Ford has built engines for more than a century, and throughout that history, certain designs have earned a reputation that goes far beyond marketing or nostalgia. These engines became trusted not because they were the most powerful or advanced, but because they simply kept running when everything else wore out.

Legendary reliability is not accidental. It usually comes from conservative engineering, strong materials, and years of real world refinement. Ford has often favored designs that could survive abuse, poor maintenance, and extreme conditions. That philosophy created engines that owners relied on for decades.

Many of Ford’s most reliable engines were never flashy. They did not chase cutting edge technology or extreme performance figures. Instead, they focused on simplicity, durability, and serviceability. That approach allowed them to rack up high mileage with minimal drama.

Another reason these engines became legends is versatility. They powered trucks, sedans, vans, and work vehicles across the globe. When an engine performs reliably in many roles, its reputation grows naturally.

Some of these engines lasted through multiple generations with only minor updates. Others became the foundation for entire engine families. In each case, real world results proved their worth far better than any brochure.

This list focuses on Ford engines known for legendary reliability, not hype or popularity. These are engines that mechanics respect, owners trust, and history has validated. Each entry explains why the engine mattered, how it performed over time, and why it earned its reputation.

No vehicles are repeated, and each engine is discussed on its own merits. These are engines that built Ford’s reputation the hard way, mile after mile.

Let us begin with one of the most durable and widely respected engines Ford has ever produced.

Also Read: 10 Classic American Cars With Incredible Horsepower Relevant Today

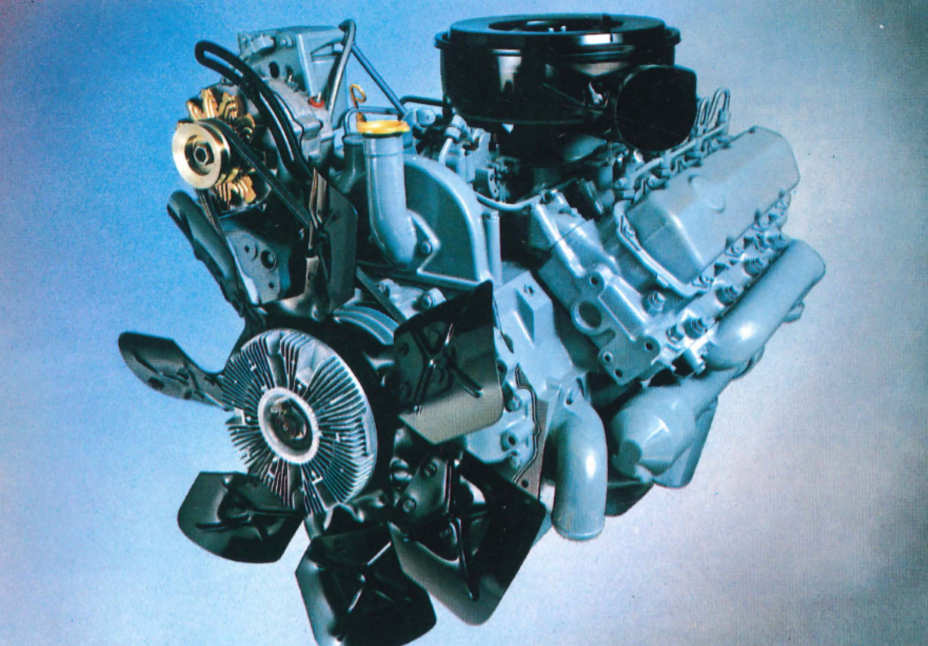

1. Ford 300 Inline-Six

The Ford 300 inline six is widely considered one of the most reliable engines ever built by Ford. Its reputation was earned through decades of hard use in trucks, vans, and work vehicles.

This engine was designed with simplicity as the top priority. The inline layout reduced complexity and made internal components easier to service and maintain.

Displacement measured 4.9 liters, which allowed the engine to produce strong low end torque. That torque made it ideal for hauling, towing, and daily work tasks.

Power output was modest, but that was never the point. The engine delivered consistent performance without stressing internal components.

One of the biggest strengths of the 300 was its thick cast iron block. It was built to handle abuse and high mileage without cracking or warping.

Internal parts were overbuilt. The crankshaft, rods, and bearings were designed to last far longer than typical service intervals.

