Few engine layouts achieve the balance and harmony of an inline-6. Known for their natural smoothness and even power delivery, these engines have powered everything from luxury sedans to sports cars for decades.

The configuration’s perfect internal geometry gives it an effortless feel that drivers immediately recognize. Yet, not all inline-6 engines have stood the test of time equally well.

Some remain mechanical masterpieces that run with silky precision even after hundreds of thousands of miles, while others struggle with reliability, cost, and durability issues once age sets in.

This article compares two sides of that legacy five inline-6 engines that remain paragons of refinement and endurance, and five that tarnished the layout’s reputation. The differences are shaped by engineering priorities, materials, and the real-world results of design choices.

I’m writing this because the inline-6 is returning to modern cars after years of decline, and understanding which versions have proven their worth helps enthusiasts and buyers alike recognize true craftsmanship.

These engines represent the best and worst examples of how balance can either be maintained through time-tested design or lost through poor execution. Longevity and smoothness may sound simple but only a few engines truly achieve both.

Also Read: 12 Engines That Defy All Longevity Expectations

5 Inline-6 Engines That Stay Smooth Forever

The best inline-6 engines do more than sound and feel refined they maintain that quality through years of use.

When properly designed, this configuration offers minimal vibration and balanced internal motion, which naturally extends engine life. The secret lies not only in mechanical geometry but also in materials, cooling, and maintenance accessibility.

I’m writing about these five engines because they represent the peak of precision and durability. They’ve earned reputations for running smoothly well past 200,000 miles, often requiring nothing more than routine upkeep.

Each was built during a time when engineers prioritized internal harmony and mechanical simplicity over excessive complexity.

From German luxury icons to Japanese straight-six workhorses, these engines demonstrate how balance and restraint create longevity. They remain benchmarks against which modern designs are judged. Their durability isn’t theoretical it’s proven by decades of service in both daily driving and performance applications.

Each entry here celebrates a legacy of mechanical integrity and craftsmanship that continues to influence modern engineering. These inline-6 engines don’t just stay smooth; they remind us that simplicity, when executed correctly, becomes the most sophisticated form of reliability.

