The turbocharger has revolutionized the automotive industry, transforming modest engines into powerhouses that deliver exhilarating performance while maintaining reasonable fuel efficiency.

This forced induction technology has become increasingly prevalent across all segments of the automotive market, from economical compact cars to high-performance sports machines. However, not all turbocharged vehicles are created equal.

While some manufacturers have perfected the art of turbocharger reliability, producing engines that can endure hundreds of thousands of miles without issues, others have struggled with persistent turbo failures that plague owners with expensive repairs and endless frustration.

Understanding the difference between reliable and problematic turbocharged engines is crucial for anyone considering a vehicle purchase or dealing with turbo-related issues.

A turbocharger failure isn’t just an inconvenience it’s a significant financial burden that can cost anywhere from $1,500 to $6,000 or more, depending on the vehicle and whether you’re installing an OEM or aftermarket unit.

Beyond the immediate repair costs, turbo failures can cause collateral damage to other engine components, potentially leading to even more expensive repairs down the line.

The reliability of a turbocharged engine depends on numerous factors, including engineering quality, manufacturing precision, cooling system design, oil delivery mechanisms, and even the driving conditions the vehicle typically encounters.

Whether you’re a prospective buyer researching your next vehicle, a current owner experiencing turbo issues, or simply an automotive enthusiast interested in engineering reliability, this guide will provide valuable insights into the best and worst turbocharged engines on the road today.

5 Cars That Rarely Blow Turbos

These exceptionally engineered vehicles feature turbocharged powertrains designed with conservative boost pressures, robust bearing systems, and advanced cooling architectures that protect their forced induction components from premature failure.

Their thoughtful engineering includes properly sized oil supply lines, effective heat management through strategically positioned intercoolers, and sophisticated engine management systems that prevent harmful conditions like pre-ignition or excessive exhaust gas temperatures.

From demanding highway pulls to stop-and-go traffic that creates thermal cycling stress, these remarkable turbochargers continue delivering reliable boost without developing shaft play, seal degradation, or catastrophic bearing failure that plagues lesser designs.

The combination of adequate lubrication, proper cool-down procedures facilitated by electric coolant pumps, and quality component selection creates turbocharged engines that defy the common perception of forced induction unreliability while delivering the performance benefits that enthusiasts desire.

1. Toyota Supra (2020+) with BMW B58 Engine

The modern Toyota Supra, though developed in partnership with BMW, has quickly established itself as one of the most reliable turbocharged sports cars available today. At its heart lies the BMW B58 3.0-liter inline-six turbocharged engine, which has proven to be exceptionally robust across multiple applications.

This engine represents the culmination of BMW’s decades of forced induction experience, incorporating lessons learned from previous turbo platforms while introducing advanced technologies that enhance both performance and longevity. The B58’s turbocharger is a masterpiece of engineering, featuring a twin-scroll design that improves throttle response while reducing thermal stress.

The turbo utilizes high-quality materials throughout its construction, including a lightweight turbine wheel that spins up quickly while minimizing bearing loads.

The bearing system itself employs advanced lubrication technology that ensures adequate oil flow even during aggressive driving, preventing the oil starvation that plagues many turbo failures.

Additionally, the integrated exhaust manifold design helps manage heat more effectively, reducing the thermal cycling that can crack housings and deteriorate seals over time. Toyota’s involvement in the Supra’s development has ensured that reliability standards meet their famously stringent requirements.

The cooling system is exceptionally well-designed, with adequate capacity to manage both engine and turbocharger heat under sustained high-load conditions.

The engine management system includes sophisticated protection algorithms that prevent over-boosting, excessive exhaust gas temperatures, and other conditions that could damage the turbo.

These software protections work seamlessly in the background, allowing enthusiastic driving while preventing the operator from inadvertently causing damage.

Real-world reliability data supports the B58’s reputation for durability. Owners regularly report trouble-free operation well past 100,000 miles, with many examples approaching 200,000 miles without turbo-related issues.

The tuning community has also embraced this engine, with numerous examples running significantly increased boost levels on stock turbos without failures a testament to the overbuilt nature of the components.

When failures do occur, they’re typically related to neglected maintenance rather than inherent design flaws, with oil change intervals being the most critical factor in longevity.