Cooling systems were simple and effective. Overheating issues were rare, even under heavy loads.

The valvetrain design was straightforward. Fewer moving parts meant fewer failure points over time.

Fuel delivery systems were basic and dependable. Whether carbureted or fuel injected, the engine remained tolerant of imperfect conditions.

Oil consumption was typically low, even at high mileage. Many examples ran well past 300,000 miles without major internal work.

Another key factor was ease of maintenance. Mechanics appreciated how accessible everything was under the hood.

Parts availability remained excellent for decades. This kept repair costs low and encouraged long term ownership.

The engine performed reliably in extreme environments. Hot climates, cold winters, and rough terrain did little to shorten its lifespan.

What truly made the 300 legendary was consistency. It did not suddenly develop major flaws as it aged.

Even when neglected, the engine often continued running with minimal complaints. That durability built enormous trust.

Fleet operators relied on it because downtime was rare. Private owners trusted it because repairs were predictable.

The Ford 300 inline six was not exciting, but it was honest. It did exactly what it promised, every day. That dependability is why it remains one of the most respected Ford engines ever built.

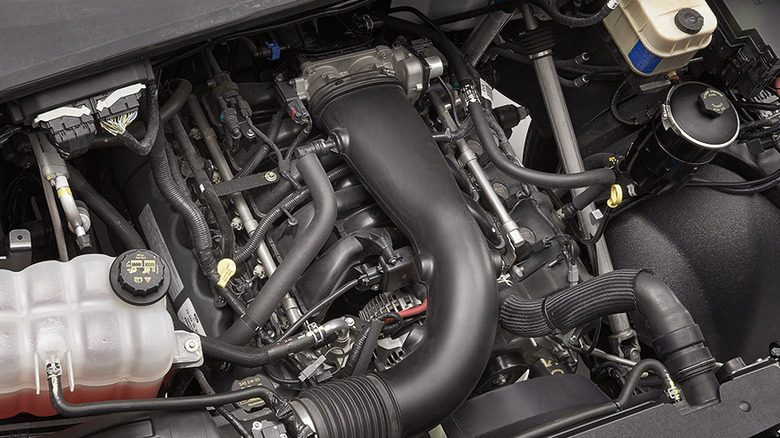

2. Ford 4.6 Modular V8

The Ford 4.6 Modular V8 earned its reputation through longevity, consistency, and widespread real world use. It became one of Ford’s most dependable engines across cars, trucks, and fleet vehicles.

Introduced as part of Ford’s modular engine family, the 4.6 was designed with durability as a core goal. It replaced older pushrod V8s with a more modern layout while keeping reliability front and center.

One of its defining strengths is conservative tuning. Ford never pushed the engine to extreme output levels, which reduced stress on internal components.

The block and heads were built to last. Strong materials and precise machining helped the engine handle high mileage without major internal failures.

Oil control is another reason the 4.6 proved so durable. Many examples ran hundreds of thousands of miles with stable oil pressure and minimal consumption.

Cooling systems were well matched to the engine’s needs. Overheating problems were rare when basic maintenance was followed.

The timing system contributed to reliability. While more complex than older designs, it proved dependable when serviced properly.

The engine tolerated daily use extremely well. Stop and go driving, highway cruising, and long idle times did not shorten its lifespan significantly.

One reason mechanics respected the 4.6 was predictability. When issues occurred, they were usually gradual rather than catastrophic.

Spark plug and ignition systems were straightforward. Repairs were simple and affordable compared to more complex engines.

The engine handled neglect better than most modern V8s. While maintenance mattered, occasional missed services did not immediately cause failure.

Another advantage was smooth operation. Reduced vibration helped preserve mounts, accessories, and surrounding components.

The 4.6 also aged gracefully. Performance did not drop sharply as mileage increased. Fleet use played a major role in proving reliability. Police departments and commercial operators relied on it daily.

Parts availability remained excellent for decades. This kept repair costs low and extended service life. The engine’s design avoided exotic materials or untested systems. That conservative approach paid off long term.

What truly made the 4.6 legendary was consistency across millions of units produced. It was not the most powerful V8 Ford ever built, but it was one of the most trustworthy.

The Ford 4.6 Modular V8 earned its reputation mile by mile, becoming a benchmark for dependable V8 design.

