When most engines groan at the thought of six figures on the odometer, a rare few seem to laugh in the face of high mileage. These are the mechanical marvels that keep running decade after decade, proving that true engineering excellence never fades with time.

From overbuilt cast-iron legends of the past to precision-tuned modern powerplants, these engines have earned cult status for their ability to endure neglect, heat, abuse, and countless miles while still performing smoothly.

They represent the peak of durability, reliability, and thoughtful design, engines so well-made that even after hundreds of thousands of miles, they refuse to quit. In this list of “10 Engines That Laugh at High Mileage,” we celebrate those timeless powerplants that turned durability into an art form, inspiring confidence in every turn of the key and setting benchmarks for mechanical longevity that few others have matched.

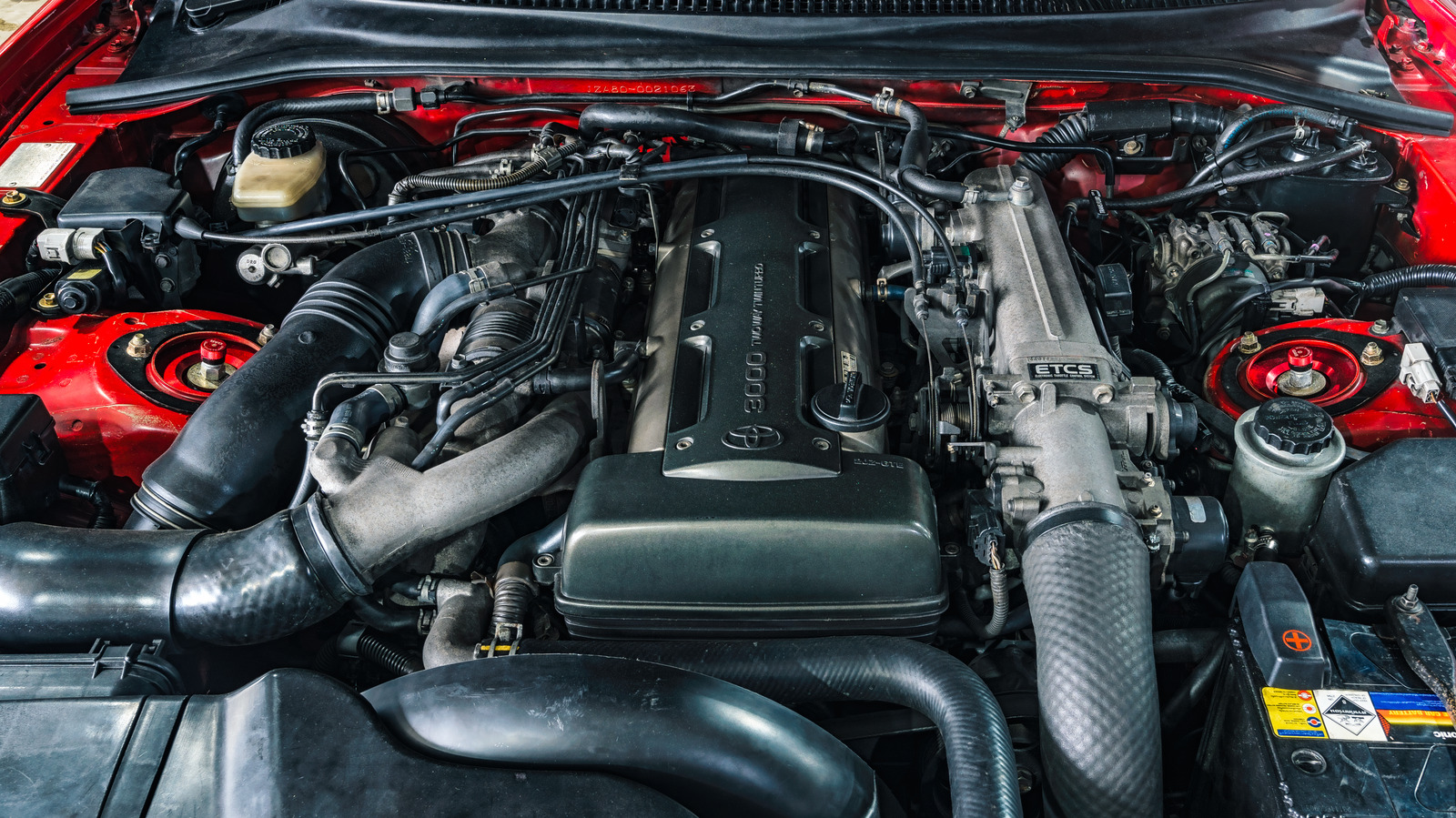

1. Toyota 2JZ-GE/GTE Engine

The Toyota 2JZ-GE and 2JZ-GTE engines, particularly the turbocharged GTE variant from the MK4 Supra, have achieved near-mythical status among enthusiasts. Produced between 1991 and 2007, the 3.0-litre inline-six became famous not only for its immense tuning potential but also for its legendary durability, a testament to Toyota’s over-engineering philosophy of the 1990s.

