Nissan is entering the expanding electrified vehicle market with its e-Power technology, which delivers a distinct driving experience compared to most hybrid systems. ProcessX on YouTube showcases how this hybrid powertrain is produced through behind-the-scenes footage from Nissan’s Yokohama Plant in Japan.

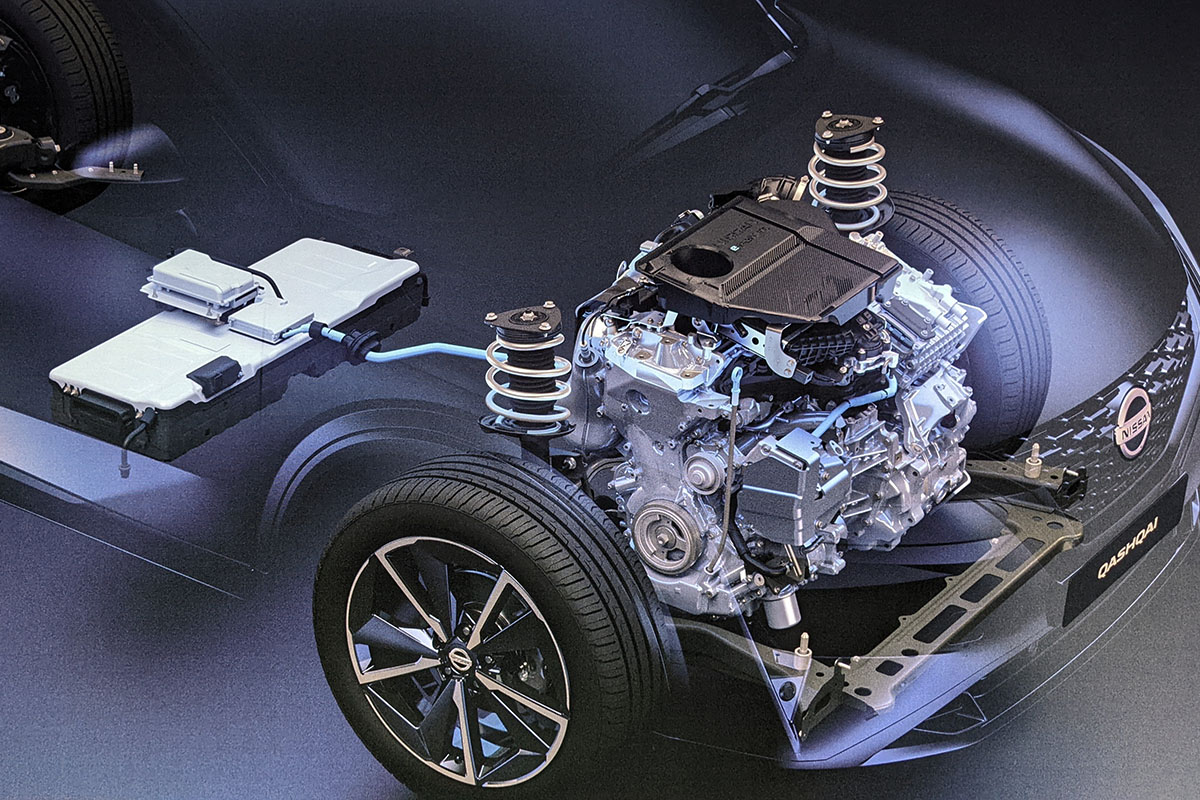

What sets e-Power apart is its configuration: the engine functions solely as a generator, while an electric motor handles all propulsion.

This gives e-Power vehicles an EV-like feel, offering immediate torque and a smooth, consistent driving character. The engine activates at certain moments, typically when recharging the battery or when the driver demands substantial power.

Nissan’s e-Power operates as a series hybrid, a layout shared by only a few mass-market models such as the quirky BMW i3 REx. Honda’s e:HEV system is frequently mistaken for a similar setup, but it only uses series mode part-time before allowing the engine to directly power the wheels at higher speeds.

Despite major manufacturers like Honda sticking with more traditional hybrid methods, Nissan stated that engine vibrations and the need for a multi-gear transmission make that approach less desirable.

The behind-the-scenes footage from ProcessX highlights the production of Nissan’s compact hatchback, the Note.

At the Yokohama Plant, the coil-winding process for the stator involves a blend of automated equipment and hands-on assembly. Workers manually complete the glass tube assembly before aligning the coil bundles with each electrical circuit.

Once ready, the stator is inserted into its housing, followed by the rotor, the part that spins due to the stator’s magnetic field, finalizing the electric motor’s core assembly.

Similarly, much of the internal combustion engine production is automated, including piston assembly and fitting the cylinder head onto the engine block.

The Note is powered by a 1.2-liter three-cylinder engine, which drives the generator supplying energy to the electric motor. This motor produces 114 horsepower and 207 lb-ft of torque.

After production, the completed e-Power units are sent to the historic Oppama Plant, where Nissan conducts full vehicle assembly.

Once assembled, each vehicle undergoes several inspections, ranging from visual evaluations to performance testing and water-intrusion checks.

Nissan has announced plans to end operations at the Oppama Plant by March 2028 as part of its cost-reduction efforts.

The Note and its e-Power system are not currently offered in the U.S. However, the Rogue will be the first American model to adopt this setup when the 2027 version arrives before the end of fiscal 2026.

Nissan also continues to offer a fully electric vehicle, the Leaf, which entered its third generation earlier this year.