The automotive industry has produced countless engine designs over the decades, but only a select few have earned the genuine respect of mechanics and engineers across the globe.

An engine worthy of mechanic respect isn’t simply one that performs well when it’s new, it demonstrates exceptional durability, reliability, ease of maintenance, and longevity that spans decades and hundreds of thousands of miles.

These engines become legendary in garages and service shops around the world, passed down through stories of vehicles that refuse to quit despite age and mileage that would have other machines in junkyards.

What makes an engine truly respectable in the eyes of mechanics goes beyond horsepower figures or acceleration times. It’s about the philosophy of engineering that went into its creation.

The most respected engines are those designed with simplicity and robustness as core principles. They avoid unnecessary complexity, use high-quality materials, and feature design elements that prevent common failure points.

Mechanics appreciate engines that don’t punish owners with expensive repairs, that don’t require constant adjustment, and that perform reliably in various climates and conditions.

Furthermore, these engines have transcended their original applications. Enthusiasts seek them for swaps and restorations, builders use them as platforms for modifications, and owners trust them in vehicles that are decades old.

The availability of parts, the wealth of knowledge accumulated by communities of users and technicians, and the proven reliability mean these engines can be maintained and kept running indefinitely.

This article explores twelve such engine machines that have earned the profound respect of mechanics worldwide through their engineering excellence, durability, and timeless performance.