At its core, the 2JZ features a cast-iron block that delivers exceptional rigidity and strength. The 2JZ-GTE, equipped with forged internals and sequential twin turbos, was built to withstand extreme stress while maintaining smooth power delivery.

The engine’s forged steel crankshaft, robust bottom end, and seven main bearing caps provide a solid foundation capable of handling enormous horsepower figures often exceeding 1,000 bhp with upgraded components.

The 2JZ’s efficient oiling system, combined with under-piston oil squirters, ensures continuous cooling and lubrication during high-load conditions. Meanwhile, dual knock sensors safeguard the engine from detonation by adjusting ignition timing automatically, protecting vital components during spirited driving or high boost levels.

The 2JZ’s reputation for longevity stems from its strong internal design and consistent performance under varied conditions. Many engines have surpassed 200,000–300,000 miles with only regular oil and coolant maintenance.

Its design minimizes mechanical weaknesses, with most issues arising only from age. Over time, seals and gaskets may harden and leak, while components such as the timing belt tensioner bracket or crank pulley can wear out, but these are expected over decades of use rather than design flaws.

To maintain peak reliability, frequent oil changes using high-quality lubricants are crucial. Proper coolant management prevents overheating and corrosion, while using OEM replacement parts ensures compatibility and long-term stability. With these basic practices, the 2JZ remains nearly indestructible.

The Toyota 2JZ-GE/GTE represents the perfect blend of engineering strength, reliability, and performance potential. Its unmatched resilience and capacity for power have made it a cornerstone of both motorsport and tuning culture, symbolizing an era when engines were built to last and to be pushed far beyond their factory limits.

2. Mercedes-Benz OM617 Diesel Engine

The Mercedes-Benz OM617 is widely regarded as one of the most durable and dependable diesel engines ever built. Produced from 1974 to 1991, these 3.0-litre inline-five turbodiesel-powered vehicles, like the W123 and W126 models, are often praised as the most reliable cars ever made. Its combination of overbuilt engineering, mechanical simplicity, and unmatched longevity has made it a benchmark for diesel durability worldwide.

The OM617’s strength begins with its cast-iron block and head, materials chosen for their exceptional heat tolerance and wear resistance. Its fully mechanical fuel injection system eliminates complex electronics, ensuring simple operation and easy maintenance even in remote or harsh conditions.

The engine’s modest power output keeps internal stresses low, allowing many examples to exceed 500,000 miles, with some surpassing one million miles, a true testament to Mercedes’ 1970s engineering philosophy, which prioritized longevity over performance.

Several key factors contribute to the OM617’s legendary reliability. Its robust construction and hand-assembled components reflect Mercedes’ meticulous attention to detail during its “golden era” of craftsmanship.

The mechanical simplicity means fewer points of failure, and the engine’s excellent oil cooling system helps control temperature under heavy load. Furthermore, it’s notably tolerant of poor-quality diesel, making it popular in regions like Africa and the Middle East, where reliability under tough conditions is essential.

Despite its durability, the OM617 requires regular care to maintain its lifespan. Neglected oil changes and air intake leaks can cause premature piston ring wear, while a loose pulley bolt on turbo models can lead to mechanical imbalance.

To prevent these issues, owners should perform oil and filter changes every 5,000 miles, adjust valves periodically, and ensure correct torque on the pulley bolt. Routine cleaning of the engine bay also helps spot leaks early.

Decades after production ended, the OM617 remains a symbol of mechanical excellence. It’s a favourite among enthusiasts for off-road use, biodiesel conversions, and restoration projects, thanks to its reliability and abundant parts support from Mercedes’ classic division.

Today, well-preserved OM617-powered cars command high resale values, proof of the engine’s enduring appeal and its place as one of the most respected diesel engines in automotive history.