The Supra’s turbo reliability is further enhanced by its sensible performance calibration. Unlike some manufacturers that push turbos to their absolute limits to achieve impressive power figures, Toyota and BMW have been conservative with boost levels and thermal loads, ensuring the turbocharger operates well within its comfortable operating range.

This approach sacrifices perhaps a few horsepower but pays dividends in long-term reliability. The result is a sports car that delivers thrilling performance without the anxiety of impending turbo failure that accompanies some competitors.

2. Porsche 911 Turbo (997.2 and Newer)

Porsche has long been synonymous with automotive excellence, and their turbo technology exemplifies this reputation. The 911 Turbo, particularly from the 997.2 generation onward (2010+), represents the gold standard in turbocharged reliability.

These vehicles utilize sophisticated twin-turbo systems that deliver breathtaking performance while demonstrating remarkable durability that defies the typical stereotype of high-performance turbo failures.

Porsche’s engineering philosophy emphasizes longevity and repeatability, ensuring that their turbos can deliver peak performance lap after lap, year after year.

The 911 Turbo’s twin-turbocharger setup employs Variable Turbine Geometry (VTG) technology, which allows the turbine housing’s geometry to change based on engine speed and load.

This innovation eliminates turbo lag while optimizing efficiency across the entire rev range, but more importantly from a reliability standpoint, it allows each turbo to operate in its most efficient zone, reducing thermal stress and mechanical wear.

The VTG system is manufactured to aerospace tolerances, with components that can withstand extreme temperatures and rotational speeds without degradation. Porsche’s attention to detail extends to every aspect of the turbo system’s supporting infrastructure.

The oil delivery system ensures that turbos receive adequate lubrication under all conditions, including during aggressive cornering when oil surge can starve other components.

The cooling system is massively oversized for the application, featuring multiple heat exchangers and sophisticated thermal management that keeps turbos operating at optimal temperatures even during track use.

The engine management system monitors dozens of parameters in real-time, making microsecond adjustments to protect the turbos from harmful conditions while maintaining performance.

Owners of 911 Turbos consistently report exceptional reliability, with many examples exceeding 150,000 miles on original turbos without issues.

Even more impressive is the number of track-focused cars that endure countless high-speed laps, endurance races, and spirited driving sessions without turbo failures.

This real-world durability stems not just from superior engineering but from Porsche’s commitment to using only premium materials and manufacturing processes.

Every turbo component undergoes rigorous quality control, and individual turbos are flow-tested and balanced before installation. The financial aspect of 911 Turbo ownership also reflects their reliability.

While these vehicles command premium prices, their strong resale values partially result from their reputation for dependability. Prospective buyers know that a properly maintained 911 Turbo is unlikely to saddle them with expensive turbo repairs, making even high-mileage examples attractive.

This stands in stark contrast to some performance vehicles that depreciate rapidly due to anticipated repair costs, demonstrating that reliability translates directly into retained value.

Also Read: 8 Checks That Stop a Chevy Colorado From Breaking Down Early

3. Subaru WRX (2015-2021 with FA20DIT Engine)

Subaru has built its performance reputation on turbocharged boxer engines, and the FA20DIT powering the 2015-2021 WRX represents a significant leap forward in reliability compared to previous generations.

This 2.0-liter direct-injection turbocharged engine addresses many of the weaknesses that plagued earlier Subaru turbo motors, incorporating modern technology and improved materials that dramatically enhance durability.

While earlier WRX models earned mixed reliability reputations, the FA20DIT has proven itself as a robust platform that can handle both daily driving and spirited performance.

The FA20DIT’s turbocharger features a twin-scroll design that improves efficiency and reduces stress on components. Unlike single-scroll turbos that pulse unevenly, the twin-scroll configuration separates exhaust pulses from different cylinder pairs, creating more consistent flow and reducing turbulence-induced wear.

The turbo itself uses high-quality bearings and seals that resist the breakdown issues common in cheaper units. Subaru’s choice of materials prioritizes heat resistance and durability, with housings and internal components designed to withstand the raised temperatures inherent in boxer engine layouts, where turbos often sit in cramped, heat-saturated spaces.

One key factor in the FA20DIT’s reliability is its conservative factory tuning. Subaru engineers calibrated this engine to operate well within the turbocharger’s capabilities, avoiding the excessive boost pressures and aggressive timing maps that can accelerate wear.

The boost levels are moderate, exhaust gas temperatures remain reasonable, and the engine management system includes multiple safeguards against conditions that could damage the turbo.

