Engines are the backbone of every vehicle, and their ability to withstand heat often defines their true reliability. Overheating can spell disaster, leading to costly repairs or even complete engine failure.

Yet, some engines are engineered with such resilience, precision cooling systems, and robust construction that they can endure extreme conditions without breaking a sweat. These engines aren’t just about horsepower; they represent the perfect balance of performance, efficiency, and durability.

In this article, 10 Engines That Rarely Overheat Even in Extreme Conditions, we explore power plants that have stood the test of time and temperature. From Toyota’s dependable workhorses to Honda’s high-revving icons, Lexus’ indestructible V8s, and Mercedes’ overbuilt diesels, these engines prove that smart engineering can conquer heat stress.

Whether you’re an enthusiast, a commuter, or someone who values long-lasting reliability, these examples highlight why certain engines remain legendary for their ability to keep cool under pressure.

1. Toyota 1ZZ Engine: A Reliable Workhorse

The Toyota 1ZZ engine, part of the ZZ family, was produced between 1997 and 2008. As an inline-four DOHC gasoline engine, it was designed with fuel efficiency in mind, making it a suitable choice for Toyota’s more economical vehicles. Displacement options ranged from 1.4 to 1.8 liters, producing between 120–145 horsepower and 122–127 lb-ft of torque.

The 1ZZ was widely used across Toyota’s lineup, from practical sedans to sportier models. It powered cars such as the Toyota Corolla, MR2 Spyder, Matrix, Wish, and Allion, as well as the Pontiac Vibe. Toyota even offered a factory-backed supercharger kit (2003–2004), which boosted performance with an additional 40 hp and 38 lb-ft of torque. This versatility highlighted the engine’s balance of efficiency and adaptability.

The 1ZZ earned a reputation for durability and longevity, often lasting well beyond 200,000 miles with proper care. Its relatively simple design made it easy to maintain, while Toyota’s Variable Valve Timing–intelligent (VVT-i) technology improved both efficiency and performance. Additionally, its fuel economy made it a popular choice for daily commuters and long-distance drivers.

Despite its strengths, the 1ZZ was not without problems. The most well-documented issue was excessive oil consumption, particularly in pre-2003 models, due to stuck piston rings.

Later revisions addressed this flaw, making newer engines more reliable. Other recurring problems included timing chain tensioner oil leaks, ECM (engine control module) malfunctions, and the need for manual valve adjustments, a decision that drew criticism for its complexity.

Owners are advised to follow Toyota’s recommended maintenance schedule, with particular emphasis on regular oil and filter changes. Checking oil levels frequently is crucial to prevent long-term damage from excessive consumption. For buyers considering vehicles equipped with this engine, models manufactured after 2003 are generally safer choices due to improvements in design and reliability.

The Toyota 1ZZ stands out as a reliable, efficient, and versatile engine that balances performance with economy. While early models faced oil-related issues, proper maintenance and opting for newer versions ensure it remains a durable and dependable choice for a wide range of vehicles.

2. Honda B-Series Inline-Four: The Iconic VTEC Powerhouse

The Honda B-Series inline-four engine, produced between 1988 and 2001, holds a legendary place in automotive history. Known for its robust construction, tuning potential, and pioneering VTEC (Variable Valve Timing and Electronic Control) system, the B-Series became a benchmark for performance-oriented four-cylinder engines.

With displacements ranging from 1.6 to 2.0 liters, these engines produced 100–200 horsepower and 111–140 lb-ft of torque, striking a balance between efficiency and spirited driving.

The B-Series powered some of Honda’s most popular vehicles during the late 20th century, including the Civic, CRX, Integra, and CR-V. The introduction of VTEC technology allowed the engine to deliver fuel efficiency at lower RPMs while unlocking higher performance at higher revs.

This dual nature made the B-Series beloved by both everyday drivers and motorsport enthusiasts. Models like the Civic Type R and Integra GS-R showcased the engine’s potential, while grassroots racers quickly embraced it for tuning and modifications.

The B-Series earned its reputation for reliability and longevity. Engines like the B16A were engineered to last over 250,000 km (155,000 miles), with many examples surpassing 300,000 miles when maintained with quality oil and regular servicing.

The robust design, combined with high-revving capability and power output, cemented the engine as one of the most respected inline-fours of its era. Its adaptability also meant that enthusiasts could modify it extensively without compromising its durability.

Despite its strengths, the B-Series was not flawless. Some owners reported excessive oil consumption, cracked exhaust manifolds, and head gasket failures. Failures of the VTEC solenoid could also lead to reduced fuel efficiency. Still, these problems were relatively minor compared to the engine’s strong reputation for dependability.

The success of the B-Series is tied closely to Honda’s engineering philosophy. VTEC technology not only boosted performance but also ensured efficiency and durability. Additionally, the thriving global community of Honda enthusiasts provides extensive support, aftermarket parts, and knowledge, which helps keep these engines running strong decades after production ended.

