Car enthusiasts often emphasize the importance of proper maintenance regular oil changes, fluid checks, belt replacements, and timely servicing.

Yet, history has shown that some engines just refuse to quit, even when neglected. Whether it’s because of bulletproof engineering, overbuilt internals, or sheer mechanical simplicity, these engines often keep running long after they should have seized.

For many Americans, especially those who’ve owned budget commuters, hand-me-down vehicles, or workhorses that spent more time being driven than cared for, these engines are legends.

They highlight the resilience of automotive engineering at its finest, showing how some motors can survive missed oil changes, low-quality fuel, or long intervals between tune-ups.

Here are ten engines known for surviving poor maintenance, making them favorites for used car buyers, mechanics, and collectors alike.

1. Toyota 22R/22RE

Few engines have earned the reputation of Toyota’s 22R and its fuel-injected sibling, the 22RE. Found in trucks like the Toyota Pickup and 4Runner during the 1980s and 1990s, this 2.4-liter four-cylinder is legendary for its durability.

Owners routinely abused these engines, running them with dirty oil, neglected timing chains, or skipped valve adjustments, and they still kept chugging.

Off-roaders especially loved the 22RE because it tolerated dust, mud, and overheating better than most motors.

While underpowered by today’s standards, the engine could easily surpass 300,000 miles, even if owners treated it like an afterthought. Mechanics often joke that the 22RE didn’t need maintenance it only needed fuel.

Our Toyota 22RE 2.4-liter Long Block Crate Engine is currently available at a special price. The 22R is often referred to as the 22RE, and both names are correct when describing this 2366 cc naturally aspirated engine. It was widely used in Toyota pickups and SUVs, including the popular 4Runner.

Our extensive inventory includes flat-top piston 22RE models produced between 1985 and 1995, ensuring coverage for a broad range of applications.

Unlike many companies that offer rebuilt 22RE engines, our units are fully remanufactured and fitted with a selection of upgraded components specifically engineered to improve both performance and durability, giving these long blocks a longer and stronger life on the road.

2. Chevrolet Small Block V8 (350)

For decades, the Chevy 350 small-block was the engine of choice for American cars, trucks, and hot rods. From Impalas and Camaros to Silverados and Suburbans, this engine powered millions of vehicles.

Its simplicity, overbuilt design, and widespread availability of parts made it nearly indestructible. Many owners skipped oil changes, overheated them while towing, or neglected carburetor tuning, yet the 350 kept running with a steady rumble.

Farmers, mechanics, and backyard tinkerers loved it because even if something went wrong, the fix was usually cheap and simple. Even today, junkyards are full of small-blocks that still run, proving that this engine was designed to take abuse.

3. Ford 300 Inline-Six

Ford’s 300 cubic-inch straight-six, found in trucks from the 1960s through the 1990s, is another engine that earned cult status. Built with massive internals and designed for low-end torque, this motor powered everything from F-Series pickups to industrial equipment.

Its slow-revving nature meant that even with dirty oil or poor maintenance, it rarely experienced catastrophic failure. Farmers often ran them with barely any care, and mechanics frequently found these engines with hundreds of thousands of miles and uneven maintenance records.

Known for its tractor-like reliability, the Ford 300 inline-six became one of the most beloved truck engines in America, cementing its place in automotive history.

Ford introduced the 300 cubic-inch “Big Six” inline engine to the F-Series lineup in the 1965 model year. Its design was based on the smaller 240 cid I-6, with the 300 distinguished by a longer cylinder stroke while retaining the same bore size.

Known later as the 4.9-liter straight-six after Ford adopted metric conventions in 1983, this engine quickly earned a reputation for exceptional durability, strength, and low-end torque.

Over its 31-year production run, the 300 became famous for its unmatched longevity, flexibility, and ability to deliver a broad torque curve that suited a wide range of driving conditions.

Although it is best remembered for its role in the F-Series pickup trucks, the 300 was also widely used in agricultural and construction machinery, tractors, medium-duty utility and dump trucks, delivery vehicles, and even generators. Following the 1996 model year, Ford officially retired the engine, replacing it with the smaller 4.2L V6.

