Diesel engines have long been the workhorses of America powering everything from pickup trucks to heavy-duty commercial haulers.

Known for their torque, fuel efficiency, and durability, a good diesel engine can serve you faithfully for hundreds of thousands of miles.

But as any experienced owner knows, not all diesels are created equal. While some start up reliably even on freezing mornings, others can turn ownership into an ongoing mechanical headache.

Below, we break down five diesel engines that have earned legendary reputations for reliability, and five that are known for their chronic failures so you know exactly which ones deserve your trust and which ones to avoid.

Diesel Engines That Start Every Time

Diesel engines have a reputation for toughness, longevity, and raw power, but their true test lies in reliability. For drivers who can’t afford a morning delay or a roadside hiccup, a diesel engine that starts every time isn’t just convenient, it’s peace of mind.

In this article, we highlight the diesel engines that have earned a reputation for unwavering dependability, even in the harshest conditions, giving owners confidence that their vehicle will fire up no matter what.

1. Cummins 6.7L Turbo Diesel (Ram Trucks)

The 6.7-liter Cummins turbo diesel is one of the most respected names in American trucking for good reason. Found in Ram 2500 and 3500 pickups, this inline-six delivers enormous torque while maintaining impressive longevity.

Owners often report crossing 300,000 miles with routine maintenance. The high-pressure common-rail injection system provides smooth performance and quick cold starts even in sub-zero temperatures, something older diesels struggled with.

The engine’s cast-iron block and simple inline design make it easier to service than competing V8 diesels. Whether you’re towing a fifth wheel through Colorado or idling through city traffic, the 6.7L Cummins rarely misses a beat.