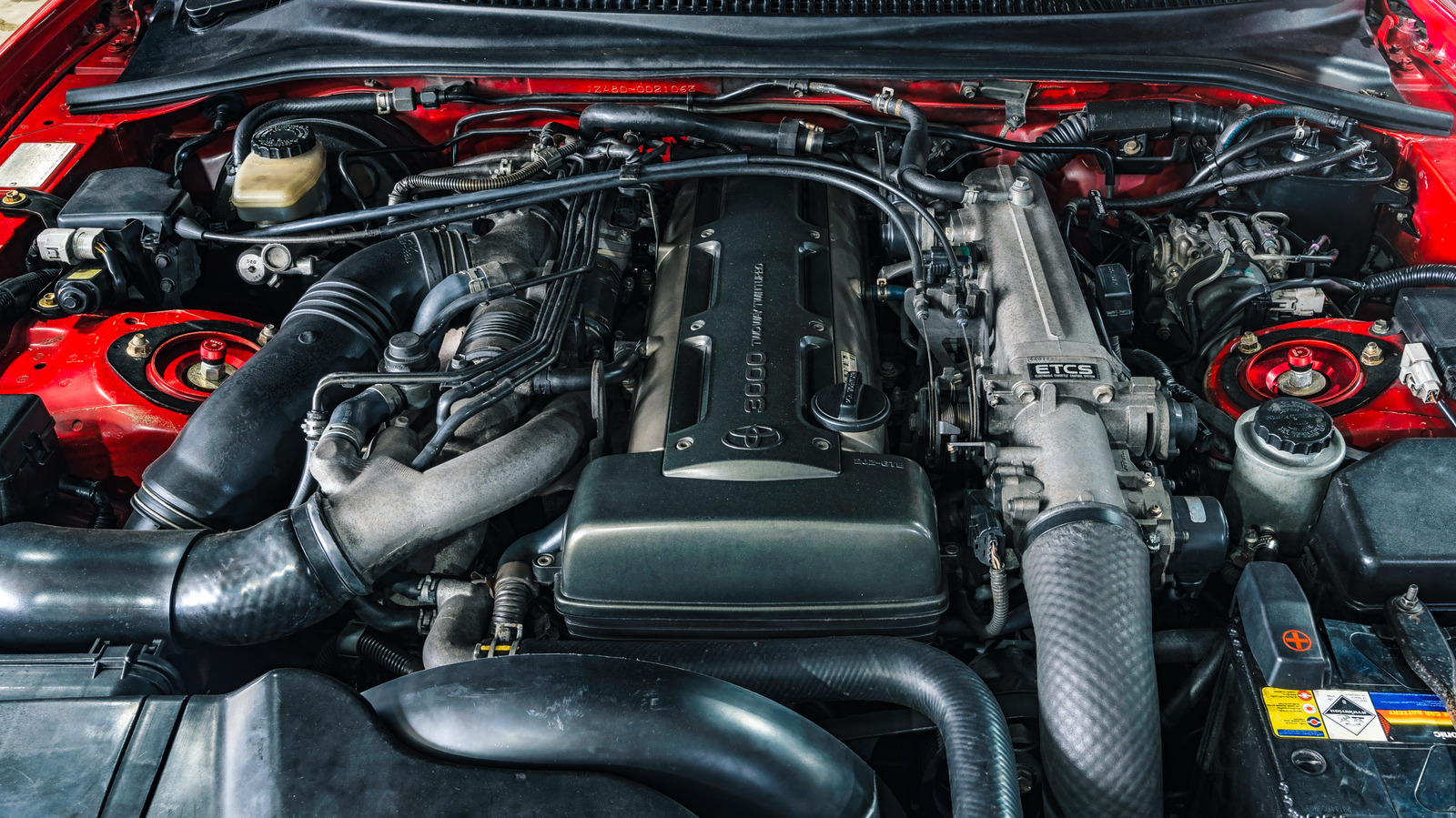

1. Toyota 2JZ-GE / 2JZ-GTE

The Toyota 2JZ series remains one of the most respected inline-6 designs ever built. Found in cars like the Toyota Supra and Lexus GS300, this engine gained legendary status for its combination of strength, smoothness, and reliability.

Its cast-iron block, paired with an aluminum head, gives it the perfect balance between rigidity and thermal control. Even after decades, many 2JZ engines run quietly and consistently, often outlasting the cars themselves.

I’m writing about the 2JZ because it represents mechanical engineering at its purest. Toyota built it during a time when overengineering was a point of pride.

The internals, such as the forged crankshaft and robust pistons, were designed to handle immense stress. Even in turbocharged form, the engine remains remarkably stable, capable of extreme power outputs without sacrificing refinement.

The 2JZ’s smoothness comes from precision machining and near-perfect internal balance. It idles cleanly, revs effortlessly, and rarely suffers from the vibration issues that affect lesser engines. Maintenance is straightforward, and parts availability ensures long-term serviceability.

Owners around the world continue to trust the 2JZ for both street and track use, and its resilience has become a benchmark across the automotive community. This engine isn’t just famous for performance it’s respected for lasting smoothness under every condition imaginable.

2. BMW M54

The BMW M54, produced from 2000 to 2006, powered models such as the 330i, 530i, and Z4. It remains one of the finest naturally aspirated engines BMW ever made, praised for its velvety character and enduring reliability.

The straight-six layout, combined with double VANOS variable valve timing, gave it both flexibility and refinement rarely matched in its class.

I’m writing about the M54 because it perfectly demonstrates how precision engineering can produce long-term smoothness. Unlike later BMW engines burdened by complexity, the M54 strikes a balance between sophistication and simplicity.

