The automotive engineering, few achievements are as remarkable as creating an engine that maintains its smoothness, reliability, and performance characteristics decades after rolling off the production line.

While modern engines boast impressive technology and efficiency, there’s something truly special about powerplants that have proven their mettle through years of real-world testing by millions of drivers worldwide.

The concept of engine longevity extends far beyond simple durability. A truly exceptional engine doesn’t just survive for decades it continues to deliver the same refined operation, smooth power delivery, and reliable performance that it exhibited when new.

This remarkable feat requires a perfect storm of engineering excellence: superior metallurgy, precise manufacturing tolerances, thoughtful design philosophy, and robust construction that can withstand the constant thermal cycling, mechanical stress, and chemical exposure that defines internal combustion engine operation.

These powerplants have earned their reputation not in controlled laboratory conditions, but on highways, city streets, and driveways around the world.

They’ve powered family sedans through hundreds of thousands of miles, carried work trucks through decades of heavy duty, and maintained their composure in enthusiast vehicles that have been lovingly maintained and occasionally pushed to their limits.

Their smooth operation after decades of service isn’t just a testament to their original design and construction, but also to the wisdom of their creators who understood that true automotive excellence isn’t measured in peak horsepower or acceleration times, but in the ability to deliver consistent, reliable performance year after year, mile after mile.

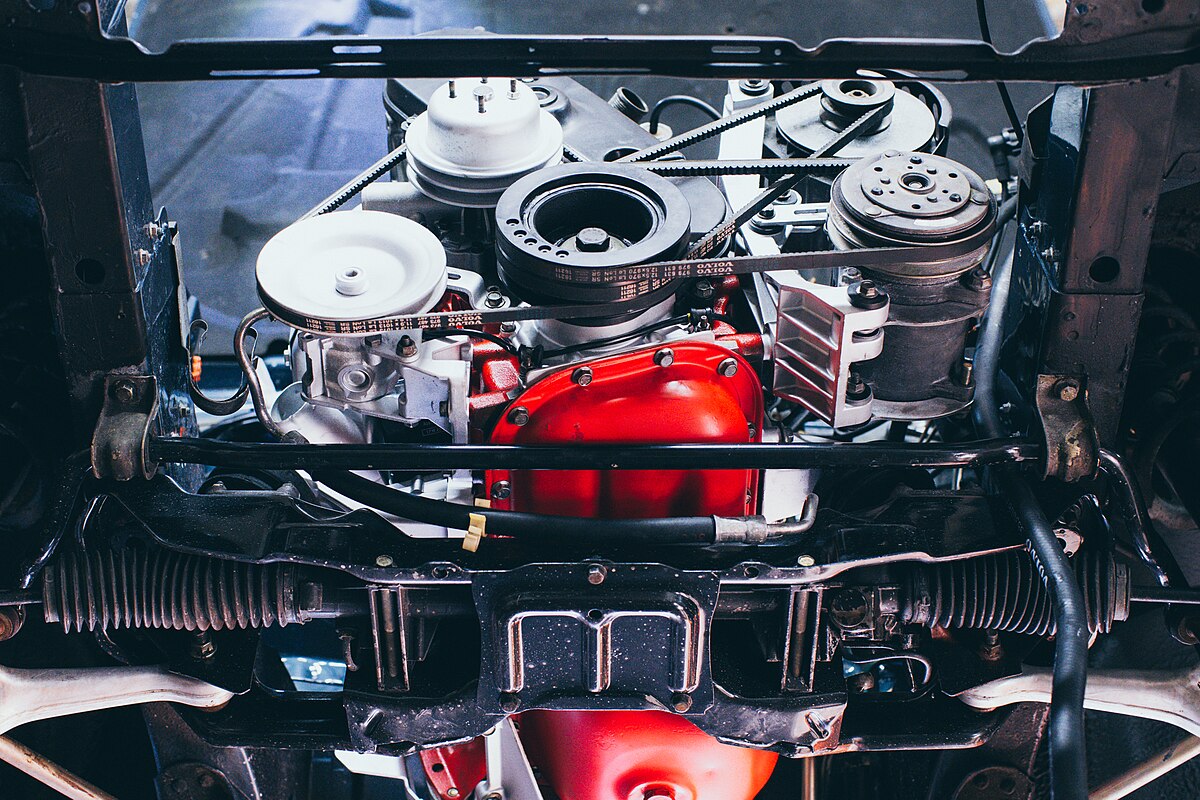

1. Toyota 22R/22RE (1981-1995)

The Toyota 22R and its fuel-injected sibling, the 22RE, stand as monuments to the philosophy that simplicity and robust engineering create lasting excellence.

These 2.4-liter inline-four engines powered millions of Toyota trucks, 4Runners, and other vehicles through some of the most demanding conditions imaginable, earning a reputation for unflappable reliability that borders on the legendary.