3. Ford 5.4 Triton V8 Two-Valve

The Ford 5.4 Triton V8 in its two valve form stands as one of Ford’s most reliable large displacement engines. While later versions faced criticism, the early two valve design proved exceptionally durable.

This engine was built for trucks and work vehicles where durability mattered more than performance numbers. That focus shaped every part of its design.

Displacement allowed the engine to deliver strong low end torque. This made it ideal for towing, hauling, and sustained load operation.

The two valve layout kept the valvetrain simple. Fewer moving parts reduced the chances of failure over time.

Internal components were designed with strength in mind. Crankshafts, rods, and pistons were built to handle heavy use.

Cooling systems were robust and forgiving. Even under demanding conditions, the engine maintained stable operating temperatures.

Oil circulation was reliable and consistent. Proper lubrication helped prevent premature wear in high mileage engines.

One of the biggest advantages was tolerance. The engine handled poor fuel quality and harsh environments better than many competitors.

Maintenance requirements were straightforward. Routine oil changes and basic service were usually enough to keep it running strong.

Spark plug issues that affected later designs were far less common in the two valve version. This contributed to its reliability reputation.

The engine was commonly used in fleet and commercial applications. High mileage examples were the norm rather than the exception.

Idle quality remained stable even as engines aged. This helped preserve accessories and drivetrain components. Another strength was predictability. Failures rarely occurred suddenly without warning signs.

The engine aged slowly. Many owners reported stable performance well past 250,000 miles. Parts availability was excellent. This made repairs affordable and encouraged long term ownership.

The design avoided unnecessary complexity. No advanced systems were added that could compromise durability.

What made this engine legendary was trust. Owners relied on it to work every day without complaint. While not refined or exciting, it delivered exactly what it promised.

The two valve 5.4 Triton became a backbone engine for Ford trucks during its era. Its reputation was earned through real work, not marketing.

The Ford 5.4 Triton V8 two valve remains one of the most dependable large V8 engines Ford has ever produced.

4. Ford 351 Windsor V8

The Ford 351 Windsor V8 is one of the most respected engines Ford ever produced. Its reputation for reliability was built over decades of use in performance cars, trucks, and work vehicles.

This engine was designed during an era when durability mattered more than efficiency targets. As a result, it was built with thick cast iron components and generous tolerances.

Displacement allowed the engine to produce strong torque without high stress. Power delivery felt relaxed and dependable rather than strained.

One of the Windsor’s biggest strengths is simplicity. The pushrod design kept the valvetrain straightforward and easy to service.

Internal components were heavily overbuilt. Crankshafts, connecting rods, and bearings were designed to survive sustained abuse.

Cooling systems were effective and forgiving. The engine handled high temperatures without frequent overheating issues.

Oil circulation was reliable. Proper lubrication helped prevent premature wear even in high mileage applications.

The engine tolerated modifications well, but it also ran reliably in stock form for decades. Many examples remained untouched internally. Fuel systems were simple and robust. Carbureted setups proved easy to maintain and adjust.

The Windsor responded well to regular maintenance but was also forgiving of occasional neglect. This helped it earn trust among owners. Idle quality remained stable over time. Even as mileage increased, the engine continued to run smoothly.

The 351 Windsor was used in demanding environments. Trucks, muscle cars, and marine applications all relied on it. Parts availability became one of its greatest advantages. Replacement components remained affordable and widely available.

Mechanics appreciated how accessible everything was. Repairs were straightforward and predictable. The engine aged gracefully. Performance degradation was slow and gradual rather than sudden.

Another reason for its legendary status is versatility. It performed reliably across many vehicle types and uses. What truly defined the 351 Windsor was balance. It delivered power, durability, and serviceability in equal measure.

Owners trusted it because it rarely failed without warning. That predictability mattered.Even today, many original examples continue running with minimal internal work.

The Ford 351 Windsor V8 earned its reputation through real world durability rather than marketing claims.

5. Ford 2.3 Lima Inline-Four

The Ford 2.3 Lima inline four is one of the most durable small displacement engines Ford ever built. Its reliability was proven through decades of use in compact cars, trucks, and industrial applications.

This engine was designed with simplicity at its core. The inline layout minimized complexity and reduced failure points. Displacement was modest, but torque delivery was consistent and usable. The engine was never overstressed.