3. Toyota 22R / 22R-E Engine

The Toyota 22R and 22R-E engines have earned legendary status for their unmatched reliability and longevity. Produced from 1981 to 1997, these 2.4-litre inline-four powerplants were the heart of vehicles like the Hilux, 4Runner, and Celica, earning a reputation as “the engine that won’t die.” Their combination of simplicity, strength, and ease of maintenance made them a favorite among off-roaders, farmers, and DIY mechanics alike.

Toyota designed the 22R/22R-E with durability and simplicity at the forefront. The engine features a cast-iron block for exceptional strength paired with an aluminum head for weight savings and efficient heat dissipation. Its chain-driven timing system eliminates the need for frequent timing belt replacements, further reducing maintenance costs.

Operating at relatively low power output, the 22R’s internal components endure less stress, allowing the engine to routinely achieve 300,000–400,000 miles, with many surpassing 500,000 miles when properly maintained.

The 22R series embodies Toyota’s philosophy of overbuilt simplicity. Its robust cast-iron construction and durable timing chain contribute to its long service life, while the understressed operation minimizes wear and the risk of major failures.

The mechanical layout is straightforward, making repairs and maintenance simple even in remote locations. Parts availability remains high worldwide, ensuring that owners can easily keep these engines running for decades.

The 22R uses a carburetor, offering mechanical simplicity and easy tuning, while the 22R-E features fuel injection, improving fuel efficiency and throttle response. Despite this added sophistication, both variants share the same core reliability traits that define the series.

Longevity depends on regular oil changes, cooling system care, and proactive timing chain guide replacement, the latter being one of the few weak points, as the original plastic guides can wear or break over time. Keeping these components serviced ensures trouble-free operation.

The Toyota 22R/22R-E remains a symbol of indestructible engineering, a simple, dependable workhorse that continues to power vehicles worldwide decades after production ended. With its ease of maintenance, global parts support, and legendary durability, the 22R stands as one of the greatest four-cylinder engines ever built.

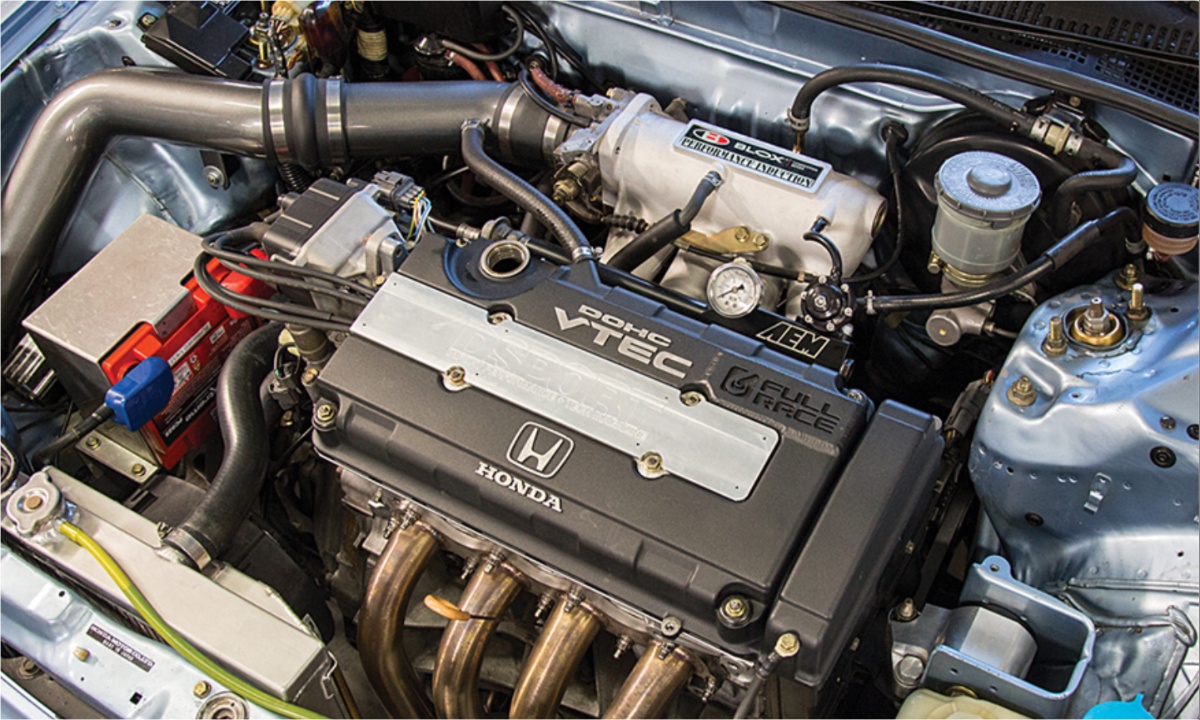

4. Honda B-Series VTEC Engines

The Honda B-Series engines, including the renowned B16A and B18C, are widely regarded as masterpieces of engineering that combine high-revving performance with unwavering reliability.

