American muscle cars have always been about excess big power, bold styling, and an unapologetic focus on straight-line performance.

But beneath the hood of the most beloved muscle cars lies another trait that enthusiasts value just as much as horsepower: toughness.

The toughest muscle car engines aren’t just powerful; they’re durable, overbuilt, and capable of surviving years of abuse, whether that means drag strip launches, street racing glory days, or decades of daily driving with imperfect maintenance.

These engines earned their reputations not through marketing hype, but through real-world punishment, repeatable reliability, and an ability to take modifications without self-destructing.

What follows is a carefully considered list of the 10 toughest engines ever installed in muscle cars, focusing on factory-installed powerplants that proved nearly indestructible in stock form and even stronger when tuned.

This list spans the golden era of muscle as well as later modern interpretations, highlighting engines that American enthusiasts still trust today for restorations, restomods, and high-horsepower builds.

1. Chevrolet Small-Block 350 (Gen I)

No engine better represents American mechanical toughness than the Chevy 350 small-block. Introduced in 1967 and used extensively throughout the muscle car era, the 350 earned a legendary reputation for durability, simplicity, and adaptability.

Found in Camaros, Chevelles, Novas, and Corvettes, this engine was built with thick cast-iron blocks, stout crankshafts, and conservative factory tuning that prioritized longevity.

What made the 350 especially tough was its tolerance for abuse. Overheating, missed oil changes, hard launches many engines survived all of it. Even when pushed beyond factory limits, the bottom end proved remarkably resilient.

Its widespread use also meant constant refinement, making replacement parts cheap and plentiful. To this day, it’s common to find original 350s still running after 200,000 miles, which is extraordinary for an engine conceived in the 1960s.

2. Chrysler 426 HEMI (Second Generation)

The 426 HEMI wasn’t just powerful it was massively overbuilt. Designed initially for NASCAR and drag racing, Chrysler’s legendary HEMI featured a thick block, forged internals, and hemispherical combustion chambers that handled extreme cylinder pressures with ease.

Installed in iconic muscle cars like the Dodge Charger, Plymouth Road Runner, and Challenger, the 426 HEMI was engineered to survive sustained high RPM and brutal competition.

Its toughness came at a cost: weight and complexity. But those drawbacks were irrelevant when reliability under extreme stress was the goal.

Even stock 426 HEMIs could comfortably handle far more power than advertised, which is why many racers used factory engines with minimal internal modifications. Surviving original HEMIs are prized not only for performance but also for their mechanical durability.

During the peak of the horsepower wars, Detroit was responsible for some of the most legendary V8 engines in automotive history. The big three automakers battled fiercely for street supremacy, producing iconic motors like the Chevy 454, Mopar 440, and Ford 429, powerplants still celebrated for their engineering and performance decades later.

Yet among these giants, one engine commands a presence unlike any other: the 426 Hemi. When a car rolls up sporting the 426 Hemi badge, it draws attention instantly. Skeptics may dismiss it, but their bravado is merely a defense against the engine’s sheer dominance.

The 426 Hemi, often called the “mother of monsters,” stands above all other Hemi engines for its uncompromising performance. It was purpose-built for racing and represented a radical evolution in Chrysler’s approach to high-performance engines.

While not the first Hemi produced by Chrysler, it was the first to wear the iconic “Hemi” badge and the first time a Mopar brand fully embraced hemispherical combustion chambers with peak performance as the primary goal.

Chrysler’s experimentation with hemispherical chambers actually dates back to World War II, when engineers used them in the XIV-2220 bomber prototype. That supercharged 2,220-cubic-inch inverted V16 produced 2,500 horsepower, but the chambers were chosen for consistent performance at high altitudes rather than sheer power.

Similarly, early Hemi engines in Chrysler, Dodge, and DeSoto passenger cars from 1951 to 1958 were designed for efficiency and reliability across various conditions, though their horsepower potential later made them legends in drag racing, most famously in “Big Daddy” Don Garlits’ Swamp Rat dragsters.

The 426 Hemi itself was born from the need to dominate NASCAR. Its predecessor, the 426 Wedge engine, excelled in torque-heavy competitions but struggled on high-speed tracks.