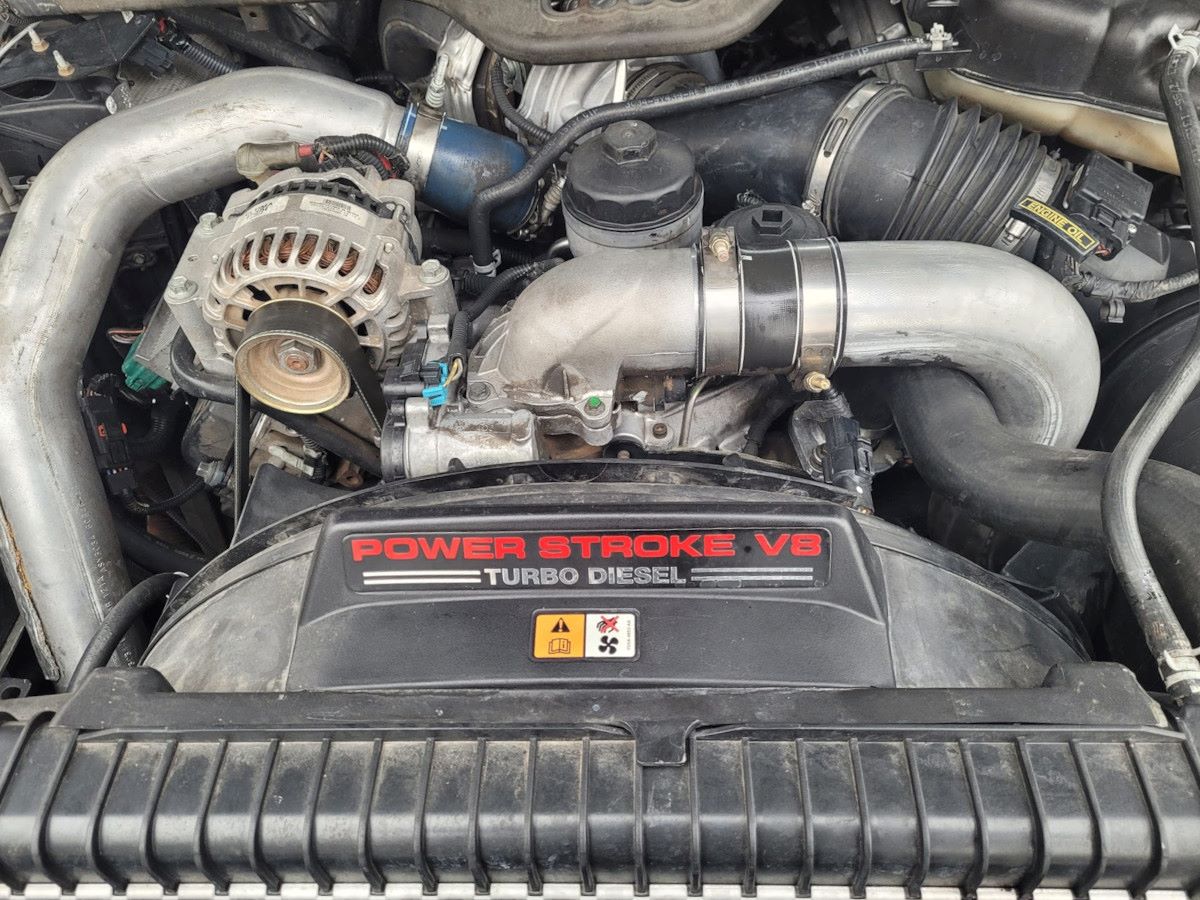

2. Ford 7.3L Power Stroke (1999–2003 Super Duty)

Ask any diesel enthusiast which engine “just works,” and the 7.3 Power Stroke will be mentioned immediately.

Produced from 1999 to 2003, this legendary V8 diesel earned a reputation for being almost bulletproof. It’s not the most powerful diesel by modern standards, but it’s incredibly dependable.

The 7.3L’s mechanical simplicity, combined with strong internals and a lack of complex emissions systems, means it avoids many of the problems that plague later diesels.

Cold starts, even in the dead of winter, are rarely a problem thanks to robust glow plugs and reliable fuel delivery.

Many 7.3-equipped trucks are still running strong today, proving that durability sometimes beats outright horsepower.

The 2000 Ford F-250 is a 4-door truck with a base MSRP of $33,825.00 and comes with a 3-year / 36,000-mile warranty. It is powered by a V-8 7.3L diesel engine with OHV valve configuration, producing 235 HP at 2,700 rpm and 500 ft-lb of torque at 1,600 rpm.

The engine has a displacement of 444 ci (7,300 cc), an oil capacity of 15.0 quarts, and uses 15W-40 as the recommended oil. This powertrain is paired with a 4-speed automatic transmission.

Fuel economy is rated at 13 mpg in the city and 17 mpg on the highway, and the vehicle has a curb weight of 6,085 lbs. The F-250 comes with 225/70R19 tires and dual hydraulic disc brakes on both the front and rear.

It has a total seating capacity of six people and a fuel tank capacity of 29 gallons. The driveline is available with an optional 4X4 system and can offer up to two driveline modes. For lighting, it uses 9007 headlight bulbs.

In terms of dimensions, the 2000 F-250 measures 245.8 inches in length, 95.5 inches in width, and 78.1 inches in height, with a wheelbase of 156.2 inches and a ground clearance of 7.0 inches.

It has a tongue hitch weight of 2,000 lbs and a maximum towing capacity of 14,500 lbs. Overall, the 2000 Ford F-250 combines robust diesel power, substantial towing capabilities, and a spacious cabin, making it a reliable option for both work and utility purposes.

Also Read: 5 Pickup Trucks That Always Sell for Top Dollar vs 5 That Don’t

3. Duramax 6.6L LBZ (2006–2007 Chevrolet/GMC HD Trucks)

Before emissions regulations complicated diesel design, GM struck gold with the LBZ Duramax. Produced for just two years, this engine is widely regarded as the most reliable of the Duramax family.

The LBZ featured a stronger block, improved injectors, and an upgraded turbo system all contributing to both power and dependability.

Owners often boast about trouble-free startups and smooth performance even after years of towing and hauling. The lack of a diesel particulate filter (DPF) means fewer clogged systems and better cold-weather reliability.

The LBZ remains a sought-after engine among diesel truck buyers who want a modern yet dependable workhorse.

The 6.6L Duramax LBZ was a short-lived generation of the Duramax 6600, introduced for the 2006 model year and retired midway through 2007.

Mechanically, it was identical to its predecessor, the 2006 LLY, but the LBZ was calibrated for higher horsepower and torque outputs, producing a peak of 360 horsepower and 650 lb-ft of torque, compared to the LLY’s 310 horsepower and 605 lb-ft.

The LBZ was notable for being the first Duramax diesel offered in the GMC Savana and Chevrolet Express 2500/3500 vans. For the 2006 model year, a six-speed manual transmission was offered alongside the Allison six-speed automatic; however, the manual transmission was discontinued in 2007, leaving the Allison 1000 as the sole transmission available for the Sierra and Silverado.

Chevrolet Express and GMC Savana vans, which featured a significantly detuned version of the Duramax diesel, were equipped only with a GM 4L85E four-speed automatic transmission.

