Few mechanical creations earn the kind of loyalty a great V8 engine commands. These powerplants defined generations of vehicles, symbolizing endurance, sound, and strength. Yet not every V8 meets that promise.

Some earn reputations for running hundreds of thousands of miles with only basic care, while others become known for premature failures, leaks, and costly rebuilds. This contrast is what separates engineering brilliance from rushed design and cost-cutting.

In today’s automotive climate, many enthusiasts still trust the V8 format for its dependable torque and familiar rhythm.

But longevity depends on design integrity, material quality, and attention to serviceability. Some automakers built engines meant to last decades, while others delivered short-lived disappointments that left owners frustrated.

This feature examines both extremes the V8s that continue to prove their worth long after newer technologies arrived, and those that could not stand the test of time.

From Ford and Toyota to General Motors and BMW, these examples show that long-term reliability still depends on fundamentals: strong metallurgy, proper oiling, and real-world testing.

The following engines reveal how the same number of cylinders can tell completely different stories of engineering success and failure.

Also Read: 5 Engines That Don’t Mind Cheap Gas vs 5 That Fail Without Premium

5 V8 Engines That Deliver Decades of Service

Among automotive milestones, few things represent mechanical trust like a well-built V8 that just keeps going. These engines are remembered not only for performance but also for durability under harsh use, poor maintenance, and aging parts.

They powered everything from half-ton pickups to luxury sedans, yet their strength came from thoughtful design rather than sheer displacement.

A reliable V8 blends simplicity with proven engineering. Strong crankshafts, generous oiling systems, and conservative compression ratios often make the difference between a short-lived engine and one that crosses 300,000 miles.

Manufacturers like Toyota, Ford, and General Motors produced several examples that earned lifelong loyalty from owners who valued consistency over flash.

These V8s earned reputations in taxis, trucks, SUVs, and even sports cars surviving time, mileage, and abuse. They prove that longevity doesn’t come from chance but from commitment to materials, testing, and balance.

Each engine in this section shows how manufacturers got it right, producing mechanical legends that continue to start, idle, and roar decades later.

The following five V8s remain benchmarks of endurance, each a reminder that sometimes the best engineering story is written not in horsepower numbers but in how long the machine keeps running.

1. Toyota 4.7L 2UZ-FE V8

The Toyota 4.7L 2UZ-FE stands as one of the most enduring V8 engines ever produced. Introduced in the late 1990s, it powered the Land Cruiser, Sequoia, Tundra, and Lexus LX470 vehicles built to handle decades of use in demanding environments. The key to its longevity lies in its conservative design. U

nlike the high-revving 1UZ-FE, the 2UZ featured an iron block, favoring strength and heat tolerance over lightness. This provided stability under high loads, essential for heavy trucks and SUVs operating in extreme temperatures.

The engine’s non-interference layout and overbuilt internals reduced failure points. With proper maintenance, owners often report 400,000 miles or more without a rebuild.

Timing belt intervals, simple oil changes, and cooling system care are usually all it needs. Its smooth torque delivery also reduced strain on transmissions and drivetrain components.

Another factor in its reputation is Toyota’s manufacturing consistency. Tolerances were tightly controlled, and the motor was known for resisting oil leaks and gasket failures that plagued rival V8s.

Even with heavy towing or off-road duty, it retained quiet operation and strong compression. The 2UZ-FE proved that endurance wasn’t about complexity or marketing hype, but about an honest mechanical approach that prioritized strength and reliability above all else.

2. Ford 5.0L Coyote V8

When Ford reintroduced the 5.0L badge in 2011, the Coyote engine revived confidence in modern V8 durability.

Designed for the Mustang GT and later adapted to F-150 trucks, this aluminum block powerplant managed to combine high output with remarkable staying power.

Engineers focused on precision oil control, deep-skirt block rigidity, and forged crank durability, making it a unit that could handle daily abuse as easily as track-day stress.

Owners frequently record over 250,000 miles on original internals, a rarity for modern high-revving engines. The Coyote’s dual independent variable cam timing enhances both efficiency and longevity by maintaining ideal valve operation under different conditions.

Regular maintenance mostly oil and filter care keeps it running without issue. The absence of major design flaws, such as cylinder head cracking or oil starvation, gives it an advantage over some older American V8s.

Its adaptability also contributes to its long-term reputation. The same core design powers Mustangs, trucks, and specialty builds worldwide, all sharing similar reliability traits.