Produced from the late 1980s to the early 2000s, these engines powered performance icons such as the Honda Civic SiR, Integra GS-R, and Integra Type R. The B-Series represented the golden age of Honda engineering when efficiency, performance, and longevity were given equal priority.

At the heart of the B-Series’ success is its ability to rev high while lasting long. Designed with forged internal components, tight tolerances, and superior oil control, these engines thrive even under extreme RPM conditions, many revving beyond 8,000 RPM. Despite their performance orientation, they routinely exceed 200,000 to 300,000 miles with only regular maintenance.

The introduction of VTEC (Variable Valve Timing and Lift Electronic Control) technology was revolutionary. It allows the engine to use two camshaft profiles, one for fuel-efficient low-RPM driving and another for aggressive high-RPM performance. This dual nature made the B-Series both practical and exhilarating, setting new standards for small-displacement performance engines.

The B-Series’ lightweight aluminum block, reinforced internals, and efficient cooling system contribute to both strength and efficiency. Its excellent oiling system ensures stable lubrication during sustained high-speed operation, preventing wear even in track or racing conditions. Honda’s focus on precision manufacturing and balance further enhanced the engine’s smoothness and reliability, hallmarks of the brand’s meticulous craftsmanship.

While inherently durable, the B-Series demands consistent maintenance to maintain peak performance. High-quality oil, timely valve adjustments, and coolant upkeep are vital. Owners who adhere to maintenance schedules often see their engines surpass 300,000 miles without internal rebuilds. The design’s simplicity also allows for straightforward servicing, appealing to enthusiasts and DIY tuners alike.

Even decades later, the B-Series remains one of Honda’s most respected engine families. Its blend of VTEC sophistication, high-revving excitement, and bulletproof dependability continues to influence engine design and inspire tuners around the world.

Whether on the street or racetrack, the Honda B-Series proves that engineering precision and reliability can coexist with thrilling performance, a timeless formula that helped cement Honda’s reputation for excellence.

5. BMW N52 Inline-6 Engine

The BMW N52 is recognized as the last naturally aspirated inline-six engine developed by the company, representing a high point in BMW’s mechanical refinement before the introduction of turbocharging. Produced from 2004 to 2015, it powered models such as the 3 Series (E90), Z4, and 5 Series.

Known for its smooth performance, balanced operation, and lasting reliability, the N52 remains one of BMW’s most respected engines among enthusiasts and mechanics alike.

The N52 showcased several innovations that set it apart from earlier BMW engines. It featured a magnesium and aluminum composite block, which reduced weight while maintaining excellent strength and heat resistance.

This lightweight construction contributed to improved fuel efficiency and vehicle balance. The introduction of Valvetronic, BMW’s variable valve lift system, allowed the engine to breathe more efficiently and respond more quickly to throttle input, improving both performance and efficiency.

The engine’s naturally aspirated design gave it a linear and predictable power delivery that complemented the signature smoothness of BMW’s inline-six layout. With proper servicing and quality oil, the N52 is capable of lasting 200,000 miles or more, making it one of the most dependable engines BMW has ever built.

Although highly regarded, the N52 has several common issues that owners should address through preventive maintenance. The electronic water pump can fail due to electronic or impeller wear, making regular replacement essential.

Oil leaks from the valve cover gasket, oil filter housing gasket, and oil pan gasket are frequent as the seals age. VANOS solenoids may become clogged, affecting variable valve timing and triggering warning lights. Some early models experienced hydraulic lifter noise, which was later improved in newer versions. The DISA valve can also fail, causing intake leaks that affect performance.

To keep the N52 reliable, oil and filter changes every 5,000 miles are recommended. When replacing the water pump, it is wise to replace the thermostat at the same time since both are part of the cooling system. Regular inspection for oil leaks and cleaning of VANOS components can prevent more serious problems. With consistent maintenance, the N52 can provide many years of dependable service.