The LBZ Duramax was ultimately phased out mid-2007 due to its inability to meet stricter Federal emissions regulations. Its successor, the LMM, incorporated an advanced exhaust aftertreatment system that included a soot-capturing diesel particulate filter.

Despite its relatively short production run, the LBZ gained popularity among performance enthusiasts due to its strengthened engine design, extensive aftermarket support, and comparatively high factory output.

It was used in 2006–2007 Chevrolet Silverado 2500 HD and 3500 HD, GMC Sierra 2500 HD and 3500 HD, Chevrolet Express 2500 and 3500, GMC Savana 2500 and 3500, Chevrolet Kodiak, and GMC TopKick.

The engine had a displacement of 6.599 liters (nominally 6.6 liters) or 402.62 CID (403 CID nominal) with a 90-degree V-8 configuration. Bore measured 4.055 inches (103 mm) with a stroke of 3.897 inches (99 mm), giving a bore/stroke ratio of 1.04, making it slightly oversquare.

The compression ratio was 16.8:1, and the firing order followed 1-2-7-8-4-5-6-3. Cylinders 1, 3, 5, and 7 were located on the passenger side bank, while cylinders 2, 4, 6, and 8 were on the driver side bank.

The engine block was made of cast gray iron, induction hardened with a deep skirt design, and the cylinder heads were cast aluminum alloy.

Fuel delivery employed a Bosch high-pressure common rail direct injection system with piezoelectric seven-hole fuel injectors and a Bosch CP3 (CP3.3) injection pump, capable of a maximum injection pressure of 26,000 psi.

The LBZ featured turbocharging with an air-to-air intercooler, using a water-cooled Garrett GT3788VA variable vane turbocharger (VVT). Minimum cylinder pressure during compression testing was 300 psi.

The reciprocating assembly included fracture-split forged alloy steel connecting rods, a nitrided forged steel crankshaft, a forged steel camshaft, and cast iron main bearing caps.

Valvetrain configuration was overhead valve (OHV) with a standard cam-in-block and mechanical roller lifters, providing four valves per cylinder (32 valves total). Cold starts were assisted by a traditional glow plug system, with one glow plug per cylinder. Engine oil capacity was 10 quarts, including an oil filter change.

4. Mercedes-Benz OM617 (1970s–1980s)

While modern diesels dominate the truck world, the OM617 stands as a symbol of reliability in passenger cars. Found in classic Mercedes models like the 300D and 300SD, this 3.0-liter inline-five diesel is legendary for starting up after decades of use.

Owners frequently recount stories of these engines surviving 400,000 to 500,000 miles with minimal internal repairs.

Its cast-iron construction, mechanical fuel injection, and absence of complex electronics make it nearly indestructible.

The OM617 isn’t fast, but it’s consistent starting up in freezing German winters or hot Texas summers with equal ease. It’s proof that reliability is timeless.

5. Caterpillar C15 (Heavy-Duty Trucks)

In the world of big rigs, few engines earn as much respect as the Caterpillar C15. Built for long-haul trucking, the C15 is known to keep running even when neglected.

Its massive displacement and conservative tuning mean it doesn’t stress components the way more modern, high-strung engines do.

Truckers praise it for dependable starts in all conditions and minimal downtime. The C15 can easily surpass one million miles with proper maintenance.

While emissions-era versions of the Cat engines had some issues, the pre-2007 C15s remain iconic examples of diesel reliability that still populate highways today.

If you’re looking at heavy-duty diesel engines, the Caterpillar C15 is likely one of the first names you’ve come across.

This powerhouse has been hauling America’s freight for decades, earning a reputation among mechanics and truckers alike for reliability and performance.

Whether you’re considering a truck with a C15 engine, searching for parts, or simply curious about what makes it tick, it’s worth understanding why this engine continues to earn respect.

At FridayParts, we’ve supplied C15 parts for years, hearing every story, fixing every problem, and answering every question about these engines. So let’s take a closer look at what makes the C15 special and what you really need to know about it.

The Caterpillar C15 is not just another diesel engine, it is the evolution of CAT’s legendary 3406E, built between 1999 and 2007. CAT engineers designed this 15.2-liter inline-6 cylinder engine to handle anything the road could throw at it. One of the defining features of the C15 is its ACERT technology.

While the term sounds technical, the system essentially allows the engine to meet emissions standards without sacrificing power.

Depending on the version, the C15 produces between 435 and 625 horsepower and 1,550 to 2,050 lb-ft of torque, providing more than enough muscle to haul 80,000 pounds up steep grades with ease.