The Coyote’s combination of engineering balance and field performance places it among the few modern V8s capable of outlasting multiple vehicle generations. It reaffirmed Ford’s legacy for building engines that merge innovation with long-term dependability.

3. Chevrolet 5.3L Vortec (LM7)

The Chevrolet 5.3L Vortec, coded LM7, is a symbol of how simplicity and solid engineering can lead to exceptional longevity. Introduced in 1999 for Silverado and Suburban models, it became the backbone of GM’s truck lineup for over a decade.

Built on the Gen III small-block platform, it balanced modern efficiency with old-school toughness. The iron block, aluminum heads, and sequential fuel injection made it durable without sacrificing refinement.

Owners frequently see 300,000 miles or more without significant internal work, provided routine maintenance is observed. The LM7’s oiling system and balanced crankshaft minimize friction wear, and its hydraulic lifters maintain consistent valve operation over long intervals.

It’s also known for surviving neglect better than most competitors, often running smoothly even after hard use and heavy towing.

The modular design simplified repairs, keeping replacement parts affordable and accessible. GM’s consistent machining and clearances made it less prone to oil leaks and gasket issues than earlier small-blocks.

Its versatility also contributed to its legacy found in trucks, SUVs, and even engine swaps for older muscle cars. The LM7 remains one of the most serviceable and forgiving V8s ever built, standing as a testament to the idea that endurance often depends on sound fundamentals and reliable design rather than flash or complexity.

4. Lexus 4.0L 1UZ-FE V8

The Lexus 1UZ-FE earned a reputation for refinement and longevity that few engines have matched. Launched in 1989 with the LS400, it represented Toyota’s commitment to crafting a luxury V8 that could last beyond half a million miles.

Its all-aluminum construction, six-bolt main bearing caps, and overspecified internals made it exceptionally smooth and durable. Built to rival the best from Europe, it often outlasted them by decades.

Owners report consistent compression and near-silent operation even after hundreds of thousands of miles. The timing belt design was easy to service, and its non-interference layout prevented catastrophic damage if it failed.

Engineers focused on balance and oil distribution, resulting in minimal internal wear. Even neglected examples often run without knocking or smoking proof of its resilience.

Another key to the 1UZ-FE’s success is its versatility. It powered sedans, coupes, and even sports cars like the SC400. Many enthusiasts repurpose them for performance builds due to their proven strength. The combination of durability, refinement, and reliability gave Lexus an unmatched reputation during the 1990s.

The 1UZ-FE wasn’t just a luxury engine; it became an engineering benchmark that showed how precision manufacturing and conservative design could create a V8 capable of lasting several decades without losing its composure or integrity.

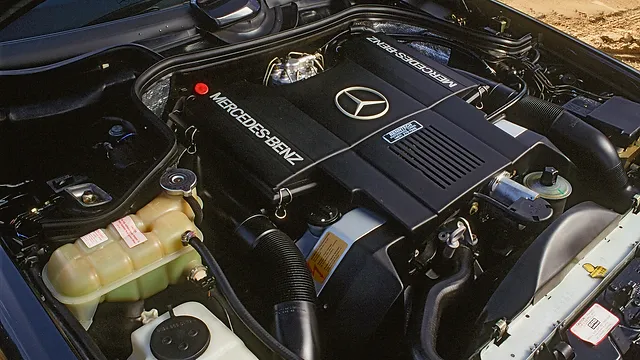

5. Mercedes-Benz 4.2L M119 V8

The Mercedes-Benz 4.2L M119 remains one of the finest examples of German precision meeting long-term durability. Produced from the late 1980s through the mid-1990s, this dual overhead cam V8 powered vehicles like the E420, S420, and the 500SL in 5.0L form.

Built during Mercedes’ peak era of engineering-first design, the M119 combined robust construction with advanced technology that still holds up today.

Its aluminum block with forged internals, variable valve timing, and efficient oil circulation made it ahead of its time. The engine’s reputation for endurance comes from the quality of its components camshafts, valve guides, and bearings that resist wear even under high mileage.

Well-maintained examples easily cross 400,000 kilometers without losing performance or oil pressure. Unlike many later engines, it avoided electronic overcomplication, relying on mechanical dependability supported by a solid fuel and ignition system.

The M119’s smoothness also contributed to its longevity. Balanced internals meant less vibration, reducing stress across ancillary components.