The Honda B-Series inline-four remains an iconic engine, celebrated for its mix of performance, reliability, and tuning potential. As a gold standard for inline-fours, it continues to inspire enthusiasts and demonstrates how engineering innovation can deliver both power and longevity.

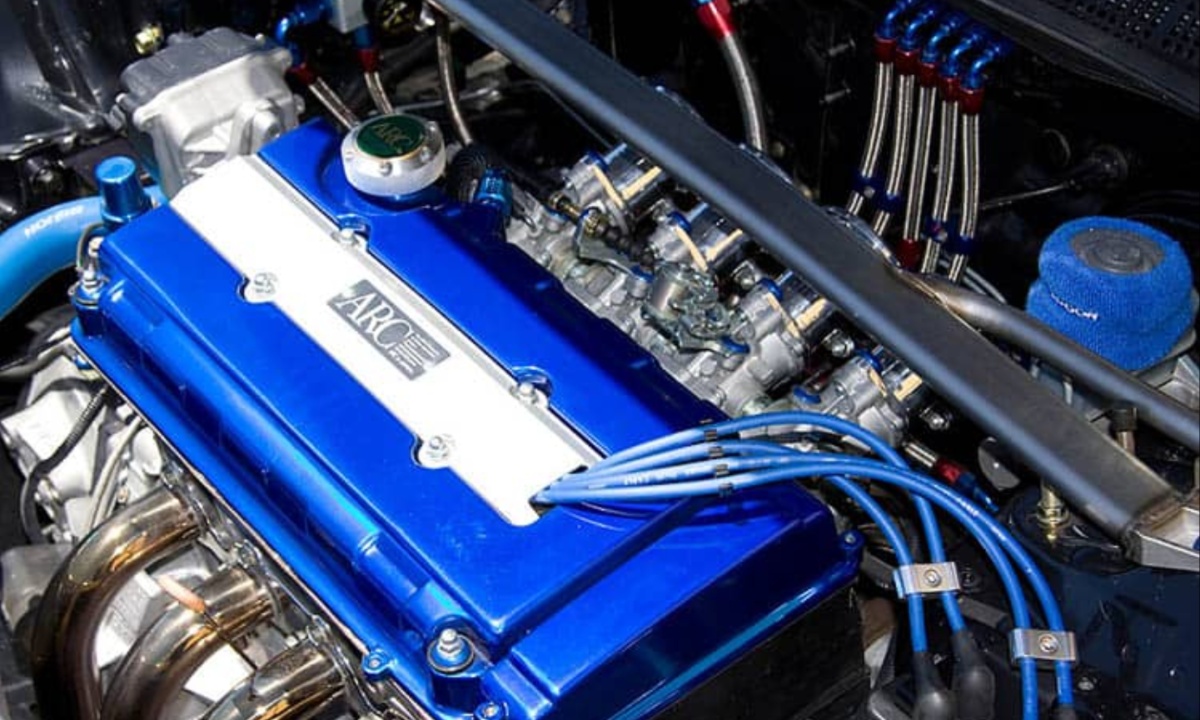

3. Honda K-Series Inline-Four: Modern Reliability Meets Performance

The Honda K-Series inline-four engine, first introduced in 2001, replaced the legendary B-Series and quickly established itself as a benchmark for modern performance and reliability. Built on a DOHC architecture and equipped with Honda’s improved i-VTEC system, the K-Series was designed to deliver high-revving power while maintaining efficiency and everyday usability.

Offered in 2.0, 2.3, and 2.4-liter displacements, it produced between 150 and 320 horsepower with torque ranging from 132 to 310 lb-ft, depending on the variant. Initially found in the Acura RSX, Civic Si, and CR-V, the engine later powered models such as the Accord and Civic Type R, further cementing its reputation across a wide range of vehicles.

One of the key advancements of the K-Series was the introduction of roller rockers in the cylinder heads, which reduced internal friction and enhanced durability.

Honda also implemented a computer-controlled ignition system, allowing the ECU to precisely manage ignition timing for both performance and fuel economy. This combination reinforced Honda’s image as a manufacturer of reliable, efficient, and spirited engines while also opening up new tuning possibilities for enthusiasts.

A defining characteristic of the K-Series is its robust and highly efficient cooling system. Equipped with under-piston oil squirters, a strong factory water pump, and durable thermostats, the engine manages heat exceptionally well, even under high-stress conditions.

The use of cast-iron cylinder sleeves and forged or cast internals ensured that the engine could endure extreme temperatures without warping or suffering long-term damage. With moderate compression ratios in most civilian applications, the engine was not overly stressed, which contributed significantly to its longevity and consistent performance.

The K-Series became a favorite in both stock form and as a platform for modification. Its reputation for durability encouraged tuners to push its limits through turbocharging, track use, and other high-performance builds.