The N52 holds a special place in BMW’s history as a symbol of balance between engineering tradition and modern innovation. Its lightweight design, smooth operation, and durable construction have made it a favorite among BMW enthusiasts.

Even years after its production ended, the N52 continues to be praised for its refined character, longevity, and mechanical simplicity, securing its legacy as one of BMW’s finest inline-six engines.

Also Read: 10 Cars With Interiors That Still Look New After 20 Years

6. Lexus/Toyota 1UZ-FE V8 Engine

When Lexus launched the LS400 in 1989, it needed a powerplant that could rival the smoothness and longevity of the best European luxury engines. The result was the Toyota 1UZ-FE, a 4.0-litre, all-aluminium V8 that redefined expectations for refinement and durability.

Designed from the ground up, the 1UZ-FE combined precision craftsmanship, robust construction, and quiet operation, setting a new benchmark for reliability in the luxury segment.

At the heart of the 1UZ-FE’s reputation is its overbuilt design. The engine features six-bolt main bearings, forged connecting rods, and dual overhead camshafts. This configuration ensured exceptional strength and stability at high revs while maintaining a silky smooth idle.

The use of aluminium for both the block and heads kept weight down without sacrificing rigidity, contributing to a balanced chassis and efficient performance.

Power delivery is linear and refined, producing around 250 horsepower in early versions, yet the engine operates with remarkable quietness. Its conservative tuning and low internal stress allow it to run for hundreds of thousands of miles, often without ever being opened for major repairs.

The 1UZ-FE earned its legendary reputation through consistent performance under demanding conditions. Many examples have exceeded 300,000 miles with little more than routine servicing.

The engine’s advanced cooling system prevents overheating, while its forged internals handle both high mileage and modification with ease. Even after decades, the 1UZ-FE remains a favourite among mechanics and enthusiasts for its toughness and resistance to wear.

Because of its strength and reliability, the engine has also become popular for performance swaps in drift cars, off-road vehicles, and custom builds. Its smooth power delivery and robust construction make it adaptable far beyond its original luxury purpose.

While the 1UZ-FE is known for being nearly indestructible, it does require periodic attention to maintain its longevity. The timing belt must be replaced every 60,000 miles to prevent serious internal damage.

Coolant leaks and air intake sealing should be checked regularly, as overheating or water ingestion can lead to failure. Routine oil and filter changes, along with proper cooling system maintenance, are key to ensuring decades of reliable service.

Today, the 1UZ-FE remains one of the most respected V8 engines ever built. Its balance of luxury, performance, and reliability perfectly represents Toyota’s engineering philosophy of the late 20th century. Whether in its original LS400 form or repurposed in a high-performance build, the 1UZ-FE continues to prove that exceptional design and careful engineering can produce an engine capable of lasting a lifetime.

7. Volvo Redblock Engines

The Volvo Redblock engines, named after their distinctive red-painted blocks, are among the most durable and respected powerplants ever produced by the Swedish automaker. Built from the 1970s through the 1990s, these inline-four and inline-five engines powered models like the 240, 740, and 940 series, and became synonymous with Volvo’s reputation for dependability and ruggedness.

The Redblock family was engineered for endurance and simplicity. Each engine featured a cast-iron block and forged internal components, giving it remarkable strength and resistance to wear.

The design was intentionally conservative, with low compression ratios and modest power output, helping reduce internal stress on moving parts. Volvo’s engineers prioritized reliability over performance, ensuring that these engines could handle harsh climates, poor fuel quality, and long service intervals with ease.

The simplicity of the Redblock’s mechanical fuel injection and ignition systems made them easy to maintain, especially in regions where advanced diagnostic tools were scarce. Many owners still service these engines with basic tools and minimal technical knowledge.

Redblock engines are well known for surpassing 300,000 miles with the original internals still intact. Their non-interference design means that if the timing belt breaks, the valves and pistons never make contact, preventing major engine damage. This design feature alone has saved countless engines from early failure.

Volvo also designed these engines to cope with extreme cold, ensuring reliable starts in sub-zero temperatures, a necessity for Scandinavian winters. Their heavy-duty oil pumps and oversized bearings further contributed to exceptional longevity, even under demanding conditions.

Although the naturally aspirated versions were modestly powered, the turbocharged Redblock variants (such as the B230FT) earned cult status among enthusiasts. Thanks to their strong bottom-end design, these engines can handle significant boost increases without failure. Many performance builders have extracted double the stock horsepower from Redblocks without compromising reliability, proving their versatility and strength.