This conservative approach means the WRX might not make class-leading power figures in stock form, but it virtually guarantees that owners won’t face turbo failures under normal operating conditions.

The supporting systems surrounding the FA20DIT’s turbo also contribute to its reliability. The intercooler system effectively manages intake temperatures, preventing the heat soak that can stress turbos and reduce their lifespan.

The oil delivery system maintains consistent pressure and flow to the turbo’s bearings, even during hard cornering or acceleration. Regular oil changes with high-quality synthetic lubricants are crucial, and Subaru has made maintenance straightforward with accessible filter locations and clear service intervals.

Owners who follow the maintenance schedule report exceptional reliability, with many examples surpassing 150,000 miles on original turbos.

The enthusiast community’s experiences further validate the FA20DIT’s durability. While the aftermarket tuning scene is robust, even moderately modified WRXs with increased boost and power output have proven reliable when tuned properly.

This tolerance for modifications indicates the turbo was designed with safety margins that extend beyond stock requirements. Of course, extreme modifications can still cause failures, but the baseline robustness means that even with some performance enhancements, these turbos hold up remarkably well compared to other platforms where even minor modifications precipitate failures.

4. Volkswagen Golf GTI (Mk7/Mk7.5 with EA888 Gen 3 Engine)

The seventh-generation Volkswagen Golf GTI, powered by the EA888 Generation 3 turbocharged engine, represents a remarkable turnaround in reliability for a platform that previously struggled with turbo issues.

This 2.0-liter turbocharged four-cylinder engine has become a benchmark for hot hatch performance while demonstrating impressive durability that has surprised even skeptics familiar with Volkswagen’s checkered reliability history.

The EA888 Gen 3 addresses virtually all the weaknesses of its predecessors, resulting in a turbocharged engine that combines performance, efficiency, and longevity.

The turbocharger used in the Mk7 GTI benefits from extensive redesign compared to earlier generations. The bearing system was completely reengineered, using higher-quality materials and improved lubrication channels that ensure adequate oil flow under all operating conditions.

Previous generation EA888 engines suffered from turbo failures caused by oil coking where oil would carbonize in hot turbo passages and restrict flow but the Gen 3 addressed this with improved oil routing and a redesigned turbo that runs cooler.

The turbo housing features better heat dissipation properties, and the integration with the exhaust manifold was optimized to reduce thermal stress. Volkswagen’s engine management strategy for the Mk7 GTI prioritizes longevity without sacrificing the engaging performance that defines the GTI character.

The boost mapping is sophisticated, providing strong mid-range torque while avoiding the peak pressure spikes that accelerate turbo wear.

The overboost function allows temporary increases in boost for overtaking and spirited driving, but duration limits and temperature monitoring prevent prolonged operation at levels that could damage components.

These protective measures work transparently, meaning drivers enjoy responsive performance without realizing the system is constantly working to preserve the turbo’s lifespan.

The cooling infrastructure supporting the EA888 Gen 3 is particularly impressive. The intercooler system is efficient and well-sized, maintaining consistent intake temperatures even during sustained high-load driving.

The engine cooling system includes provisions specifically for managing turbo temperatures, with coolant flow paths designed to remove heat from critical areas.

Additionally, the engine features a post-shutdown coolant circulation system that continues cooling the turbo after the engine is turned off, preventing heat soak and the associated oil degradation that plagues some turbo systems.

Real-world data from owners and independent mechanics confirms the Mk7 GTI’s turbo reliability. Vehicles regularly exceed 100,000 miles without turbo-related issues, a stark contrast to earlier GTI generations where turbo failures were common before 80,000 miles.

The tuning community has embraced these vehicles, with many running stage 1 and stage 2 tunes on stock turbos without failures evidence of the unit’s robust construction.

When proper maintenance is observed, particularly regarding oil change intervals and quality, these turbos demonstrate exceptional longevity.

The few failures that do occur are typically associated with neglected maintenance or extreme modifications rather than inherent design flaws.

Also Read: 10 SUVs That Rarely Rust Even in Snow States

5. Mazda CX-9 (2016+ with Skyactiv-G 2.5T Engine)

Mazda’s approach to turbocharging emphasizes reliability and real-world usability over headline-grabbing power figures, and nowhere is this philosophy more evident than in the CX-9’s Skyactiv-G 2.5T engine.