The Ford 300 inline-six, later reclassified as the 4.9L I-6, served in various Ford F-Series trucks between 1965 and 1996. It was configured as a naturally aspirated inline six-cylinder with an overhead valve design (cam in block) and used a standard distributor ignition system.

The cast-iron block and cylinder head gave the engine remarkable toughness, while its specifications included a 4.00-inch bore and 3.98-inch stroke.

Compression ratios varied across production years, starting at 8.9:1 from 1965 to 1972, dropping to 8.0:1 between 1973 and 1986, and returning to 8.8:1 from 1987 until the end of production in 1996. Depending on the application, the engine’s fuel system differed across model years, but its oil capacity remained consistent at 5 quarts with filter.

In terms of output, the Ford 300 delivered between 101 and 150 horsepower depending on the year, but its real strength lay in torque, which ranged from 223 to 283 lb-ft. This combination of solid performance, simple design, and durability secured the 300 cid inline-six a legendary place in Ford’s history and among enthusiasts who valued reliability and raw pulling power.

4. Honda D-Series

During the 1980s and 1990s, Honda Civics and Accords became the go-to cars for commuters, students, and budget-minded buyers. Many of these vehicles were driven hard and maintained poorly, yet their D-series engines ranging from 1.5 to 1.7 liters proved nearly indestructible.

Countless Civics survived teenage owners who ignored oil changes, revved them to the limiter, and neglected timing belt replacements. These engines weren’t powerful, but they were simple, efficient, and forgiving.

Mechanics frequently recall pulling valve covers off neglected D-series engines only to find them running fine, albeit with thick sludge buildup. For many Americans, this was the first car they owned, and its resilience made a lasting impression.

Honda’s D Series engines have earned a prominent place in the automotive world, particularly among enthusiasts and tuners who value reliability, efficiency, and versatility.

Compact yet capable, these engines are celebrated for their durability, excellent fuel economy, and expansive aftermarket support. Over the years, the D Series has become a cornerstone of the Honda community, powering everything from dependable daily drivers to track-ready race cars.

The lineup includes a variety of variants, each tailored to different performance goals and applications. Some of the most notable engines are the D15B, a 1.5-liter producing 130 horsepower and 100 lb-ft of torque; the D16A, a 1.6-liter generating 108 horsepower and 100 lb-ft of torque; the D16Y8, another 1.6-liter rated at 126 horsepower and 107 lb-ft of torque; and the D16Z6, delivering 125 horsepower and 107 lb-ft of torque.

While each engine has unique traits, they all share a common foundation that makes them highly adaptable for modifications and upgrades, which is one of the reasons they remain so popular.

Adaptability is perhaps the strongest appeal of the D Series. Found in a wide range of Honda models, including the Civic and CRX, these engines can be swapped and upgraded with relative ease, making them attractive to both novice builders and experienced mechanics.

Their straightforward design not only simplifies modifications but also ensures that maintenance and repairs are more accessible compared to more complex powertrains. Replacement parts are readily available, and the thriving aftermarket offers countless performance components that can dramatically enhance both power and efficiency.

The performance potential of the D Series is another reason it remains a tuner favorite. With the right modifications, these engines can rival much larger powerplants. Turbocharging is a popular upgrade that can push output well beyond 200 horsepower when paired with proper tuning.

Upgraded intake and exhaust systems improve airflow, helping the engine breathe better and run more efficiently. ECU tuning further refines performance by optimizing parameters such as fuel mapping and ignition timing. With these modifications, the D Series transforms from a reliable commuter engine into a competitive option for lightweight, high-performance builds.

Reliability is also a defining trait of the D Series. With consistent maintenance, such as timely oil changes and routine timing belt replacements, these engines are known to last hundreds of thousands of miles.

However, owners should be mindful of common issues, including oil leaks that often stem from worn valve cover gaskets, aging timing belts that should be replaced every 60,000 to 100,000 miles, and occasional overheating due to faulty thermostats or radiator problems. Addressing these minor concerns proactively helps prevent more serious failures and keeps the engine running in peak condition.