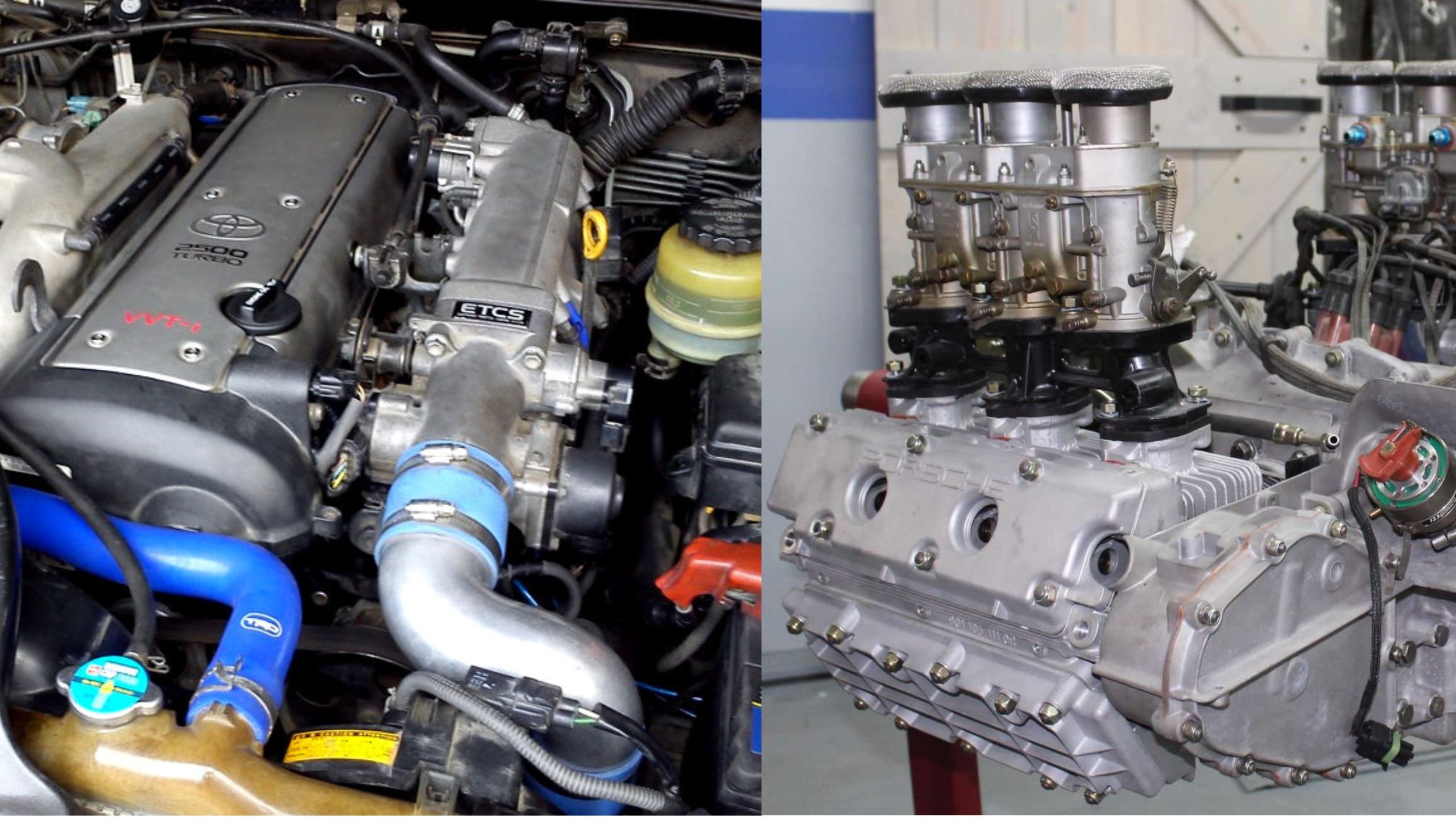

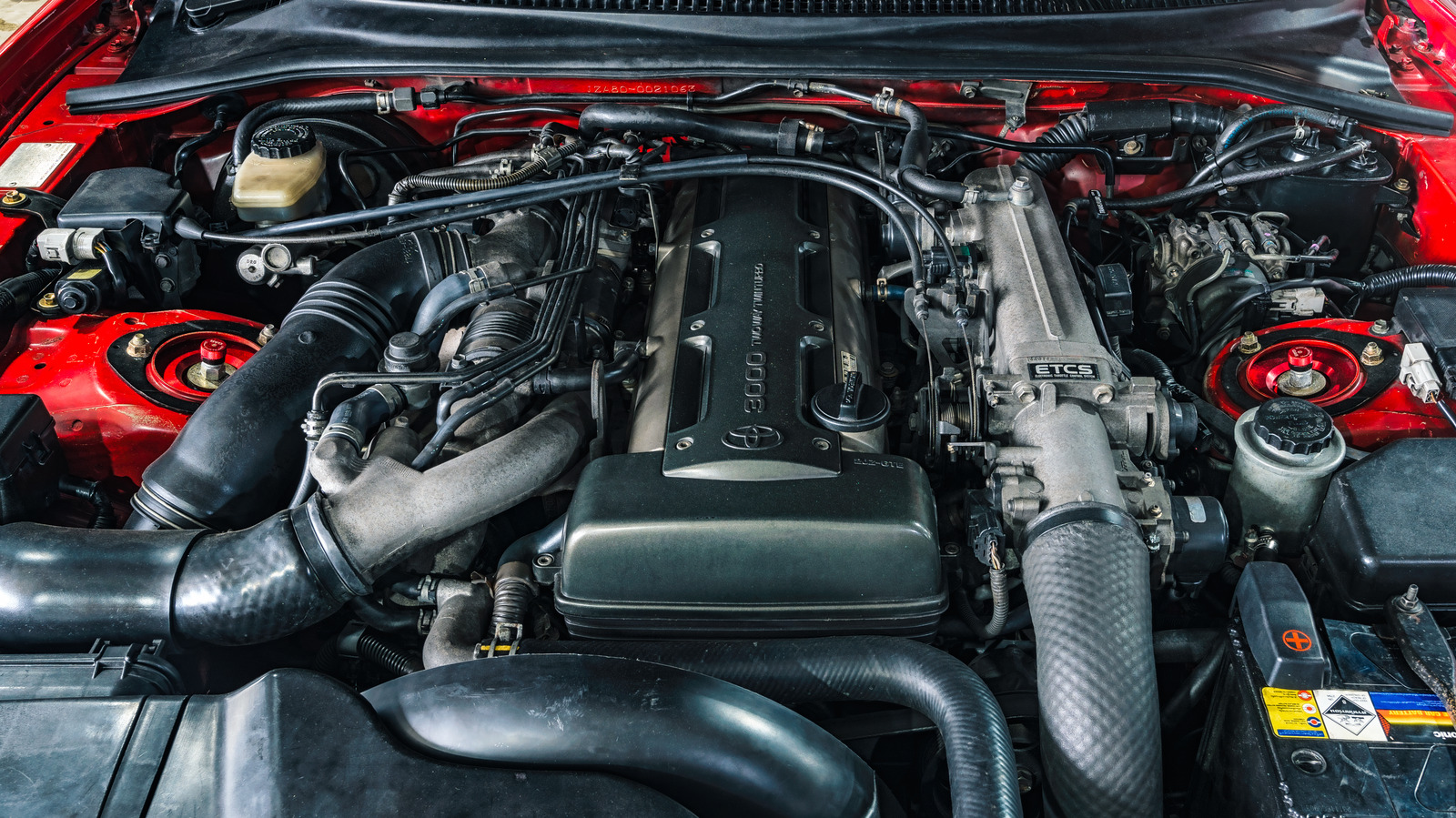

1. Toyota 2JZ-GTE Engine

The Toyota 2JZ-GTE represents the pinnacle of 1990s inline-six turbo engineering and stands as one of the most respected engines in automotive history.

Introduced in 1991, this 3.0-liter twin-turbocharged engine powered the legendary Toyota Supra, and its reputation has only grown stronger with time.

Mechanics respect this engine not merely for its impressive 320 horsepower in stock form, but for its extraordinary potential and bulletproof engineering that makes it one of the most tunable engines ever created.

What mechanics appreciate most about the 2JZ-GTE is its cast-iron engine block, which demonstrates Toyota’s commitment to durability over cost-cutting measures.

The engine’s internal components, including forged steel crankshaft and connecting rods, were engineered to handle substantial horsepower increases well beyond factory specifications.

Many examples of 2JZ-GTE engines have surpassed 500, 600, and even 700 horsepower through various modifications, yet the fundamental engine design accommodates this power with remarkable reliability.

The sequential twin-turbo system featured on the 2JZ-GTE is an engineering marvel that mechanics have studied and admired for decades.

The primary turbo handles low-to-mid-range boost, while the secondary turbo engages at higher RPMs, creating a powerband that feels almost supercharged in its consistency.

This system required sophisticated engineering, precise sequencing, and manufacturing precision that reflects Toyota’s technical capabilities at the time. Mechanics recognize this as an example of engineering executed without compromise.

Maintenance and repair of the 2JZ-GTE are straightforward for experienced technicians, with no particularly troublesome design quirks.

The engine utilizes conventional valve-train design with straightforward timing belt replacement intervals of 100,000 miles. Parts availability remains excellent even today, with both OEM components and performance alternatives readily accessible.

Mechanics have developed extensive knowledge about this engine through decades of ownership and modification, meaning expertise is widely available.

The 2JZ-GTE has become an icon in the tuning and enthusiast communities, with massive international networks of owners and builders who share knowledge about maximizing reliability while increasing performance.

Mechanics respect this engine because it responds well to competent modification the engineering is sound enough that careful upgrades consistently produce reliable results.

Mechanics worldwide recognize it as a defining achievement in automotive engineering, representing a moment when Japanese manufacturers were pushing technological boundaries while maintaining exceptional build quality.

This engine’s legacy continues to inspire respect because it represents the perfect combination of practical engineering and achievable performance.