The secret to the 22R’s incredible longevity lies in its fundamentally conservative design approach. Rather than pushing the boundaries of performance or efficiency, Toyota’s engineers focused on creating an engine that could withstand decades of abuse while maintaining smooth operation.

The engine features a robust cast-iron block with generous wall thickness, providing excellent heat dissipation and structural integrity. The cylinder head, while aluminum for weight savings, uses a simple two-valve-per-cylinder design that minimizes complexity while ensuring adequate airflow for the engine’s intended purpose.

One of the most remarkable aspects of the 22R family is their tolerance for less-than-perfect maintenance. These engines have been known to run smoothly for hundreds of thousands of miles even when subjected to extended oil change intervals, poor-quality fuel, and challenging environmental conditions.

The robust timing chain system, rather than a belt, eliminates one common failure point, while the simple carburetor (in the 22R) or throttle-body fuel injection (in the 22RE) provides reliable fuel delivery without the complexity of more advanced systems.

The internal components of the 22R series reflect Toyota’s commitment to longevity over peak performance. The crankshaft is forged steel with generous bearing journals, providing excellent durability under load.

The connecting rods are similarly robust, with conservative power-to-weight ratios that ensure long service life. The pistons and rings are designed with excellent sealing characteristics that maintain compression and oil control even after hundreds of thousands of miles.

Perhaps most importantly, the 22R engines demonstrate remarkable thermal stability. Their conservative compression ratios and well-designed cooling systems prevent the kind of thermal stress that can cause warping, cracking, or accelerated wear in other engines.

The smooth idle and steady power delivery that characterizes a new 22R can often be found in examples with 300,000 or even 400,000 miles, testament to the fundamental soundness of the design.

The 22R’s reputation extends beyond mere reliability to encompass genuine refinement. Unlike many work-focused engines that trade smoothness for durability, the 22R manages to deliver both.

The inline-four configuration provides inherently good balance, while careful attention to vibration damping and mount design ensures that the engine’s smooth character remains intact throughout its service life.

This combination of durability and refinement explains why these engines remain highly sought after in the used market, often commanding premium prices even decades after production ended.