Ultimately, Honda’s D Series has stood the test of time because it combines simplicity, performance potential, and reliability in a package that appeals to enthusiasts of all skill levels. Whether serving as a dependable stock engine or the foundation for a high-powered build, the D Series continues to hold its place as one of Honda’s most iconic and versatile powertrains.

5. Jeep 4.0 Inline-Six

When enthusiasts talk about reliable Jeep engines, the 4.0-liter inline-six always comes up. Introduced in the 1980s and used in Cherokees, Wranglers, and Grand Cherokees, this engine was a true survivor.

Its iron block and head made it extremely durable, and it tolerated neglect that would kill other engines. Jeep owners often skipped oil changes, overheated them on trails, or ran them hard in city traffic, and the 4.0 kept on running.

It wasn’t the most fuel-efficient engine, but its ability to push past 300,000 miles made it a favorite among off-roaders and commuters alike. Even when starved of maintenance, it almost always got you home.

Also Read: 5 Cars With Dependable Start-Stop Systems and 5 That Annoy Owners

6. Mercedes-Benz OM617 Diesel

In the world of diesel engines, few have a reputation as strong as the Mercedes OM617. Found in cars like the W123 and early W126 models during the 1970s and 1980s, this five-cylinder turbo-diesel was engineered to last.

Owners often neglected oil changes, ran them on poor-quality fuel, or ignored valve adjustments, yet these engines routinely racked up over 500,000 miles. Taxi fleets around the world proved their durability, often pushing them past a million miles.

In the US, they became popular with budget-conscious buyers looking for a car that simply would not quit, even if it smoked, rattled, or leaked oil. The OM617 became a legend of durability in both enthusiast and everyday driving circles.

The Mercedes OM617 is a 3.0-liter inline five-cylinder diesel engine that was produced from 1974 until 1990, powering some of the brand’s most iconic models, including the W123, W126, and the Geländewagen SUV.

Throughout its production run, the OM617 underwent several upgrades and modifications, cementing its reputation as one of the most durable and celebrated engines of its time.

The OM617 belongs to Mercedes’ R5 diesel engine family, which also includes the OM602, OM605, OM612, and OM647. Developed as a five-cylinder version of the earlier OM616 four-cylinder engine, the first OM617 was a naturally aspirated pre-chamber diesel.

It featured a robust cast-iron block, a cast-iron 10-valve cylinder head without hydraulic lifters, and a double-row timing chain that drove both a single camshaft and an in-line Bosch M injection pump. In 1979, Mercedes introduced an improved cylinder head, raised the compression ratio, and boosted output from 80 horsepower to 88 horsepower.

A major milestone came in 1977 with the introduction of the Garrett TB03 turbocharger on U.S.-market W116 sedans. This turbocharged version was refined again in 1979, raising output from 111 to 121 horsepower. A final update in 1982 pushed performance even further, with the strongest version of the OM617 delivering 125 horsepower and 250 Nm of torque.

The OM617 quickly earned a reputation as one of the most reliable diesel engines ever built, with many examples surpassing 1,000,000 kilometers in service. This legendary longevity played a crucial role in boosting Mercedes’ popularity in North America throughout the 1980s.

The turbocharged OM617 also broke new ground as the first diesel engine suitable for use in Mercedes’ luxury S-Class and mid-range models. In response to U.S. fuel economy regulations, Daimler-Benz introduced the 300 SD (S-Class Diesel) and 300 CD (Coupe Diesel), offered in the W116 and later W126 sedans as well as the C123 coupe.

7. Chrysler Slant-6

Chrysler’s Slant-6, produced from the early 1960s into the late 1980s, is another engine that thrived under neglect. Its angled cylinder design gave it a distinctive look, but its true claim to fame was reliability.

Found in everything from Dodge Darts to Plymouth Valiants and Ram pickups, the Slant-6 was nearly impossible to kill. Many owners ignored basic maintenance, and yet the engine would still start and run, even after sitting for years.