Keeping a Redblock running smoothly is straightforward. Regular oil and filter changes, typically every 5,000 miles, along with timing belt inspections and coolant system checks, are all that’s needed to ensure continued dependability. The parts are inexpensive and widely available, making maintenance affordable even decades after production ended.

Today, the Volvo Redblock remains a symbol of Scandinavian engineering discipline and functional design philosophy. It embodies durability, ease of repair, and understated capability.

Whether in daily-driven Volvos or modified performance builds, the Redblock engine continues to represent everything that made Volvo a byword for reliability. Its cult following endures, proving that sometimes the simplest engineering solutions are the most timeless.

8. Nissan VQ V6 Engine

The Nissan VQ V6 engine family, first introduced in 1994, is regarded as one of the most accomplished and reliable engine series in modern automotive history. It has powered a wide range of Nissan and Infiniti vehicles, from the performance-oriented 350Z and Infiniti G35 to practical models like the Maxima and Pathfinder.

This versatility, combined with its smooth and responsive character, helped establish the VQ as a cornerstone of Nissan’s engineering excellence for more than two decades.

Constructed with aluminium blocks and cylinder heads, the VQ engine employs dual overhead camshafts and variable valve timing to balance lightweight efficiency with strong, flexible performance.

Its timing chain system, rather than a belt, significantly reduces long-term maintenance requirements and provides dependable operation over high mileage. The engine is celebrated for its refined power delivery and smoothness across the rev range, attributes that contributed to its repeated inclusion in Ward’s 10 Best Engines list.

In terms of durability, the VQ series has consistently proven capable of surpassing 200,000 miles when properly maintained. Earlier naturally aspirated versions, such as the VQ30DE and VQ35DE, are especially known for their ability to handle demanding use without major failures.

Their robust internal components and effective cooling systems allow them to perform reliably in both high-performance and everyday driving conditions. Regular oil changes and attention to the cooling system are key factors in maintaining this longevity.

Despite its impressive reliability, the VQ is not immune to a few known issues. Some engines experience oil leaks from valve cover gaskets or increased oil consumption at higher mileage.

Timing chain phaser noise may occur if oil changes are neglected, and early VQ37 models were known for oil galley gasket failures that could affect oil pressure. Another recurring issue is the clogging of catalytic converters, often linked to excessive oil burning. These concerns, however, are well-documented and relatively easy to prevent or repair with attentive maintenance.

The best way to preserve the health of a VQ engine is through diligent upkeep. Using high-quality oil, monitoring for leaks, keeping the cooling system in optimal condition, and promptly addressing any unusual noises or performance changes can ensure continued reliability.

The Nissan VQ V6 remains a defining example of balanced engineering, powerful yet refined, advanced yet durable. Its smooth operation, wide application across models, and proven longevity have earned it enduring respect among both enthusiasts and everyday drivers, making it one of the standout engines in Nissan’s history.

9. Ford Windsor V8 Engine

The Ford Windsor V8 is one of the most iconic and enduring engines in American automotive history. Produced from 1962 to 2001, it became a cornerstone of Ford’s lineup and powered a wide variety of vehicles, including the Mustang, Falcon, F-Series trucks, and numerous vans.

Ranging in displacement from 221 to 351 cubic inches, the Windsor represented a balance of strength, simplicity, and accessibility that made it a favorite among enthusiasts, mechanics, and manufacturers alike.

The Windsor’s design philosophy was centered on reliability and serviceability. Its cast-iron block and pushrod valvetrain kept the mechanical layout simple, minimizing the number of moving parts and potential failure points. This straightforward engineering made the engine easy to maintain and repair, even with basic tools.

The sturdy bottom-end design provided a solid foundation for both everyday use and high-performance applications, allowing the Windsor to withstand decades of service in vehicles of all kinds. Many of these engines continue to run smoothly after more than 200,000 miles, particularly in trucks and vans that were driven conservatively and regularly maintained.

One of Windsor’s defining traits is its versatility. Its basic architecture was shared across numerous configurations and performance levels, from reliable family sedans to high-output muscle cars.

This adaptability, combined with an enormous aftermarket, has made it one of the most widely supported engines in history. Replacement parts, upgrade kits, and complete rebuild components are readily available, ensuring that even decades-old examples can be easily revived.