While the stock cooling system is already highly effective, enthusiasts often upgrade components such as thermostats, coolant plumbing, and water pumps to enhance thermal stability in extreme conditions. These upgrades allowed the K-Series to thrive not only as a reliable commuter engine but also as a foundation for serious motorsport applications.

The Honda K-Series inline-four represents an ideal blend of innovation, reliability, and performance. With strong internals, excellent thermal management, and broad aftermarket support, it has proven itself as a versatile engine capable of lasting for years while offering immense potential for those who wish to push its boundaries.

4. Mercedes-Benz M111: A Durable Four-Cylinder Classic

Introduced in 1992 as the successor to the legendary M102, the Mercedes-Benz M111 engine quickly established itself as one of the most dependable four-cylinder engines in the brand’s history. Produced until 2003, the M111 came in a wide range of displacements, including 1.8, 2.0, 2.2, and 2.3 liters.

Its power output varied from 121 to 194 horsepower, with torque ranging between 125 and 207 lb-ft, depending on the version. The engine found applications across many of Mercedes’ most popular models, including the C-Class, E-Class, CLK, and SLK roadster.

Built with a cast-iron block and aluminum alloy cylinder heads, it was engineered for strength and resilience, requiring little more than routine oil changes to remain in good health.

The reliability of the M111 stems from its robust construction and thoughtful engineering. Its cast-iron block provided exceptional resistance to heat-related stress, preventing warping and minimizing the likelihood of coolant leaks or head gasket failures.

Mercedes also equipped it with an over-engineered cooling system, designed to handle a wide range of operating conditions. The thermostat, for instance, featured a dual-plate design that ensured precise control over coolant flow, while the viscous clutch fan automatically increased its efficiency as temperatures rose.

For hotter climates, Mercedes even offered a tropical fan clutch to improve cooling under extreme conditions. An auxiliary fan system acted as an additional safeguard, engaging only when coolant temperatures exceeded a set threshold. These features ensured that the M111 could operate reliably at its standard high operating temperature of around 90°C without any risk of overheating.

The M111’s conservative power delivery also played a role in its long-lasting reputation. Unlike high-revving performance engines, it was not overly stressed, which meant it generated less heat and experienced less wear over time.

Owners who maintained their engines properly found that they could last hundreds of thousands of miles with few major issues. Still, like any engine, the M111 had its weak points.

Common problems included oil leaks from the camshaft adjuster, timing chain tensioner wear, crankshaft position sensor failures, and aging wiring harnesses. These issues were predictable, well-documented, and relatively straightforward to resolve when caught early.

Ultimately, the Mercedes-Benz M111 is remembered as a conservative yet highly reliable workhorse. Its heavy-duty design, precise thermal management, and simple maintenance needs make it a standout among Mercedes’ long line of engines.

Even decades after production ended, many M111-powered cars remain on the road, a testament to the engine’s durability and reputation as one of the best four-cylinders ever built.