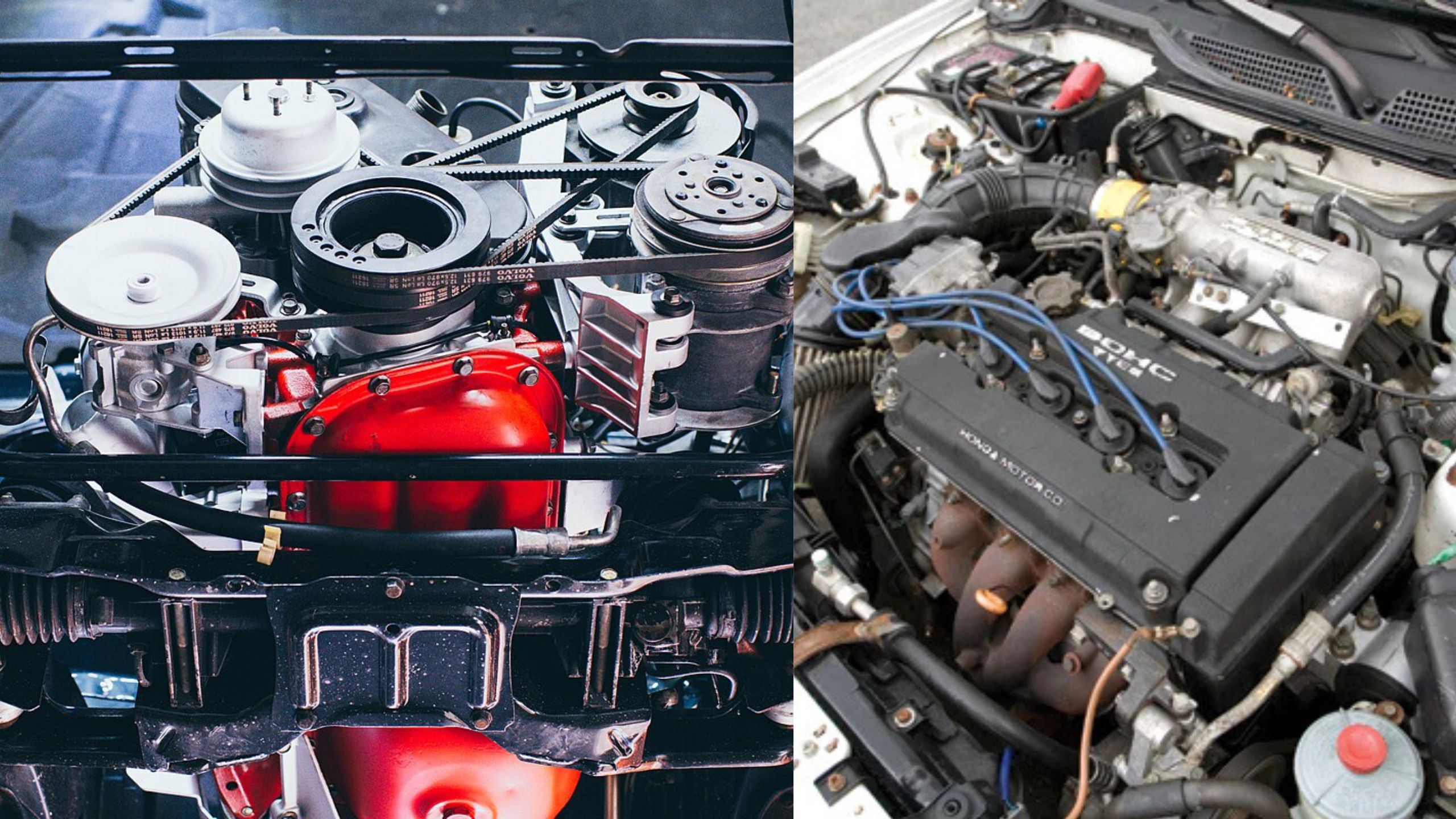

2. Honda B-Series (1988-2001)

The Honda B-series engines, particularly the B18 and B20 variants, represent the pinnacle of naturally aspirated four-cylinder engineering from the late 20th century.

These powerplants combined Honda’s legendary reliability with a level of refinement and performance that seemed almost magical when they were introduced, and remarkably, they’ve maintained these characteristics through decades of service in millions of vehicles worldwide.

The foundation of the B-series’ exceptional longevity lies in Honda’s meticulous attention to internal friction reduction and thermal management.

The engines feature Honda’s advanced VTEC (Variable Valve Timing and Lift Electronic Control) system in many variants, which not only provides excellent performance characteristics but also contributes to long-term durability by optimizing valve timing for different operating conditions.

This system reduces stress on the valvetrain while ensuring optimal combustion efficiency across the entire rpm range. The block construction of B-series engines showcases Honda’s commitment to precision manufacturing. The aluminum construction provides excellent heat dissipation while keeping weight low, but more importantly, the manufacturing tolerances are exceptionally tight.

This precision extends to every aspect of the engine’s construction, from the perfectly round cylinder bores to the precisely balanced rotating assembly. The result is an engine that maintains its smooth operation characteristics even after hundreds of thousands of miles of service.

One of the most remarkable aspects of B-series engines is their ability to maintain peak performance characteristics throughout their service life. Unlike many engines that gradually lose power and smoothness as they age, well-maintained B-series engines often feel nearly identical to new examples even after 200,000 or 300,000 miles.

This is largely due to Honda’s excellent ring seal design and superior metallurgy in the cylinder walls, which resist wear and maintain compression over extended periods.

The VTEC system itself contributes significantly to the engine’s longevity. By providing different cam profiles for low and high-rpm operation, the system ensures that the engine operates efficiently across its entire operating range.

At low rpms, the mild cam profile provides smooth idle and excellent drivability, while the high-rpm profile delivers impressive performance when needed. This versatility means that the engine rarely operates outside its optimal parameters, reducing wear and extending service life.

The smooth operation of B-series engines is legendary among enthusiasts and everyday drivers alike. The inline-four configuration provides inherent balance, but Honda’s engineers went further, implementing sophisticated balancing systems and vibration damping that create an almost electric-motor-like smoothness.

This refinement remains intact throughout the engine’s service life, with many high-mileage examples still providing the same silk-smooth operation that made them famous when new.

The combination of this smoothness with Honda’s legendary reliability has made B-series engines some of the most sought-after powerplants in the enthusiast community, where they’re prized for their ability to deliver both daily-driving refinement and weekend performance capabilities.

3. GM LS Series (1997-Present)

General Motors’ LS engine family represents one of the most significant achievements in modern American automotive engineering, combining old-school pushrod V8 architecture with cutting-edge materials science and manufacturing precision.

Since their introduction in 1997, LS engines have powered everything from Corvettes to pickup trucks, earning a reputation for exceptional smoothness, reliability, and longevity that has made them the gold standard for modern V8 performance.

The genius of the LS design lies in its marriage of proven architecture with modern materials and manufacturing techniques. The traditional pushrod, two-valve-per-cylinder layout provides inherent simplicity and compactness, while advanced aluminum construction and precise manufacturing tolerances ensure exceptional durability and performance.

The deep-skirt aluminum block design provides exceptional rigidity while keeping weight low, and the sophisticated oiling system ensures consistent lubrication even under extreme conditions.

One of the most remarkable aspects of LS engines is their ability to maintain factory-like smoothness even after hundreds of thousands of miles. This is largely due to GM’s advanced manufacturing processes, which create cylinder bores with exceptional surface finish and precise tolerances.

The piston rings and cylinder wall coatings are designed to work together as a system, providing excellent sealing that maintains compression and reduces blow-by throughout the engine’s service life.