Fleet operators loved it because it tolerated abuse and kept working with minimal upkeep. Today, enthusiasts still recall stories of Slant-6-powered cars surviving conditions that would have sidelined more delicate engines.

The Dodge Slant 6 engine, produced by Chrysler from 1959 through 2000, is one of the most recognizable inline-six engines in American automotive history.

Renowned for its rugged durability, simple design, and long service life, it became a favorite powerplant across numerous Dodge and Plymouth vehicles for decades. With its reliable performance and straightforward mechanics, the Slant 6 gained a reputation as an engine that could withstand heavy use while requiring minimal upkeep.

The engine featured a displacement of 225 cubic inches (3.7 liters) with bore and stroke measurements of 3.41 inches by 3.91 inches (86.6 mm x 99.3 mm). Depending on the model year, the compression ratio ranged between 8.0:1 and 9.2:1.

Horsepower output varied, with many versions rated around 145 hp at 4,000 rpm, while torque figures typically reached 215 lb-ft at 2,000 rpm, giving the engine strong low-end pulling power.

The fuel delivery system was handled by either a single-barrel or two-barrel carburetor, while ignition systems evolved over the years from conventional to electronic. A water-cooled setup ensured consistent operating temperatures, and the engine weighed approximately 500 pounds (227 kg).

What truly set the Slant 6 apart was its distinctive 30-degree slanted design, a feature that gave the engine both its name and its engineering advantages. The inline-six layout provided naturally smooth operation, while the tilted configuration allowed for a lower center of gravity, improved weight distribution, and a more compact engine bay.

This made the engine versatile enough to fit a wide range of vehicles while enhancing handling characteristics. The cast-iron block further added to its strength and longevity, ensuring that many Slant 6 engines are still running today, decades after leaving the factory.

Also Read: 12 Cars With the Best Resale After 200k Miles

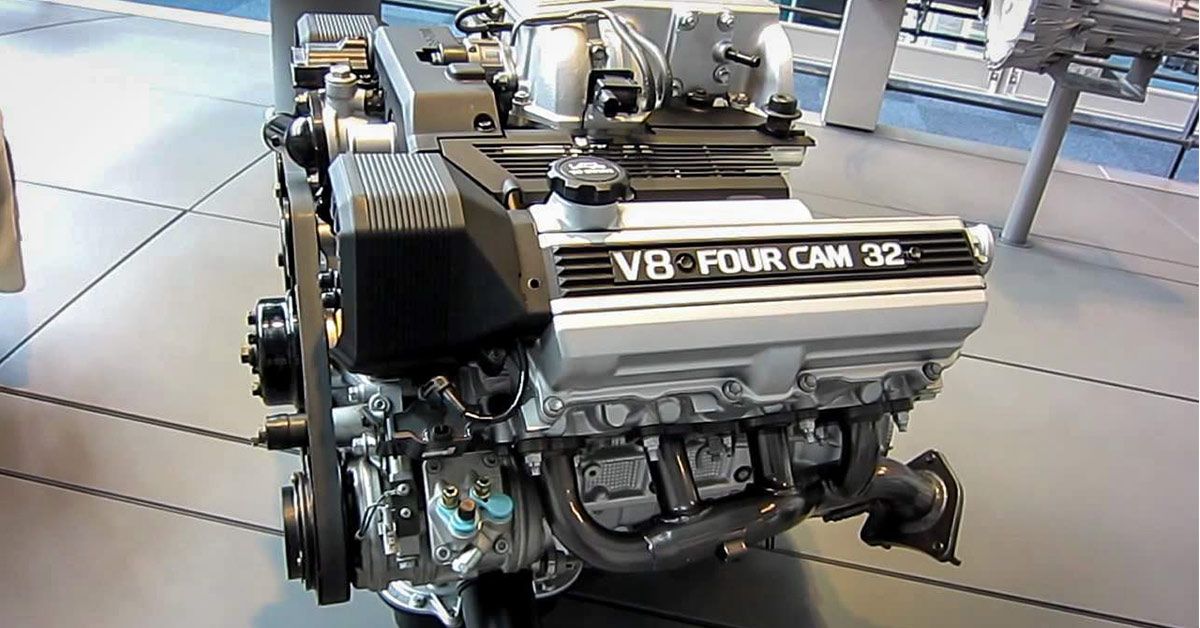

8. Toyota 1UZ-FE

The Toyota 1UZ-FE, a 4.0-liter V8 found in the Lexus LS400, was designed to rival Mercedes and BMW engines of the late 1980s. Toyota engineers overbuilt it with forged internals, a robust aluminum block, and a focus on longevity.