One of the Lima’s greatest strengths is its cast iron construction. The block was thick and resistant to cracking or warping.

Internal components were built conservatively. Pistons, rods, and bearings were designed for long service life. Cooling systems were effective and uncomplicated. Overheating issues were uncommon when basic maintenance was followed.

The engine handled forced induction surprisingly well, yet remained reliable in naturally aspirated form. Fuel delivery systems were basic and dependable. Whether carbureted or fuel injected, the engine remained tolerant of wear.

Oil consumption stayed low in well maintained engines. Many examples ran well beyond 200,000 miles. The Lima engine performed reliably in harsh environments. Dust, heat, and heavy use did not significantly shorten its lifespan.

Maintenance was simple and affordable. Routine oil changes and basic service were usually enough. Idle quality remained stable over time. Even aging engines continued to run smoothly.

Another advantage was adaptability. The engine was used in cars, trucks, and even forklifts. Parts availability remained excellent for many years. This encouraged long term ownership and repairs.

Mechanics valued the engine’s accessibility. Repairs were easy to diagnose and perform. The engine tolerated neglect better than many modern designs. Missed maintenance rarely caused immediate failure.

Performance was modest, but reliability was exceptional. That tradeoff defined its purpose. What made the 2.3 Lima legendary was endurance. It kept running long after other engines failed.

Its reputation was built quietly through hard use and consistency. The Ford 2.3 Lima inline four remains one of the most trusted small engines Ford ever produced.

6. Ford 7.3 IDI Diesel V8

The Ford 7.3 IDI diesel V8 is remembered as one of the toughest and most dependable diesel engines Ford ever offered. Its reputation was built long before modern emissions systems complicated diesel ownership.

This engine was designed for durability first. Performance figures were secondary to the ability to run day after day under heavy loads.

The indirect injection design kept combustion pressures manageable. That choice reduced stress on internal components and extended service life.

Internal parts were massively overbuilt. The block, crankshaft, and rotating assembly were designed to withstand extreme use.

Torque delivery was steady and predictable. The engine did not surge or spike, which helped preserve drivetrain components.

Cooling systems were simple and effective. Overheating issues were rare even during towing or prolonged idling.

Fuel system design favored reliability. Mechanical injection components proved durable and tolerant of fuel quality variations.

Oil circulation was consistent and robust. Proper lubrication protected internal parts over very high mileage. The engine performed well in harsh environments. Heat, cold, dust, and long idle times did little to shorten its lifespan.

Maintenance was straightforward. Routine service and basic mechanical knowledge were enough to keep it running strong. One of the engine’s greatest strengths was forgiveness. It tolerated missed maintenance better than most diesel engines.

Cold starts were reliable when systems were maintained. Glow plug operation was simple and effective. The engine aged slowly. Power loss over time was minimal compared to more complex designs.

Many examples exceeded 400,000 miles without internal rebuilds. That level of longevity built legendary status. Parts availability remained strong for many years. This kept repair costs reasonable and encouraged long term ownership.

The engine’s simplicity made field repairs possible. This mattered greatly for work trucks in remote areas. What truly defined the 7.3 IDI was trust. Owners depended on it because it rarely failed without warning.

It was not fast or refined, but it was dependable in the purest sense. The Ford 7.3 IDI diesel V8 earned its reputation through endurance, not performance. Even decades later, it remains one of the most respected diesel engines Ford ever built.