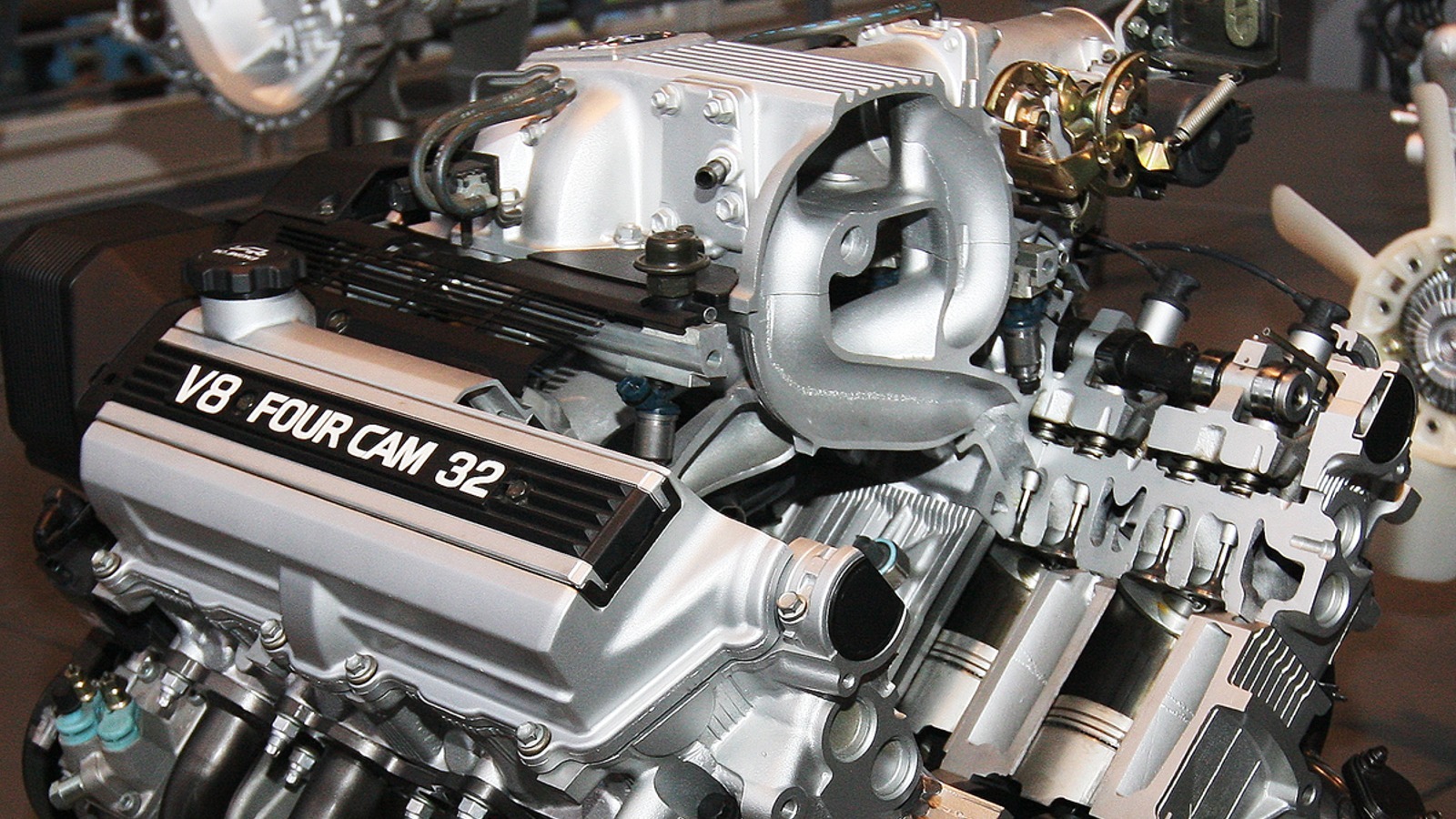

5. Lexus 1UZ-FE: The Million-Mile V8

The Lexus 1UZ-FE, produced between 1989 and 2004, is widely regarded as one of the most durable and refined V8 engines ever built. Designed by Toyota Motor Corporation, this 4.0-liter engine powered Lexus’ flagship LS400 sedan, which debuted as a direct competitor to the Mercedes-Benz S-Class and BMW 7 Series.

With outputs ranging from 256 to 500 horsepower and torque between 260 and 325 lb-ft, the 1UZ-FE balanced smoothness, power, and luxury in a way that redefined expectations in the premium sedan market. It also featured in other Lexus and Toyota models, including the GS400, SC400, Crown, and Crown Majesta.

From the beginning, Toyota’s goal with the 1UZ-FE was to create an engine that could deliver unparalleled comfort and dependability. Its design prioritized refinement, and it became famous for producing almost no noticeable vibration, an essential trait for luxury cars aimed at chauffeured executives.

Owners often praise the 1UZ-FE for its ability to run smoothly for hundreds of thousands of miles, with some examples reaching a million miles with regular maintenance.

The 1UZ-FE’s reliability is rooted in its over-engineered construction and highly effective cooling system. The engine was equipped with a large-capacity cooling system that could hold 11 to 14 quarts of coolant, giving it a significant thermal buffer and making overheating extremely rare.

Toyota also incorporated a robust water pump, precision thermostats, and a generously sized radiator into the design. Later versions introduced an Exhaust Gas Recirculation (EGR) gas cooler, which helped lower intake temperatures and reduce the risk of engine knocking.

The reinforced all-aluminum block, combined with a forged steel crankshaft and six cross-bolted main bearing caps, ensured that the engine could withstand stress without succumbing to heat-related damage.

Though renowned for its durability, the 1UZ-FE is not completely free from issues. Owners occasionally report oil and coolant leaks, camshaft or crankshaft position sensor failures, and timing belt tensioner wear. Fortunately, these problems are predictable and easily managed with routine service, particularly when replacing the timing belt and water pump at recommended intervals.

While the 1UZ-FE’s cooling system performs flawlessly in stock form, it can be pushed to its limits when heavily modified for racing or extreme horsepower builds. In such cases, aftermarket upgrades are necessary to maintain its legendary reliability. Nevertheless, in standard applications, the engine is considered nearly indestructible.

The Lexus 1UZ-FE remains a benchmark for luxury V8s, combining smooth power delivery, robust engineering, and extraordinary longevity. It stands as a testament to Toyota’s ambition to create an engine capable of lasting a lifetime, making it one of the finest powerplants in automotive history.