Despite its legendary durability, the Windsor does have some weaknesses. Oil leaks from valve cover gaskets, rear main seals, and oil pans are common as engines age. Early versions with points-style ignition systems can be less dependable than later electronic ignition setups, though this can be easily remedied through modern upgrades.

High-performance builds, while capable of tremendous power, are more susceptible to overheating, head gasket failures, and bearing wear if pushed too far without reinforcing the cooling and lubrication systems.

Owners often extend the engine’s lifespan by making sensible upgrades such as switching to electronic ignition, installing an aluminium radiator with a high-flow water pump, and replacing the timing chain with a heavy-duty double roller chain during rebuilds. These modifications enhance dependability without compromising Windsor’s authentic character.

The Ford Windsor V8’s lasting appeal lies in its rugged simplicity and mechanical honesty. It represents an era when engines were built to last, not just to perform. Its combination of strength, reliability, and adaptability has secured its place as a legend among both classic car enthusiasts and everyday drivers who value engines that are easy to maintain and hard to kill.

10. Mazda Skyactiv-G Engine

Mazda’s Skyactiv-G engine represents a modern success story in balancing innovation, efficiency, and long-term dependability. First introduced in 2011, this naturally aspirated petrol engine redefined what could be achieved without resorting to turbocharging or hybrid assistance.

It was designed to deliver excellent fuel economy and low emissions while preserving the responsive, engaging character that defines Mazda’s vehicles. Over a decade later, the Skyactiv-G has proven itself as one of the most reliable contemporary engines on the market.

At the heart of the Skyactiv-G’s design is its exceptionally high compression ratio, reaching up to 14:1 in some markets. Achieving this without requiring premium fuel was a significant engineering accomplishment.

Mazda accomplished it through a combination of advanced technologies, including a long 4-2-1 exhaust manifold, specially contoured pistons, and precision multi-hole fuel injectors. Together, these innovations promote efficient, even combustion, improving both performance and fuel economy while reducing engine knock.

Despite its advanced design, the Skyactiv-G remains refreshingly simple and robust. It avoids the complexity and potential reliability issues associated with turbocharged engines, relying instead on naturally aspirated efficiency.

A chain-driven timing system replaces the traditional belt, reducing maintenance needs and ensuring long-term mechanical stability. The engine’s forged steel crankshaft and connecting rods provide additional strength, while its robust construction reflects Mazda’s dedication to durability.

In real-world use, Skyactiv-G engines have shown remarkable longevity. Many owners report exceeding 150,000 to 200,000 miles with minimal issues when regular maintenance schedules are followed.

Key to their durability is consistent oil and filter replacement, along with the use of high-quality fuel to keep the combustion system clean. Mazda’s continuous refinement of the Skyactiv-G design since its introduction has further enhanced reliability and efficiency across newer models.

While generally trouble-free, a few issues have been noted over time. Some versions have experienced mass airflow sensor contamination, leading to irregular idling or reduced performance. A small number of 2.5-liter non-turbo models developed timing cover oil leaks, though these are typically minor and often covered by warranty.

The turbocharged variants of the Skyactiv-G family, used in certain high-performance models, have occasionally suffered cracked cylinder heads, but this remains an uncommon issue and does not affect the core naturally aspirated designs.

The Skyactiv-G engine exemplifies Mazda’s engineering philosophy: simplicity executed with precision. It demonstrates that cutting-edge efficiency and environmental responsibility can coexist with longevity and driver enjoyment.

As increasing numbers of high-mileage examples continue to perform reliably, the Skyactiv-G has earned its place among modern engines celebrated not just for performance or innovation, but for lasting dependability and thoughtful design.

From Toyota’s indestructible 2JZ to Mazda’s modern Skyactiv-G, each of these engines proves one enduring truth: great engineering stands the test of time. Whether created during the precision-focused era of the past or designed with today’s advanced technology, these powerplants combine strength, simplicity, and intelligent design.

They have powered family cars, sports icons, dependable workhorses, and refined luxury models, yet they all share one defining trait: a remarkable resistance to age and wear. For enthusiasts and everyday drivers alike, they remind us that reliability is not a coincidence.

It is achieved through care, precision, and real-world testing. In an automotive world where short lifespans have become common, these engines remain true mechanical legends, continuing to run strong mile after mile, long after others have faded away. These are the 10 Engines That Laugh at High Mileage.

Also Read: 5 Cars With Bulletproof Cooling Systems vs 5 That Overheat Often