Its aluminum block with iron liners and a well-balanced rotating assembly allow it to run quietly even past 250,000 miles when maintained properly.

Owners often describe the M54 as “butter-smooth,” and for good reason. It delivers consistent torque, minimal vibration, and a clean powerband that makes every drive enjoyable.

The engine’s cooling and lubrication systems, though requiring attention, are straightforward and inexpensive to maintain compared to newer designs.

What sets the M54 apart is its dependability through age. Even after two decades, many continue operating smoothly with original internals.

This engine represents BMW’s last era of true mechanical refinement before electronics began dominating design priorities. It endures not through luck but through sound, balanced engineering that never forgot the value of feel and longevity.

3. Mercedes-Benz M104

The Mercedes-Benz M104 inline-6, built during the 1990s, powered vehicles such as the E320, C36 AMG, and S320. It remains a standout for its unshakable balance, quiet operation, and resistance to fatigue. This engine was engineered during Mercedes’ golden era when long-term reliability took precedence over production cost.

I’m writing about the M104 because it defines durability through precision. Its dual overhead camshaft design and four valves per cylinder provided smooth, efficient power delivery long before such configurations became widespread.

The engine’s forged internals, robust bottom end, and conservative compression ratios all contribute to its ability to stay refined over years of use.

Drivers often remark on its calm demeanor. Even at high mileage, the M104 runs with near-silent composure.

Maintenance is largely preventive rather than reactive, focusing on seals and timing chain tensioners rather than deep internal repairs. It’s not uncommon to find examples exceeding 300,000 miles without major work.

This engine earns its place here because it represents the essence of old-school Mercedes engineering built to last, free of unnecessary complexity, and perfectly balanced.

Its smoothness isn’t artificial or electronic; it’s the natural result of mechanical excellence refined through decades of development. The M104 remains proof that true quality never fades with time.