Also Read: 5 Cars for Chicago City Traffic and 5 That Hate Stop-and-Go

3. Ford 428 Cobra Jet

Ford created the 428 Cobra Jet specifically to dominate drag strips, and toughness was baked into its DNA. Based on the FE engine family, the Cobra Jet featured strengthened internals, improved oiling, and better breathing to handle high-RPM launches and sustained abuse.

Installed in Mustangs, Fairlanes, and Torinos, it was one of Ford’s most feared muscle-era engines.

What separated the 428 CJ from other big-blocks was its balance of brute force and reliability. It could handle repeated quarter-mile passes without overheating or failure something many big engines of the era struggled with.

The block itself was exceptionally strong, and when paired with conservative factory tuning, it created an engine that could be punished relentlessly and still come back for more.

4. Pontiac 400 V8

Pontiac’s 400 cubic-inch V8 is often overshadowed by flashier rivals, but among enthusiasts, it’s regarded as one of the toughest engines of the muscle era.

Built with thick cylinder walls and a strong bottom end, the Pontiac 400 powered GTOs, Firebirds, and Trans Ams throughout the late 1960s and 1970s.

One of the engine’s greatest strengths was its torque-focused design, which reduced strain compared to high-revving competitors.

Pontiac engines were also known for generous oiling systems and robust crankshafts, allowing them to survive high mileage and aggressive driving. Even during the emissions-strangled 1970s, the 400 remained durable, often outlasting the bodies wrapped around it.

The Pontiac 400 6.6-liter V8 was first introduced in 1967 and quickly became a cornerstone of Pontiac’s performance lineup. This engine powered iconic models such as the GTO, Firebird, and Trans-Am Firebird, drawing inspiration from the earlier Pontiac 389 V8.

Notably, the 400 was the last Pontiac engine to feature closed-chambered heads, a design detail that marked the end of an era. At its peak in the early 1970s, the 400 produced over 300 horsepower, though tightening emissions regulations and other factors caused output to drop to around 180 horsepower by the time production ended in 1978.

The movie’s success in 1977 and 1978 helped boost Firebird sales and cemented the 400’s reputation among enthusiasts. Even after production ceased, Pontiac continued to offer the 400 in 1979 models, drawing from leftover stock from the previous year.

In 1980, Pontiac replaced the 400 with the 301 4.9-liter V8, but the new engine struggled to match its predecessor’s performance and appeal. Sales faltered, and the 301 was discontinued after 1981, leaving the 400 as one of Pontiac’s most celebrated engines.

Also Read: Top 10 Timeless Motorcycles That Make Ideal Cafe Racer Projects

5. Chevrolet LS6 454

The LS6 454, offered briefly in the early 1970s, represented the peak of Chevrolet big-block muscle. Rated at 450 horsepower, it was one of the most powerful factory engines ever installed in a muscle car, but its toughness was just as impressive.

Found primarily in the Chevelle SS, the LS6 used forged internals, high-strength components, and a block capable of handling immense torque loads.

Despite its massive output, the LS6 was surprisingly reliable when maintained properly. Its over-engineered nature allowed it to endure repeated hard use, and many examples survived decades without internal rebuilds.

Even today, the LS6 block is highly sought after for high-horsepower builds due to its structural integrity.

6. Oldsmobile Rocket 455

Oldsmobile’s 455 Rocket V8 wasn’t about revving high it was about delivering mountains of torque with minimal stress.

That design philosophy directly contributed to its toughness. Installed in models like the 442 and Cutlass, the Rocket 455 featured a robust cast-iron block and conservative operating limits.

These engines were known to last exceptionally long lives because they didn’t need to work hard to move heavy muscle cars. The low-RPM torque reduced internal strain, while the thick block and crankshaft provided long-term durability.

Many Rocket 455s survived well into the 200,000-mile range, a rare achievement for big-displacement engines of the era.

7. Dodge 440 Magnum

If the 426 HEMI was Chrysler’s race engine, the 440 Magnum was its street brawler and it was arguably tougher for everyday use.

Installed in Chargers, Challengers, Road Runners, and GTX models, the 440 combined massive displacement with simpler wedge-head design, making it easier to maintain and more forgiving under neglect.

The 440’s thick cylinder walls and massive rotating assembly allowed it to endure heavy vehicles, aggressive driving, and long highway runs without complaint.

It responded well to performance upgrades but remained reliable in stock form, which is why it’s still one of the most popular Mopar engines for restorations and restomods.