The LS family’s rotating assembly represents a masterclass in balance and precision. The forged steel crankshafts are precisely balanced and feature generous bearing surfaces that distribute loads effectively.

This consistency is a testament to the fundamental soundness of the design and the quality of the materials used throughout the engine.

The smooth idle, linear power delivery, and refined operation that make LS engines so desirable when new remain virtually unchanged throughout their extended service life, explaining why these engines have become the foundation for countless performance builds and engine swaps across the automotive enthusiast community.

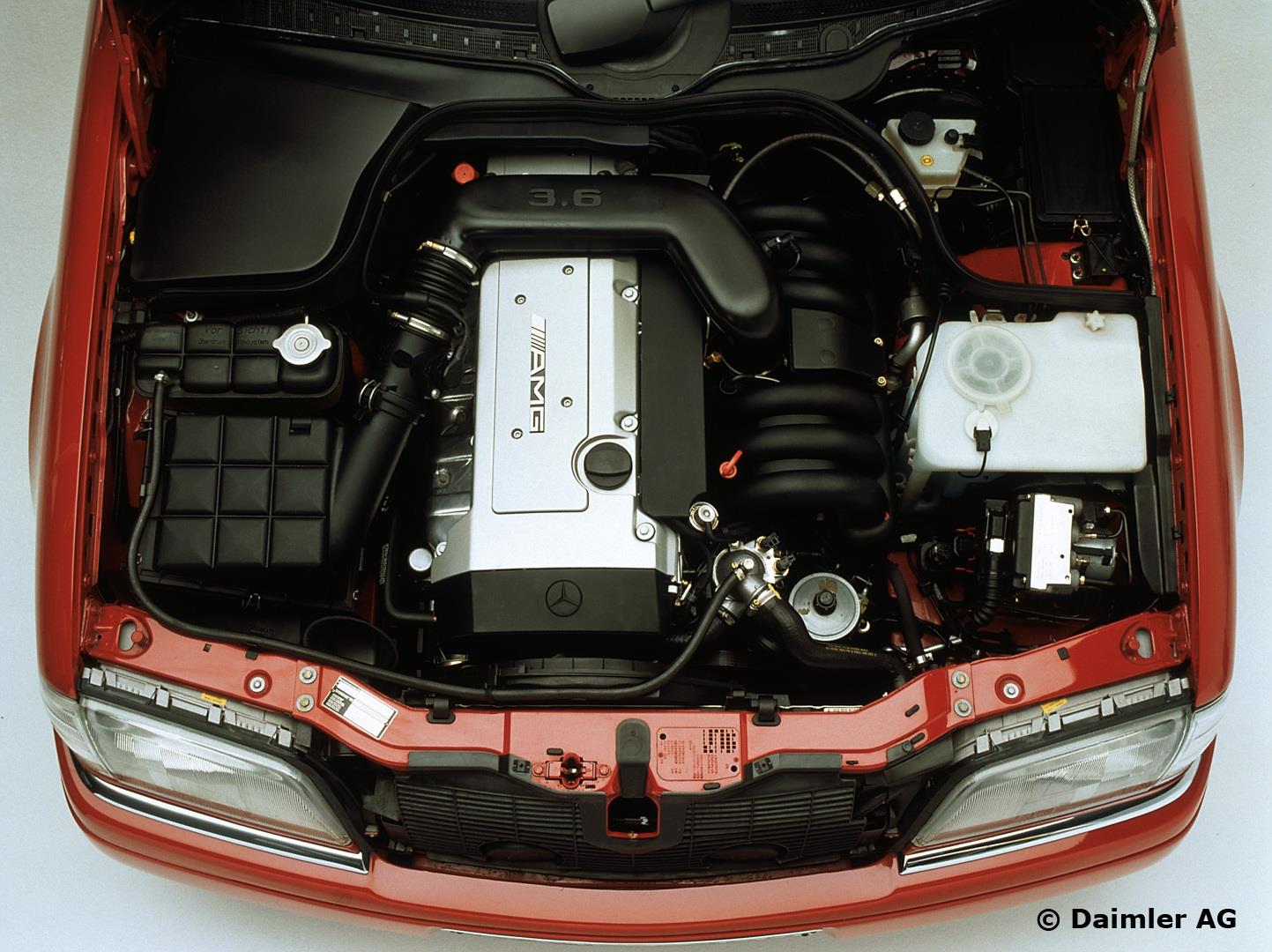

4. Mercedes-Benz M104 (1988-1997)

The Mercedes-Benz M104 inline-six engine stands as one of the finest examples of German engineering excellence, representing the culmination of decades of refinement in naturally aspirated six-cylinder design.

This 2.8 to 3.2-liter powerplant powered some of Mercedes-Benz’s most prestigious models during the 1990s, earning a reputation for silky smoothness and exceptional longevity that continues to impress enthusiasts and technicians decades after production ended.