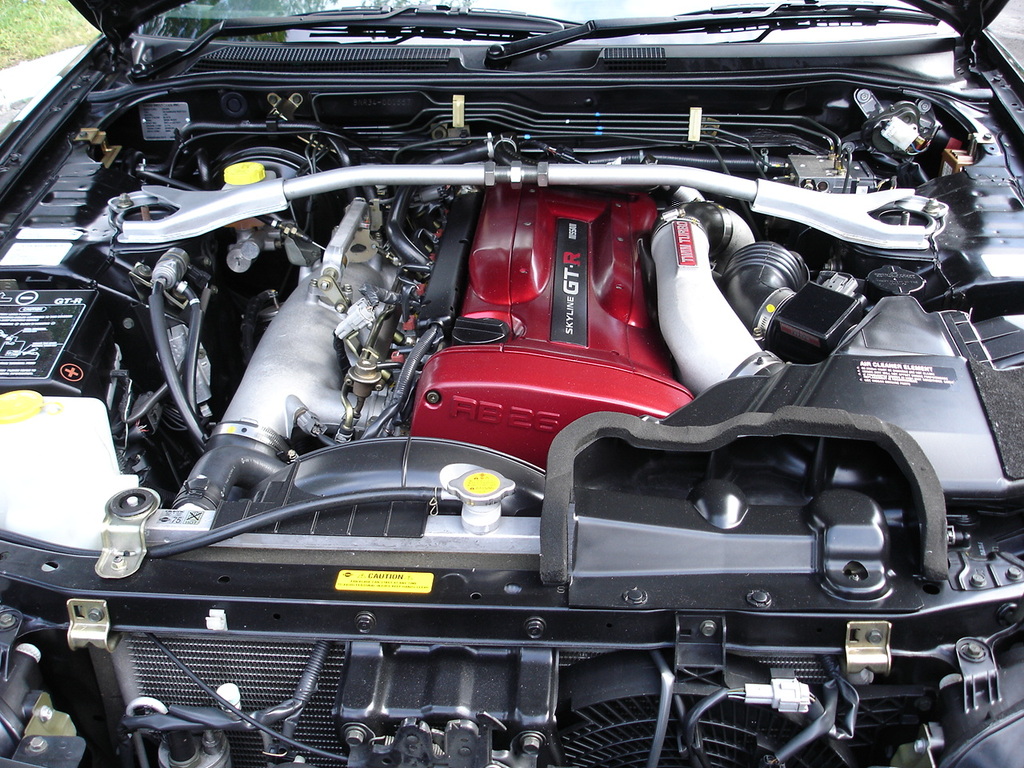

4. Nissan RB26DETT

The RB26DETT, produced by Nissan for the Skyline GT-R between 1989 and 2002, is one of Japan’s most respected inline-6 engines.

While it’s best known for its performance, its smoothness and reliability under stress are what truly distinguish it. With twin turbochargers, a cast-iron block, and a refined crankshaft design, the RB26 balances strength and stability like few engines before or since.

I’m writing about the RB26 because it embodies the engineering discipline that made Japan’s performance engines legendary.

Every component was designed with harmony in mind balanced crank rotation, equal-length intake runners, and exceptional oiling control ensure steady operation at any speed. Even under high boost, the engine feels composed rather than frantic.

Owners worldwide admire how the RB26 maintains its refinement even after heavy use. It doesn’t rattle, vibrate, or strain easily. Regular maintenance keeps it smooth indefinitely, and many examples still run flawlessly after decades of spirited driving.

The RB26 deserves mention here because it represents longevity through precision. Nissan engineered it not just to make power, but to do so gracefully and reliably.

Its continued reputation among tuners and collectors underscores a simple truth: when an engine is built on balance, smoothness and endurance naturally follow.

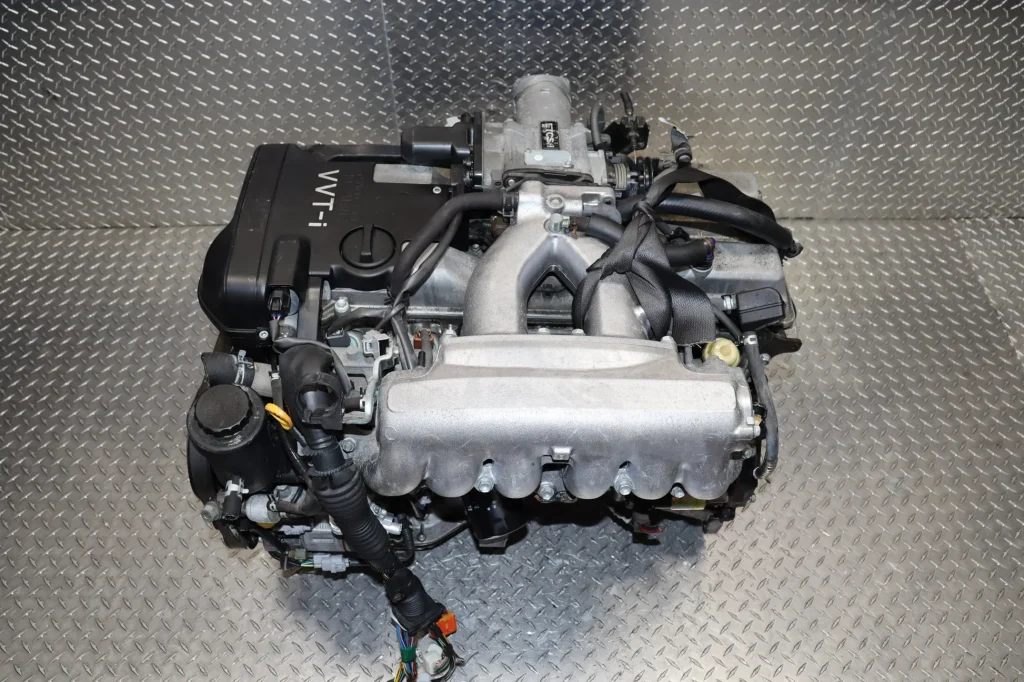

5. Lexus 1GZ-FE

The Lexus 1GZ-FE, Toyota’s 5.0-liter V12 derived from inline-6 engineering principles, shares the smoothness DNA that defines the company’s best engines. However, its foundation stems directly from the proven 1JZ and 2JZ lineage, effectively doubling their architecture.