2. Porsche 911 Flat-Six Engine (Air-Cooled Era)

The air-cooled flat-six engine that powered Porsche 911s from 1963 through 1998 represents one of automotive history’s most enduring and respected engine designs.

Mechanics worldwide have earned profound respect for this engine through decades of maintenance, repair, and restoration work. The fundamental design of a horizontally-opposed six-cylinder layout proved so effective that Porsche continuously refined and enlarged it over thirty-five years rather than replacing it entirely, testament to its inherent correctness.

Respect for the air-cooled flat-six stems from several factors that mechanics recognize immediately upon encountering the engine. First is its absolute simplicity in an era when manufacturers increasingly added complexity.

The air-cooled design eliminates the entire water cooling system, no radiator, coolant, water pump, thermostat, or hoses subject to failure.

The heads and cylinders are cooled directly by air directed through the engine bay, a design that requires precision engineering but delivers reliability through simplicity. Mechanics appreciate this straightforward approach that reduces potential failure points.

The boxer configuration offers significant advantages that experienced technicians recognize. The horizontally-opposed cylinders mean opposing pistons move in opposite directions, achieving perfect primary and secondary balance.

This creates remarkably smooth engine operation despite lower displacement compared to equivalent-displacement inline engines. The low center of gravity provided by this configuration contributed significantly to the 911’s legendary handling characteristics, demonstrating how engineering choices ripple through entire vehicle dynamics.

Power outputs evolved dramatically over the air-cooled 911’s lifespan, growing from the original 130 horsepower to nearly 300 horsepower in the final air-cooled models.

This growth occurred through steady improvement rather than revolutionary redesign a pattern mechanics respect because it demonstrates fundamental soundness.

Bore increases, displacement growth, improved breathing through better exhaust systems, and fuel injection technology were applied to an engine design proven robust enough to handle such evolution.

Maintenance of the air-cooled flat-six requires specific knowledge that mechanics develop through hands-on experience. The rear-mounted engine position in the 911 creates unique challenges, as does the air-cooling system with its complex fan and ducting.

However, mechanics respect the engine because once these particulars are understood, the work becomes straightforward. The mechanical systems are honest and direct no mysterious computer codes or proprietary diagnostic equipment required in earlier models.

Reliability records of properly-maintained air-cooled 911s are exceptional, with hundreds of thousands of examples still operating today at ages exceeding 50 years.

Many show mileage well beyond 200,000 miles, while certain examples have circulated the globe multiple times with the original engine.

This longevity stems from quality construction, rational engineering, and an engine design that doesn’t punish owners who provide basic maintenance.

Mechanics have watched these engines endure conditions that destroy other vehicles, building respect through direct observation of their durability and the simplicity of keeping them running.