The M104’s exceptional character begins with its fundamental architecture. The inline-six configuration is inherently well-balanced, producing minimal vibration due to the perfect primary and secondary balance characteristics of the layout.

Mercedes-Benz engineers built upon this natural advantage with sophisticated engine mounts, precisely balanced rotating components, and careful attention to reducing noise, vibration, and harshness throughout the engine’s operating range.

The construction quality of the M104 reflects Mercedes-Benz’s commitment to creating engines that would maintain their refinement throughout extended service lives.

The cast-iron block provides exceptional thermal stability and durability, while the aluminum cylinder head incorporates advanced four-valve-per-cylinder technology that was cutting-edge for its era.

The timing chain system, rather than a belt, eliminates a common maintenance item while providing precise valve timing throughout the engine’s service life.

One of the most remarkable aspects of the M104 is its sophisticated fuel injection and ignition management systems. The engine features advanced electronic controls that continuously optimize fuel delivery and ignition timing based on operating conditions, ensuring optimal performance and efficiency while minimizing stress on internal components.

The engine’s power delivery is extraordinarily linear and smooth, with none of the harshness or vibration that can develop in lesser engines as they age.

The sophisticated engine management system continues to provide optimal performance throughout the engine’s service life, maintaining the same responsive throttle action and smooth power delivery that made these engines so highly regarded when new.

Also Read: 10 Trucks That Mechanics Say Are Built Like Tanks

5. BMW M30 (1968-1993)

The BMW M30 inline-six engine represents one of the longest-running and most refined powerplants in automotive history, serving as the heart of BMW’s performance and luxury vehicles for over two decades.

This remarkable engine family, ranging from 2.5 to 3.4 liters, established BMW’s reputation for building smooth, sophisticated engines that maintain their character throughout extended service lives, becoming legendary among enthusiasts for their combination of performance, refinement, and exceptional longevity.

The M30’s extraordinary durability and smoothness stem from its fundamentally conservative yet sophisticated design philosophy. BMW’s engineers created an engine that prioritized long-term reliability and refinement over maximum power output, resulting in a powerplant that could deliver decades of smooth service.

The cast-iron block provides exceptional thermal stability and structural integrity, while the aluminum cylinder head incorporates advanced combustion chamber design that promotes efficient burning while minimizing stress on internal components.

The precision of BMW’s manufacturing processes during the M30’s production run was exceptional, even by today’s standards. The engine features extremely tight tolerances throughout, from the perfectly honed cylinder bores to the precisely balanced rotating assembly.

This attention to detail pays dividends throughout the engine’s service life, as the tight clearances and precise balancing maintain the engine’s smooth operation characteristics even after hundreds of thousands of miles.

One of the most remarkable aspects of the M30 is its sophisticated fuel injection system, which was advanced for its era and contributed significantly to the engine’s longevity.

The Bosch fuel injection provides precise fuel metering that optimizes combustion efficiency while preventing the kind of rich or lean conditions that can accelerate engine wear. The system’s reliability and precision remain consistent throughout the engine’s service life, maintaining optimal performance and efficiency.

The engine’s power band remains broad and usable, with none of the harshness or irregular operation that can develop in lesser engines as they age. This consistency has made the M30 one of the most sought-after engines among BMW enthusiasts, who prize its combination of performance, refinement, and proven longevity.