Enthusiasts often praise it for combining refinement with toughness, able to perform both in city conditions and at autobahn speeds for decades. Even today, many original units run quietly with minimal oil consumption.

This engine represents Mercedes’ engineering ideals before cost-cutting entered the picture. Built to last rather than to meet production quotas, the M119 stands as one of the few European V8s from its era that consistently proves its worth through long service life and minimal mechanical failures.

5 V8 Engines That Don’t

Not every V8 that reaches production earns the reputation its maker intended. Some promised strength and performance but ended up known for leaks, failures, or expensive repairs that arrived long before their time.

Despite impressive specifications on paper, these engines suffered from weak materials, poor lubrication design, or rushed engineering that couldn’t withstand real-world use. Over time, their shortcomings became cautionary tales among owners and mechanics alike.

A short-lived V8 doesn’t necessarily fail because of power output it often breaks down because the basics weren’t right. Flawed oil passages, fragile timing systems, or heat management issues can ruin what might otherwise be a brilliant design.

Owners expecting long service found themselves facing head gasket replacements, camshaft wear, or total rebuilds before 150,000 miles.

These engines reflect the difference between marketing success and mechanical longevity. They remind enthusiasts that a V8’s reputation isn’t earned by its sound or acceleration, but by how long it keeps running without draining the owner’s wallet.

The following five engines represent cases where promise turned to disappointment powerplants that, despite bold beginnings, could not deliver the durability expected from a true V8 workhorse.

1. Cadillac 4.6L Northstar V8

The Cadillac Northstar 4.6L V8 was meant to symbolize American engineering sophistication when it debuted in the early 1990s. On paper, it had all the right traits dual overhead cams, aluminum construction, and smooth high-end performance.

In practice, however, it became one of the most problematic engines GM ever produced. Its main flaw was in head gasket durability. Poor head bolt thread design in the aluminum block caused the bolts to pull out over time, leading to catastrophic overheating and coolant loss.

Once this failure began, repair costs often exceeded the vehicle’s value. The tightly packed engine bay made maintenance complex, and servicing even minor issues required extensive disassembly.

The cooling system itself was fragile, and oil leaks around the pan and valve covers became common as the miles accumulated. Despite its refinement when new, the Northstar’s upkeep demands and recurring failures turned many luxury Cadillacs into short-lived ownership experiences.

Some later revisions improved gasket materials and cooling paths, but the early damage to its reputation was irreversible.

The Northstar remains a lesson that innovation without mechanical durability can destroy consumer trust. Its performance was strong, but its longevity fell far short of expectations for a premium V8.

2. BMW 4.4L N62 V8

BMW’s 4.4L N62 V8, found in models such as the 545i, 745i, and X5 from the early 2000s, combined performance with luxury refinement but at a heavy long-term cost.

Its complex design included variable valve timing on both camshafts and a variable intake system, delivering smooth power delivery when new. Unfortunately, this sophistication came with a host of reliability problems that emerged with age.

Valve stem seals are among its most infamous weaknesses, causing heavy oil consumption and smoke from the exhaust. Even low-mileage examples often show this issue, and repairs require significant labor.

The N62 also suffers from coolant transfer pipe leaks beneath the intake manifold, a design that forces major engine disassembly to replace a single worn seal. These jobs are both time-consuming and expensive, discouraging owners from long-term ownership.

Electrical and sensor issues further complicate the experience, making the N62 notorious among independent mechanics. Although the engine feels powerful and refined when functioning correctly, it simply doesn’t hold up under typical ownership conditions.

Most examples require thousands in maintenance before reaching 150,000 miles. For an automaker once known for bulletproof inline-sixes, the N62 stands as proof that complexity can be the enemy of lasting reliability.

3. Jaguar 4.0L AJ-V8

The Jaguar 4.0L AJ-V8, introduced in the late 1990s, was supposed to represent a modern and refined powerplant for luxury models such as the XJ8, XK8, and later the S-Type.

While it offered smooth power delivery and an impressive exhaust note, its long-term durability proved far below expectations. Early versions suffered from a combination of design and material flaws that caused severe wear over time.

The most notorious problem came from the use of Nikasil cylinder liners in early engines. High sulfur fuel in many markets caused chemical reactions that eroded the liner surface, leading to loss of compression and excessive oil consumption.

Even after Jaguar switched to steel liners, timing chain tensioner failures became common. The original plastic guides often cracked or disintegrated, resulting in catastrophic internal damage if not replaced promptly.