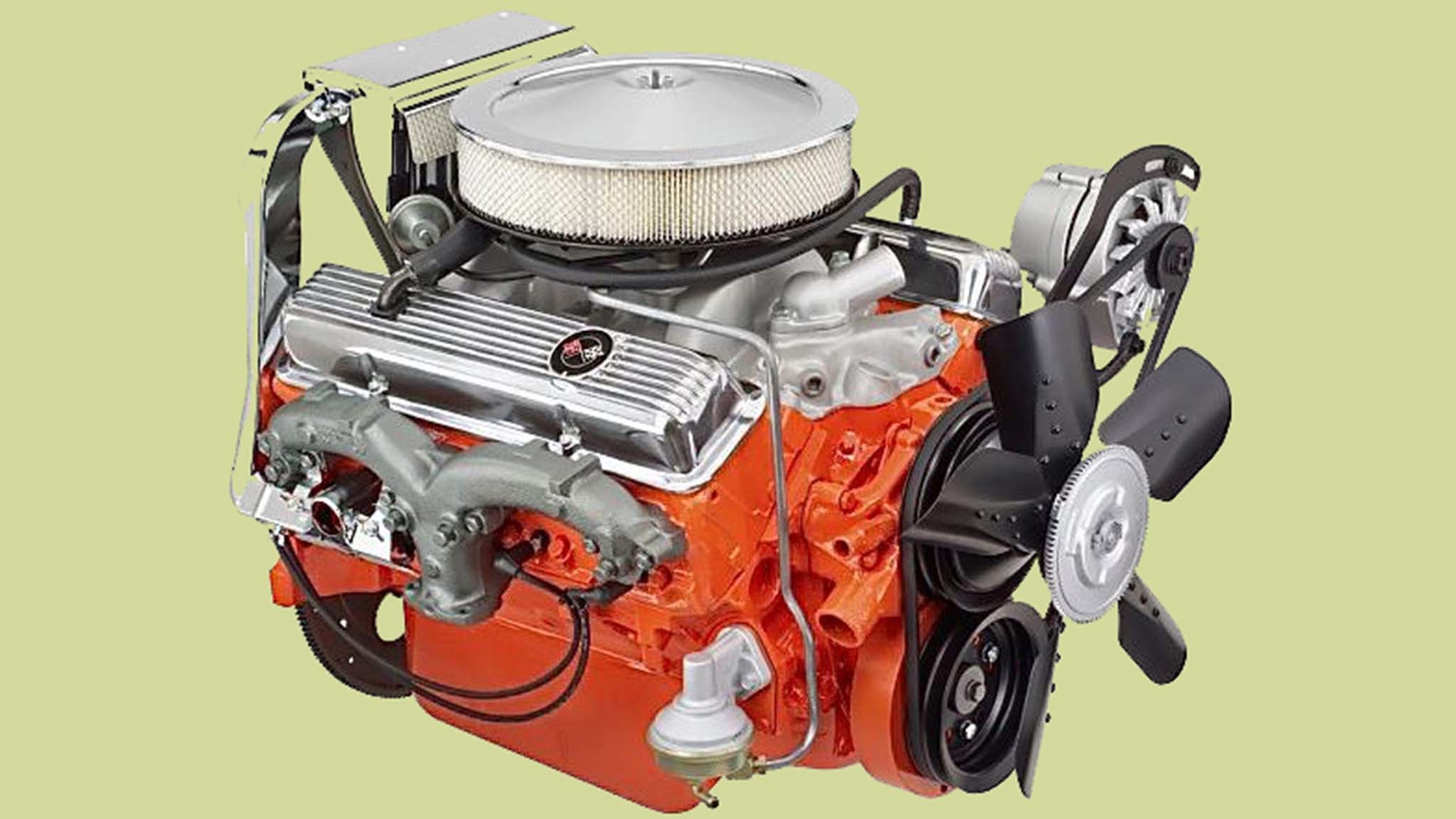

3. Chevrolet Small-Block V8

The Chevrolet small-block V8, first introduced in 1955, has earned its position as perhaps the most respected engine in American automotive history.

Mechanics worldwide acknowledge this engine as the beginning of modern V8 engineering and the foundation upon which countless derivatives have been built.

The original 265-cubic-inch engine was a revelation compact, lightweight, powerful, and efficiently manufactured qualities that immediately impressed not just customers but the engineers and mechanics tasked with maintaining these vehicles.

What mechanics respect most about the small-block design is its modularity and fundamental soundness. The original 1955 design proved flexible enough to accept continuous improvement over decades.

Displacement grew from 265 cubic inches to 302, 307, 327, 350, 400, 427, and eventually 454 cubic inches. Through successive generations spanning nearly forty years, the basic engine architecture remained recognizable, yet reliability and performance increased steadily.

This ability to evolve while maintaining core compatibility is something mechanics deeply respect. The small-block V8’s contribution to automotive democratization cannot be overstated. Before its introduction, V8 power was expensive and exclusive.

The small-block brought V8 capability to mid-level consumers, starting with the Chevrolet Corvette and quickly spreading to other Chevrolet and Pontiac models.

This accessibility meant vast numbers of mechanics gained familiarity with V8 technology, and the engine’s straightforward design meant even technicians of modest experience could diagnose and repair it effectively. This democratization of knowledge has benefited the small-block’s longevity and reputation.

Simplicity characterizes the small-block design in ways mechanics instinctively respect. The engine uses conventional overhead-valve architecture pushrods operate valves through simple mechanical linkages, an approach some dismissed as outdated even during the small-block’s development.

However, mechanics recognize that this simplicity delivered exceptional reliability, low manufacturing costs, and straightforward maintenance. The pushrod design creates compact heads and short valve trains, reducing potential resonance problems and improving reliability at high RPMs.

Performance potential of the small-block V8 has proven nearly unlimited within reason. The basic engine architecture accommodates boring, stroking, turbocharging, supercharging, and combination approaches that produce anywhere from 300 to over 1,000 horsepower in extreme examples.

Mechanics respect how the engine responds to competent modification careful engineering produces reliable results because the fundamental design is sound. Countless street rods, race cars, and performance vehicles have used the small-block as their foundation, accumulating centuries of collective modification experience.

The aftermarket support for the small-block small-block V8 remains extraordinary decades after production ended. Parts are available from dozens of manufacturers, ranging from restoration components identical to originals to modern high-performance pieces utilizing latest technology.

Mechanics can source internal components, gasket sets, intake manifolds, cylinder heads, and complete engines at virtually any price point. This availability means small-block V8-powered vehicles can be maintained indefinitely, and knowledge about their maintenance is widely available worldwide.

Reliability statistics for well-maintained small-block V8s are remarkable, with countless examples running strong at 200,000 to 500,000 miles.

Original owner testimonials frequently describe vehicles that exceeded expectations, with some achieving over 300,000 miles on original engine and drivetrain without major problems.

When rebuilds become necessary, mechanics find the process straightforward due to conventional design and decades of accumulated knowledge. The small-block V8’s position as the most respected American engine is earned through proven performance spanning generations.