This 2.5-liter turbocharged four-cylinder engine represents Mazda’s first significant foray into modern turbocharging for their mainstream vehicles, and the company’s conservative, methodical approach has resulted in one of the most reliable turbo engines in the family SUV segment.

Mazda’s reputation for building long-lasting naturally aspirated engines translates remarkably well to forced induction when executed with their characteristic engineering rigor.

The Skyactiv-G 2.5T’s turbocharger is notable for its relatively small size and modest boost levels, reflecting Mazda’s priority on low-end torque and efficiency over peak horsepower.

This conservative sizing means the turbo operates well within its capabilities under normal driving conditions, significantly reducing wear and extending lifespan.

The turbo features a robust bearing system with excellent oil supply characteristics, and the materials used throughout the unit prioritize durability over weight savings.

Mazda’s decision to avoid pushing boundaries in terms of specific output pays dividends in reliability the engine produces adequate power for the heavy CX-9 while ensuring the turbo isn’t constantly operating at its limits.

One unique aspect of the Skyactiv-G 2.5T is Mazda’s Dynamic Pressure Turbo technology, which optimizes exhaust pulse timing to improve turbo response at low engine speeds.

This technology allows the relatively small turbo to deliver strong low-end torque without requiring high boost pressures that would stress components.

Many CX-9s have exceeded 100,000 miles without any turbo-related issues, and the few problems reported typically involve peripheral components rather than actual turbo failures.

Mechanics and service departments report seeing very few turbo failures on these engines, a remarkable achievement for a first-generation turbocharged engine from a manufacturer without extensive recent turbo experience.

This reliability has extended Mazda’s reputation for building durable vehicles into the turbocharged era, proving that forced induction can be just as reliable as naturally aspirated engines when engineered properly and not pushed beyond reasonable limits.

4 Cars That Constantly Fail Turbos

These problematic vehicles suffer from turbocharged powertrains plagued by inadequate oil supply systems, insufficient cooling capacity, and aggressive tuning parameters that push components beyond their designed operating limits.

Their flawed engineering includes undersized oil feed lines that starve bearings during high-load conditions, marginal intercooler designs that allow excessive intake temperatures, and engine management calibrations that prioritize peak performance over component longevity.

The combination of cost-cutting measures in critical components, aggressive boost pressures that exceed safe margins, and inadequate thermal management creates turbocharged engines that reinforce negative perceptions about reliability while generating substantial warranty claims and diminished resale values that reflect their documented propensity for expensive forced induction failures requiring complete turbocharger replacement.

1. BMW N54 Engine (2006-2016 335i, 135i, and others)

The BMW N54 engine, while beloved by enthusiasts for its massive tuning potential and smooth twin-turbo power delivery, has earned an unfortunate reputation as one of the most problematic turbocharged engines in recent memory.

This 3.0-liter inline-six twin-turbo powerplant appeared in numerous BMW models from 2006 to 2016, including the popular 335i, 135i, and various other models.

Despite its impressive performance capabilities and the engineering prestige of BMW’s name, the N54 has plagued owners with persistent turbo failures that occur with alarming frequency, often well before 100,000 miles and sometimes even before warranty expiration.

The N54’s turbo problems stem from multiple design and manufacturing issues that create a perfect storm for premature failure. The turbos themselves utilize wastegates that are prone to failure, with the wastegate rattle becoming such a common issue that it’s almost expected among N54 owners.

These wastegates stick open or closed, causing boost control problems that can lead to overboost conditions or complete loss of turbo function.

The wastegate actuators are mechanically linked to vacuum-operated diaphragms that deteriorate over time, particularly when exposed to the extreme heat cycles experienced in the cramped BMW engine bay.

When these fail, the resulting boost irregularities can cause drivability issues and potentially damage other engine components. Beyond the wastegate problems, the N54’s turbos suffer from oil seal failures that allow oil to enter the intake system or exhaust system.

These seal failures are often attributed to heat management issues the turbos run extremely hot in BMW’s packaging, and the seals simply cannot withstand the prolonged high temperatures.

Oil consumption problems are common symptoms of failing turbo seals, with owners reporting needing to add oil between changes as the turbos progressively worsen.

BMW’s handling of the N54 turbo issues has been inconsistent, contributing to owner frustration. While the company extended warranties for some owners and replaced turbos under warranty for certain cases, many owners outside warranty periods were left to absorb the full cost of repairs.