Also Read: 10 Cars That Survive Road Trips Like Champions

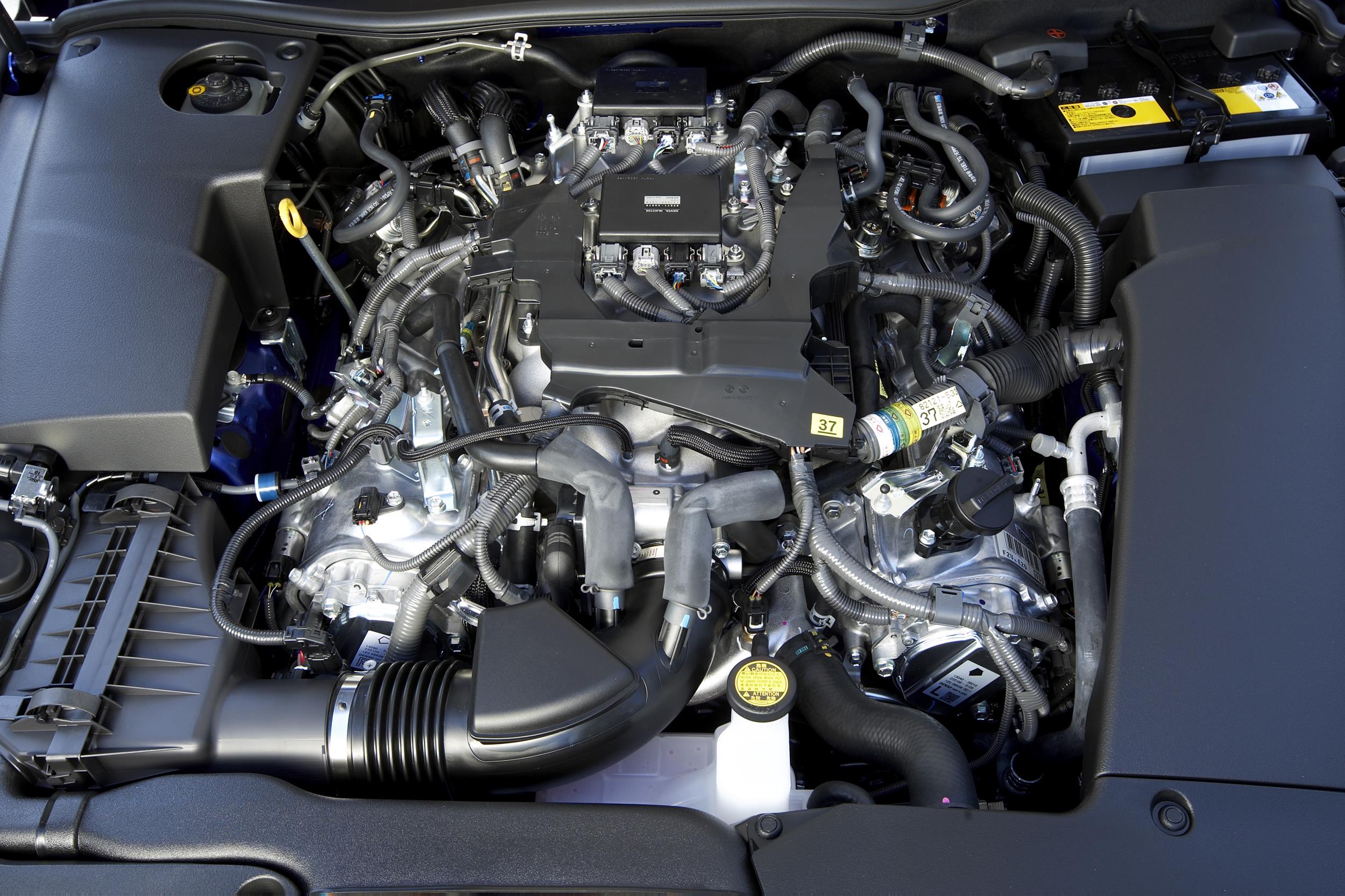

6. Lexus 2UR-GSE: The Reliable High-Performance V8

The Lexus 2UR-GSE engine, introduced in 2007, marked a new era for Toyota’s luxury-performance division. Developed to replace the outgoing UZ engines, the 2UR-GSE brought modern engineering and efficiency technologies such as dual VVT-i and Toyota’s D4-S direct injection system.

With a displacement of 5.0 liters, this naturally aspirated 32-valve DOHC V8 delivers between 422 and 482 horsepower along with 371 to 399 lb-ft of torque, making it a powerhouse for Lexus’ high-performance F models. It has been featured in the IS F, RC F, GS F, LC 500, and IS 500 F-Sport Performance, where it balances reliability with thrilling driving dynamics.

Unlike standard UR-series engines that emphasized longevity and refinement, the 2UR-GSE was engineered with performance in mind. Co-developed with Yamaha, the engine incorporated advanced cooling features and durable materials that allowed it to withstand the rigors of sustained high-RPM use.

Owners and enthusiasts often highlight the engine’s ability to exceed 200,000 miles with proper care, a remarkable achievement for a performance-oriented V8.

The cooling system of the 2UR-GSE is one of its defining strengths. Beyond its standard coolant-based system, the engine uses integrated oil jets to spray the underside of the pistons, providing crucial thermal control under heavy loads.