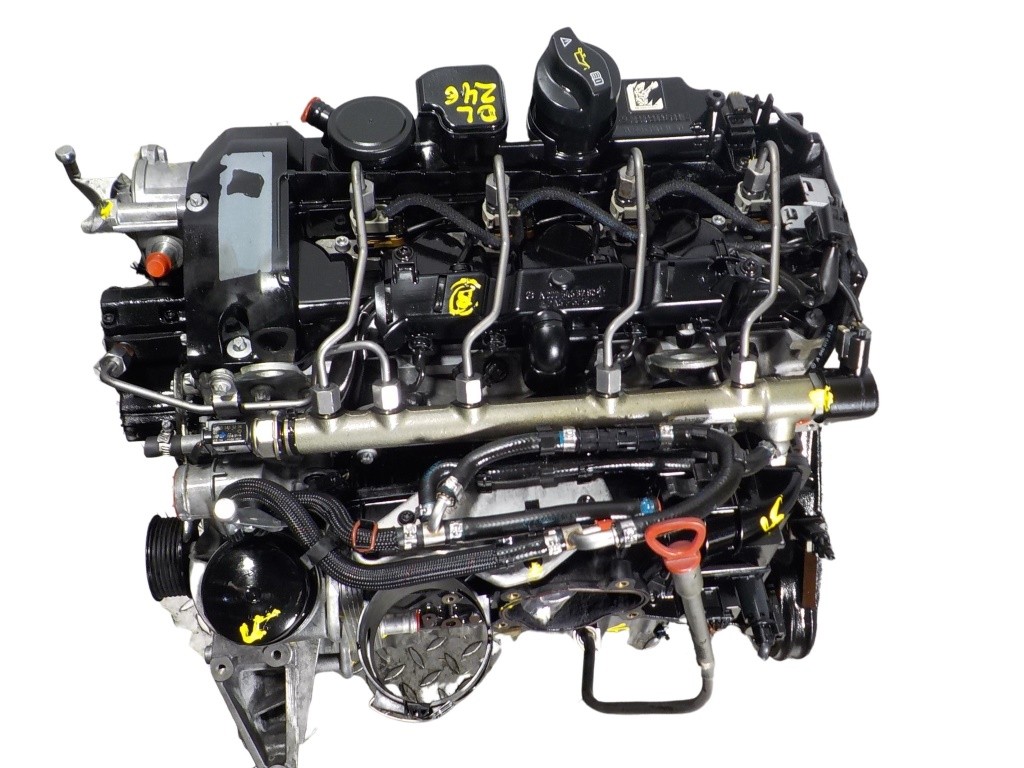

4. Mercedes-Benz OM617 Diesel Engine

The Mercedes-Benz OM617 diesel engine earns enormous respect from mechanics worldwide for representing the height of 1970s and 1980s diesel engineering.

This five-cylinder turbodiesel powered Mercedes sedans, particularly the W123 and later W124 models, establishing a reputation for durability that resonates with mechanics to this day.

The OM617 exemplifies how thoughtful engineering creates engines that operate reliably for decades and hundreds of thousands of miles.

Mechanics respect the OM617 first and foremost for its exceptional longevity. Examples are well-documented with 500,000, 600,000, and even 700,000-plus miles on original engines.

These aren’t anomalies but relatively common in countries where Mercedes-built vehicles are carefully maintained. This extraordinary lifespan stems from conservative engineering Mercedes designed this engine to survive extended use in service vehicle applications where mechanical failure meant costly downtime.

The engine was built for function first, performance second. The OM617’s direct-injection diesel combustion system represents engineering excellence from an era when fuel injection was still relatively new.

Direct injection delivers fuel precisely into the combustion chamber at precisely-timed moments, optimizing the combustion process for maximum efficiency and minimum emissions.

While modern diesels have adopted sophisticated electronic controls, the OM617’s mechanical injection system demonstrates that sound principles of diesel combustion don’t require computer sophistication. Mechanics appreciate the mechanical honesty of this approach.

Turbocharging on the OM617 demonstrated Mercedes’ engineering philosophy the turbo isn’t a device to extract maximum power but rather a tool to maintain adequate power while running at lower, more efficient engine speeds.

This conservative approach to turbo boost levels results in exceptional turbo longevity and minimal stress on engine components. Mechanics recognize that this philosophy directly contributes to the engine’s reputation for reliability, as conservative operating parameters mean lower component stress and longer service life.

The OM617’s construction quality reflects Mercedes-Benz’s manufacturing standards during this period. The engine block is cast iron with substantial wall thickness, bearing surfaces are precisely machined, and internal clearances are tight enough to maintain proper function throughout hundreds of thousands of miles.

The cylinder head design is straightforward, with conventional valve operation via pushrods, an architecture mechanics understand intuitively and service routinely without complication.

Maintenance of the OM617 is straightforward and predictable, with no particular design quirks that catch mechanics off-guard. Oil changes, filter service, fuel filter replacement, and belt changes follow conventional diesel procedures.

Mechanics appreciate that Mercedes designed the engine for practical service and maintainability components are accessible, procedures are logical, and special tools are rarely necessary.

This philosophy extends to repair procedures; when components fail, replacement is typically straightforward. The global Mercedes-Benz ownership culture means the OM617 engine benefits from worldwide community knowledge and support.

Owners and mechanics in Europe, Asia, Africa, and the Americas have accumulated centuries of collective experience maintaining these engines.

Online forums, service manuals, and community knowledge mean expertise is widely available. The OM617 exemplifies how an engine earns respect not through complexity or performance alone, but through unwavering reliability that builds trust across generations and continents.

Also Read: 5 Trucks That Farmers Trust for Life vs 5 They Avoid

5. Honda B-Series Engine (B16 & B18)

The Honda B-Series engines, particularly the B16A and B18C variants, have earned tremendous respect from mechanics and enthusiasts worldwide for their revolutionary approach to four-cylinder performance.

These compact, high-revving engines powered Honda Civic and Integra models during the 1990s and early 2000s, establishing a template for modern high-revving performance engines that influenced manufacturers globally.

Mechanics respect the B-Series for demonstrating how to extract maximum performance from modest displacement through engineering precision.

The B-Series engines exemplified Honda’s philosophy of “maximum performance from minimum displacement.” The B16A produced 170 horsepower from just 1.6 liters, achieving a power-to-displacement ratio that seemed remarkable in the 1990s.

This efficiency wasn’t achieved through excessive turbocharging or other forced-induction methods but rather through exceptionally high redline the B16A could safely operate to 8,000 RPM, and beyond in modified forms.

Mechanics respect how Honda achieved this through precision engineering rather than brute force approaches. The B-Series valve-train design demonstrates mechanical excellence that mechanics recognize immediately.

Honda employed a dual-stage intake valve lift system in certain markets, where intake valves would open to partial lift at lower engine speeds for improved low-end torque, then transition to full lift at higher RPMs for better high-RPM breathing.

This elegant mechanical solution accomplished without electronics in base engines exemplifies engineering sophistication that mechanics deeply respect. The system improved performance across the RPM range without adding complexity.

Durability of well-maintained B-Series engines is exceptional, with countless examples exceeding 200,000 miles with original engines and hundreds of examples reaching 300,000-plus miles.

This reliability surprises people unfamiliar with Honda’s engineering philosophy high redline doesn’t necessarily mean fragility if internal components are properly engineered. Mechanics respect the B-Series because it proves that high-revving engines can be reliable when designed with proper tolerances, materials, and stress analysis.