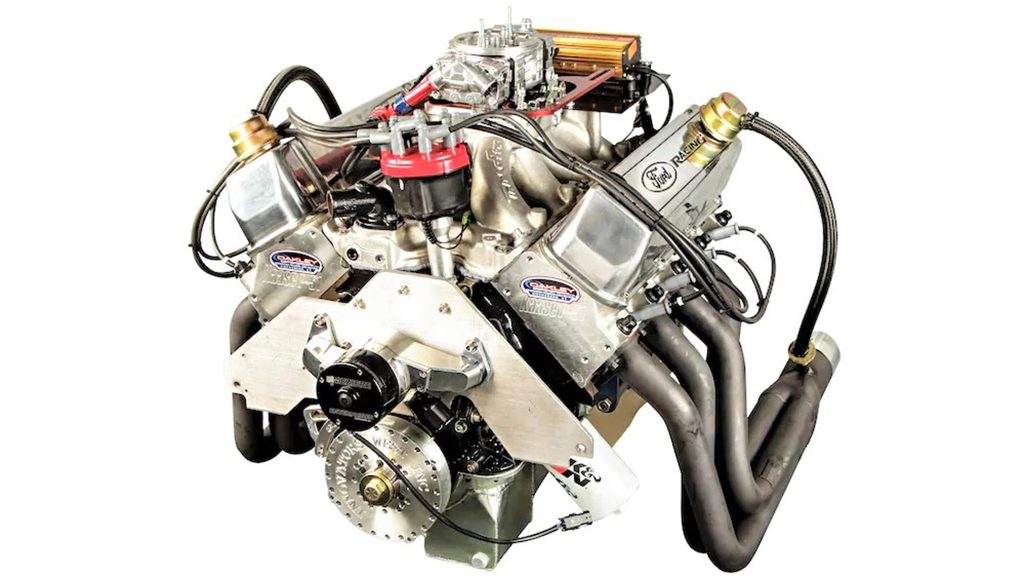

7. Ford 302 Small Block V8

The Ford 302 small block V8 stands as one of the most versatile and reliable engines in Ford history. Its longevity came from simple design and careful evolution over many years.

This engine was developed during a time when durability was prioritized. Engineering focused on long service life rather than peak output.

Displacement allowed for balanced performance and manageable stress. Power delivery was smooth and consistent. The pushrod valvetrain kept complexity low. Fewer moving parts reduced long term failure risk.

Internal components were strong and well matched. Crankshafts and bearings were designed for extended use. Cooling systems were straightforward and reliable. The engine handled heat well under varied conditions.

Fuel delivery systems evolved over time but remained dependable. Both carbureted and fuel injected versions proved durable. Oil control was excellent. Many high mileage examples maintained stable oil pressure throughout their lives.

The engine tolerated modifications well, yet also thrived in stock form. That flexibility added to its popularity. Idle quality remained stable even as engines aged. Smooth operation reduced wear on accessories.

The 302 was used across many vehicle types. Cars, trucks, and utility vehicles all relied on it. Parts availability became one of its biggest advantages. Replacement components were affordable and widely available.

Mechanics valued the engine’s accessibility. Repairs were simple and rarely required specialized tools. The engine handled daily driving and heavy use equally well. That adaptability built widespread trust.

One reason for its legendary status is predictability. Problems usually developed slowly rather than suddenly. The 302 aged gracefully. Performance degradation was gradual and manageable.

Fleet use proved its reliability repeatedly. High mileage examples became common rather than rare. What made the 302 special was balance. It delivered enough power while remaining easy to maintain.

Owners appreciated how forgiving it was. Minor neglect rarely resulted in immediate failure. The Ford 302 small block V8 earned its reputation over decades of consistent service.

8. Ford 3.0 Vulcan V6

The Ford 3.0 Vulcan V6 earned a reputation for reliability by doing everything well enough and almost nothing poorly. It was never designed to impress on paper, yet it proved itself over decades of daily use.

This engine focused on simplicity. The pushrod design kept the valvetrain compact and reduced the number of moving parts.

Displacement allowed for adequate power without stressing internal components. Performance felt relaxed and predictable rather than aggressive.

One of the Vulcan’s greatest strengths was durability. The block and internals were built conservatively to handle long service life. Cooling systems were simple and effective. Overheating problems were uncommon when basic maintenance was followed.

Oil circulation remained consistent. Many high mileage engines maintained stable oil pressure deep into their lifespan. Fuel delivery systems were straightforward and tolerant. The engine handled varying fuel quality without complaint.

Idle quality remained stable even as mileage increased. Smooth operation helped preserve mounts and accessories. The Vulcan performed well in stop and go driving. Traffic conditions did little to shorten its life.

Maintenance was inexpensive and easy. Routine service kept the engine running reliably for years. One reason for its longevity was low specific output. The engine was never pushed near its limits.

Parts availability was excellent. This made repairs affordable and encouraged owners to keep vehicles longer.

The engine tolerated neglect better than many modern designs. Missed oil changes rarely caused immediate failure. Fleet use helped cement its reputation. Taxis and service vehicles relied on it daily.