When it comes to classic American muscle car engines, few have earned the reverence of the Dodge 440 V8. This legendary powerplant defined an era of high-performance driving and continues to capture the imagination of enthusiasts decades later. Its combination of raw power, durability, and accessibility made it a defining engine of the muscle car period.

The Dodge 440 didn’t appear out of nowhere; it grew from Chrysler’s established RB (Raised Block) series of big-block V8s. Introduced in 1966, the 7.2-liter engine was engineered to deliver immense torque while remaining dependable enough for everyday driving.

It represented the peak of Chrysler’s wedge-head engine development, providing substantial performance without the cost and complexity associated with the company’s more famous hemispherical combustion chamber engines, like the 426 Hemi.

Many automotive historians view the 440 as one of the most practical high-performance engines of the muscle car era, balancing power, affordability, and reliability in a way few others could.

Over its 12-year production run from 1966 to 1978, the Dodge 440 evolved to meet increasingly strict emissions regulations, yet its fundamental architecture and character remained intact. This continuity helped cement its place as an enduring icon, delivering the torque, performance, and accessibility that made muscle cars truly memorable.

8. Ford 302 Small-Block

While not as physically massive as big-blocks, the Ford 302 earned its place through sheer resilience.

Used extensively in Mustangs during the late 1960s and early 1970s, the 302 featured a compact, lightweight design with a strong block that tolerated high RPM better than many larger engines.

Its toughness came from simplicity and balance. The 302 didn’t overstress components, and its forgiving nature made it ideal for daily driving and amateur racing alike.

Many original engines survived decades with minimal maintenance, proving that durability doesn’t always require massive displacement.

Few engines in automotive history carry the legendary status of Ford’s 302 small block. Born from the esteemed Windsor engine family, the 302 quickly became a cornerstone of Ford’s performance lineup and left an enduring mark on muscle car culture.

While Chevy fans often point to the 305 as its natural rival, the story of the 302 demonstrates why it continues to be a favorite among Ford enthusiasts even decades later.

The 302 small block debuted in 1968 as an evolution of the Windsor V8. By the mid-1960s, the Windsor family was already well-established, with the 289 cubic-inch V8 proving itself in both durability and performance.

As the muscle car wars intensified, Ford sought an engine that could deliver a balance of horsepower and torque while fitting neatly under the hoods of popular models like the Mustang, Torino, and Mercury Cougar.

With a 4.00-inch bore and 3.00-inch stroke, the 302 was essentially a stroked version of the 289, maintaining the lightweight, compact design of the Windsor platform. Its small displacement and impressive performance potential made it a versatile choice for enthusiasts who wanted power without the weight of big-block engines.

Ford quickly put the 302 to work across both performance and mainstream applications. One of the most famous factory configurations was the Boss 302, introduced in 1969 for Trans-Am racing, a series that rewarded high-revving small blocks.

The Boss 302 featured upgraded components such as 4-barrel carburetors, improved cylinder heads, and solid lifter cams, allowing it to rev beyond 6,000 RPM while producing an advertised 290 horsepower, a figure widely regarded as conservative.

The Boss 302-powered Mustang became a legend on both the street and the track, famously competing against the Chevrolet Camaro Z/28 and solidifying the engine’s reputation as one of the finest small-block designs of its era.

Through the 1970s and 1980s, the 302 remained a workhorse, powering trucks, passenger cars, and performance models like the Fox-body Mustang GT. When the fuel-injected 5.0-liter variant emerged in the 1980s, it cemented the 302’s status further, giving birth to the iconic “5.0 Mustang” and introducing a new generation to the joys of V8 muscle.

Meanwhile, General Motors introduced the Chevrolet 305 small block in 1976 as a more fuel-efficient alternative to the 350. With a 3.736-inch bore and 3.48-inch stroke, the 305 shared much of the 350’s architecture but offered less performance potential.

The engine found its way into Camaros, Monte Carlos, and even full-size trucks, delivering respectable torque and everyday drivability.

However, its smaller bore and emissions-era tuning left it underpowered compared to the 302, leading some enthusiasts to view it as a compromised engine during the late ’70s and early ’80s when smog regulations further constrained performance.

The Ford 302’s combination of compact design, versatility, and high-revving performance helped it rise above contemporaries like the Chevy 305, leaving a legacy that continues to define Ford’s muscle car heritage.