Class-action lawsuits were filed regarding the turbo failures, though settlements provided limited relief for affected owners. The reputation damage from the N54’s reliability problems was significant enough that BMW completely redesigned the follow-up N55 engine to use a single twin-scroll turbo instead of twin turbos, partially to address the reliability concerns that had plagued the N54 platform and tarnished BMW’s reputation for engineering excellence.

2. Ford EcoBoost 3.5L V6 (2010-2016 Generations)

Ford’s EcoBoost brand promised efficiency without sacrificing power, but the early versions of the 3.5L V6 EcoBoost engine have delivered expensive turbo failures to countless F-150 truck owners.

This twin-turbocharged V6 appeared in 2010 as a revolutionary alternative to traditional V8 engines, offering comparable power with better fuel economy.

However, the first and second generations of this engine, spanning from 2010 to 2016, have developed a notorious reputation for turbo failures that occur with troubling regularity, often leaving owners stranded and facing repair bills that can exceed $5,000.

The most common failure mode in these EcoBoost turbos involves the turbine wheel disintegrating while the engine is running, sending metal fragments throughout the intake and exhaust systems.

This catastrophic failure often occurs suddenly and without warning, though some owners report hearing unusual whistling or whining sounds in the days or weeks before complete failure.

When the turbine wheel disintegrates, debris can enter the intake system and cause severe engine damage, turning what would be an expensive turbo replacement into a potentially engine-destroying event.

The root cause appears to be a combination of bearing failure and inadequate lubrication under certain operating conditions, particularly during the heat-soak periods after shutting down a hot engine.

Ford F-150 trucks with the 3.5L EcoBoost are often used for towing and hauling, which places enormous stress on the turbochargers.

However, this acknowledgment that improvements were necessary came too late for hundreds of thousands of earlier owners who had already experienced failures or lived with the anxiety of impending turbo problems.

The reliability issues significantly impacted the EcoBoost’s reputation, with many truck buyers specifically seeking older V8-powered F-150s to avoid the turbo problems altogether.

Class-action lawsuits were filed, and Ford faced criticism for not extending warranties or offering recalls despite the widespread nature of the failures, leaving many owners feeling abandoned after purchasing what they believed would be a reliable work truck.

3. Chevrolet Cruze 1.4L Turbo (2011-2015)

The Chevrolet Cruze was positioned as General Motors’ answer to fuel-efficient compact cars, with the 1.4L turbocharged engine offering a balance of economy and adequate power.

However, this small turbocharged four-cylinder engine has developed a troubling track record of premature turbo failures that have frustrated owners and damaged Chevrolet’s reputation in the compact car segment.

The problems are so widespread that they’ve become a defining characteristic of first-generation Cruze ownership, with many examples failing well before 100,000 miles and some experiencing issues even before reaching 60,000 miles.

The most prevalent issue with the Cruze’s turbocharger involves the PCV (Positive Crankcase Ventilation) system, which is integrated into the valve cover. When this system malfunctions a common occurrence on these engines it causes excessive crankcase pressure that forces oil into the turbocharger’s intake side.

This oil contamination damages the turbo’s compressor wheel and bearings, leading to progressively worsening performance and eventually complete failure. The PCV valve itself is not serviceable separately; the entire valve cover must be replaced at significant expense.

Many owners only discover the PCV issue after the turbo has already been damaged, necessitating both a valve cover replacement and a new turbocharger.

Oil consumption problems plague these engines and directly contribute to turbo failures. Many Cruze owners report excessive oil consumption, often requiring a quart or more between oil changes.

This consumption stems from multiple sources, including piston ring design issues and the aforementioned PCV problems, but the net effect is that the engine runs low on oil, starving the turbocharger of adequate lubrication.

Multiple owner forums and complaint boards contain thousands of posts from frustrated Cruze owners dealing with turbo problems, yet GM maintained that failures were within normal expectations.

This stance has damaged customer loyalty, with many former Cruze owners vowing never to purchase another GM product. The reliability problems have also devastated the Cruze’s resale value, with used car buyers actively avoiding examples with the 1.4L turbo engine, particularly those approaching or exceeding 80,000 miles where failures become increasingly common.