The cylinder heads feature a high-pressure water jacket between the exhaust ports and spark plugs, targeting one of the hottest areas of the engine and reducing the risk of detonation. Additionally, the cylinder head covers incorporate an internal ventilation system, drawing in fresh air to reduce oil degradation and extend component life.

Its durability is also the result of high-strength construction. The forged steel crankshaft, lightweight aluminum alloy pistons, and titanium intake valves ensure stability and resilience at high operating temperatures.

Reinforced three-layer steel head gaskets and robust crankshaft bearing caps further contribute to its strength under extreme conditions. Even the factory water pump was deliberately engineered to resist cavitation, a common cooling issue in performance engines during sustained high-RPM driving.

Despite its strength, the 2UR-GSE does have a few minor issues. Owners have reported cam chain tensioner noise and valley plate gasket leaks, but these are well-documented and manageable with preventative maintenance. When properly serviced, the engine’s cooling system and hardware continue to deliver the reliability Lexus is known for, even when the car is driven hard on the road or track.

The Lexus 2UR-GSE stands out as one of the finest modern performance V8s. Its combination of durability, intelligent cooling design, and high-output capability makes it not only a reliable daily driver but also a true enthusiast’s engine capable of blending luxury with motorsport-grade engineering.

7. BMW M57 Diesel: A Rare Blend of Power and Reliability

The BMW M57 diesel engine, produced between 1998 and 2013, stands out as one of the brand’s most dependable powerplants, challenging BMW’s mixed reputation for reliability. This 3.0-liter turbocharged water-cooled inline-six was equipped with common rail injection and came in multiple displacements, including 2.5, 2.9, and 3.0 liters.

Power outputs ranged from 148 to 282 horsepower, while torque was particularly impressive at 221 to 428 lb-ft, giving the engine strong pulling capability and flexibility. Over its production run, BMW refined the M57 with different turbocharger options, which improved performance without sacrificing durability.

Despite being less common in gasoline-dominant markets, the M57 found a solid base of applications in models like the BMW E39 525d, E46 330d, and E90 325d.

What set the M57 apart was its combination of robust construction and sophisticated cooling, making it one of the most reliable BMW engines ever built. The cast-iron block used in most versions provided exceptional resistance to heat-related warping, while later aluminum block designs were still engineered with strength in mind.

The engine’s conservative factory mapping limited internal stress and allowed plenty of headroom for modifications without compromising reliability. Its strong internal components meant that even when tuned, the M57 retained impressive stability and durability.

The cooling system played a major role in the engine’s longevity. It featured a multi-layered approach that included an oil-to-coolant heat exchanger, a pressurized coolant system to prevent hot spots, and multiple fans controlled by the ECU for optimal airflow.

The turbocharger was also water-cooled, with an auxiliary pump running after shutdown to prevent oil coking from heat soak. These design choices ensured that overheating was extremely rare, even under sustained heavy loads or in demanding driving conditions.

Beyond design, the diesel’s inherent characteristics further enhanced reliability. The M57’s lower combustion temperatures, combined with the greater thermal mass of its cast-iron block, allowed it to absorb and dissipate heat gradually.

Its lower redline compared to gasoline engines reduced internal friction and wear, adding to its lifespan. Owners who adhered to regular oil changes and replaced aging plastic cooling components found the engine capable of running hundreds of thousands of miles with minimal issues.

Although some drivers reported problems with carbon build-up, glow plugs, and turbochargers, these were predictable concerns rather than fundamental design flaws. With proper upkeep, the BMW M57 became a benchmark for long-lasting diesel engines, offering both strong performance and exceptional durability.