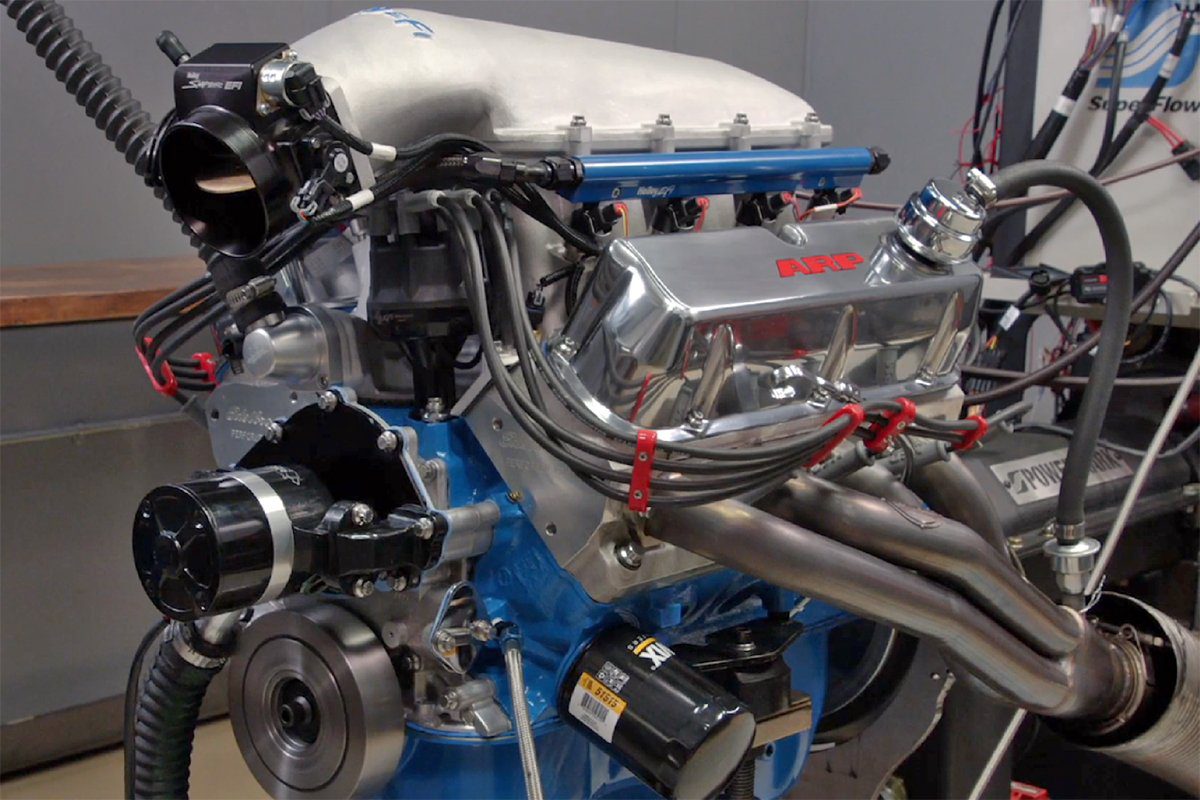

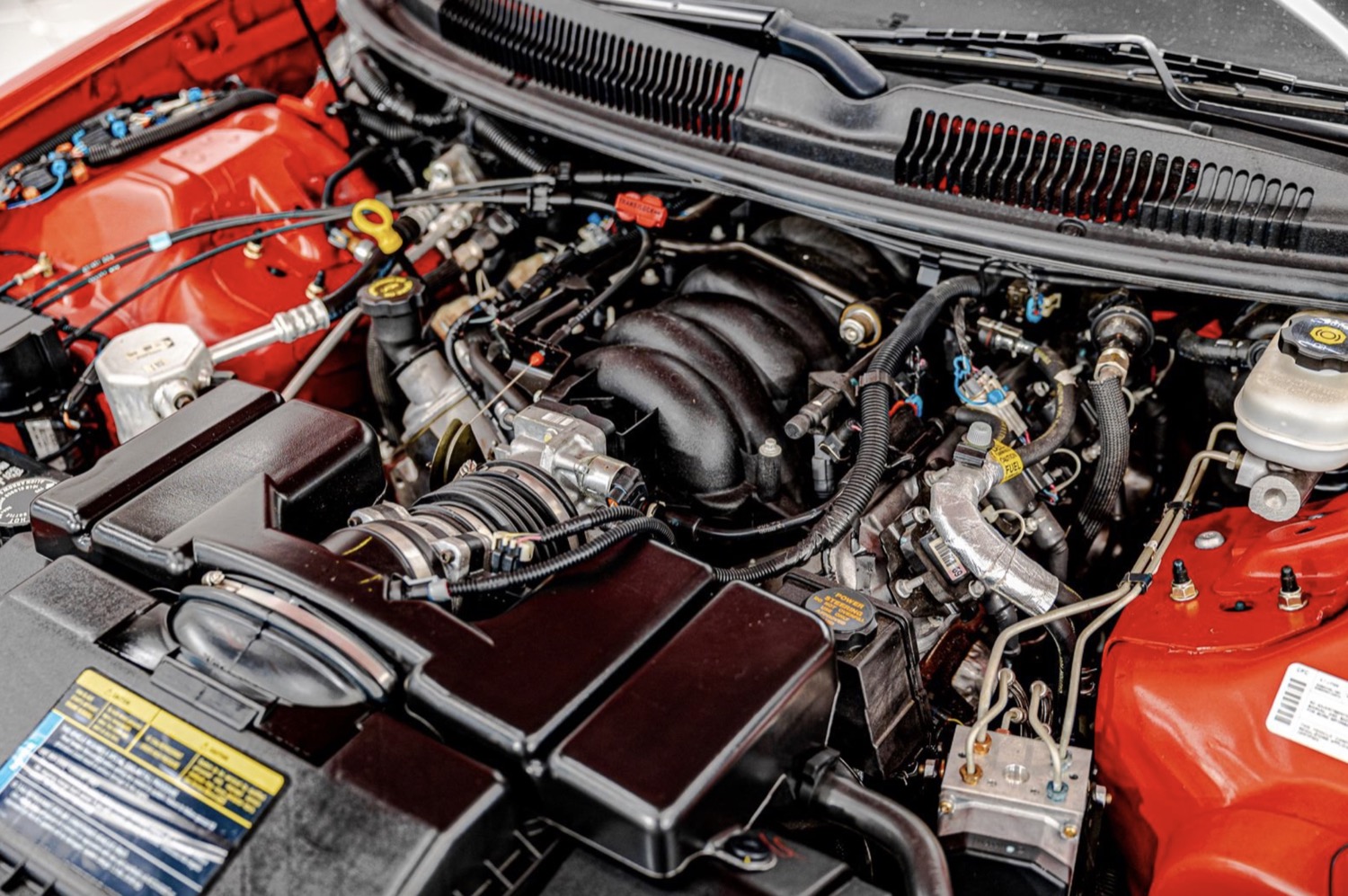

9. Chevrolet LS1 (Fourth-Gen F-Body Era)

The LS1 marked the modern return of muscle car toughness when it debuted in the late 1990s Camaro and Firebird.

Though aluminum-blocked, the LS1 was engineered with exceptional strength, using deep-skirt block design, cross-bolted main caps, and advanced metallurgy.

What made the LS1 legendary was its ability to handle huge power increases without internal modifications. Stock bottom ends routinely survived 500+ horsepower, something unheard of in earlier eras.

Combined with reliability, fuel efficiency, and long service life, the LS1 redefined what a tough muscle engine could be in the modern age.

The Chevy LS1 346 engine made its debut in 1997 as the centerpiece of the all-new C5 Chevrolet Corvette, marking a major leap forward in GM’s small-block engineering. While it retained the traditional 4.4-inch bore spacing of previous Chevy small blocks, the LS1 shared very little else with its predecessors.

It was the first all-aluminum small block produced by Chevrolet, a move that significantly reduced engine weight and improved performance.

The LS1 incorporated numerous durability and performance upgrades, including improved cylinder head flow, a four-bolt main cap design reinforced with two additional 8mm cross bolts, and a distributorless ignition system controlled by the engine’s ECU.

Performance-focused engineering continued with redesigned aluminum heads and an intake optimized for airflow, producing 245 cfm straight from the factory. These improvements allowed the LS1 to generate 345 horsepower at launch, an impressive figure for the era, while shedding roughly 50 pounds compared to previous small blocks.