The B-Series engine influenced an entire generation of aftermarket tuners and enthusiast mechanics who cut their teeth learning engine modification and performance tuning on these vehicles.

Countless professional mechanics began their careers in tuning shops working on B-Series engines, learning principles that apply across automotive platforms.

This cultural influence means respect for the B-Series extends beyond the engines themselves into the mechanics and enthusiasts who learned fundamental performance engineering through B-Series modification and tuning.

6. Volvo B230 Engine

The Volvo B230 engine, produced from 1984 through the early 2000s, earns substantial respect from mechanics worldwide for its reputation as an extraordinarily reliable and durable powerplant.

This 2.3-liter naturally-aspirated four-cylinder engine powered Volvo sedans, wagons, and other vehicles, becoming legendary among mechanics for routinely exceeding 300,000 miles with basic maintenance.

The B230 exemplifies how sound engineering and conservative design philosophy create engines that transcend their original applications and remain respected decades after production ends.

Mechanics respect the B230 first for its exceptional longevity and the consistency of its reliability. While some engines are occasionally bulletproof while others fail early, B230 engines demonstrate remarkable uniformity the vast majority achieve at least 250,000 miles, with many surpassing 400,000 miles.

This consistency indicates fundamental soundness in design rather than luck. Volvo engineered this engine for durability first and foremost, which explains why mechanics around the world view the B230 with genuine affection born from reliable performance.

The B230 engine block is cast iron with substantial wall thickness and conservative internal stress levels. The crankshaft and connecting rods are forged steel, components built to handle continuous operation without catastrophic failure.

Bearing surfaces are precisely machined, and Volvo’s manufacturing standards ensured tight tolerances throughout engine construction.

These design choices increase manufacturing costs compared to budget engines, but Volvo’s engineering philosophy prioritized reliability over profit maximization.

Volvo’s approach to turbocharging the B230 demonstrates engineering philosophy that mechanics recognize and respect. The turbo variant maintains conservative boost levels, keeping combustion pressures within the engine’s design envelope rather than extracting maximum power at the cost of reliability.

The turbocharged B230 produces reliable power while maintaining the engine’s fundamental durability characteristics. This conservative approach to performance enhancement means the engine responds predictably to maintenance and doesn’t surprise mechanics with premature failures.

Volvo’s global reach during the B230’s production years means this engine operates worldwide in countless vehicles, giving mechanics across continents direct experience with its reliability.

European mechanics, North American technicians, and technicians throughout Asia and beyond have collectively maintained hundreds of thousands of B230 engines.

This global distribution of vehicles and diversity of operating conditions have proven the B230’s ability to function reliably in virtually any automotive application, from luxury sedans to cargo vehicles and performance applications.

7. Mazda 13B Rotary Engine

The Mazda 13B rotary engine represents a unique engineering approach that earns respect from mechanics for entirely different reasons than piston engines.

Produced from 1974 through 2012 and powering RX series vehicles, the rotary engine’s continuation across nearly four decades speaks to its fundamental appeal and Mazda’s commitment to this technology.

Mechanics respect the 13B for its innovative design, remarkable power-to-displacement ratio, and the challenge it presents to those who service it. The rotary engine’s fundamental design diverges radically from conventional piston engine architecture.

Rather than pistons moving linearly, an epitrochoidal rotor spins within a specially-shaped chamber, creating four combustion events per complete rotor revolution.

This produces extremely smooth power delivery with minimal vibration, something immediately apparent to anyone familiar with how rotary-powered vehicles feel.

Mechanics respect how Mazda’s engineers achieved this smoothness through elegant design rather than complex mechanical solutions.

Power output from the 13B’s 1.3-liter displacement is remarkable, with the engine producing 280 horsepower in its final form a power-to-displacement ratio that rivals turbocharged four-cylinder engines.

This efficiency stems from the rotary’s ability to operate at extremely high RPMs safely; redlines around 9,000 RPM were common. Mechanics recognize this as an engineering achievement that challenges conventional assumptions about engine design.

The high-revving rotary proved that innovative architecture could deliver performance impossible with traditional piston engines of equivalent displacement.

Mazda’s recent announcement that rotary technology would return in future vehicles suggests this unique engine architecture will continue to earn respect from coming generations of mechanics.

The 13B represents a legacy of engineering confidence in pursuing unconventional solutions to performance and efficiency challenges.

Mechanics worldwide respect Mazda for maintaining a commitment to rotary technology despite pressure to standardize on piston engine architecture.

This loyalty to innovative engineering through nearly fifty years represents a commitment to technical excellence that transcends conventional practices.

8. BMW M10 Engine

The BMW M10 four-cylinder engine, produced from 1961 through the 1980s, earns significant respect from mechanics worldwide for its longevity, reliability, and foundational importance to BMW engineering.

This compact 1.5-to-2.0-liter engine powered numerous BMW 2002 models and became the basis for BMW’s early performance reputation.

Mechanics respect the M10 for demonstrating how thoughtful engineering creates engines that transcend their original applications and remain respected decades after production ends.

The M10 engine block is constructed from aluminum alloy with exceptional precision and quality control standards. This lightweight construction helped BMW achieve class-leading performance and handling during the 1960s and 1970s when the 2002 models were among the most engaging driver’s cars available.

Mechanics recognize that the aluminum construction required precise engineering to achieve the necessary durability; the block walls are thick enough to handle years of service without distortion or failure.

Mechanical simplicity characterizes the M10 design in ways mechanics instinctively respect. The overhead cam valve-train uses straightforward mechanical principles with no unnecessary complexity.

The fuel injection system in later models is mechanical rather than electronic, meaning diagnosis and repair follow logical mechanical principles that experienced mechanics can troubleshoot without computer assistance.