Though reserved mainly for the Toyota Century, its near-perfect internal symmetry and vibration-free operation reflect the mastery of inline-6 balancing extended to a larger scale.

I’m writing about the 1GZ-FE because it represents how Toyota used the strengths of the inline-6 layout to build ultimate refinement.

Each bank of cylinders mirrors the mechanical calm of the JZ family, producing the same velvety idle and linear power delivery, but multiplied. Owners report remarkable reliability, with engines often surpassing 250,000 miles in chauffeur duty without major overhaul.

Its construction relies on forged internals, conservative tuning, and excellent cooling capacity. Despite its size, it remains nearly silent and vibration-free, a result of perfect internal alignment and minimal friction.

This engine’s inclusion is justified because it demonstrates how the core principles that make inline-6 engines so enduring can scale effortlessly into even more complex configurations.

The 1GZ-FE remains a tribute to balance and reliability living proof that when mechanical harmony guides design, longevity naturally follows.

5 Inline-6 Engines That Don’t Stay Smooth Forever

While the inline-6 layout is naturally balanced, not every example achieves lasting smoothness. Some engines start strong but lose refinement over time due to cost-cutting, weak materials, or overcomplicated technology.

Their initial promise of silk-like performance often fades into rough idling, oil consumption, or mechanical fatigue once high mileage arrives.

I’m writing about these five engines because they highlight how even a naturally perfect design can fail when execution falters. These cases reveal that mechanical geometry alone doesn’t guarantee long-term quality reliability depends on thoughtful engineering, not brand reputation or cylinder count.

The engines listed here suffer from common long-term flaws: fragile timing components, excessive heat buildup, or poor lubrication design. Some were rushed to meet emission standards or turbocharging trends, while others simply lacked the robust materials their predecessors enjoyed.

Each of these inline-6 engines teaches a valuable lesson. Smoothness requires consistency in design, manufacturing, and maintenance planning. When any of those are compromised, refinement quickly fades.

These engines serve as reminders that even a legendary configuration can lose its legacy if durability isn’t built into every bolt and bearing from the start.

1. BMW N54

The BMW N54, introduced in 2006, was BMW’s first mass-produced twin-turbo inline-6. It powered cars like the 335i, 135i, and early 740i models. While it delivered breathtaking performance and responsiveness, its reputation for longevity and smoothness suffered as the years passed.

I’m writing about the N54 because it perfectly illustrates how complexity can erode reliability. On paper, it was a masterpiece direct injection, twin turbos, and advanced electronics but in practice, it became known for carbon buildup, failing injectors, and high-pressure fuel pump failures. These problems often emerged well before 100,000 miles, disrupting the engine’s balance and refinement.

Over time, oil leaks from valve cover gaskets and turbo seals worsened, leading to uneven running and vibration.

Turbo wastegate issues added more inconsistency, causing the engine to lose its once-silky delivery. Owners who loved its performance often grew frustrated with its maintenance frequency and cost.

The N54 earns its place here because it demonstrates how innovation can outpace reliability. It was powerful and ahead of its time, but its long-term behavior betrayed BMW’s heritage of smooth, enduring inline-6 engines. Instead of lasting grace, it offered short-lived brilliance a reminder that advanced engineering without durability doesn’t equal lasting refinement.

2. Jaguar AJ16

The Jaguar AJ16 inline-6, used in models like the XJ6 and XJS during the mid-1990s, was initially praised for its smooth operation and classic character. However, as the years passed, it became clear that while the engine ran beautifully when new, it aged poorly without rigorous care.