In 2001, further upgrades to the intake and exhaust manifolds added 5 more horsepower and 15 additional pound-feet of torque. Specialized versions, like the Callaway-modified C5 Corvette, pushed the LS1 to 400 horsepower and 405 lb-ft of torque, demonstrating the engine’s tuning potential.

Beyond the Corvette, the LS1 also found its way into the Pontiac TransAm and Chevrolet Camaro. In these applications, GM officially rated the engine between 305 and 325 horsepower, though enthusiasts often claim the true output was significantly higher.

With its combination of advanced materials, innovative engineering, and strong performance, the LS1 quickly became a benchmark for modern small-block V8s and remains a celebrated engine in American muscle car history.

10. Ford 351 Cleveland

Rounding out the list is the Ford 351 Cleveland, an engine known for its massive cylinder heads and exceptional airflow. Installed in Mustangs and other Ford muscle cars, the Cleveland was designed to make power easily while maintaining structural strength.

Its thick block and strong internals allowed it to survive aggressive driving and racing conditions. While oiling quirks required attention, properly maintained Cleveland engines were exceptionally durable. Many enthusiasts still consider it one of Ford’s strongest classic V8 designs.

Toughness in muscle car engines isn’t just about surviving abuse it’s about consistency, longevity, and the ability to deliver power year after year.

By the late 1960s, Ford was aggressively modernizing its engine lineup. Existing engines were growing in displacement, the 352 expanded to 390, then 406, 427, and 428 cubic inches, while the small-block 292 Y-block was replaced in 1962 by a new compact engine that quickly grew to 260, then 289, and finally the 302 in 1968.

That same year, Ford introduced a new big-block family, the 429, which would be transformed into the Boss 429 in 1969 and later into the wedge-head 429 Cobra Jet for 1970. With these upgrades, Ford covered both big-block and small-block applications, but a gap had emerged in its intermediate and pony car lineup.

To address this, Ford introduced the 351 Windsor in 1969, but only a year later, the company revealed an all-new 351 Cleveland engine.

Conceptually, the 351W was an extension of the 289/302 design, but the new 351C was part of an entirely new 335 engine family and shared little in common with its small-block relatives, even featuring a different firing order. The Cleveland, produced at Ford’s Engine Plant Number 2, represented a major investment; a $100-million expansion added 510,000 square feet of production space specifically for the new engine.

Dealers highlighted its advanced engineering, including a computer-designed, lower and wider cylinder block produced with precision thin-wall casting, compound canted valves for maximum intake and exhaust flow, an exhaust-heated intake manifold to aid warm-up, lightweight pistons with generous valve clearance, and a five-main-bearing nodular iron crankshaft for strength and reduced weight.

While the bore and stroke were identical to the 351 Windsor, the Cleveland featured a completely different block; the water pump housing was cast into the 351C block, unlike the flat-front 351W, making visual identification straightforward.

The most significant changes came in the heads, which were heavily influenced by the Boss 302 and 429 designs. Initially, Ford offered two head castings: two-barrel carbureted engines had moderately large ports with 2.04/1.65-inch intake/exhaust valves, while four-barrel versions featured massive 2.19/1.71-inch valves, comparable in intake size to Chevrolet’s legendary 427 L88.

The 351C also introduced canted valves, with intake valves angled approximately nine degrees toward the intake port and exhaust valves four degrees to the side, allowing for larger diameters and smoother port contours. Each valve had its own pedestal, and while both two- and four-barrel engines used hydraulic cams, the four-barrel cam was slightly hotter.

Airflow improvements were substantial, though the massive four-barrel heads could be overkill for street performance; NASCAR builders often reduced port size by roughly 30 percent with epoxy to improve efficiency.

The two-barrel 351C produced 250 horsepower at 4,600 rpm, while the four-barrel version generated 300 horsepower at 5,400 rpm, ten more than the 1969 351W four-barrel. Interestingly, peak torque for the 351C four-barrel was rated at 380 lb-ft at 3,400 rpm, slightly lower than the 385 lb-ft at 3,200 rpm of the 351W four-barrel, reflecting the engine’s focus on high-RPM power delivery.

The engines on this list earned their reputations through decades of real-world use, proving that American muscle wasn’t just loud and fast, but also mechanically resilient.

Whether classic cast-iron monsters or modern aluminum innovations, these engines remain benchmarks for durability in performance automotive history.