This simplicity extends through the entire engine there are few mysterious failures or complex computer codes to confound mechanics. The M10 laid technical foundation for BMW’s evolution into a performance-focused manufacturer.

The experience Bavarian engineers gained developing this engine informed subsequent designs that powered BMW’s rise to prominence in the global automotive performance market.

Mechanics recognize the M10 as representing a crucial moment in automotive history, where German engineering discipline created an engine that set performance standards for an entire class of vehicles and influenced automotive development for decades.

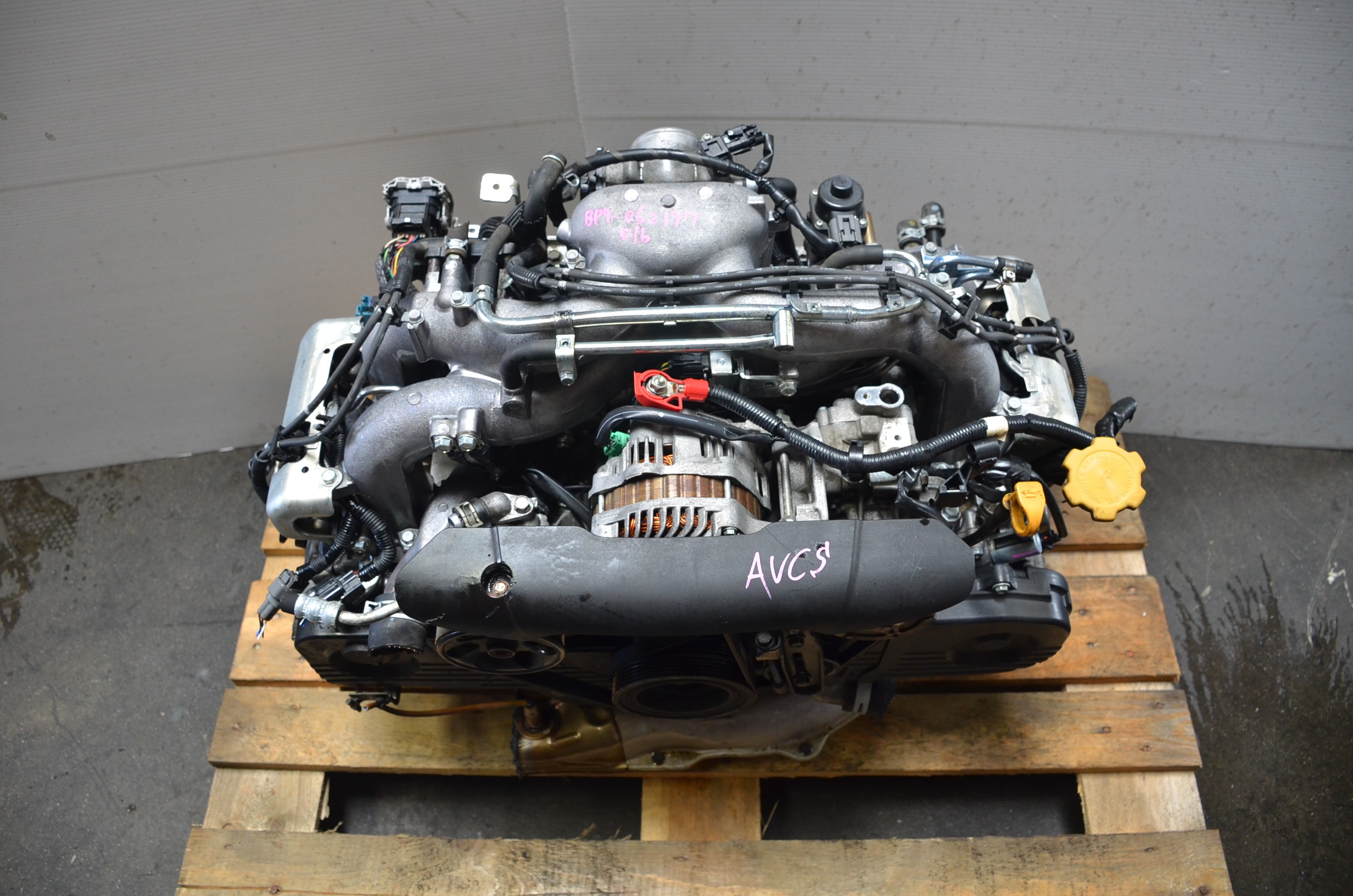

9. Subaru EJ25 Engine

The Subaru EJ25 2.5-liter boxer engine earns widespread respect from mechanics for its remarkable reliability, distinctive architecture, and proven longevity across millions of vehicles.

Produced from 1996 through early 2000s and later re-engineered for subsequent generations, the EJ25 powered Subaru Outback, Legacy, and Forester models, becoming an icon for dependability in all-wheel-drive vehicles.

Mechanics respect the EJ25 for consistently delivering reliable service across diverse operating conditions and climates. The EJ25’s horizontally-opposed configuration provides advantages mechanics immediately recognize.

The boxer architecture creates inherently balanced engine operation, as opposing pistons move in opposite directions, achieving perfect primary and secondary balance.

This results in smooth power delivery with minimal vibration, something immediately apparent to mechanics accustomed to conventional V6 or inline-four engines.

The boxer configuration also maintains a low center of gravity, contributing to Subaru’s reputation for vehicle handling and all-wheel-drive capability.

Reliability of the EJ25 has proven exceptional, with countless examples achieving 200,000-plus miles and many reaching 300,000 miles or beyond with proper maintenance.

This reliability is remarkably consistent across different model years and applications, indicating fundamental soundness in design. Mechanics worldwide have extensive experience maintaining EJ25 engines in Outback, Legacy, and Forester vehicles, accumulating knowledge that shows these engines respond well to consistent maintenance with few premature failures.