As a result, even with minimal maintenance, these engines often last 300,000 miles or more. Many early Lexus buyers treated the LS400 like a simple commuter, skipping service intervals, yet the 1UZ kept running smoothly.

Car enthusiasts often buy neglected examples today, clean them up, and find that the engine still performs like new. It’s one of the few luxury car engines known for surviving owner neglect.

The Toyota 1UZ-FE is a 4.0-liter (3,968 cc, 242.1 cu·in) naturally aspirated V8 gasoline engine that was produced by Toyota Motor Corporation from 1989 to 2004. Designed with a 90° V-configuration, the 1UZ-FE quickly became known for its durability, smoothness, and advanced engineering, making it one of Toyota’s most respected powerplants.

This engine features an aluminum cylinder block supported by a five-bearing crankshaft, along with dual overhead camshafts (DOHC) operating four valves per cylinder for a total of 32 valves. Both the block and cylinder heads are made of aluminum to reduce weight without compromising strength.

From its debut until 1994, the 1UZ-FE used a multi-port fuel injection (MFI) system, after which Toyota upgraded it to a sequential multi-point fuel injection (SFI) system for improved efficiency and responsiveness. The final evolution of the engine, introduced after 1997, added Variable Valve Timing (VVT-i) on the intake camshafts, further refining performance and fuel economy.

The 1UZ-FE has a bore of 87.5 mm (3.44 in) and a stroke of 82.5 mm (3.25 in). Its compression ratio evolved over the years, starting at 10.0:1 (1989–1994), increasing to 10.4:1 (1994–1997), and reaching 10.5:1 in later versions.

Depending on the model year and application, the engine produced between 256 and 296 horsepower (259–300 PS, 191–221 kW) and delivered peak torque ranging from 245 lb-ft (333 Nm) at 4,000 rpm to 309 lb-ft (420 Nm) at 4,600 rpm.

9. GM 3800 Series II V6

The GM 3800 V6, especially the Series II version from the 1990s and 2000s, became one of the most reliable engines in American cars. Found in Buicks, Pontiacs, and Chevys, it powered millions of mid-size sedans and coupes.

Owners often treated these cars as simple appliances, neglecting maintenance while still expecting them to run. The 3800 could tolerate long oil change intervals, overheating episodes, and neglected intake gaskets, yet it kept running.

Many mechanics describe it as an “engine that just won’t die,” and even today, you can find high-mileage examples still serving as daily drivers.

10. Nissan KA24

The Nissan KA24, a 2.4-liter four-cylinder found in trucks like the Hardbody and the early Frontier, as well as in the 240SX, is another motor known for its toughness.

Owners frequently neglected maintenance, especially in work trucks, yet the KA24 kept running reliably. It wasn’t the most refined or powerful engine, but it had a strong bottom end and forgiving design.

Even when starved of oil changes or pushed hard on highways, it often made it past 200,000 miles. Today, these engines are beloved in drift and tuner communities, where they take abuse and still hold up surprisingly well.

While proper maintenance is always recommended, the engines listed above prove that some designs were simply ahead of their time in durability.

These motors became legends not just because they lasted, but because they endured owners who neglected them, abused them, or used them in ways the engineers probably never imagined.

From Toyota’s bulletproof four-cylinders to Ford’s workhorse inline-sixes, these engines built reputations that still resonate in America’s car culture today.

For anyone looking at a used car or truck, finding one of these engines under the hood is a sign of reassurance: even if its past is questionable, chances are it has a lot of life left.