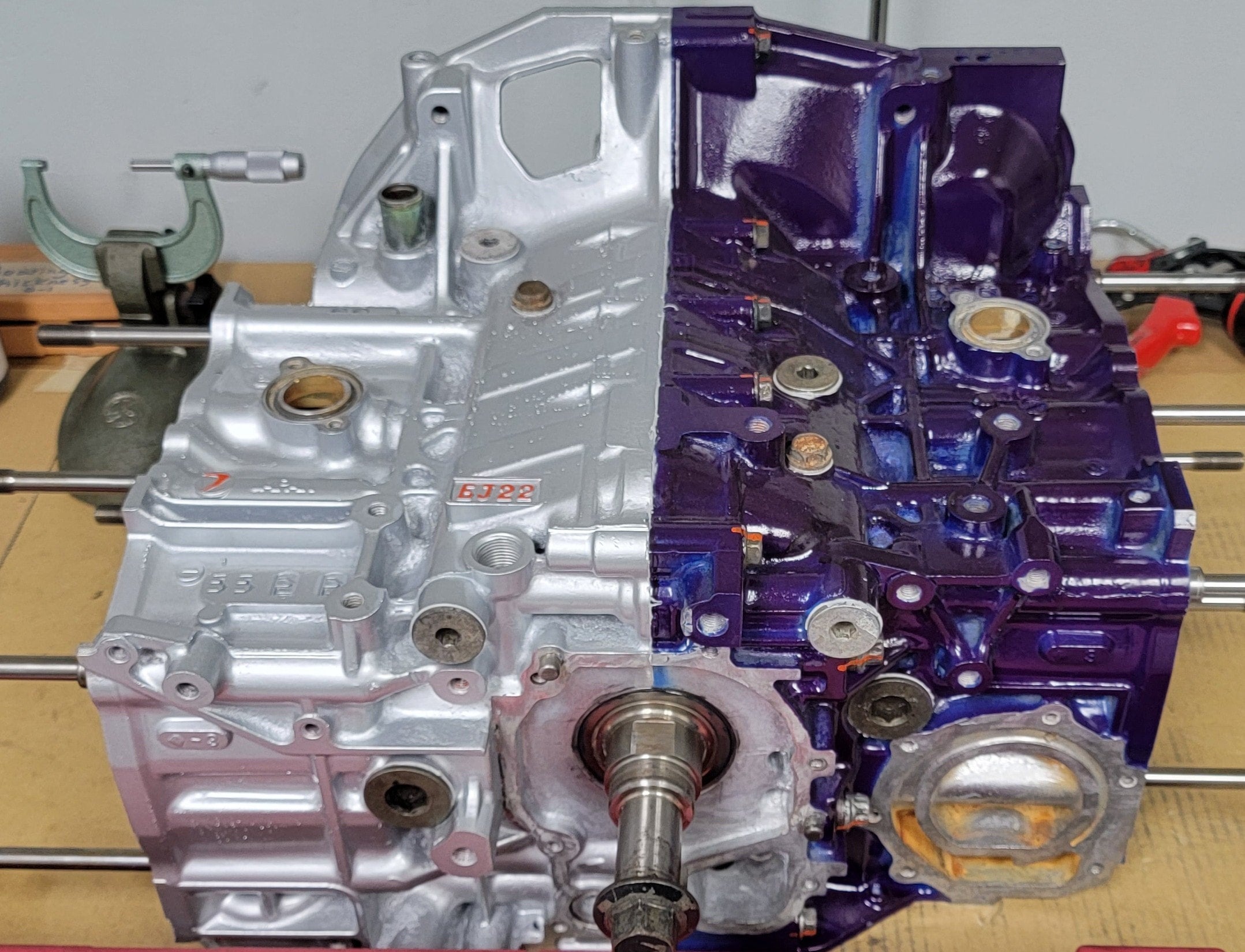

6. Subaru EJ22 (1989-1996)

The Subaru EJ22 naturally aspirated boxer engine stands as one of the most reliable and smooth-operating engines ever produced, earning a reputation for exceptional longevity that has become legendary among Subaru enthusiasts and automotive technicians worldwide.

This 2.2-liter horizontally opposed four-cylinder engine powered millions of Subaru vehicles through their most formative years, establishing the brand’s reputation for building engines that maintain their character and reliability throughout extended service lives.

The fundamental advantage of the EJ22’s design lies in its horizontally opposed architecture, which provides inherent balance and smooth operation characteristics that remain consistent throughout the engine’s service life.

Unlike traditional inline or V-configured engines, the boxer layout places opposing pistons 180 degrees apart, naturally canceling out primary vibrations and creating an exceptionally smooth-running engine.

This inherent balance means that EJ22 engines maintain their smooth idle and vibration-free operation even after hundreds of thousands of miles.

The construction quality of the EJ22 reflects Subaru’s commitment to creating engines that would serve as the foundation for their all-wheel-drive vehicles operating in challenging conditions worldwide.

The aluminum block and heads provide excellent heat dissipation while keeping weight low, crucial for maintaining proper weight distribution in Subaru’s all-wheel-drive systems.

The cylinder sleeves are cast-iron, providing excellent durability and wear resistance that maintains compression and oil control throughout extended service.

One of the most remarkable aspects of the EJ22 is its tolerance for less-than-perfect maintenance while still maintaining smooth operation. These engines have been documented running smoothly with over 400,000 miles, often in vehicles that have seen hard use in challenging climates and conditions.

The engine’s power band remains broad and usable, with excellent low-end torque that makes it ideal for daily driving applications. This consistency, combined with the engine’s legendary reliability, has made the EJ22 one of the most sought-after engines for engine swaps and conversions, where its proven durability and smooth operation characteristics are highly prized.

7. Mazda B6/BP (1987-2002)

The Mazda B6 and BP engine family represents the pinnacle of small-displacement naturally aspirated engineering, combining exceptional smoothness with impressive longevity in a compact, lightweight package.

These 1.6 and 1.8-liter inline-four engines powered some of Mazda’s most beloved vehicles, including the original Miata, establishing a reputation for rev-happy performance and silk-smooth operation that remains intact even after decades of service.

The secret to the B6/BP engines’ exceptional character lies in Mazda’s obsessive attention to reducing internal friction and optimizing airflow. These engines feature some of the most advanced head designs of their era, with carefully shaped ports and combustion chambers that promote efficient burning while minimizing pumping losses.

