute to oil consumption issues.

The aluminum block construction utilizes Nikasil cylinder bore coatings that, while providing excellent performance characteristics when new, prove susceptible to wear and scoring under certain operating conditions.

The coating can develop microscopic channels that allow oil to bypass piston rings, leading to increasing consumption rates as mileage accumulates. Additionally, the coating’s interaction with certain fuel additives and contaminants can accelerate wear patterns.

The cylinder head design represents another significant source of oil consumption problems in AJ-V8 engines. The aluminum heads utilize pressed-in valve seats and guides that can shift or wear under thermal cycling, creating clearances that allow oil to flow past valve stem seals into the combustion chambers.

The valve stem seals themselves, while initially effective, deteriorate rapidly under the extreme temperature conditions found in the aluminum heads. The sophisticated variable valve timing system adds complexity that creates additional potential failure points for oil sealing.

Piston ring design and specifications contribute significantly to AJ-V8 oil consumption issues. The engines utilize relatively low-tension rings designed to minimize friction and maximize performance, but these rings prove inadequate for maintaining proper sealing as bore wear occurs.

The ring package design, while sophisticated, demonstrates susceptibility to carbon buildup and glazing that reduces sealing effectiveness. The engine’s high-performance nature subjects rings to extreme pressures and temperatures that accelerate wear patterns and contribute to increasing oil consumption over time.

Real-world AJ-V8 oil consumption experiences vary significantly, but problematic engines typically consume between one and four quarts per 1,000 miles depending on operating conditions and engine condition.

Many owners report that consumption begins gradually but accelerates rapidly once problems develop, making constant monitoring essential for preventing engine damage.

The engines demonstrate particular sensitivity to extended drain intervals and inferior oil quality, with consumption rates increasing dramatically when proper maintenance schedules are not maintained.

The cost of addressing AJ-V8 oil consumption issues through engine rebuilds or replacement often exceeds the vehicle’s value, making these engines particularly challenging for long-term ownership.