The engine block is made from gray iron with a deep skirt design, giving it exceptional strength to withstand high stress without cracking. Its cylinder head employs a four-valve design, allowing the engine to breathe more efficiently. This improves both fuel economy and power delivery when you need it most.

For those focused on specifications that really matter, the C15 has a bore of 5.4 inches and a stroke of 6.75 inches, resulting in its 15.2-liter displacement. The compression ratio sits at 18:1, optimized for diesel efficiency.

In real-world conditions, most drivers can expect fuel consumption between 5.5 and 7 miles per gallon, depending on load and driving conditions.

The engine weighs approximately 3,090 pounds dry, has an oil capacity of 10.5 gallons, a coolant capacity of 11.5 gallons, and operates between 1,200 and 2,100 RPM, with peak torque available at 1,200 RPM.

The C15 is equipped with a single turbocharger with wastegate control on most models, though some versions featured twin turbos. Fuel systems vary depending on the year: early models use HEUI (Hydraulically Actuated Electronic Unit Injection), while later models adopted common rail injection.

Both systems perform well but require different maintenance approaches. One standout feature of the C15 is its Jake brake capability. When descending a mountain with a full load, this engine brake can save wear on your service brakes—and potentially lives.

The C15’s compression release brake can provide up to 600 braking horsepower, offering tremendous stopping power for trucks carrying 40 tons of cargo.

Also Read: 8 SUVs That Sell for Top Dollar After 15 Years

Diesel Engines That Constantly Fail

While diesel engines are often celebrated for their durability and power, not all of them live up to the hype. Some models have earned a reputation for constant breakdowns, frustrating owners with reliability issues, expensive repairs, and endless maintenance headaches.

In this article, we dive into the diesel engines that consistently fail, helping buyers and enthusiasts steer clear of trouble before it starts.

1. Ford 6.0L Power Stroke (2003–2007)

After the legendary 7.3L, Ford’s 6.0L Power Stroke was supposed to be the next evolution but it turned into one of the most problematic diesels ever made.

Designed under tight emissions pressure, the 6.0L introduced features like EGR cooling and variable geometry turbos that often failed.

Head gasket issues, oil cooler failures, and turbo problems were common, especially when the engine was pushed hard.

Cold-start issues also plagued owners, with some trucks requiring extensive repairs before reaching even 150,000 miles.

Many owners resorted to “bulletproofing” their engines an expensive process that replaced weak components just to make them reliable.

2. GM 6.5L Turbo Diesel (1992–2000)

Before the Duramax era, GM’s 6.5L diesel was the mainstay for Chevrolet and GMC trucks but it wasn’t a strong one.

The electronically controlled injection pump, known as the DS4, was notoriously unreliable, especially under heat. Drivers often experienced stalling, hard starts, and failure to crank at all.

While these engines could be coaxed to run with aftermarket upgrades, they lacked the strength and efficiency of later models.

For anyone seeking dependable cold starts or long-term reliability, the 6.5L remains one of the least desirable diesel options ever offered in a light-duty truck.

The 6.5L Detroit Diesel engine was introduced in 1992 as the upgraded successor to the 6.2L Detroit Diesel, marking the second collaboration between Detroit Diesel and General Motors.

While most 6.5L engines were equipped with a turbocharger to enhance performance, some naturally aspirated versions were also produced. The engine featured an emission control system and was praised for its excellent fuel economy, even with turbocharging.

Throughout its production run, the 6.5L Detroit Diesel was used in a wide range of vehicles, from pickup trucks to vans and SUVs.

Its applications included the Chevrolet Blazer, Chevrolet Tahoe, Chevrolet K Series (1500, 2500, and 3500), Chevrolet C-3500HD, Chevrolet Suburban, Chevrolet C/K, Chevrolet Vans, GMC Yukon, GMC Suburban, GMC C/K, GMC C-3500HD, GMC Vans, Holden Suburban, AM General Hummer H1, and the AM General HMMWV.

The 6.5L Detroit Diesel came in several variants, including L49, L56, L57, L65, LQM, and LQN. The L56 variant was turbocharged and featured an emission control system, making it suitable for half-ton and lightweight three-quarter-ton trucks.

Most one-ton and heavy-duty three-quarter-ton trucks used the turbocharged L65, which included a soot trap to reduce exhaust emissions.

Both L49 and L57 were naturally aspirated. Some engines included additional emission control systems such as EGR and catalytic converters, depending on the variant.

Horsepower and torque varied across the different variants, with output ranging from 180 to 215 horsepower and 360 to 540 lb-ft of torque, depending on whether the engine was turbocharged or naturally aspirated.