The global Subaru owner culture means the EJ25 benefits from worldwide community knowledge and support. Subaru’s success in markets worldwide means EJ25 engines operate in diverse climates and conditions from arctic regions to tropical environments, high altitude to sea level, with consistent reliability statistics across all conditions.

This geographic and climatic diversity makes EJ25 reliability statistics particularly impressive; the engine proves itself dependable in virtually any automotive operating condition.

10. Ford LS-Series Engine

The Ford LS-series engine family, particularly the LS3, earns tremendous respect from mechanics worldwide for its exceptional engineering, reliability, and revolutionary approach to large-displacement V8 technology.

Originally developed for General Motors, the LS architecture has influenced automotive industry thinking globally. However, Ford’s adoption of LS-derived technology for their GT supercars and performance applications demonstrates the universal respect this engine design commands among automotive engineers and mechanics.

The LS engine architecture revolutionized V8 design by dramatically increasing displacement while maintaining compact physical dimensions.

The LS3 produces 430 horsepower from 6.2 liters through engineering sophistication rather than exotic materials or extreme operating parameters.

Mechanics respect how this efficiency was achieved through computer-optimized combustion chambers, advanced fuel injection systems, and precision manufacturing standards that ensure consistent performance across production runs.

Reliability of LS engines has proven exceptional, with countless performance applications successfully operating at horsepower levels far exceeding stock specifications.

The engine block and internal components are engineered with sufficient margin to accommodate significant horsepower increases without immediate failure.

Mechanics have observed LS engines reliably producing 600, 700, and even 800-plus horsepower in supercharged and turbocharged applications, testament to the fundamental soundness of the original design.

Maintenance of LS engines follows conventional procedures that mechanics understand intuitively. Oil changes, filter service, fluid replacement, and belt service follow established patterns.

The engine uses proven technologies fuel injection, computer engine management, conventional valve-train that mechanics of any experience level can service competently.

Diagnostic procedures utilize industry-standard equipment and software, meaning LS engine problems can be diagnosed and corrected efficiently in virtually any service facility.

11. Diesel Mercedes-Benz OM646 Engine

The Mercedes-Benz OM646 diesel engine, powering modern Mercedes-Benz models from the early 2000s onward, earns substantial respect from mechanics for representing contemporary diesel engineering excellence.

This 2.0-to-3.0-liter common-rail turbodiesel demonstrates how modern technology, when engineered thoughtfully, creates engines that achieve remarkable durability and reliability.

Mechanics respect the OM646 for continuing Mercedes-Benz’s legacy of engineering diesels that operate reliably for decades and hundreds of thousands of miles.

The OM646’s common-rail fuel injection system represents a fundamental advancement in diesel technology that mechanics recognize immediately.

Fuel pressure is maintained at extremely high levels in a central rail, with electronic control systems directing fuel to injectors with precision timing and duration.

This system achieves optimal combustion conditions at all engine speeds and loads, improving efficiency, reducing emissions, and enhancing performance compared to earlier mechanical injection systems. Mechanics appreciate how this technology improves both reliability and environmental responsibility.

Electronic engine management on the OM646 is sophisticated, employing numerous sensors to monitor engine operation and adjust parameters continuously

While this complexity means modern diagnostic tools are necessary for comprehensive service, mechanics recognize that the systems are logically designed and well-integrated.

Mercedes-Benz provides extensive documentation and training support, and independent mechanics have developed competency with OM646 diagnostics through continuous learning and experience.

The OM646 represents how modern technology, when engineered with quality and durability as foundational principles, creates engines that equal or exceed earlier mechanical designs in practical reliability.

This engine demonstrates that electronic complexity doesn’t necessarily mean reduced durability if systems are designed, manufactured, and maintained thoughtfully. Mechanics respect this engine for proving that sophisticated technology and exceptional reliability are compatible objectives.

12. Toyota 1JZ-GTE Engine

The Toyota 1JZ-GTE 2.5-liter twin-turbocharged inline-six engine earns tremendous respect from mechanics worldwide as a masterpiece of 1990s turbocharged engineering.

Produced from 1992 through the early 2000s and powering Toyota Mark II, Chaser, and Cresta models primarily in the Japanese market, the 1JZ-GTE became legendary among tuners and performance enthusiasts.

Mechanics respect this engine for its extraordinary potential, reliability under stress, and engineering excellence that enabled countless high-performance applications.

The 1JZ-GTE represents Toyota’s response to Nissan’s RB26DETT engine in the legendary Japanese automotive performance rivalry. While the 1JZ-GTE never achieved the international prominence of the 2JZ-GTE, many mechanics consider it an equal or superior engineering achievement.

The engine produces 280 horsepower in stock form, though this conservative figure dramatically understates the engine’s potential. Toyota’s legendary understating of power figures meant actual performance exceeded official specifications considerably.

The sequential twin-turbo system on the 1JZ-GTE demonstrates engineering sophistication that mechanics recognize immediately. The primary turbo handles low-and-mid-range boost, while the secondary turbo engages at higher engine speeds, creating a smooth power delivery across the entire RPM range.

This system required precise engineering, sophisticated sequencing mechanisms, and manufacturing precision that reflects Toyota’s technical capabilities.

Mechanics respect how this system functions reliably while delivering consistent boost pressure. The 1JZ-GTE represents a legacy of engineering confidence in complex systems executed with precision and attention to detail.

Mechanics respect this engine for proving that sophisticated technology, when designed and manufactured with quality as paramount, creates engines that survive abuse better than simpler, less precisely engineered designs. The 1JZ-GTE’s enduring reputation reflects direct observation of its reliability in demanding performance applications over decades.

Also Read: 5 SUVs That Refuse to Rattle Inside vs 5 That Sound Old Too Soon