I’m writing about the AJ16 because it symbolizes how elegance and engineering precision can be undone by fragile reliability.

Jaguar developed it as a refinement of the earlier AJ6, with improved breathing and fuel efficiency. Unfortunately, the aluminum head and aging gasket materials often caused coolant leaks and overheating, compromising long-term smoothness.

Once heat stress set in, the AJ16 lost its composure. Warped cylinder heads, oil seepage, and rough idling became common in higher-mileage examples. Even with careful maintenance, these engines often required significant overhauls by 150,000 miles.

The AJ16’s inclusion here reflects how craftsmanship without robustness can’t sustain refinement. While the engine had charm and a silky feel in its youth, its mechanical fragility limited its lifespan.

It remains a cautionary example of how even a beautifully balanced inline-6 can’t remain smooth forever if cooling, sealing, and metallurgy aren’t up to long-term demands.

3. Volvo B6304

Volvo’s B6304, part of the “white block” inline-6 family, powered the 960 and early S80 models in the 1990s. It was advanced for its time, offering smooth power delivery and respectable performance. However, its long-term reliability record tells a different story.

I’m writing about the B6304 because it demonstrates how mechanical ambition without structural durability can limit longevity.

The engine’s aluminum block and head provided weight savings, but the design proved sensitive to heat and maintenance neglect. Cooling issues, worn cam seals, and oil leaks around the rear main seal often appeared with age.

As mileage increased, many owners reported erratic idle and oil consumption that dulled the engine’s signature refinement.

Timing belt tensioners also became a weak point, leading to potential valve damage if neglected. These weaknesses made it expensive to maintain, especially compared to Volvo’s older red-block engines that were nearly indestructible.

Despite its pleasant manners when new, the B6304 struggled to retain that composure with time.

Its inclusion here serves as an example of how lightweight construction and complex cooling pathways can compromise long-term smoothness. The engine’s sophistication was real but so were its vulnerabilities once years of wear set in.

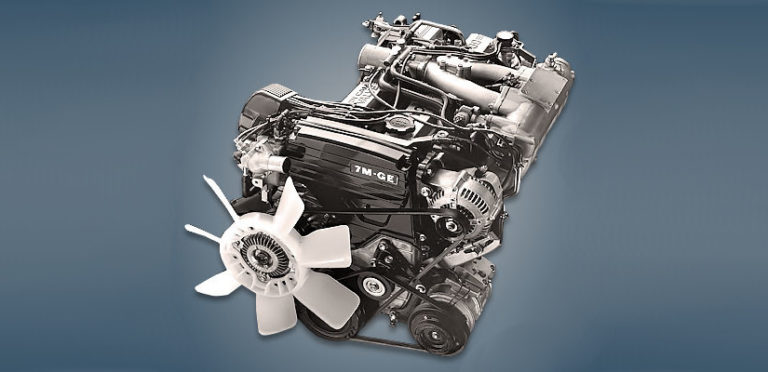

4. Toyota 7M-GE / 7M-GTE

The Toyota 7M inline-6 family, found in the late 1980s Supra and Cressida, carried big expectations but suffered from one of Toyota’s most infamous reliability missteps. The 7M-GE and its turbocharged sibling, the 7M-GTE, were powerful and refined when new but became notorious for blown head gaskets and uneven wear as mileage accumulated.

I’m writing about the 7M because it’s a textbook case of how a small design flaw can ruin long-term balance. The head bolts were under-torqued from the factory, allowing coolant to seep between the block and head over time. Once that happened, overheating and warping followed, degrading the engine’s natural smoothness.

Even after repairs, the 7M’s refinement rarely returned to original form. The once-silent idle became rougher, and the turbo models developed uneven boost characteristics due to aging seals and inconsistent compression.

This engine earns its place here not because it lacked potential it had plenty but because it showed how execution matters more than theory.