Another advantage was predictability. When issues appeared, they usually developed slowly. The engine aged gradually. Power loss over time was minimal and manageable. It did not rely on complex electronics. Fewer sensors meant fewer failure points.

The Vulcan also handled long idle times well. This mattered for commercial use. What made this engine legendary was trust. Owners rarely worried about unexpected breakdowns. The Ford 3.0 Vulcan V6 proved that modest engineering done right can outperform ambitious designs done poorly.

9. Ford 6.8 Triton V10

The Ford 6.8 Triton V10 is one of the most durable heavy duty gasoline engines Ford has ever produced. Its reliability was proven through demanding commercial and recreational use.

This engine was developed for high load operation. Motorhomes, buses, and work trucks depended on its strength. The V10 layout delivered smooth and consistent torque. Power delivery felt steady rather than abrupt.

One of the engine’s biggest strengths was robustness. Internal components were designed to handle sustained stress. Cooling systems were large and effective. Heat management remained stable even under continuous load.

Oil circulation supported long service intervals. Proper lubrication protected the engine during heavy use. Despite its size, the engine was predictable in operation. Throttle response was smooth and easy to manage.

Fuel efficiency was not its focus, but reliability was. Owners accepted consumption in exchange for durability. The engine handled long idle periods well. This mattered greatly for commercial applications.

Maintenance requirements were straightforward. Routine service kept the engine operating reliably. Spark plug issues that affected some variants were manageable with proper care and updates.

The V10 tolerated towing exceptionally well. It maintained performance without excessive strain. Many examples exceeded 300,000 miles without internal rebuilds. That longevity built strong trust.

Parts availability remained solid for many years. Repairs were practical and affordable. The engine aged slowly. Power delivery remained consistent over time.

Another advantage was simplicity compared to modern turbocharged designs. Fewer forced induction components reduced failure risk. Fleet operators valued its predictability. Downtime was rare and manageable.

The engine did not rely on advanced electronics. Mechanical durability was the priority. What made the 6.8 V10 legendary was endurance. It kept working when conditions were demanding. The Ford 6.8 Triton V10 became a cornerstone engine for heavy duty gasoline applications.

10. Ford 460 Big Block V8

The Ford 460 big block V8 is one of the most durable and respected engines Ford has ever produced. Its reputation for reliability was built through decades of hard use in trucks, motorhomes, and heavy duty applications.

This engine was designed with displacement and strength as priorities. Large internal components allowed it to operate without stress even under heavy loads.

Torque delivery was effortless and consistent. The engine produced strong pulling power at low rpm, which reduced strain during towing and hauling.

One of the biggest reasons for its longevity was conservative tuning. Ford did not push the engine near its limits in stock form. The cast iron block was exceptionally thick. Cracking or warping was rare, even under extreme operating conditions.

Internal components were overbuilt by modern standards. Crankshafts, rods, and bearings were designed to survive long service lives. Cooling systems were large and effective. Overheating issues were uncommon when maintained properly.

Oil circulation was robust and reliable. Many engines maintained stable oil pressure well into high mileage. Fuel delivery systems were simple and durable. Carbureted setups were easy to maintain and tolerant of wear.

The engine handled poor fuel quality better than many smaller or more advanced designs. This made it suitable for remote use. Maintenance was straightforward. Basic mechanical knowledge was enough to keep the engine running reliably.

One of the engine’s greatest strengths was predictability. Problems usually developed slowly rather than causing sudden failure. The 460 performed well in continuous operation. Long highway drives, towing, and extended idle times did not shorten its life significantly.

Many examples exceeded 300,000 miles without internal rebuilds. In motorhome use, that longevity was especially valuable. Parts availability remained strong for decades. This kept repair costs reasonable and encouraged owners to keep vehicles longer.

The engine tolerated neglect better than most modern designs. Missed maintenance rarely resulted in immediate damage. Another advantage was simplicity. No forced induction or advanced electronics reduced failure points.

The engine aged gradually. Power loss over time was minimal and manageable. Fleet and recreational users trusted it because downtime was rare. That trust built its legendary status.

While fuel efficiency was not its strength, reliability always was. The Ford 460 big block V8 earned its reputation through sheer endurance and mechanical honesty. It remains one of the most reliable large displacement gasoline engines Ford ever built.

Also Read: 10 V8 Engines That Produce the Most Torque in History