Cooling system leaks and crankshaft seal failures also plagued the AJ-V8, forcing many owners into costly repairs far too early in the vehicle’s life.

Although the later 4.2L variant resolved some of these issues, the original 4.0L left a deep mark on Jaguar’s reliability record. It demonstrated how advanced design without rigorous durability testing can lead to short-lived luxury, leaving owners frustrated despite the car’s charm and performance potential.

4. Audi 4.2L V8 (B6/B7 S4)

The Audi 4.2L V8 used in the B6 and B7 S4 sedans looked promising on paper all-aluminum construction, five valves per cylinder, and a rich exhaust tone that appealed to enthusiasts.

Unfortunately, ownership experience revealed a host of mechanical and serviceability flaws that severely limited its long-term appeal. The biggest issue lies in timing chain placement at the back of the engine, a packaging decision that made even routine maintenance extraordinarily difficult.

When timing components wear or fail, the repair requires removing the entire engine from the car, making it one of the most labor-intensive jobs in its class.

Chain guide wear, tensioner collapse, and cam adjuster faults became widespread, often appearing before 100,000 miles. Oil consumption, valve cover leaks, and carbon buildup added to the frustration, making ownership costly even for well-maintained cars.

Heat management was another weak point. The compact design led to high operating temperatures that accelerated component wear and oil breakdown.

While performance was impressive when everything worked, few owners could justify the expense of keeping the 4.2 running properly. It remains a cautionary engine for enthusiasts who value engineering ambition but expect mechanical reliability something this Audi V8 rarely delivered beyond its early years.

5. Chrysler 4.7L PowerTech V8

The Chrysler 4.7L PowerTech V8, introduced in 1999, was designed to modernize Chrysler’s truck and SUV lineup with improved efficiency and smoother operation compared to the older Magnum engines.

It powered vehicles such as the Jeep Grand Cherokee, Dodge Dakota, and Dodge Ram 1500. On release, it promised balanced performance and lighter construction, but time revealed a series of flaws that kept it from achieving long-term reliability.

Its most critical weakness was oil sludge buildup. Narrow oil passages, high operating temperatures, and sensitive maintenance requirements meant that missed oil changes could quickly lead to catastrophic failure.

Engines with neglected service intervals often suffered from seized camshafts, dropped valve seats, and bottom-end bearing damage. Even well-maintained examples experienced timing chain tensioner wear and cooling system leaks, resulting in costly repairs long before 200,000 miles.

The engine’s compact design also made repair work difficult, discouraging regular service. Once problems began, repairs often spiraled into complete engine replacements, which further damaged its reputation.

Unlike Chrysler’s later HEMI series, the 4.7 lacked both durability and aftermarket support. Many owners eventually replaced vehicles outright rather than invest in engine overhauls.

The PowerTech V8 stands as a missed opportunity an engine that combined ambition with fragile engineering choices.

It served as an important lesson for Chrysler engineers, showing that efficiency gains and modern architecture mean little without the foundation of robust internal design and dependable oil management.

Across decades of automotive history, the V8 engine has represented more than just power; it has symbolized trust, endurance, and engineering pride. Yet as these examples show, not every V8 fulfills that promise.

The difference between the engines that last for generations and those that fade early often comes down to the fundamentals sound materials, proper oil circulation, and attention to thermal control.

Engines such as Toyota’s 2UZ-FE, Ford’s Coyote, Chevrolet’s 5.3L LM7, Lexus’s 1UZ-FE, and Mercedes’s M119 proved that balanced engineering always pays off. Each one focused on strong internal components, logical design, and easy serviceability.

They earned their reputations not through marketing but through years of dependable operation in the hands of real owners. These engines continue to demonstrate that true longevity requires restraint in design and discipline in manufacturing.

By contrast, the Cadillac Northstar, BMW N62, Jaguar AJ-V8, Audi 4.2, and Chrysler 4.7L PowerTech highlight what happens when complexity or cost-cutting override practicality.

They were powerful and advanced for their time, but weak gaskets, oiling flaws, and maintenance challenges turned them into financial liabilities. Their stories show that technology without reliability undermines the very reputation a V8 should uphold.

Ultimately, a long-lasting V8 is more than an engineering exercise; it’s a relationship between sound design and real-world use.

Those that endure prove that durability never goes out of style, while those that fail remind manufacturers that lasting trust is built one reliable mile at a time.