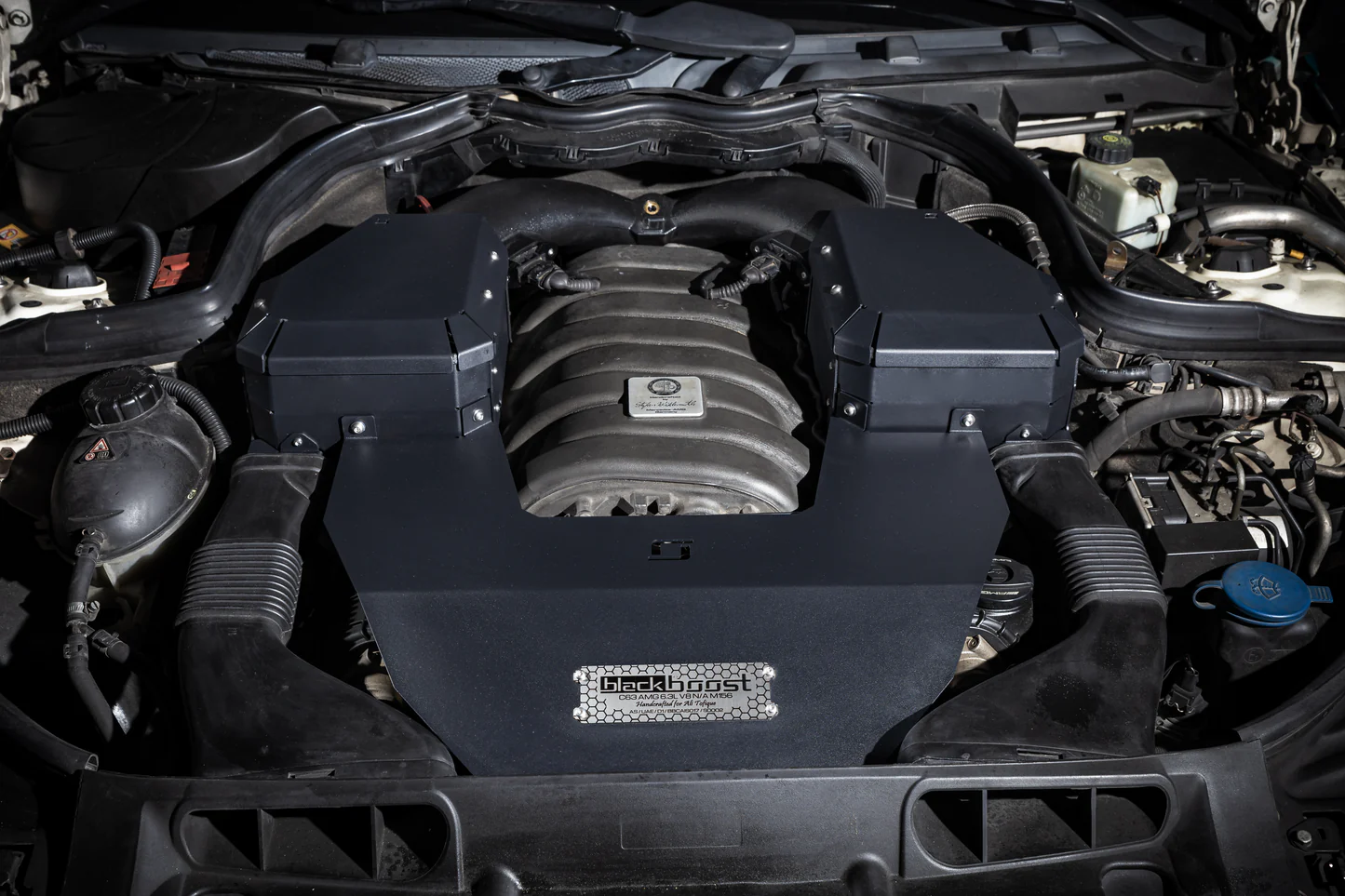

5. Mercedes-Benz M156 6.3L AMG V8

The Mercedes-Benz M156 6.3L AMG V8 engine represents the pinnacle of high-performance naturally aspirated V8 engineering, yet it has developed a troubling reputation for excessive oil consumption that can reach alarming levels.

Despite its impressive power output, sophisticated construction, and advanced engineering features, this hand-built powerplant has proven susceptible to oil consumption issues that can transform the AMG ownership experience from exhilarating to anxiety-inducing.

The M156’s oil consumption problems stem primarily from its extreme performance orientation and the compromises necessary to achieve its impressive power density.

The engine utilizes a dry sump lubrication system designed to maintain consistent oil supply under high-performance driving conditions, but this complex system creates multiple potential failure points where oil can be consumed or lost.

The system’s sophisticated oil scavenging pumps and multiple oil reservoirs make it particularly sensitive to seal deterioration and system component failures that can lead to internal oil consumption.

Cylinder head design represents a significant contributor to M156 oil consumption issues. The aluminum heads incorporate advanced port designs and sophisticated valve train components that operate under extreme stress conditions.

The valve stem seals, while initially effective, deteriorate under the extreme temperatures generated by the high-performance operation. The aluminum construction subjects these seals to thermal cycling that causes premature failure and allows oil to flow past valve stems into the combustion chambers.

The sophisticated variable valve timing system adds complexity that creates additional sealing challenges. The piston and ring package design in the M156 emphasizes performance over longevity, utilizing specifications that prove problematic for long-term oil consumption control.

The pistons operate under extreme pressures and temperatures that stress ring sealing capabilities beyond normal limits. The bore surface, while precisely manufactured, demonstrates susceptibility to wear patterns that create paths for oil to bypass the ring package.

The engine’s high-revving nature subjects these components to accelerated wear cycles that contribute to increasing consumption rates over time.

Real-world M156 oil consumption experiences vary considerably, with some engines demonstrating acceptable consumption while others require constant monitoring and frequent oil additions.

Problem engines typically consume between one and three quarts per 1,000 miles, with consumption rates often increasing dramatically after 50,000-70,000 miles.

The engine’s sophisticated monitoring systems provide warnings when oil levels become critically low, but the rapid consumption rates can overwhelm even vigilant owners.

The cost of addressing M156 oil consumption through engine rebuilds often approaches or exceeds $30,000, making it one of the most expensive oil consumption problems in the automotive industry.

Also Read: 5 Cars That Rarely Have Starter Issues vs 5 That Constantly Do