The result is an engine that not only produces impressive power for its displacement but does so with remarkable smoothness and efficiency. The construction quality of B6/BP engines reflects Mazda’s commitment to creating powerplants that could withstand high-rpm operation while maintaining their refinement throughout extended service lives.

The cast-iron block provides excellent thermal stability and structural integrity, while the aluminum cylinder head incorporates advanced four-valve-per-cylinder technology with sophisticated valve train geometry that ensures optimal airflow at all engine speeds.

One of the most remarkable aspects of these engines is their ability to maintain their high-rpm smoothness throughout their service life. Unlike many engines that develop harshness or vibration as they age, well-maintained B6/BP engines often retain their ability to rev smoothly to their 6,500+ rpm redlines even after hundreds of thousands of miles.

This is largely due to Mazda’s excellent internal balance and the precision of their manufacturing processes. The timing belt system in B6/BP engines, while requiring periodic maintenance, is robust and well-designed.

The interference design means that timing belt replacement is critical, but when properly maintained, the system provides precise valve timing throughout the engine’s service life.

The combination of this smoothness with proven longevity has made B6/BP engines highly sought after in the enthusiast community, where they’re prized for their ability to deliver engaging performance while maintaining the reliability needed for daily transportation.

8. Ford 300 Inline-Six (1965-1996)

The Ford 300 cubic inch (4.9-liter) inline-six engine stands as one of the most durable and long-lived powerplants in American automotive history, serving as the workhorse engine for Ford trucks and vans for over three decades.

This remarkable engine earned its reputation through consistent, smooth operation in demanding commercial and fleet applications, where reliability and longevity were far more important than peak performance figures.

The 300’s exceptional durability stems from its fundamentally conservative design philosophy, which prioritized longevity and reliability over maximum power output.

The cast-iron construction throughout provides exceptional thermal stability and structural integrity, while the long-stroke design creates excellent low-end torque characteristics that reduce stress on the drivetrain.

The engine’s displacement and conservative tuning mean that it rarely operates near its stress limits, contributing significantly to its legendary longevity.

The precision of Ford’s manufacturing processes for the 300 was exceptional, particularly considering its intended role as a commercial-duty engine.

The seven-main-bearing crankshaft provides excellent support and reduces stress concentrations, while the robust connecting rods and pistons are designed with generous safety margins.

The cylinder head design, while simple by modern standards, incorporates excellent port shapes and combustion chamber geometry that promote efficient burning and smooth operation.

One of the most remarkable aspects of the Ford 300 is its ability to maintain smooth operation even under severe duty cycles. These engines have been documented providing smooth, reliable service in commercial applications with over 500,000 miles, often in vehicles that have seen continuous heavy-duty operation.

The engine’s tolerance for extended maintenance intervals and challenging operating conditions is legendary among fleet operators and commercial users. The valve train system of the 300 is particularly noteworthy for its simplicity and durability.

The pushrod, two-valve-per-cylinder design eliminates complexity while providing adequate airflow for the engine’s intended applications. The hydraulic lifters provide automatic lash adjustment throughout the engine’s service life, maintaining consistent valve timing while eliminating the need for periodic adjustments.

This combination of smoothness and proven longevity has made the 300 a favorite among enthusiasts who appreciate its honest, no-nonsense character and legendary reliability.

9. Lexus 1UZ-FE (1989-2000)

The Lexus 1UZ-FE V8 engine represents one of the finest achievements in automotive engineering, combining German-level refinement with Japanese reliability in a package that redefined expectations for luxury car powerplants.

This 4.0-liter all-aluminum V8 served as the heart of Lexus’s flagship LS400, establishing the brand’s reputation for building engines that maintain their silk-smooth operation and whisper-quiet refinement throughout extended service lives.

The 1UZ-FE’s exceptional character begins with Toyota’s decision to completely reimagine what a luxury car engine should be, rather than simply adapting existing designs.

The all-aluminum construction provides excellent heat dissipation and weight distribution, while the sophisticated 32-valve design with four valves per cylinder ensures optimal airflow and combustion efficiency.

The deep-skirt block design provides exceptional rigidity that maintains precise tolerances throughout the engine’s service life. The precision of Toyota’s manufacturing processes for the 1UZ-FE was revolutionary for its era, setting new standards for production engine tolerances and surface finishes.

The cylinder bores feature a sophisticated plateau-honed finish that provides excellent ring sealing while minimizing friction, contributing to both the engine’s smoothness and longevity. The rotating assembly is balanced to incredibly tight tolerances, creating an engine that operates with almost electric-motor-like smoothness.

One of the most remarkable aspects of the 1UZ-FE is its sophisticated engine management system, which was years ahead of its competition when introduced.

The system continuously monitors and adjusts dozens of parameters to optimize performance, efficiency, and emissions while protecting the engine from potentially damaging conditions. This intelligent management contributes significantly to the engine’s longevity by preventing operation outside optimal parameters.