The inline-6 design should have ensured lasting smoothness, yet careless manufacturing and weak gaskets doomed it. The 7M reminds us that even a company as reliable as Toyota can stumble when precision isn’t maintained through every production step.

5. Chrysler 225 Slant-6 (Late Versions)

The Chrysler 225 Slant-6 was once celebrated for its durability, but by the 1980s, its reputation began to fade. Initially introduced in the 1960s, the early versions were nearly indestructible, but emissions-era modifications and cost-cutting slowly eroded its smoothness and longevity.

I’m writing about this engine because it shows how continuous alterations can ruin a proven design. The later versions, tuned for stricter emissions standards, suffered from lean mixtures, weaker carburetion, and poor ignition control. As a result, the once-silky inline feel turned coarse and inconsistent.

The cast-iron block and sturdy internals still had potential, but detuned power and rough idle patterns became common complaints.

The addition of complex vacuum lines and unreliable feedback systems also increased maintenance headaches. Over time, the engine developed hard-start issues, uneven combustion, and vibration that earlier models never experienced.

The 225 Slant-6 deserves mention here because it highlights how external regulations and shortcuts can degrade a great engine’s legacy.

Its original balance and endurance were undone by compromise, proving that even simplicity can be spoiled when precision gives way to production expediency. What was once an icon of reliability ended its life struggling to maintain the refinement it once defined.

The inline-six engine has long stood as a symbol of mechanical balance and refinement. Its even firing order and natural symmetry produce a smoothness that V6 and V8 engines often struggle to match.

Over the decades, some inline-six engines have proven nearly unbreakable, maintaining their calm precision long after odometers passed the 300,000-mile mark.

Others, though, could not keep that promise, their weaknesses showing up through wear, oil leaks, and unwanted vibration. This contrast between lasting success and disappointing decline defines the story of the inline-six.

Engines like Toyota’s 2JZ-GE and BMW’s M54 demonstrate how durability and refinement can coexist. Their secret lies in robust construction, simple mechanical layouts, and careful tuning that avoids stress.

The Mercedes-Benz M104 carries that same spirit, delivering quiet strength that has endured for decades. Nissan’s RB26DETT, though built for racing, shows that performance does not have to come at the cost of long-term reliability.

Even the humble Jeep 4.0L proves that balance and toughness can live together in a workhorse engine. These powerplants survive the years not by chance but through disciplined design strong internals, efficient cooling, and materials that resist fatigue.

On the opposite side are engines that began with promise but aged poorly. BMW’s N54, for example, offered thrilling turbocharged performance but suffered from carbon buildup and complex fuel systems that broke down too soon.

Similar stories can be found across other brands that chased innovation without long-term testing. When engineers push for more power or higher efficiency without reinforcing durability, the result often appears smooth at first but fades with time.

The lesson is that smoothness cannot rely only on balance or technology; it must come from strength, lubrication stability, and restraint in design.

What stands out from comparing both groups is how simplicity remains a friend to longevity. Engines that depend on mechanical purity rather than electronics tend to keep their refinement far longer.

The best examples avoid unnecessary components, use stronger materials, and feature generous oiling systems.

Their smoothness is not just a quality felt when new but a character that endures as miles accumulate. They reward consistent maintenance but rarely punish owners with sudden failures.

The weaker inline-sixes remind us that even a perfect layout can be undermined by cost cutting or excessive complexity.

As turbocharging and emissions systems grew more demanding, some designs lost the natural harmony that once defined this engine type. The decline of smoothness over time became a sign that mechanical precision had given way to over-engineering.

Across decades of automotive progress, the inline-six continues to represent balance, endurance, and grace. The best of them age with dignity, staying quiet, stable, and powerful even when others begin to shake.

The worst, however, show how fragile refinement can be when durability is sacrificed. Together they prove that true engineering success is measured not by horsepower figures, but by how smoothly an engine runs after years of service and how confidently it still turns every mile into motion.

Also Read: 5 V8 Engines That Deliver Decades of Service vs 5 That Don’t