The most popular versions were the turbocharged L56 and L65, which were commonly used in half-ton, three-quarter-ton, and one-ton pickups.

In 1999, AM General acquired the manufacturing rights to the 6.5L Detroit Diesel and continued producing the engine for the HMMWV even after Detroit Diesel discontinued the engine in 2002.

3. Navistar DT466E (Late 1990s–2000s)

Though the mechanical DT466 is celebrated for its durability, the electronic DT466E introduced in the late ‘90s had serious reliability problems.

Its injection system depended on precise electronic controls that were prone to failure, particularly under fleet conditions.

The result? Hard starts, loss of power, and frequent injector replacements. The electronic fuel control modules were also expensive and hard to diagnose, frustrating both drivers and mechanics.

For school buses and medium-duty trucks that used this engine, downtime became all too common.

4. BMW N47 2.0L Diesel (Europe/US Imports)

While not as common in American trucks, the N47 engine found in imported BMW diesels like the 328d and X5 diesel gained a notorious reputation.

The primary failure point is its timing chain located at the back of the engine, making it extremely difficult (and expensive) to service.

When the chain starts to stretch or fail, owners experience poor starting, rough idling, and eventually catastrophic engine failure.

While efficient and smooth when new, the N47’s design flaw means it rarely lives up to the diesel reputation for longevity or dependability.

The N47 engine was introduced in 2007 as a worthy successor to the previous M47 generation. It powered various versions of the BMW E87 and E81 models. The N47 is a turbocharged four-cylinder diesel engine with a 16-valve configuration.

Its most notable upgrade over the M47 was the addition of a lightweight aluminum cylinder block with cast-iron liners, as well as the use of two overhead camshafts. Each cylinder has a diameter of 84 mm and four valves.

Inside the block, the connecting rods and crankshaft operate with a piston stroke of 90 mm and a piston height of 47 mm, resulting in a compression ratio of 16.5:1. The intake valves measure 27.2 mm in diameter, while the exhaust valves are 24.6 mm with a stem thickness of 5 mm.

This 2.0-liter engine employs a Common Rail injection system operating at pressures up to 2,200 bar, with electromagnetic injectors and a turbocharger.

The earliest versions of the N47, producing between 116 and 143 horsepower, were equipped with a Garrett GTB1749VK turbine. The timing chain is positioned at the rear of the engine.

Fuel consumption varies between 4.9 and 6.8 liters per 100 kilometers. This inline four-cylinder engine features a cylinder diameter of 84 mm and four valves per cylinder.

The compression ratio remains 16.5:1, with a piston stroke of 90 mm. The engine employs high-precision Common Rail fuel injection and produces CO₂ emissions between 116 and 191 g/km.

Depending on the version, the N47 features twin turbocharging or standard turbocharging, and some models come equipped with an optional start-stop system.

Overheating poses another concern, as excessive temperatures may cause cracks to form between the cylinders. To prevent such damage, maintaining fuel and oil quality is crucial, only the manufacturer-recommended lubricants should be used.

Routine inspections every 15,000 kilometers are advised to ensure reliability. With proper maintenance, timely replacement of components, and use of quality fluids, the N47 engine can achieve a service life of up to 300,000 kilometers.

5. Dodge 5.9L Cummins ISB 24-Valve (1998–2002)

This one might surprise some diesel fans because the Cummins name is often synonymous with reliability. However, the 24-valve ISB version from the late ‘90s introduced the VP44 injection pump a unit infamous for early failures.

These pumps were extremely sensitive to fuel quality and electrical issues, leading to frequent hard starts or no-start conditions.

While the mechanical components of the engine were solid, the electronics surrounding it often let owners down. Many trucks were eventually converted to aftermarket systems just to keep them reliable.

Diesel ownership in the U.S. is all about choosing the right engine one that delivers power without constant worry.

Models like the Cummins 6.7L, Ford’s 7.3L Power Stroke, and the LBZ Duramax have earned their status as legends because they start every time and keep running no matter the conditions.

On the other hand, engines like Ford’s 6.0L Power Stroke and GM’s 6.5L Turbo Diesel serve as cautionary tales of how complicated designs and weak components can ruin a diesel’s reputation.

When shopping for a diesel-powered vehicle whether it’s a used pickup, a highway hauler, or a European import understanding these histories can save you thousands in repairs and countless headaches.

In the diesel world, reliability isn’t about power figures; it’s about the confidence that when you turn the key, it’ll roar to life every single time.