The valve train system of the 1UZ-FE showcases Toyota’s attention to reducing friction and wear throughout the engine. The dual overhead cam design provides precise valve control, while the sophisticated hydraulic lash adjusters maintain optimal valve clearances throughout the engine’s service life.

This combination of luxury-car smoothness with legendary Toyota reliability has made the 1UZ-FE one of the most respected engines among enthusiasts, who prize its ability to deliver sophisticated performance while maintaining the dependability that Toyota engines are famous for worldwide.

10. Volvo B230F (1985-1996)

The Volvo B230F represents the culmination of decades of development in robust, reliable four-cylinder engine design, serving as the backbone of Volvo’s lineup during some of the company’s most successful years.

This 2.3-liter naturally aspirated engine powered millions of Volvo sedans and wagons worldwide, earning a reputation for exceptional smoothness and legendary longevity that has made it one of the most beloved engines among Volvo enthusiasts and automotive technicians alike.

The B230F’s exceptional durability and refinement stem from Volvo’s philosophy of over-engineering for longevity rather than optimizing for maximum performance or minimum cost.

The cast-iron block features generous wall thickness and sophisticated cooling passages that ensure consistent thermal management throughout the engine’s service life.

The aluminum cylinder head incorporates advanced eight-valve technology with sophisticated port shapes that promote excellent airflow while maintaining durability.

One of the most remarkable aspects of the B230F is its sophisticated fuel injection system, which was advanced for its era and contributed significantly to the engine’s smooth operation and longevity.

The Bosch LH-Jetronic system provides precise fuel metering that optimizes combustion efficiency while preventing the rich or lean conditions that can accelerate engine wear.

The system’s reliability and precision remain consistent throughout the engine’s extended service life, maintaining optimal performance and fuel economy.

The construction quality of the B230F reflects Volvo’s commitment to building engines that would provide decades of reliable service. The forged steel crankshaft features seven main bearings that provide excellent support and reduce stress concentrations, while the connecting rods and pistons are designed with generous safety margins that ensure long service life even under challenging conditions.

The timing belt system, while requiring periodic maintenance, is robust and well-engineered. The B230F’s reputation for smoothness is legendary among Volvo owners, who often report that their engines maintain the same refined idle and smooth acceleration characteristics even after 300,000 or 400,000 miles.

The engine’s combination of smoothness, reliability, and longevity has made it a favorite among enthusiasts who appreciate its honest, dependable character.

Many B230F engines continue to provide smooth, reliable service well into their third decade of operation, testament to the fundamental soundness of Volvo’s engineering philosophy and the quality of their manufacturing processes.

11. Acura/Honda J35 (1998-Present)

The Honda J35 V6 engine family represents the pinnacle of naturally aspirated V6 development, combining Honda’s legendary reliability with sophisticated engineering that delivers exceptional smoothness and performance throughout extended service lives.

This 3.5-liter powerplant has served as the foundation for Honda and Acura’s premium vehicles for over two decades, establishing a reputation for maintaining its refined operation and impressive performance characteristics even after hundreds of thousands of miles.

The J35’s exceptional character begins with Honda’s advanced aluminum construction and sophisticated manufacturing processes that create an engine with exceptional precision and durability.

The aluminum block features Honda’s advanced cylinder sleeve technology that provides excellent wear resistance while maintaining optimal heat transfer characteristics.

The sophisticated SOHC VTEC cylinder heads incorporate variable valve timing and lift that optimizes performance across the entire operating range while contributing to long-term durability. One of the most remarkable aspects of the J35 is its ability to combine impressive performance with exceptional smoothness and refinement.

The 60-degree V6 configuration provides inherent balance characteristics that are enhanced by Honda’s sophisticated balancing and vibration damping systems.

The result is an engine that operates with remarkable smoothness throughout its rev range, maintaining this character even after extensive service.

The VTEC system in J35 engines represents some of Honda’s most advanced variable valve timing technology, providing optimal valve timing and lift characteristics for different operating conditions.

This system not only enhances performance and efficiency but also contributes to the engine’s longevity by ensuring that the valvetrain operates under optimal conditions throughout the engine’s service life.

The system’s reliability and precision remain consistent throughout hundreds of thousands of miles. The precision of Honda’s manufacturing processes for the J35 is evident in the engine’s ability to maintain its performance characteristics throughout extended service.

The engine features extremely tight tolerances throughout, from the precisely honed cylinder bores to the carefully balanced rotating assembly. This attention to detail pays dividends throughout the engine’s service life, as the tight clearances and precise balancing maintain the engine’s smooth operation and performance characteristics.

The fuel injection and engine management systems of the J35 are sophisticated even by current standards, featuring advanced sequential port injection that provides precise fuel metering for each cylinder.

The engine’s ability to deliver both daily-driving refinement and impressive performance capabilities, while maintaining these characteristics throughout hundreds of thousands of miles, represents the very best of modern naturally aspirated engine development.