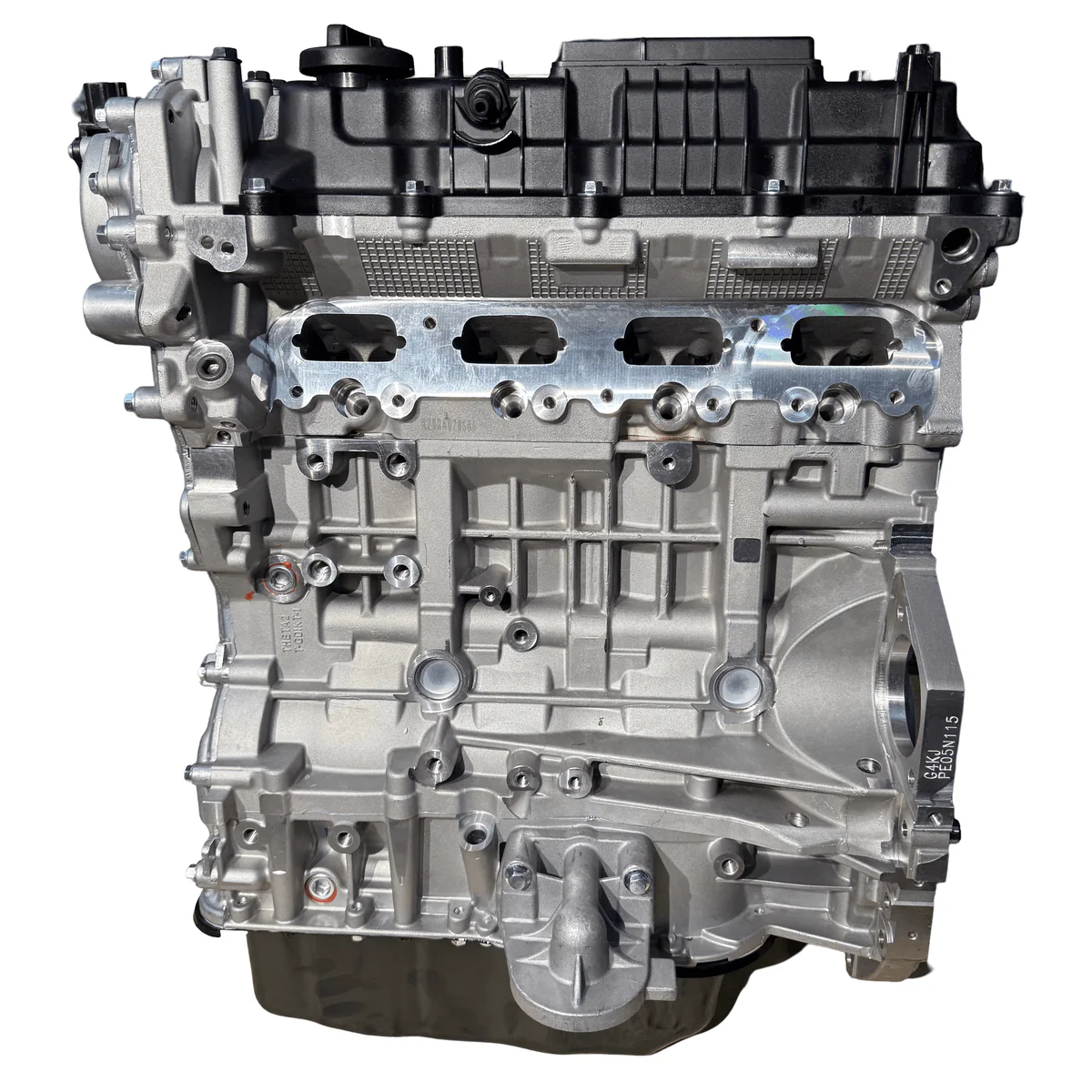

4. Hyundai/Kia Theta II 2.0L Turbo Engine

The Hyundai and Kia Theta II 2.0-liter turbocharged engine, found in popular models like the Hyundai Sonata, Santa Fe Sport, and Kia Optima, has become synonymous with reliability problems that extend well beyond just turbo failures.

However, the turbocharger issues in these engines deserve special attention due to their frequency and the catastrophic nature of the failures.

These engines, produced from approximately 2011 through 2019, have generated thousands of complaints, multiple recalls, and class-action lawsuits, with turbo failures being among the most common and expensive problems owners face.

The Theta II turbo failures often stem from the engine’s broader problems with metal debris contamination and inadequate lubrication. These engines have well-documented issues with bearing wear that generates metal particles in the oil system.