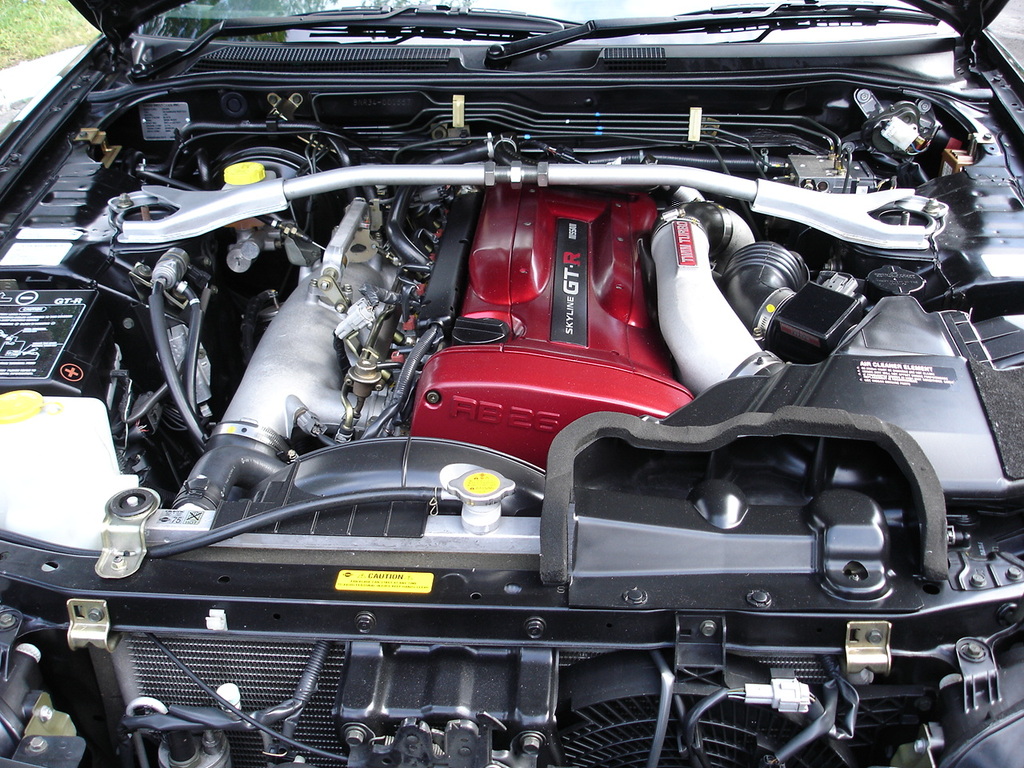

8. Nissan RB26DETT: A Racing Legend with Enduring Reliability

The Nissan RB26DETT, produced from 1989 to 2002, is one of the most iconic performance engines ever built. As the beating heart of the Nissan Skyline GT-R in the R32, R33, and R34 generations, this 2.6-liter twin-turbo straight-six was designed with motorsport in mind.

In its stock form, it produced between 280 and 320 horsepower with torque ranging from 260 to 289 lb-ft, though its true potential far exceeded these factory figures. While many RB26DETT engines have been pushed to their limits through aftermarket tuning, in unmodified condition, it stands out as a highly reliable and durable powerplant.

What made the RB26DETT so robust was its design, which incorporated features typically reserved for endurance racing engines. The cast-iron block provided immense strength and rigidity, allowing it to withstand the extreme pressures of high boost without warping.

Forged internals further improved durability, while oil squirters beneath the pistons helped control heat by reducing piston crown temperatures. To handle high exhaust gas temperatures, Nissan fitted sodium-filled exhaust valves, which efficiently conducted heat away from the valve face, improving longevity under sustained high-RPM use.

The cooling system was equally well-engineered. With a coolant capacity of more than nine liters, the RB26DETT could absorb and dissipate significant amounts of heat during demanding track sessions.

The N1 racing variant came with a high-flow water pump featuring a six-blade impeller, which minimized cavitation and ensured consistent coolant circulation at high engine speeds.

Combined with an effective viscous clutch fan and the GT-R chassis’ optimized airflow through the radiator, the RB26DETT was well protected from overheating under factory conditions.

Still, like many performance engines, the RB26DETT was not without its weak spots. The stock oil pump, for instance, was known to struggle at extremely high RPMs, leading many tuners to upgrade to higher-flow aftermarket units.

Similarly, engines pushed far beyond stock power levels often required upgraded radiators, improved ducting, or additional cooling fans to maintain stability. Issues such as piston ring wear or overheating typically arose only when modifications pushed the engine beyond its intended limits.

In stock form, however, the RB26DETT was both reliable and resilient, embodying Nissan’s commitment to blending racing technology with road-going performance. Its advanced engineering ensured that overheating was rare, even in extreme conditions, making it not only a motorsport legend but also one of the most dependable performance straight-sixes ever built.

9. Mercedes-Benz OM617 Diesel: The Indestructible Workhorse

The Mercedes-Benz OM617 diesel engine, produced from 1974 to 1991, is widely regarded as one of the most durable powerplants ever built. This 3.0-liter inline-five was installed in a broad range of Mercedes vehicles, including the 300D, 300SD Turbo, 300CD, and G-Class W460/W461, as well as in commercial models like the 409D.

Power outputs ranged between 80 and 230 horsepower with torque figures from 124 to 184 lb-ft, which were modest by modern standards but more than adequate for its time. What the OM617 lacked in outright performance, it more than made up for in durability, often running for well over 500,000 miles without requiring a rebuild.

The OM617’s reliability stemmed from its overbuilt design. Constructed entirely from cast iron, including both block and cylinder head, it was engineered to endure heat stress, high loads, and decades of use without significant degradation.

The indirect injection (IDI) system kept peak combustion temperatures lower than those found in modern direct injection diesels, reducing thermal strain on the engine. Even in turbocharged form, the engine was conservatively tuned to prioritize longevity over maximum power output. Its oil was actively cooled to regulate temperatures, an especially important feature in the higher-heat turbocharged versions.

The cooling system itself was simple but highly effective. Generous coolant passages, a robust water pump, and reliable thermostats helped maintain consistent circulation.