These particles circulate through the engine and eventually reach the turbocharger, where they act as abrasives in the precision bearings. The turbo bearings, which require clean oil for survival, rapidly deteriorate when contaminated with metal particles.

This creates a cascading failure scenario where engine problems cause turbo damage, and turbo damage can further contaminate the oil system, potentially destroying other engine components in a domino effect.

Another significant contributor to turbo failures in these engines involves the oil delivery system design. The turbos require consistent oil pressure and flow for cooling and lubrication, but the Theta II engines have experienced issues with inadequate oil pressure under certain conditions.

Some failures are attributed to the engine’s direct injection system, which creates additional carbon buildup that can restrict oil passages and affect turbo lubrication.

The combination of potential oil pressure issues, contamination from bearing wear, and carbon-related restrictions creates multiple pathways to turbo failure, making these engines particularly vulnerable to turbo problems across various driving conditions and mileage ranges.

The symptoms of Theta II turbo failure include metal grinding or rattling sounds from the turbo area, excessive blue or white smoke from the exhaust, dramatic loss of power, and illuminated check engine lights with boost-related codes.

In many cases, owners report that the turbo failure is accompanied by or preceded by other engine issues, particularly unusual noises suggesting internal engine damage.

This correlation has led many mechanics to recommend replacing not just the turbo but conducting thorough engine inspections, as turbo failure often indicates broader engine problems.

The National Highway Traffic Safety Administration (NHTSA) has investigated these engines multiple times, and both manufacturers have faced lawsuits alleging they knew about the problems but failed to adequately address them.

For owners of turbocharged Theta II engines, the experience has often meant expensive repairs, significant depreciation of their vehicles’ values, and a complete loss of trust in the Hyundai and Kia brands.

5. Mini Cooper S (R56 Generation, 2007-2013)

The second-generation Mini Cooper S, known as the R56, represents one of the most disappointing reliability stories in modern automotive history, with turbo failures being among its many well-documented problems.

This generation Mini, produced from 2007 to 2013, was supposed to bring BMW engineering excellence to the small car segment following BMW’s acquisition of the Mini brand.

Instead, the turbocharged 1.6-liter engine developed in partnership with PSA Peugeot Citroën has proven to be spectacularly unreliable, with turbo failures occurring with such regularity that they’re considered nearly inevitable by knowledgeable Mini mechanics and long-term owners.

The R56 Mini Cooper S turbo problems manifest in several ways, with the most common being wastegate failure and turbo seal deterioration.

The wastegate mechanism, which controls boost pressure, is prone to rattling and sticking, symptoms that often appear before 60,000 miles on many examples.

When the wastegate fails, the turbo cannot properly regulate boost pressure, leading to either overboost conditions that can damage the engine or underboost situations that rob the car of performance.

The turbo seals also fail prematurely, allowing oil to leak into the intake or exhaust systems. Oil consumption becomes excessive, and characteristic blue smoke appears from the exhaust, particularly during deceleration or startup after the car has been sitting.

The root causes of R56 turbo failures are multifaceted but center on thermal management issues and questionable design choices. The turbo sits in an extremely cramped engine bay with limited cooling airflow, subjecting it to heat cycles that exceed the design capabilities of the seals and bearing components.

The engine also runs notoriously hot, with cooling system problems being another common R56 weakness that exacerbates turbo stress.

Additionally, the timing chain system in these engines has failure-prone tensioners that can allow excessive chain slack, creating engine vibrations that transmit through to the turbo and accelerate bearing wear.

The combination of heat, vibration, and stressed components creates an environment where turbo longevity is severely compromised.

The financial burden of R56 Mini Cooper S ownership due to turbo problems is substantial relative to the vehicle’s value. These cars have depreciated dramatically, partially due to their terrible reliability reputation, yet repair costs remain high due to the labor-intensive nature of turbo replacement in the cramped engine bay.

BMW and Mini’s response was to completely redesign the engine for the next generation, abandoning the PSA partnership in favor of a BMW-designed engine, but this acknowledgment that the R56 engine was fundamentally flawed came too late for the hundreds of thousands of owners who had already purchased these cars.

Many former Mini owners cite the R56 experience as the reason they’ll never buy another Mini or BMW product, representing a significant brand loyalty loss stemming from the turbo and related reliability failures.

Also Read: 12 Vehicles That Rarely Need a Jump Start