When problems did occur, they were typically the result of neglect, such as clogged radiators, failed thermostats, or poor maintenance rather than flaws in the engine’s design. The simplicity of its mechanical fuel injection and cooling setup also meant fewer components that could fail compared to the more complex electronic systems used in later engines.

Another advantage of the OM617 was its excellent thermal stability. The heavy cast-iron construction absorbed and released heat slowly, preventing sudden temperature spikes and reducing the risk of thermal shock or cracking.

This characteristic gave the OM617 a wide operating margin, allowing it to tolerate minor issues like a partially clogged radiator or worn water pump without immediately overheating, something that would cripple more fragile modern engines.

While the OM617 required routine maintenance, regular oil changes, occasional timing chain replacement, and new motor mounts, it rewarded owners with unmatched dependability.

Its resilience, combined with its ability to run on low-quality fuel, made it a favorite for both civilian and military applications worldwide. Ultimately, the OM617 exemplifies the Mercedes philosophy of the era: engines designed not just to perform, but to outlast generations of drivers.

10. General Motors LS Engine: America’s Modern V8 Icon

The General Motors LS engine family, introduced in 1997, has become one of the most celebrated modern V8 platforms in the world. Ranging from 4.8 liters up to 8.4 liters, the LS has powered everything from Chevrolet Corvettes and Camaros to trucks and SUVs, while also becoming the go-to choice for engine swaps across nearly every type of vehicle imaginable.

Its versatility, affordability, and durability have made it a legend in both factory and aftermarket circles. GM continues to produce LS crate engines, including the LS3, LS376/480, and LS376/525, providing enthusiasts with factory-backed options that deliver between 430 and 525 horsepower with torque figures as high as 486 lb-ft.

In its most powerful applications, such as the supercharged LS9 and LT-based derivatives, output climbs well over 700 horsepower, making it one of the broadest and most adaptable engine families ever produced.

A major reason for the LS engine’s enduring popularity is its reliability. Designed with modern computer-aided engineering, the LS combined lightweight aluminum construction with proven pushrod architecture, striking a balance between strength and efficiency.

Unlike the larger, more complex dual-overhead-cam V8s of its European and Japanese rivals, the LS retained a compact design that reduced friction, simplified maintenance, and minimized points of failure.

Components such as roller-rocker valve trains and roller camshafts further reduced heat-generating friction, while forged crankshafts and robust internals gave the engine significant tolerance for modifications and forced induction.

The LS engine’s ability to avoid overheating is rooted in its advanced cooling system. Many variants feature all-aluminum blocks and heads, which dissipate heat more effectively than cast-iron alternatives.

The cooling system incorporates a high-capacity water pump, electronically controlled cooling fans, and optimized coolant passages that target critical areas such as exhaust valve seats. Perhaps most uniquely, the LS platform includes a steam tube system that vents trapped air and steam from the top of the cylinder heads.

This prevents hot spots from forming and ensures consistent coolant flow under extreme operating conditions, a feature especially valuable in racing and towing applications.

Temperature control is further managed by the Engine Control Module (ECM), which continuously monitors sensor data to maintain the engine in its ideal operating range, typically between 195°F and 205°F. High-density aluminum radiators, often paired with modern LS installations, maximize coolant volume and surface area for efficient heat exchange.

Meanwhile, electronic cooling fans provide on-demand airflow, operating only when necessary for improved efficiency compared to traditional mechanical fans. These integrated systems allow the LS engine to remain stable in environments ranging from street driving to competitive motorsport.

Although no engine is completely flawless, some LS units have experienced oil consumption, camshaft phaser failures, or cylinder head cracking. The platform’s track record for durability is exceptional. With proper maintenance, LS engines regularly exceed 200,000 miles in daily use, and when modified, they can reliably sustain double or triple their factory output with appropriate supporting upgrades.

In sum, the GM LS engine represents the ideal blend of modern engineering and traditional V8 toughness. It is lightweight yet strong, simple yet highly adaptable, and reliable enough to withstand both daily driving and extreme motorsport use.

This balance of performance, dependability, and availability has secured its place as not just one of the greatest American engines, but one of the most iconic engines in automotive history.

From practical daily drivers to motorsport legends, these engines showcase what happens when manufacturers prioritize durability alongside performance. Their robust cooling systems, careful engineering, and proven track records demonstrate that reliability doesn’t have to come at the expense of power or efficiency.

While no engine is completely immune to wear or failure, these ten stand out for their rare ability to handle extreme conditions without overheating.

Whether built for cross-country journeys, city commutes, or high-speed track days, each engine on this list represents more than just mechanical excellence; it represents peace of mind for drivers who demand dependability.

In a world where modern engines often prioritize complexity, these powerplants remind us that simplicity, strength, and thoughtful design can create machines that last for decades. If you’re searching for engines that embody true endurance, these ten are among the finest examples ever built.

Also Read: 10 Cars With The Best Resale Reliability vs 10 That Drop Quickly